Numerical Analysis of a Model Scramjet Engine with Two Intake

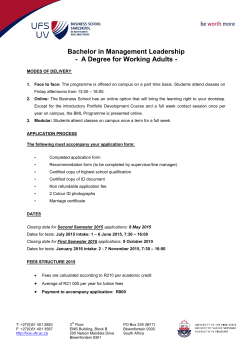

47th AIAA/ASME/SAE/ASEE Joint Propulsion Conference & Exhibit 31 July - 03 August 2011, San Diego, California AIAA 2011-5831 Numerical Analysis of a Model Scramjet Engine with Two Intake Side Walls and a Cavity Flame-Holder Hyo-Won Yeom1, Bong-Gyun Seo2, and Hong-Gye Sung3 Korea Aerospace University, Goyang Gyeonggi-do, South Korea, 412-791 A detailed 3D numerical simulation of the flow and H2-air mixing characteristics in a model scramjet engine with two intake-sidewalls and a cavity flame-holder was conducted. Turbulence closure was achieved by a model combining the low-Reynolds-number k-e twoequation model and Sarkar and Wilcox’s compressible turbulent correction model. The governing equations were solved numerically by means of a finite-volume, preconditioned flux-differencing scheme. Cases with and without intake side walls were considered. Intake side walls were found to strongly affect the inlet flow structure, which became more complex in the non-uniform flow field on the cross section perpendicular to the engine axis. The complex and non-uniform flow affected the H2-air mixing pattern inside the combustion chamber, unlike the pattern of the case without side walls. Mixing efficiency and fuel propagation rate were evaluated for the two cases with and without side walls. To verify the accuracy of the simulation, the computed wall pressure was compared with experimental data. Nomenclature a1, a3, a5 Ck Cε1, Cε2 Cμ c E h k Mt Mt0 H( ) hk P Pk Ru Tturb t u x Wk Yk a1 , a 2 , a γ δij ec 3 = = = = = = = = = = = = = = = = = = = = = = = = = model constant of damping factor model constant of turbulent time scale model constants of turbulent energy dissipation model constant of turbulent viscosity speed of sound specific total energy specific enthalpy turbulent kinetic energy turbulent Mach number reference turbulent Mach number Heaviside step function specific enthalpy of species k static pressure production of kinetic energy universal gas constant turbulent time scale time velocity spatial coordinate molecular weight of species k mass fraction of species k model constants for compressible correction specific heat ratio Kronecker delta compressible dissipation 1 Graduate Research Assistant, School of Aerospace and Mechanical Engineering, hwyeum@kau.ac.kr Graduate Research Assistant, School of Aerospace and Mechanical Engineering, bo190a@kau.ac.kr 3 Professor, School of Aerospace and Mechanical Engineering, hgsung@kau.ac.kr, AIAA Associate Fellow 1 American Institute of Aeronautics and Astronautics 2 Copyright © 2011 by the American Institute of Aeronautics and Astronautics, Inc. All rights reserved. es m mt r s k ,s e t ij = dissipation rate = molecular viscosity tk = Kolmogorov time scale = turbulent viscosity = density = model constants = viscous stress tensor Subscripts i, j, k = spatial coordinate index Superscripts % ˝ = time average = Favre average = fluctuation associated with mass-weighted mean I. Introduction O ver the last several decades, a great deal of research on scramjet engines has been performed in several countries, at a number of institutes and universities. The scramjet engine is currently being considered as an appropriate option for several hypersonic applications, such as hypersonic missiles and reusable launch vehicles. Most of the previous research has been experimental, but numerical studies are now on the rise and play an important role in studying scramjet engine. Numerical efforts are particularly appropriate to scramjet engine studies due to the complexity of the flow structures in supersonic and hypersonic vehicles, and the inherent limitations of experimental study for detailed flow investigation. Most numerical studies, however, have treated either the inlet flow, which is supersonic and/or hypersonic, or the combustor section, which contains fuel injection/mixing and combustion. The interaction between the two sections has generally only been passively considered. Fuel injection/mixing, ignition, flame-holding, and flame characteristics in the supersonic flow field have been studied with a uniform inlet profile or no inlet effect. Many numerical studies have focused on supersonic combustion, fuelair mixing enhancement, injection type, and other specifics. The researchers expanded 2D intake simulation (no variation in span-wise direction) to the inlet profile of 3D combustor simulation.1-3 This technique unfortunately ignores the effects of disturbances caused by intake flow conditions, such as size/type of intake sidewall, or nonuniform turbulence boundary thickness. There