User Projects Presented at the Connection Events

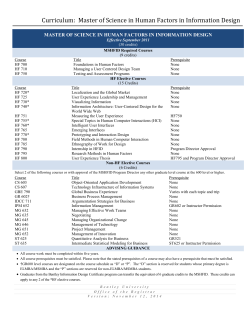

User Projects Presented at the Connection Events Winners of Bentley’s prestigious Be Inspired Awards will be making presentations on their extraordinary projects at the event locations noted below. We encourage you to attend all of those of interest to you and your readers. If you do sit in on a presentation and would like us to try to arrange an interview with the speaker, or to secure additional information on the project presented, please contact your local Bentley marketing contact, Christine.Byrne@bentley.com, or Michaela.Romero@bentley.com. Click on each date to access events details, the agenda, and the registration page. Philadelphia 18-19 May 20015 Chicago 19-20 May 2015 Oslo 19-20 May 2015 Amsterdam 20-21 May 2015 Toronto 21-22 May 2015 Atlanta 2-3 June Los Angeles 4-5 June 2015 Chennai 9-10 June Houston 16-17 June 2015 Brisbane 19-20 August List of User Projects Presentations User Success: Harnessing the Power of SITEOPS to Win More Business A.J. Whitaker, PE, PLS, Atlas Civil Design Los Angeles, 4-5 June 2015 EMERSON COLLEGE BUILDING, 5960 West Sunset Boulevard, Hollywood, California 90028 Summary A.J. Whitaker began using SITEOPS in 2009 while heading the civil engineering team of a leading commercial design firm. His first SITEOPS model was an aggressive hillside 35-acre senior housing complex in San Diego. He used SITEOPS to not only win the project, but secure a relationship with a great client that lasts to this day. In this presentation, Whitaker will share the story of how he leveraged his reputation as a SITEOPS expert to expand his network, win over big clients, and ultimately start his own company. In a competitive market, having a tool that consistently saves clients both time and money is a huge advantage. Through a series of brief case studies, Whitaker will demonstrate how SITEOPS can work for you to grow your business. User Success: Factors and Trends that will Drive Innovation in the Transportation Sector Luis A. Porrello, D.Sc., P.E. Senior Vice President and National Transportation Market Leader CDM Smith Los Angeles 4-5 June 2015 EMERSON COLLEGE BUILDING, 5960 West Sunset Boulevard, Hollywood, California 90028 Summary Transportation infrastructure development in the United States is perhaps at its most significant point since the deployment of the interstate highway system. This is the result of a convergence of three significant elements: 1. A dramatic change is expected to occur in the nature of the demand for the system and, in turn, its purpose. 2. The failure of the gas tax as a sustainable and effective user fee for funding transportation infrastructure. 3. The exponential deterioration of existing infrastructure to the point that system renewal is equally critical as system expansion. The following constructs, resultant from the above change agents, will be described with respect to how they will drive innovation in this area: 1. The big picture – What are the factors, and how are they changing, that we need to get ahead of when thinking about our future transportation system? (e.g. Population growth, climate change, global competitiveness, e-commerce, and other socioeconomic variables that create the demand for infrastructure). 2. Alternative user fees – Tolls on the interstate highway system, mileage-based user fees, managed lanes. 3. Freight – Implication of efforts related not only to addressing current and future demand but also leveraging technologies to create a more seamless freight system. 4. Connected and autonomous vehicles (including aerial) –What opportunities are there to leverage private and public efforts to improve the planning, design, and operation of our transportation system? 5. Big data – A catch-all category for Internet of Things, BIM, 3-4-5D design, and all other ideas related to the vast amount of realtime information to which our industry will have access. What does this all mean to our industry's capability to provide and manage transportation infrastructure. User Success: Bentley Map for Utility Asset Modeling Jeffrey C. Kepley, CADD Manager, Caltrans Los Angeles 4-5 June 2015 EMERSON COLLEGE BUILDING, 5960 West Sunset Boulevard, Hollywood, California 90028 Summary Caltrans has been a user of MicroStation for over 25 years, producing all of its design and construction documentation. The SAMIT Project (Subsurface Asset Management Interface Tool) uses MicroStation and Bentley Map to document and model the location of subsurface and above-ground utilities in the Caltrans Right of Way. Accurate location data and attributes are captured and provided to project engineers for the purpose of planning new projects, to avoid costly conflicts with exiting subsurface utilities, and to determine where additional information should be collected on site prior to planning any construction