Double-layer anti-reflection coating containing a

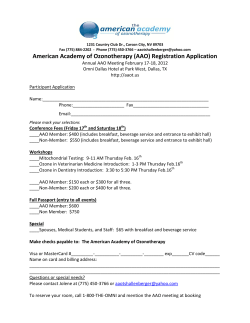

Double-layer anti-reflection coating containing a nanoporous anodic aluminum oxide layer for GaAs solar cells Tianshu Yang,1 Xiaodong Wang,1,2 Wen Liu,1 Yanpeng Shi,1 and Fuhua Yang1,2,* 1 Engineering Research Center for Semiconductor Integrated Technology, Institute of Semiconductors, Chinese Academy of Sciences, Beijing 100083, China 2 xdwang@semi.ac.cn * fhyang@semi.ac.cn Abstract: Multilayer anti-reflection (AR) coatings can be used to improve the efficiency of Gallium Arsenide (GaAs) solar cells. We propose an alternate method to obtain optical thin films with specified refractive indices, which is using a self-assembled nanoporous anodic aluminum oxide (AAO) template as an optical thin film whose effective refractive index can be tuned by pore-widening. Different kinds of double-layer AR coatings each containing an AAO layer were designed and investigated by finite difference time domain (FDTD) method. We demonstrate that a λ /4n – λ /4n AR coating consisting of a TiO2 layer and an AAO layer whose effective refractive index is 1.32 realizes a 96.8% light absorption efficiency of the GaAs solar cell under AM1.5 solar spectrum (400 nm-860 nm). We also have concluded some design principles of the double-layer AR coating containing an AAO layer for GaAs solar cells. ©2013 Optical Society of America OCIS codes: (310.1210) Antireflection coatings; (310.4165) Multilayer design; (310.6628) Subwavelength structures, nanostructures. References and links 1. M. A. Green, Solar Cells: Operating Principles, Technology, and System Applications (Prentice-Hall, Inc., 1982), Chap. 10. 2. D. J. Aiken, “High performance anti-reflection coatings for broadband multi-junction solar cells,” Sol. Energy Mater. Sol. Cells 64(4), 393–404 (2000). 3. S. Chhajed, M. F. Schubert, J. K. Kim, and E. F. Schubert, “Nanostructured multilayer graded-index antireflection coating for Si solar cells with broadband and omnidirectional characteristics,” Appl. Phys. Lett. 93(25), 251108 (2008). 4. M. F. Schubert, F. W. Mont, S. Chhajed, D. J. Poxson, J. K. Kim, and E. F. Schubert, “Design of multilayer antireflection coatings made from co-sputtered and low-refractive-index materials by genetic algorithm,” Opt. Express 16(8), 5290–5298 (2008). 5. S. J. Oh, S. Chhajed, D. J. Poxson, J. Cho, E. F. Schubert, S. J. Tark, D. Kim, and J. K. Kim, “Enhanced broadband and omni-directional performance of polycrystalline Si solar cells by using discrete multilayer antireflection coatings,” Opt. Express 21(S1 Suppl 1), A157–A166 (2013). 6. M. P. Lumb, W. Yoon, C. G. Bailey, D. Scheiman, J. G. Tischler, and R. J. Walters, “Modeling and analysis of high-performance, multicolored anti-reflection coatings for solar cells,” Opt. Express 21(S4), A585–A594 (2013). 7. E. Wang, F. Yu, V. Simms, and H. Brandhorst, “Optimum design of antireflection coating for silicon solar cells,” in Photovoltaic Specialists Conference, 10 th, (Palo Alto, Calif, 1974), 168–173. 8. K. Robbie and M. J. Brett, “Sculptured thin films and glancing angle deposition: Growth mechanics and applications,” J. Vac. Sci. Technol. A 15(3), 1460–1465 (1997). 9. K. Robbie, G. Beydaghyan, T. Brown, C. Dean, J. Adams, and C. Buzea, “Ultrahigh vacuum glancing angle deposition system for thin films with controlled three-dimensional nanoscale structure,” Rev. Sci. Instrum. 75(4), 1089–1097 (2004). 10. S. R. Kennedy and M. J. Brett, “Porous broadband antireflection coating by glancing angle deposition,” Appl. Opt. 42(22), 4573–4579 (2003). #191494 - $15.00 USD (C) 2013 OSA Received 31 May 2013; revised 13 Jul 2013; accepted 15 Jul 2013; published 22 Jul 2013 29 July 2013 | Vol. 21, No. 15 | DOI:10.1364/OE.21.018207 | OPTICS EXPRESS 18207 11. J. Q. Xi, M. F. Schubert, J. K. Kim, E. F. Schubert, M. F. Chen, S. Y. Lin, W. Liu, and J. A. Smart, “Optical thin-film materials with low refractive index for broadband elimination of Fresnel reflection,” Nat. Photonics 1, 176–179 (2007). 12. H. Masuda and M. Satoh, “Fabrication of gold nanodot array using anodic porous alumina as an evaporation mask,” Jpn. J. Appl. Phys. 35(Part 2, No. 1B), L126–L129 (1996). 13. A. P. Li, F. Muller, A. Birner, K. Nielsch, and U. Gosele, “Hexagonal pore arrays with a 50-420 nm interpore distance formed by self-organization in anodic alumina,” J. Appl. Phys. 84(11), 6023–6026 (1998). 14. H. Masuda, K. Yasui, Y. Sakamoto, M. Nakao, T. Tamamura, and K. Nishio, “Ideally ordered anodic porous alumina mask prepared by imprinting of vacuum-evaporated al on Si,” Jpn. J. Appl. Phys. 40(Part 2, No. 11B), 1267 (2001). 