have been some studies that consider the effects of intake flow conditions which could affect flow structure, fuel-air mixing enhancement, ignition, and supersonic combustion inside a combustor. Abdel-Salam4 conducted a numerical investigation of a Mach 2.5 dual-mode scramjet combustor. A three dimensional model of the combustor configuration was used. The study was concerned with the effect of the inlet boundary layer in the flow of a dual-mode combustor. They observed that the thickness of the boundary layer has strong effects on the structure of the flow-field and the combustion characteristics. Kirchhartz5 conducted experiments in the T4 Stalker Tube to assess the combustion of hydrogen injected directly into the boundary layer of a circular constant-area supersonic combustion chamber (M > 4). The wall-boundary layer conditions at the fuel-injection station were varied to study the effects on the ignition and combustion of the injected hydrogen. They reported that a thicker boundary layer promotes combustion and is more effective for ignition. Korkegi6 performed comparison of shock-induced flat plate ramp(2-D) and flat plate ramp with sidewall(3-D) incipient turbulent separation. The skewed shock wave interacts with the sidewall turbulent boundary layer in rectangular diffusers or inlets and leads to separation and possible flow breakdown. In a rectangular supersonic inlet, the first oblique shock wave interacts with both the sidewall boundary layers and the corner flows. This can create large, complex 3-D separation zone. Driscoll7 conducted experiments to quantify these flow separation patterns. For the scramjet with and without intake side walls, shock-boundary interactions near the intake side walls make the flow structure at the entrance of the combustor complex. Shock wave-turbulent boundary layer interaction near the two intake side walls leads to deflection of the flow entering the inlet, and the flow structure becomes more complex. 2 American Institute of Aeronautics and Astronautics The inlet flow may be turned inwards due to the shock wave interaction with the turbulent boundary layer in the inlet, which can lead to inlet flow separation.8 The production of swirl as the stream ribbons passes through the interaction between the leading edge shock wave and the shock wave generated by the side wall.9 The effects of sidewall compression in 3D scramjet inlet have also been studied.10,11 The side wall compression causes the ramp shock to bend farther upward and if the location of the cowl lip is unchanged, more mass flow spillage will occur.11 The whole process from fuel injection to complete combustion in a scramjet engine is completed in a very short time because the mean flow in a combustor is so fast in the supersonic regime. Mixing enhancement is one of the most important factors to realize the scramjet. Flow patterns near the injectors and flame holder determine the mixing efficiency. Therefore, a three dimensional numerical analysis was conducted to investigate the flow structures and fuel-air mixing characteristics with and without intake side walls, in terms of flow patterns. II. Geometry The scramjet engine used for simulation in this work was designed by Korea Aerospace Research Institute (KARI). The engine is composed of four major parts; intake ramp, wedge shaped cowl, intake sidewall, and combustor with cavity flame-holder, as shown in Fig. 1. Four sonic injectors with injection angle of 45 deg. inject H2 into the main stream. The engine has a width of 100 mm. A full description is presented by Kang et al. 12 a) b) c) Figure 1. Schematic of model Scramjet engine[12]. III. Numerical Approach The Favre averaged governing equations based on the conservation of mass, momentum, energy, and species concentration for a compressible flow can be written as ¶r ¶r u% j + =0 ¶t ¶x j 3 American Institute of Aeronautics and Astronautics (1) ( ) ¶r u%i ¶ ( r u%i u% j + pd ij ) ¶ t ij - r u ¢¢j ui¢¢ + = ¶t ¶x j ¶x j (2) % ¶ u%it ij - r h¢¢ui¢¢ ¶q j ¶r E% ¶ ( r E + p ) u% j + = ¶t ¶x j ¶x j ¶x j (3) ( ) ¶r Y%k ¶ r u% j Y%k ¶ + = ¶t ¶x j ¶x j ( ) ( ) æ ö ¶Y% çç r Dk k - r u ¢¢j Yk¢¢÷÷ , k = 1,..., N ¶x j è ø (4) For a multi-component mixture, pressure and specific total internal energy can be written as follows; E = e+ N ui ui p , e = h2 r (5) N T h = å Yk hk = å Yk æç Dhof , k + ò C p , k (T ¢ ) dT ¢ ö÷ T ref è ø k =1 k =1 (6) N Yk k =1 Wk p = r Ru T å (7) The governing equations are solved numerically with finite-volume formulation. A. Numerical Method The conservation equations for moderate and high Mach number flows are well coupled, and standard numerical techniques perform adequately. In regions