Commissioning - Stage 3 â Dynamic System Testing (Hot

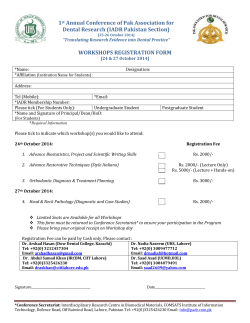

COMMISSIONING PROJECT DELIVERY GROUP STAGE 3 – DYNAMIC SYSTEM TESTING (HOT COMMISSIONING) During Stage 3 testing, equipment and controls that have been individually tested during Stage 2 are now grouped and tested as functional scoped systems. System boundaries facilitate handover and provide safe isolation points. SYSTEM TESTING Testing of the control logic features a complete test of the system with water or inert material in order to reach steady-state operation. These tests include: Power house generators at a plant site in the Canadian arctic completely assembled and ready for pre-operational testing • Validation of functional description ♦ Testing of equipments and system interlocks ♦ Verification of alarms and trips ♦ Functional testing of start and stop sequences ♦ Tuning and filtering of control loops and signals • Bringing plant to steady-state operation ♦ Conveyors run unloaded CONTACTS ♦ Pumps run with water and flow verified ♦ Entire plant tested with water or inert material Rick Plotzki Global Director - Commissioning Tel: +1 604 629 9514 x6514 RPlotzki@hatch.ca METHODOLOGY Tarik Haroon Western North America Tel: +1 403 920 3102 tharoon@hatch.ca • Safety: areas of the plant are now functional while others are still under construction or in Stage 2 testing. Elmer Maquiling Central North America Tel: +61 8 9278 4300 dmaquiling@hatch.ca Stephane Belec Eastern North America Tel: +1 514 864 5500 x6246 sbelec@hatch.ca Jon Neal Brazil Tel: +31 3308 7203 jneal@hatch.ca Raj Jaganathan Australia/Asia Tel: +61 7 3166 7777 x6276 Rjaganathan@hatch.au Andries DuToit Africa & Europe Tel: +27 (0)11 239 5665 adutoit@hatch.co.za Rick Plotzki South & Central America Tel: +1 604 629 9514 x6514 rplotzki@hatch.ca In addition to testing and tuning the plant’s control logic, Stage 3 system testing focuses on preparing a smooth transition to the operations team. ♦ Clear definition and barricading of systems under test as well as strict access control (permit to work) provides safe working conditions for all • Multidisciplinary system testing which requires equipment and instruments to work simultaneously ♦ Hatch’s multidisciplinary teams maintain a high level of coordination between field engineers and automation engineers in the control room in order to effectively tune control sequences ♦ Vendors on site are continually managed to support the commissioning of specialty equipment and facilitate warranty sign-off • Handover to Operations ♦ Operators and maintenance personnel embedded in the pre-operational testing team take an increased responsibility in the testing program to prepare for a smooth handover ♦ Walkdowns with the operations’ team identify punch items which are managed in iPas CS, Hatch’s commissioning software ♦ Handover packages (HOPs) compiled from iPas CS summarize the status of the system prior to acceptance and serve as a basis to perform subsequent commissioning tests safely and effectively Stage 3 testing ensures that the plant will be able to safely handle process material. Systems are handed over to the operations team who will first introduce process material during Stage 4 process commissioning. 04CAPA086/02/2015

© Copyright 2025