activities. User Success: The “Living Model” – Transferring Ownership from Consultant to Municipality for Planning, Design, and Beyond Duncan Lee, PE, Principal Civil Engineer, City of Huntington Beach Philadelphia, 18 – 19 May 2015 THE FRANKLIN INSTITUTE 222 N 20th St, Philadelphia, PA 19103 Summary Hydraulic modeling is an essential element in water system planning and operations. Most agencies desire to perform this important task with in-house staff. However, many ultimately rely on third-party consultants. The primary objective of this presentation is to provide a potential user or program manager with an understanding of what it takes to run a model in-house. Duncan Lee will discuss how the City of Huntington Beach was able to evaluate its ability to fill its reservoir on a daily basis, based on different scenarios of bringing water supply into their systems. He will also discuss the challenges the City of Huntington Beach faced and how they solved those challenges. User Success: Philadelphia Water Department’s Deployment of ProjectWise Geospatial Management Thomas Kaufmann, Engineering Plans Design Supervisor, Philadelphia Water Department Philadelphia, 18 – 19 May 2015 THE FRANKLIN INSTITUTE 222 N 20th St, Philadelphia, PA 19103 Summary In this presentation, Thomas Kaufmann, PWD’s engineering plans design supervisor, explains how his department was able to improve its document management system using ProjectWise Geospatial Management. With its ProjectWise database growing quickly, Philadelphia Water Department needed to better manage thousands of pre-construction and construction documents. To achieve its goal, PWD deployed ProjectWise V8i Geospatial Management and created a basemap in the ProjectWise administrator, which can now be seen by the entire department. CAD Files With the basemap successfully created, PWD began geospatially scanning CAD files using ProjectWise Client, which allows users to select a file, group of files, query, or folder to scan. Once geocoding of the project folders was complete, the improvement in the ability to manage the documents was immediate. PWD’s ProjectWise database is also tied to its project management system (CAPIT) database. This allows PWD to perform project folder searches based on CAPIT data and display these folders on a map. Those folders can also be color coded by additional CAPIT data. Construction Photographs Before digging begins on a PWD project, the contractor takes a series of pre-construction photos using devices that can capture geospatial data. ProjectWise Geospatial Management allows the metadata from those geocoded photos to be captured by ProjectWise and displayed on a map. User Success: Practical Application of GIS to Hydraulic Modeling Frank Grablutz, Senior Project Engineer, Aqua Pennsylvania, Inc. Al Polidori, Hydraulic Engineering Analyst, Aqua Pennsylvania, Inc. Philadelphia, 18 – 19 May 2015 THE FRANKLIN INSTITUTE 222 N 20th St, Philadelphia, PA 19103 Summary Aqua Pennsylvania, Inc. (Aqua) is an investor-owned water company serving customers in 31 counties throughout Pennsylvania. Aqua’s operations include a large contiguous system serving four counties bordering the city of Philadelphia in southeastern Pennsylvania, along with numerous smaller water systems scattered throughout the state. Aqua developed a steady-state hydraulic model of the southeastern Pennsylvania system in the 1980s. This was a comprehensive model constructed using data available at the time. The model was utilized for planning purposes for several years, but its use was limited to one or two expert users who were able to overcome any shortcomings in the model using their expertise of the distribution system. Aqua began developing a geographic information system (GIS) of its distribution system in 2005. Work processes were established such that any changes to the distribution system are incorporated into the GIS in a timely fashion. In 2007 Aqua obtained Bentley’s WaterGEMS software to construct a new and better model of its distribution system. This presentation will describe how Aqua has integrated GIS into its hydraulic modeling effort. It will focus on practical solutions to problems most utilities would face when attempting to combine GIS and hydraulic modeling. User Success: Complex Steel Truss and Super Column Design Utilizing RAM Software Samantha Fioravanti PE, SE (Senior Project Designer) Mark Orsini PE, SE (Senior Project Executive) O’Donnell & Naccarato Philadelphia, 18 – 19 May 2015 THE FRANKLIN INSTITUTE 222 N 20th St, Philadelphia, PA 19103 Summary This presentation reviews the various analysis methods required to design the complex structure and the benefit of utilizing Bentley software to achieve an efficient and economical design. RAM Structural System and RAM Elements are being utilized for the analysis of a unique three-story building that will hover 65 feet above an