of low Mach number flows, however, the energy and momentum equations are practically decoupled, and the system of conservation equations becomes stiff. Over the entire scramjet flow path, the flow fields are governed by a wide variety of time scales (from subsonic flow in the cavity flame-holder to hypersonic flow in main stream). Such a wide range of time scales causes an unacceptable convergence problem. To overcome this problem, a two-step dual time-integration procedure is applied for flows at all Mach numbers. First, a rescaled pressure term is used in the momentum equation in order to circumvent the singular behavior of pressure at low Mach numbers. Second, a dual time-stepping integration procedure is established. The pseudo-time derivative may be chosen in order to optimize the convergence of the inner iterations by using an appropriate preconditioning matrix that is tuned to rescale the eigenvalues to render the same order of magnitude, so as to maximize convergence. To unify the conserved flux variables, a pseudo-time derivative of the form Γ∂Z/∂τ can be added to the conservation equation.13 Since the pseudo-time derivative term disappears upon convergence, a certain amount of liberty can be taken in choosing the variable Z. While dual time stepping and LU-SGS are applied for second-order time integration, a control volume method is used to integrate inviscid fluxes represented by AUSMPW+ and MUSCL as well as viscous fluxes represented by central difference. A multi-block feature using an MPI library was used to speed up the calculation. B. Turbulence Model and Compressibility Correction The standard k-e model, which was proposed for high Reynolds number flows, is traditionally used with a wall function and the variable y+ as a damping function. However, the flow situation with separation has singularity on the wall because of y+. Thus, a low Reynolds number k-e model was developed for near-wall turbulence. Within certain distances from the wall, all energetic large eddies will reduce to Kolmogorov eddies (i.e. the smallest eddies in turbulence), and all the important wall parameters such as friction velocity, viscous length scale, and mean strain rate at the wall can be characterized by the Kolmogorov micro scale. Yang and Shih proposed a time-scale-based k-e model for the near-wall turbulence related to the Kolmogorov time scale as its lower bound, so that the equation can be integrated to the wall. The advantages of this model are (a) 4 American Institute of Aeronautics and Astronautics no singularity at the wall, and (b) adaptability to separation flow, since Ry instead of y+ is used as the independent variable in the damping function. Thus, the model could be applicable to more complex flows.14 The low Reynolds number models have been designed to maintain the high Re formulation in the log-law region and further tuned to fit measurements for the viscous and buffer layers. As the Mach number of a turbulent flow increases, the velocity fields can no longer be assumed to be solenoidal. Turbulence modeling for compressible flow has to account for the additional correlations involving both the fluctuating thermodynamic quantities and the fluctuating dilatation. The interaction of a shock wave with a turbulent boundary layer leads to a significant increase in turbulence intensity and shear stress across the shock15. To take account of the important features of the high-speed flow and shear layer over the cavity, this study employed the compressible-dissipation and pressure-dilatation correction proposed by Sarkar.15-18 Wilcox’s model18 is applied for wall-bounded flow. Not only did the Low Reynolds number k-e with Sarkar’s model adequately predict the impinging point of the jet on the diffuser wall, but the separation point, as compared with experimental data, also captured the dynamic motion near operational pressure.19,20 The Low Reynolds number k-e with Wilcox’s model showed better accuracy than Sarkar’s model.21 The turbulent kinetic energy and its dissipation rate are calculated from the turbulence transport equations written as follows: ¶r k ¶ ( r u% j k ) ¶ + = ¶t ¶x j ¶x j ææ m çç ç m + t s k èè ¶re s ¶ ( r u% j e s ) ¶ + = ¶t ¶x j ¶x j ö ¶k ÷ ø ¶x j ææ m çç ç m + t se èè ö ÷÷ + Pk - r ( e s + e c ) + p ¢¢d ¢¢ ø (8) ö ( Ce 1 Pk - Ce 2 re s ) +L ÷÷ + Tturb ø (9) ö ¶e s ÷ ø ¶x j where e c and p ¢¢d ¢¢ represent compressible-dissipation and pressure-dilatation, respectively, and F ( M t ) = éë M t 2 - M t 0 2 ùû H ( M t - M t 0 ) e c = a1 F ( M t ) e s p ¢¢d ¢¢ = -a 2 Pk F ( M t ) + a 3 re s F ( M t ) (10) (11) (12) The turbulent Mach number is M t 2 = 2k / c 2 . The closure coefficients for