15. W. Liu, X. Wang, R. Xu, X. Wang, K. Cheng, H. Ma, F. Yang, and J. Li, “Long-range-ordered Ag nanodot arrays grown on GaAs substrate using nanoporous alumina mask,” Mater. Sci. Semicond. Process. 16(1), 160– 164 (2013). 16. J. Gjessing, E. S. Marstein, and A. Sudbø, “2D back-side diffraction grating for improved light trapping in thin silicon solar cells,” Opt. Express 18(6), 5481–5495 (2010). 17. http://www.lumerical.com/ 18. I. Rey-Stolle and C. Algora, “Optimum antireflection coatings for heteroface AlGaAs/GaAs solar cells—Part I: The influence of window layer oxidation,” J. Electron. Mater. 29(7), 984–991 (2000). 19. I. Rey-Stolle and C. Algora, “Optimum antireflection coatings for heteroface AlGaAs/GaAs solar cells—Part II: The influence of uncertainties in the parameters of window and antireflection coatings,” J. Electron. Mater. 29(7), 992–999 (2000). 20. S. Wilson and M. Hutley, “The optical properties of'moth eye'antireflection surfaces,” J. Mod. Opt. 29, 993– 1009 (1982). 21. R. Bräuer and O. Bryngdahl, “Design of antireflection gratings with approximate and rigorous methods,” Appl. Opt. 33(34), 7875–7882 (1994). 22. J. Tang, P.-f. Gu, X. Liu, and H. Li, Modern Optical Thin Film Technology (Press of Zhejiang University, 2006), Chap. 3. 23. B. Yan, H. Pham, Y. Ma, Y. Zhuang, and P. M. Sarro, “Fabrication of in situ ultrathin anodic aluminum oxide layers for nanostructuring on silicon substrate,” Appl. Phys. Lett. 91(5), 053117 (2007). 1. Introduction Compared with Silicon, Gallium Arsenide (GaAs) is a major material applied in concentrator solar cells and space solar cells for its higher photoelectric conversion efficiency and antiradiation ability. The light transmitted into GaAs can be absorbed quickly as GaAs is a direct band gap semiconductor. In other words, the active layer of a GaAs solar cell as thin as several microns is enough to make full use of the transmitted light [1]. The major loss of light is the reflection of the bare cell surface. To reduce the surface reflection and improve the solar cell efficiency, single-layer and multilayer anti-reflection (AR) coatings are widely studied [2–6]. Compared with the single-layer AR coating, the multilayer AR coating has better AR effect for reducing reflection in broader band of the solar spectrum [7]. However, the variety of materials which can be used as AR coatings is not wide. A designed thin film with a specified refractive index always has no perfect match in real materials, which is a main problem in multilayer AR coatings application. Producing nano-porous material is a main way to realize optical thin films with specified refractive indices. Oblique-angle deposition is a vapour-deposition technique widely used to grow nanostructured thin-film materials, and it has good control over the refractive index profile [8–10]. An optical thin film with an ultra-low refractive index of n = 1.05 was realized by this technique and a graded-index coating consisting of TiO2 and SiO2 nanorod layers was successfully demonstrated to reduce reflection over a broad range of wavelengths [11]. But this technique needs precise control over the process conditions, which raises the difficulty in practical application. We propose an alternate method that is using a self-assembled nanoporous anodic aluminum oxide (AAO) template as an optical thin film. AAO is an Al2O3 thin film with self-organized hexagonal arrays of uniform parallel nanopores. AAO has been widely used as a template for fabricating a periodic nano-structure [12–15], however using AAO as an AR structure is rarely reported. The component of AAO is Al2O3 which has little absorption of visible light. The interpore distance of AAO can be made as small as 50 nm [13] which is far less than visible light wavelengths. In this case, the AAO thin film behaves approximately as a homogenous layer with an effective refractive index [16] which can be #191494 - $15.00 USD (C) 2013 OSA Received 31 May 2013; revised 13 Jul 2013; accepted 15 Jul 2013; published 22 Jul 2013 29 July 2013 | Vol. 21, No. 15 | DOI:10.1364/OE.21.018207 | OPTICS EXPRESS 18208 customized by tuning the fill factor of pores in pore-widening process. In this paper, we designed different kinds of double-layer AR coatings for GaAs solar cells using AAO and TiO2. The effective refractive index of AAO was optimized by finite difference time domain (FDTD) method in order to realize a maximum light absorption efficiency (LAE) of the GaAs solar cell. 2. Simulation model and numerical method Fig. 1. Schematic diagram of the simulation model: perspective view (a), top view (b), and side view (c). Numerical simulations were performed using the FDTD solutions package from Lumerical software [17]. The simulation model of a GaAs solar cell is shown in Fig. 1. The bare GaAs solar cell consists of a