existing building. The typical steel framing layout is transferred by a complex steel truss platform to six super columns, three of which will punch through the existing three-story building below. The box trusses and super columns act together to create large moment frames that transfer the gravity and lateral forces from the building above to the foundations below. RAM Structural System is being used to design the traditional steel framing levels. The reactions from that analysis are then applied to a RAM Elements model of the truss platform and super column frame. This complicated 3D model is then subdivided into individual 2D and 3D truss models to improve analysis speed, simplify the design process, and address localized deflections on the long span infill trusses, box trusses, and truss girders. User Success: Intelligent BIM Models for Improved Lifecycle Management of Public Infrastructure Ad Steenbakkers, Senior Information Advisor, City of Eindhoven and co-founder Data-Aquilae Amsterdam, 20 May 2015 HOTEL NH BARBIZON PALACE Prins Hendrikkade 59-72, 1012 AD Amsterdam, Netherlands Summary The City of Eindhoven, Noord-Brabant, Netherlands, is achieving its vision of becoming a smart city by applying a BIM lifecycle approach to the city’s infrastructure. The smart-city strategy combines data from multiple disciplines in a 3D city model, and allows open data use by developers and architects. This makes projects less costly and more efficient, enables better collaboration between citizens and the city council at the beginning of projects, and ultimately improves the quality of life for the citizens of Eindhoven. With financial support from the province, the City of Eindhoven invested EUR 30,000 to build a 3D city model. The City of Eindhoven combined this city model into a 3D data model with the use of point clouds, scalable DTMs, subsurface objects such as 3D sewerage, and imodels for easy access of BIM models. This unified data model is called the Gebiedsmodel. Bentley Descartes, Bentley Navigator, ProjectWise, MicroStation, and an i-model plugin were used in the process. User Success: AutoPIPE Helps Queensland Alumina Limited Streamline Engineering Design Processes Using AutoPIPE Saves Time and Money Mark Upston, Senior Director Structural Solutions, Bentley Systems Brisbane, 19-20 August Hilton Brisbane 190 Elizabeth Street, Brisbane Queensland, 4000 Australia Summary In this presentation you will learn how Queensland Alumina Limited (QAL), one of the world’s largest alumina refineries, used Bentley AutoPIPE on a 40-year-old facility to streamline its engineering design process. Alumina production involves some of the most extreme operating conditions of any plant. Over time, pump and pipe support failures, along with structural damages caused significant maintenance costs as well as AUD 500,000 in lost production revenue per day due to downtime. QAL used AutoPIPE to verify field measurements, validate experimental data, and model pipe work in the field. The on-site design team used AutoPIPE to solve numerous design supporting and structural problems, which saved QAL millions in maintenance and lost revenue costs. User Success: Classifying Content for better management with ProjectWise Glenn Williams, Assistant Administrator – Office of Design Policy & Support, Georgia Department of Transportation Tom Atkinson, Information Management Sale Executive, Bentley Systems Atlanta, 2-3 June 2015 WYNDHAM ATLANTA GALLERIA 6345 Powers Ferry Rd Atlanta, GA 30339 Summary This presentation explains how the Georgia Department of Transportation (GDOT) configured ProjectWise to require document classification upon creation, as well as how those classifications are used to help manage project-related content. Through standard configuration and some custom add-on tools, GDOT has simplified the ability to locate various sets of content such as “Final PDF Plan Sets.” See how GDOT is now leveraging those classifications to comply with records management requirements. User Success: Water Distribution System Case Study – Modeling to Solve Full-scale Operational Challenges Alex Harman, Engineer II, Water Resources, Gwinnett County Atlanta, 2-3 June 2015 WYNDHAM ATLANTA GALLERIA 6345 Powers Ferry Rd Atlanta, GA 30339 Summary The Gwinnett County Department of Water Resources is located 30 miles northeast of Atlanta and serves more than 800,000 customers. The department utilizes a full pipe Bentley water model, which has over 385,000 elements. Because of an elevation change of 550 feet from the northern end of the county to the south, the county implemented a master reduced pressure zone, with eight master pressure reducing valves (PRVs). The original master valves along the boundary were oversized for projected growth, which did not occur as expected. In 2014, the master valves were resized for current and near future population flow rates. The Bentley