the compressible corrections are: a1 = 1.5 , a 2 = 0.4 , a 3 = 0.2 , M t 0 = 0.25 C. Computational Conditions and Computational Domain The computational code is paralleled with a multi-block feature using an MPI library to speed up the computation. The scramjet engine was simulated at an altitude of 31 km. The inlet conditions are: 1.040 kPa pressure, temperature 224 K, and flight Mach number of 7.6. Figure 2 shows the computational domain and boundary conditions of the engine. The computational domain consists of 11 blocks. The external zone with 5 blocks includes the intake ramp and intake sidewall. The internal zone consists of blocks 6 to 11. The external zone has intake ramps and intake side walls which are set as wall boundary condition. In the case with no intake side walls, the wall boundary is replaced with a symmetric boundary. The supersonic boundary was applied for the inlet and outlet. The wall is assumed to be adiabatic. The sonic injector conditions are: total pressure of 263.8 kPa, total temperature of 300 K, and overall equivalence ration of 0.11 The computation was performed in two parts -- part 1 (#1 to #6) and part 2 (#6 to #11) -- independently, to save computational time and memory size. Block 6 was overlapped and used as the inlet boundary zone of part 2 to preserve the accuracy and the consistency of the part2 calculation. Parts 1 and 2 have 1.2 million and 1.37 million grid points, respectively. The block 6 consists of 338,100 grid points. Four sonic injectors are located in part 2. A typical computational step is 10-7 sec. for the unsteady calculation. 5 American Institute of Aeronautics and Astronautics a) b) Figure 2. Computational multi-block domain and boundary condition: a) boundary conditions and b) block arrangement IV. Results A. Flow Structure and Verification Figure 3 shows the pressure distribution along the center line of the bottom wall for two cases: with two side walls and without two side wall at the intake. In the overlapped zone, the pressure distribution of part 1 agrees well with that of part 2. The experimental data were obtained for the case with intake side walls. The numerical data and the experimental data are in fairly good agreement, except far down stream of the combustor. The pressure in the combustor in the case with intake side walls oscillates higher than the level of pressure fluctuations in the case without intake side walls because shock-wall and shock-boundary interactions occur more strongly and the compression of intake air is much more non-uniform due to the side walls. At the intake ramp, the pressure distribution of the two cases is almost identical because the effects of the intake side walls at the center of the intake ramp are weaker than that the effects near the side walls. Figure 4 shows shock wave patterns in the center x-z plan of the engine with the intake side walls; a complex combination of multiple shocks and expansion waves originate from the intake’s contraction and expansion. The shock starting from cowl tip impinges and Figure 3. Pressure distribution along the center of the bottom reflects on the bottom surface, impinges wall. and reflects on the top wall, and impinges 6 American Institute of Aeronautics and Astronautics and reflects again until the compression wave propagates far down stream of the cavity. Figure 5 shows Mach number distribution in cross section at the intake cowl tip for two cases. In the case of two intake side walls, the core streams are observed at three locations: center, left, and right in the cross section, and the maximum Mach number is located near the side walls. The flow is, however, very uniform in the y- direction in the case without intake side walls. It should be noted that the side walls significantly affect the flow structure at the entrance of the combustor. a) b) Figure 4. Shock wave system of model Scramjet engine with intake side walls. a) With intake side walls b) Without intake side walls Figure 5. Mach number contour in Y-Z plane at the leading edge of cowl. B. Effect of Intake side walls on flow structure To demonstrate the effects of intake side walls, the flow structure near the intake side walls and at the entrance of the combustor is shown in Figs. 6 and 7. Shock/boundary-layer and shock-shock interactions occur at the intake side walls. The ramp shocks from the intake ramps claw at the boundary layer of the intake side walls. The ramp shocks deflect the flow and change the shape of the boundary layer. In Fig. 7, only one shock starting from the first ramp occurs in IP 1 plane, but two shocks from the first and the second ramps appear in IP 2 and IP 3 planes at 0.02 m and 0.08m downstream of the leading edge of the second ramp, respectively. SBI 1 and SBI 2 Figure 6. Intake flow structure with two intake side walls. are caused by the interaction between ramp 7 American Institute of Aeronautics and Astronautics shock and boundary layer of sidewall. SBI 1 and SBI 2 mean shock-boundary interactions caused by the first ramp shock and the second ramp shock, respectively. The flow distortion with helical motion from side wall to center may be intuitively expected from the motion of SBI 1 and SBI 2 as shown in Fig. 7. The flow deflection caused by the interaction between the shock and the turbulent boundary layer makes the intake flow structure more complex and the shock-shock interactions affect flow deflection. As shown in Figs. 5, 6, and 7, the inlet with intake side walls has helical flow induced by the deflected flow at intake side walls. Mach number increases up to about 4.0 near both side walls because of the helical flow, which develops from side wall to center region as some of the flow along the side walls moves toward the center of the combustor. a) IP 1 (at X=0.3 m) b) IP 2 (at X = 0. 44 m) c) IP 3 (at X = 0. 49 m) Figure 7. Mach contour at three Y-Z planes in the intake. a) IP1: 0.3m, b) IP2: 0.02m c) IP3:0.0.8 m downstream of the leading edge of the second ramp. a) With intake side walls b) Without intake side walls Figure 8. Mach number iso-surface and stream-lines at the entrance of combustor. Figure 8 represents streamlines at the entrance of the combustor. In the case of no intake side wall, the flow deflected toward the center of the duct recovers towards the axial direction before the injector location. However, in 8 American Institute of Aeronautics and Astronautics the case with intake side walls, the deflected flow from both side walls recovers after passing the cavity flameholder behind the injectors and penetrates into the center of the combustor. a) With intake side walls b) Without intake side walls Figure 9. Intake shock structure at combustor entrance. 9 American Institute of Aeronautics and Astronautics a) With intake side walls b) without intake side walls Figure 10. Shock-boundary interactions on the half cross section, from center to side wall, at entrance of combustor: white color represents sonic velocity. Shock-boundary interaction is dashed red lines and sonic line is presented by white line. The each Y-Z planes is shown in Fig. 9. Figure 9 shows the gradient density inside the combustor for the two cases. The flow patterns in the combustor with the side walls are much more complicated. Several shocks starting from the inlet cowl corners and the side walls are deflected toward the center region of the combustor, which corrupts the flow structure as shown the cross section IP7. Figure 10 shows density gradient in Y-Z planes, through IP4 to IP8 representing upstream of cavity, enlarged to examine shock-boundary interaction on the walls. The curved cowl shock reflects from the side and the top walls(IP4 and IP5) and impinges the bottom walls, which produces large separation flow at IP 7 and IP 8. Thus it may be expected that the side walls will affect the fuel-air mixing structure in the combustor. The details of the mixing characteristics are discussed in section C. a) With intake side walls b) Without intake side walls Figure 11. Pressure distribution inside combustor. 10 American Institute of Aeronautics and Astronautics Figure 11 shows pressure distribution at the bottom wall of the combustor. Reflected shock-wall (or boundary layer) interaction leads to pressure increase in the interaction region. In the case without intake side walls, pressure distribution is a uniform band at the bottom wall. In the case with the intake side walls, the reflected shock impinges more strongly near the side walls and at the center of the lower wall. The pattern of the flow structure is transformed by the effect of the intake side walls. In the case without intake side walls, a higher level of pressure fluctuations along the bottom wall is observed. The quasi-uniform shock structure forces the pressure distribution into a band shape. In the case with the intake side walls, the deflected flow from the intake side walls disperses the flow structures and contribute to an increase in a local pressure inside the combustor. C. Effects of Intake Side Walls with Fuel Injection There is a general perception that fuel injection, ignition, and combustion are closely associated with boundary layer conditions on the wall. Although the mean flow inside a supersonic combustor may not be at a high enough temperature for ignition or combustion, the aerodynamic heating on the wall