model was utilized to choose the appropriate valve size for each site and to ensure adequate fire flow for both residential and commercial fires. In September 2014, all eight PRVs were installed, and by mid-November the flow and pressure monitoring equipment at these sites was reporting data to the county’s SCADA system. During PRV startup, the model was critical in setting the appropriate downstream pressures for proper system operation. An extended period simulation was used to generate recommended flow rates at any point during the day. Implementation of these flow rates was achieved through trial and error, with the goal of having all eight PRVs opening at least once each day. By early December, all eight PRVs were controlling pressures as expected and allowing water to circulate adequately to avoid water age issues. User Success: How ArcelorMittal implemented a reality-based equipment maintenance program to improve the operating bottom line of its USD 5 billion dollar plant in 12 months. Scott Piech, Division Manager – USA Maintenance, ArcelorMittal USA Chicago 19-20 May 2015 MILLENNIUM KNICKERBOCKER HOTEL 163 E Walton Pl Chicago, IL 60611 Summary ArcelorMittal and Nippon Steel Sumitomo Metals formed a joint venture to purchase a steel plant in Calvert, Alabama in 2013. ThyssenKrupp built the plant for USD 5 billion in 2010. Less than four years later, the joint venture sold the facility at a 70% discount. The challenge for ArcelorMittal’s reliability team was to quickly implement a reliability-based equipment maintenance program for the plant. With plant output about to double, it was necessary to act quickly to ensure the equipment could meet the growing demands of production. In this presentation you will learn how the reliability team successfully implemented a reliability-based equipment program at the plant in 12 months using Bentley’s AssetWise APM software. The plan focused on identifying failure modes for critical pieces of equipment to minimize the consequences of failures and utilizing Bentley software to capture these failure modes. The team then developed conditionbased inspection routes for these failure modes. As the failure modes for more equipment were identified, the amount of condition-based inspection points for the plant increased. This had a direct correlation to the increase in plant performance. User Success: The O’Hare Modernization Program (OMP) developing the future for the Chicago Department of Aviation (CDA) Anthony Lewandowski, IT/Design Technology Manager, CH2M Chicago 19-20 May 2015 MILLENNIUM KNICKERBOCKER HOTEL 163 E Walton Pl Chicago, IL 60611 Summary While it normally takes more than 10 years to construct a runway, the OMP’s first phase was slated to complete the first runway in six; while also moving a railroad, creek, major airport guard post, lighting control vault, and high pressure water main. Not only was this a very aggressive schedule to design and construct this jigsaw of projects, but it was all done while not impacting operations at one of the busiest airports in the world. While ProjectWise was intended to aid in the design and construction of the program, its ultimate benefit was to leverage all its capabilities to serve the CDA into the future for all their design and maintenance needs. User Success: The M-1 Rail Streetcar Project Matt Simon, Vice President, HNTB Chicago 19-20 May 2015 MILLENNIUM KNICKERBOCKER HOTEL 163 E Walton Pl Chicago, IL 60611 Summary The M-1 Rail Streetcar project is helping Detroit lay the groundwork to regain its status as an iconic city. Upon completion of this project, ridership is expected to be 1.8 million in 2016, growing to 3.3 million annual riders by 2035. This will help to create a dynamic living and working environment in the heart of Detroit along the region’s most active, iconic, and dynamic corridor. As a high-profile project, it was important to develop a collaborative team that strived to bring innovation to a geat project. A critical area of risk associated with the project was underground infrastructure. This presentation will highlight how HNTB used innovative solutions to reduce risk, reduce schedule, and deliver the project at a lower cost utilizing resources across eight offices. User Success: SHWE Jacket & Topsides Transportation and Installation Wenjie Wu, lead structural engineer, Dockwise Houston 16-17 June 2015 JW MARRIOTT HOUSTON 5150 Westheimer Road Houston, TX 77056 Summary In this presentation, Wenjie Wu will explain how Dockwise was able to deliver an innovative solution for the SHWE jacket and topsides transport and installation (T&I) project. As part of the USD 1.5 billion SHWE field development project, Dockwise set a weight record when it installed the nearly 22,000-metric ton jacket and 30,000-metric ton topsides with deck support frame for the SHWE platform. Dockwise performed the engineering design for the T&I contract, as well as provided transportation and launch operation of the jacket, and transportation and floatover operation of the topsides. Dockwise also provided operational support for jacket and topsides load-out. MOSES and SACS, Bentley’s offshore platform analysis, design, and installation software, were used in this project. The engineering challenges were tackled by numerous analyses and design iterations based on MOSES and SACS simulations. User Success: Efficiency Gains with Interoperability of Pipe Stress Using AutoPIPE and 3D CAD Systems David Glasscock, Pipe Stress Manager, Fluor Houston 16-17 June 2015 JW MARRIOTT HOUSTON 5150 Westheimer Road Houston, TX 77056 Summary Information mobility is increasingly important for improved design quality, project efficiency, and overall collaboration. In this presentation, Fluor shows how to increase productivity by reusing intelligent 3D models instead of building new pipe stress models. Its workflow focuses on the advantages of accurately and effectively sharing these design engineering results with other project groups such as CAD designers, structural engineers, and clients. User Success: Bentley Technology at CenterPoint Energy: How CenterPoint Energy utilizes Bentley Technology in Gas Distribution, and Electric Transmission and Distribution Robert Tusini, Engineering Technician, CenterPoint Houston 16-17 June 2015 JW MARRIOTT HOUSTON 5150 Westheimer Road Houston, TX 77056 Summary CenterPoint Energy is a public utility company that delivers electric transmission and distribution, and gas distribution. The utility serves 5 million metered gas and electric customers in Arkansas, Louisiana, Minnesota, Mississippi, Oklahoma, and Texas. Bentley technology is being used by CenterPoint for electric substation, transmission, distribution, and real-time operations. Current business and technical initiatives: ProjectWise upgrade, OpenPlant evaluation, and Bentley Substation pilot. User Success: Cutting analysis and design man-hours by more than half increases your financial success and customer satisfaction. A project example from Kongsberg Oil & Gas Technologies. Ayman Awad Mohamed Abdelhadi, Senior Engineer Oslo 19-20 May 2015 SCANDIC FORNEBU Martin Lingesvei 2 1364 Fornebu, Norway Summary Attendees to this presentation will learn how to increase productivity in initial FEED and tender phase by providing fast input for piping and structural estimates and a 3D skeleton for CAD designers. The speaker will also cover the benefits to using many layout options and presenting cost-efficient solutions to the client. User Success: Chacao Bridge – Global analysis and design of a two-main-span suspension bridge in Chile Kristin Nessa, Aas Jacobsen Norway Oslo 19-20 May 2015 SCANDIC FORNEBU Martin Lingesvei 2 1364 Fornebu, Norway Summary Chacao Bridge is a two-main-span continuous suspension bridge crossing the 2.5 kilometer-wide Chacao channel in southern Chile. The bridge sight experiences harsh environmental conditions with strong winds, strong currents, and, most notably, high seismicity adding challenges to the bridge design. User Success: Norwegian Strait Crossings - A study of multi-span suspension bridges supported by floating foundations Arne Bruer, TDA, Norway Oslo 19-20 May 2015 SCANDIC FORNEBU Martin Lingesvei 2 1364 Fornebu, Norway Summary As part of a ferry-free coastal highway along the west coast of Norway, new and exciting bridge concepts are being explored. A possible solution for crossing the deep and wide fjords are multi-span suspension bridges supported by floating foundations. One such fjord is Bjørnafjorden south of Bergen, with a length of nearly 5 kilometers and water depths exceeding 500 meters. User Success: The Information-driven Maintenance Organization Why We Do What We Do and How We Justify It Ralph Blanchard, ArcelorMittal Dofasco Toronto 21-22 May 2015 Pantages Hotel Toronto 200 Victoria Street Toronto, ON M5B 1V8 Canada Summary Our success of maintenance professionals depends on their ability to make timely and accurate decisions. But typically they have too much data, so how do they get the value out of it? And how do we justify the manpower required? At ArcelorMittal Dofasco, the centralized reliability and maintenance team is responsible for over CDN 4 billion in assets across 10 business units. Prior to using AssetWise, APM maintenance would simply track work order completion comments. But with AssetWise APM the data consolidation and analysis is automated, trustworthy, and easily understood. Condition data is fed directly from the equipment so the data quality is high, but there is a massive amount of data that is often difficult to sift through. There was pressure from management to justify the manpower required until the company deployed a system that put the results at the forefront. The system tracks a massive amount of data and reports on an exception