upstream of the injector is able to supply enough heat energy for ignition. Some of the heated flow on the wall enters into the cavity and forms recirculation zones. Figure 12 shows iso-surfaces of H2 mass fraction near the cavity flame-holder. The fuel cores are quickly bended downstream after being injected perpendicularly into the cross stream and then gradually mixed with the air. Figure 13 shows iso-surfaces of H2 mass fraction and stream-lines zoomed at the cavity flame-holder. The rotation in the case with sidewalls is more active and constrains the fuel’s upper section and then allows the fuel’s bottom section to expand. The rotation direction in case with no side walls is opposite to that of the side wall case. Figure 14 shows fuel mixing. Fuel mass fraction is represented by iso-surfaces at 0.05 and 0.001. Stream-line with temperature legend is nearby bottom wall. Some of the hot flow on the wall enters into the cavity and forms a recirculation flow. The revolving flows split the cavity flow into several zones. Each fuel stream which penetrates the cavity is isolated from other fuel streams due to the flow deflection at the intake side walls. The direction of the recirculating flow is represented by arrows. Each pair of the four fuel streams downstream of the cavity flame-holder is merged until, finally the four streams become two streams, because the streams injected by injectors #1 and #4 are bent by the deflected flow on the side walls. In the case without side walls, the fuel streams flow side by side without being merged. The revolving flow in the cavity moves toward the side walls. Figure 15 shows stream-line and fuel mass fraction in the cavity. The mass fraction for the two cases is not very different, but the flow pattern is somewhat different because a rotation ring in the cavity forms in the case with side walls. The flow pattern may be due to the inwards rotational direction, as shown in Fig. 13. a) With intake side walls b) Without intake side walls Figure 12. Iso-surfaces of H2 mass fraction near cavity flame-holder. 11 American Institute of Aeronautics and Astronautics a) With intake side walls b) Without intake side walls Figure 13. Iso-surface of H2 mass fraction and stream-lines at cavity flame-holder. a) With intake side walls b) Without intake side walls Figure 14. H2 injection and mixing enhancement 12 American Institute of Aeronautics and Astronautics a) Locations of the X-Z planes b) With intake side walls c) Without intake side walls Figure 15. H2 mass fraction and stream-lines in X-Z planes at the cavity flame-holder. Figure 16 shows temperature contour and fuel mass fraction pattern inside the cavity and downstream of the cavity. The locations of the y-z plane are 4.5 mm and 59 mm downstream of the leading edge of the cavity. As shown in Fig. 14a, fuel spreads toward the center of the cavity because two of the fuel streams injected by injectors #1 and #4 are bent by the flow deflected from the side walls. In contrast, in the case without intake side walls, the two fuel streams injected by injectors #2 and #3 spread toward the side walls. At the plane 59 mm downstream of the leading edge of the cavity flame-holder, all four fuel streams have semicircle shapes. In the case with intake side walls, however, the fuel streams are combined. 13 American Institute of Aeronautics and Astronautics a) With intake side wall b) Without intake side wall Figure 16. Temperature contour and H2 mass fraction contour lines at the middle of the cavity (top) and 50 mm downstream of the end of the cavity (bottom). After fuel injection, the flow structure inside the combustor undergoes transitions. Figure 17(a) shows a history of the pressure changes in the combustor, including the cavity flame-holder. Both with intake side walls and without intake side walls, the pressure increases and impinging points move upstream at the same time. The flow right behind the cavity flame-holder in particular suffers more severe flow structure changes. In the case without intake side walls, it takes about 0.5 msec to rearrange the flow structure, but about 0.8 msec in the case with intake side walls. The difference is caused by the pattern of the fuel-air mixing and the effects of intake side walls. With intake side walls, it takes longer for the fuel to be spread because the deflected flow from the intake side walls disperses the flow structure. Figures 17 (b), (c) and (d) represent local equivalence ratio at specific locations in the combustor. At the location closest to the injector (Fig.17 (b)), the local equivalence ratio is distributed over 1 in several locations in the y-z plane and decreases downstream of injector. The fuel injected from injectors near the side walls spreads toward the combustor center and forms a relatively narrower fuel region with high equivalence ratio. It seems more rapidly mixed with the air stream in case with side walls To quantify the level of mixing, mixing efficiency is considered. This efficiency is defined using the following formulation. hmix ( x) = ò rY ua dA ò rY udA H2 (13) H2 Where ρ is density, YH is mass fraction of hydrogen, u is the velocity component normal to the area dA . The 2 parameter a is decided by local equivalence ratio. If the ratio is less than 1, a has a value of 1. If not, the value is given the reciprocal of the local equivalence ratio.22 This means that if the local equivalence ratio is less than 1, the mixing is regarded as completed. Also, the mixing does not occur when the equivalence ratio is much larger than 1. Figure 18 (a) represents histories of the efficiencies for both cases. The efficiency transition takes place quickly. At 0.1 ms, the efficiency is rapidly rising behind the injector and reaching 1, but it drops to 0 in the middle of the combustor. This means that the fuel has not yet reached the exit of the combustor. After 0.2 ms, the fuel is observed from the injection point to combustor exit. Although the location where the mixing efficiency reaches 1 is moved 14 American Institute of Aeronautics and Astronautics downstream, it keeps its value far downstream. The fuel mass maximum fraction decreases from 1 to an almost negligible value in a short range due to fuel lean injection (0.11) a) History of pressure distribution b) 30mm downstream of cavity center c) 80 mm downstream of cavity center d) 130 mm downstream of cavity center Figure 17. History of pressure distribution along the center line of the bottom wall and local equivalence ratio distribution along span-wise direction at specific location of x. H: height from bottom wall. a) b) Figure 18. History of a) mixing efficiency and b) maximum hydrogen mass fraction through combustor 15 American Institute of Aeronautics and Astronautics V. Conclusion A 3D numerical simulation with fuel injection was conducted in order to illuminate the flow characteristics and H2-air mixing characteristics in a model scramjet engine with two intake-sidewalls and a cavity flame-holder. Cases with and without sidewalls were studied; flow patterns for the two cases were found to be quite difference. The flow deflections caused by shock formation and shock/boundary interaction at the intake side walls influence the flow structure over the entire flow path from intake to combustion. The computed wall pressure was compared with the experimental data obtained with the intake side walls. The pressure distribution along the center-line of the bottom wall agrees well with that of experimental data taken in the same combustor. Shock-boundary layer and shock-shock interactions are generated on the intake side walls. The ramp shocks occurring at the intake ramps claw at the boundary layer of the intake side walls. Because of this, the ramp shocks deflect the flow and the boundary layer shape. The deflected flow makes the intake flow structure more complex and produces helical flow at the inlet. In the case without intake side walls, a higher level of pressure fluctuations along the bottom wall is observed in the combustor. Without intake side walls, quasi-uniform shock structure induces pressure distribution with band shapes, but the flow deflected from the intake side walls disperses the flow structure with three local peaks. Thus the increase in local pressure inside the combustor is caused partially by the reflected shock. In the case with intake side walls, it takes more time for the fuel to spread out in the combustor. The helical flow bends the two fuel streams injected from injectors #1 and #4 near the side walls toward the center of the chamber and recovers behind the cavity flame-holder. The pattern and direction of revolving flow inside the cavity flameholder are transformed. In the case of intake side walls, it is observed that each stream of fuel which penetrates the cavity is isolated from other fuel streams. For the fuel mixing efficiency transition, at 0.1 ms the efficiency is rapidly rising behind injector and reaching 1, but it drops to 0 in the middle of the combustor. After 0.2 ms, the fuel mixing efficiency reaches 1 and keeps the value far downstream. The fuel mass maximum fraction decreases from 1 to an almost negligible value in short range due to very low fuel lean injection. References 1 Sun, M. B., Wang, Z. G., Lian, J. H., and Geng, H., “Flame Characteristics in Supersonic Combustor with Hydrogen Injection Upstream of Cavity Flameholder,” J. Propulsion and Power, Vol. 24, No. 4, 2008, pp. 688-696. 