basis, bringing the non-normal conditions to the attention of maintenance. The dashboard in AssetWise APM is the intelligent single source of truth to gauge current asset health and trigger the work in time to avoid asset failure. It is the pulse of assets that run our business. The process and results based KPIs that we report to management on a regular basis will be shared. User Success: Applied Geomatics – MicroStation in the Field David Marion, Manager of Geomatics, The City of Mississauga Toronto 21-22 May 2015 Pantages Hotel Toronto 200 Victoria Street Toronto, ON M5B 1V8 Canada Summary The City of Mississauga is a long-standing user of Bentley and Intergraph technologies. The City has been an Enterprise License Subscription subscriber for several years. The City’s staff has extensive knowledge and experience using MicroStation to maintain core data assets. This includes development technologies such as User Commands, MicroStation Command Language (MCL), and Macro extension development in Visual Basic for Applications. In 2010, there was a need to have field-based infrastructure inspection, cataloging and reporting abilities that leveraged the City of Mississauga’s core data assets. These interfaces would require the inclusion of images (pictures), accurate coordinate location services (GPS), and the use of bar code reader and other Bluetooth devices such as optical reflectometers. The presentation will focus on the development and deployment of technologies and strategies for three important assets at the City of Mississauga: 1. Sidewalk inspection and deficiency logging 2. Regulatory and Warning Road Sign inventory 3. LED Street Light Retrofit project The presentation will also touch on newer technologies such as Map Mobile and GeoWeb Map Publisher, and it will discuss where the City sees field technologies evolving in the next five years. User Success: Embracing Information Modeling as the Future of Rail Systems Design Robert Henderson, Designer- Signals, Hatch Mott MacDonald Toronto 21-22 May 2015 Pantages Hotel Toronto 200 Victoria Street Toronto, ON M5B 1V8 Canada Summary Discover why leading owner-operators are embracing information modeling as the future of rail systems design. Hatch Mott MacDonald developed a new technique to introduce efficiency and intelligence into conventional rail systems design utilizing Bentley promis•e. This new system allows for quick, accurate reactions to scope changes and enables more efficient use of senior design staff for ensuring quality checking and review. It includes features to automate drawing and BOM creation, and enhance basic checking processes. The intelligent 3D model is linked in real time to the schematics required for rail systems and signal design. The system also has a single database for users including a collaborative environment that significantly reduces design times while improving accuracy and enabling standardization across multiple projects. User Success: HAMMER Hacks: Transient Simulations for Smarter Operations, The ROI of Connecting a Global Team, Sharing Information, and Improving Project Safety with Bentley Jean-Luc Daviau, Sr. Hydraulic Specialist, WSP Toronto 21-22 May 2015 Pantages Hotel Toronto 200 Victoria Street Toronto, ON M5B 1V8 Canada Summary Learn how WSP used Bentley HAMMER on this major project in Dubai, UAE. Designing a capital cost-efficient, smoothly operating sewage force main in a hot built environment required advanced hydraulic transient analysis. The total cost of the new system was minimized without compromising safety, thanks to a physically correct model of the sewage pump station and force main – including both pressurized and gravity-flow sections and transitions. Attendees will learn how the WSP consulting team used Bentley HAMMER at the expert level to mitigate risks, deliver the project faster, and minimize operating costs. User Success: Water Distribution System Improvement, Reduction in Unaccounted-for-water and Leakage Control Sujit Bandekar, Sr. Engineering Manager, L&T Construction Basil Mathew, Asst. Engineering Manager, L&T Construction Chennai 9-10 June ITC Grand Chola No. 63, Mount Road, Guindy Chennai- 600032 Summary Learn how L&T Construction used WaterGEMS on this INR 1.53 billion project in Bangalore, India. Understanding the water network, which dates to 1965, was a crucial part of this project. The water distribution system, which includes 1,583 kilometers of piping, had a high rate of water leakage. See how WaterGEMS was used to replicate the field conditions in the water model, and how using its Trace Analysis functionality enabled L&T engineers to identify which reservoirs supplied which area of the network. Once the current conditions were accurately modeled and understood, L&T engineers used WaterGEMS to design the network to meet service levels for the next 10 years, with reduced water leakage.

© Copyright 2025