2 Kumaran, K., and Babu, V., “Mixing and Combustion Characteristics of Kerosene in a Model Supersonic Combustor,” J. Propulsion and Power, Vol. 25, No. 3, 2009, pp. 583-592. Kal, S., and Hannemann, K., “CFD Analysis of the Hyshot Ⅱ Scramjet Experiments in the HEG Shock Tunnel,” 15th AIAA International Space Planes and Hypersonic Systems and Technologies Conference, Vol. 25, No. 3, 2009, AIAA 2008-2548. 4 Abdel-Salam, T. M., Tiwari, S. N., and Mohieldin, T. O., “Three-Dimensional Numerical Study of a Scramjet Combustor,” 40th AIAA Aerospace Sciences Meeting and Exhibit, Reno, NV, 2002, AIAA 2002-0805. 5 Kirchhartz, R. M., Mee, D. J., Stalker, R., J., Jacobs, P. A., and Smart, M. K., “Supersonic Boundary-Layer Combustion: Effects of Upstream Entropy and Shear-Layer Thickness,” J. Propulsion and Power, Vol. 26, No. 1, 2010, pp. 57-66. 6 Korkegi, R. H., “Comparison of Shock-Induced Two- and Three-Dimensional Incipient Turbulent Separation,” AIAA Journal, Vol. 13, No. 4, 1975, pp. 534-535. 7 Egle, W., Driscoll, J., and Benek, J., “Experimental Investigation of Corner Flows in Rectangular Supersonic Inlets with 3D Shock-Boundary Layer Effects,” 49th AIAA Aerospace Sciences Meeting including the new Horizons Forum and Aerospace Exposition, Orlando, Florida, 2011, AIAA 2011-857. 8 Yeom, H. W., Kim, S. J., Sung, H. G., Kang S. H., and Yang, S. S., “Intake Side Wall Effect of a Scramjet Engine with a Cavity Flame-Holder Using a Unified 3D Numerical Analysis,” Asian Joint Conference on Propulsion and Power, Miyazaki, Japan, 2010, pp. 757-762. 9 Reinartz, B. U., and Gaisbauer, U., “Numerical Investigation of 3D Intake Flow,” 17th AIAA International Space Planes and Hypersonic Systems and Technologies Conference, San Francisco, California, 2011, AIAA 2011-2351. 10 Gruhn, P., and Gülhan, A., “Expermental Invetigation of a Hypersonic Inlet with and Without Sidewall Compression,” J. Propulsion and Power, Vol. 27, No. 3, 2011, pp. 718-729. 11 Nguyen, T., Behr, M., Reinartz, B. U., Hohn, O., and Gülhan, A., “Numerical Investigations of the Effects of Sidewall Compression and Relaminarization in 3D Scramjet Inlet,” 17th AIAA International Space Planes and Hypersonic Systems and Technologies Conference, San Francisco, California, 2011, AIAA 2011-2256. 3 16 American Institute of Aeronautics and Astronautics 12 Kang, S. H., Lee, Y. J., and Yang, S. S., “Numerical Investigation about the Ground Test Results of Model Scramjet Engine,” KSPE Spring Conference, Incheon, Korea, 2008, pp. 328-331. 13 Hsieh, S. Y., and Yang, V., “A Preconditioned Flux-Differencing Scheme for Chemically Reacting Flows at All Mach Numbers,” International Journal of Computational Fluid Dynamics, Vol. 8, Issue 1, 1997, pp. 31-49. 14 Yang, Z. and Shih, T. H., “New Time Scale Based k - e Model for Near-Wall Turbulence,” AIAA Journal, Vol. 31, No. 7, 1993, pp. 1191- 1198. 15 Sarkar, S., Erlebacher, B., Hussaini, M., and Kreiss, H., “The Analysis and Modeling of Dilatational Terms in Compressible Turbulence,” J. Fluid Mechanics, Vol. 227, 1991, pp. 473~493. 16 Sarkar, S., “Modeling the Pressure-Dilatation Correlation,” ICASE, Hampton, VA, 1991, Rept. 91-42. 17 Dash, S., and Kenzakowski, D. C., “A Compressible-Dissipation Extension of the k-Epsilon Turbulence Model and Building-Block Data for its Validation,” AIAA and SDIO, Annual Interceptor Technology Conference, Huntsville, AL, 1992. 28p. 18 Wilcox, D. C., “Effects of Compressibility,” Chap. 5 of Turbulence Modeling for CFD, 2nd Ed., DCW Industries Inc.,1998, Chapter 5. 19 Yeom, H. W., Kim, S. J., and Sung, H. G., “An Investigation of the Compressibility-Correction Turbulence Models in Supersonic Flow with Flow Separation,” Annual Progressive Presentation, Korea Aerospace University HPCL, TM 07-003, 2007. 20 Yeom, H. W., Yoon, S. G., and, Sung, H. G., “Flow Dynamics at the Minimum Starting Condition of a Supersonic Diffuser to Simulate a Rocket’s High Altitude Performance on the Ground,” Journal of Mechanical Science and Technology, Vol. 23, No. 1, 2009, pp. 254-261. 21 Yeom, H. W., Kim, S. J., and Sung, H. G., “An Investigation of the Compressibility-Correction Turbulence Models,” Annual Progressive Presentation, Korea Aerospace University HPCL, TM 10-012, 2010. 22 Peterson, D. M., Tylczaky, E. B., and Candler G. V., “Hybrid Reynolds-Averaged and Large-Eddy Simulation of Scramjet Fuel Injection” 17th AIAA International Space Planes and Hypersonic Systems and Technologies Conference, San Francisco, California, 2011, AIAA 2011-2344. 17 American Institute of Aeronautics and Astronautics

© Copyright 2025