GaAs substrate and an Al0.8Ga0.2As window layer of 15 nm thick (as used in Refs [18,19].). The GaAs substrate is set infinitely thick by placing the bottom edge of the simulation region into the GaAs layer and using perfectly matched layers (PML) boundary conditions. Ideally, PML boundaries will absorb all incident light with zero reflection. In this case, the GaAs substrate is assumed to absorb all light passing through its top surface. Above the bare GaAs solar cell is a double-layer AR coating. Layer2 is TiO2 and layer1 is AAO. The period (the distance between two centers of adjacent pores) of AAO is fixed at 50 nm, which is far less than visible light wavelengths. In this case the AAO thin film can be regarded as a homogenous layer with an effective refractive index. To obtain AAO thin films with different effective refractive indices, the diameter of a pore is a variable which can be tuned from 20 nm to 50 nm. Correspondingly the fill factor of pores can be tuned from 0.145 to 0.906. The thickness of each layer (h1 and h2) of the AR coating has been designed and the design principles are explained in Sec. 3. A plane-wave light source is used to illuminate the structure at normal incidence. The wavelengths range of the source is from 400 nm to 860 nm, which lies in the intrinsic absorption spectrum of GaAs. After running the simulation, the reflectance curve and the LAE of the GaAs solar cell under AM1.5 solar spectrum (400 nm-860 nm) were calculated. #191494 - $15.00 USD (C) 2013 OSA Received 31 May 2013; revised 13 Jul 2013; accepted 15 Jul 2013; published 22 Jul 2013 29 July 2013 | Vol. 21, No. 15 | DOI:10.1364/OE.21.018207 | OPTICS EXPRESS 18209 3. Design principles of layer thicknesses of the double-layer AR coating 3.1 Effective refractive indices calculation of the AAO thin films with different fill factors of pores Fig. 2. Schematic diagram of an AAO thin film: perspective view (a), top view (b), and side view (c). The effective refractive indices of the AAO thin films with different fill factors of pores should be calculated before designing the layer thicknesses of the AR coating. One estimation method is to assume that the effective refractive index is simply given by the weighted average neff = f ⋅ n0 + (1 − f ) ⋅ n1 (1) of the refractive indices of the two materials [20]. For the AAO thin film in Fig. 2, n0 is the refractive index of air, n1 is the refractive index of Al2O3, and f is the fill factor of pores. Derived from Eq. (1), the effective refractive index of the AAO thin film in Fig. 2 is 1.66. Brauer et al. performed rigorous calculations which showed that Eq. (1) was only a rough approximation and presented a relatively complex estimation method [21]. In their method, the effective refractive index is 1.64 for the same AAO thin film above. We compared the degree of approximation of these two estimation methods by FDTD method and confirmed the second was more accurate. #191494 - $15.00 USD (C) 2013 OSA Received 31 May 2013; revised 13 Jul 2013; accepted 15 Jul 2013; published 22 Jul 2013 29 July 2013 | Vol. 21, No. 15 | DOI:10.1364/OE.21.018207 | OPTICS EXPRESS 18210 Fig. 3. Reflectance curves of the AAO thin film above and two dielectric thin films with refractive indices derived from method1 and method2 respectively. We used the same plane-wave light source to illuminate three thin films with the same thickness at normal incidence in simulations by FDTD method respectively, and three reflectance curves were calculated. Results are shown in Fig. 3. The black solid line is the reflectance curve of the AAO thin film in Fig. 2. The blue dot line and the red dash line are the reflectance curves of two imaginary dielectric thin films with refractive indices of 1.66 and 1.64, respectively. Considering the reflectance difference only results from the refractive index difference in this case (the thickness is the same and the absorption of light is ignored), the refractive index of 1.64 derived from the second estimation method is more approaching the effective refractive index of the AAO thin film. Therefore we calculated the effective refractive indices of the AAO thin films with different fill factors of pores using the second method. Fig. 4. Fill factors of pores and effective refractive indices of the AAO thin films with different pore diameters. The results are shown in Fig. 4. As the pore diameter changing from 20 nm to 50 nm, the fill factor of pores changes from 0.145 to 0.906 and the effective refractive index of the AAO thin film changes from 1.64 to 1.10. #191494 - $15.00 USD (C) 2013 OSA Received 31 May 2013; revised 13 Jul 2013; accepted 15 Jul 2013; published 22 Jul 2013 29 July 2013 | Vol. 21, No. 15 | DOI:10.1364/OE.21.018207 | OPTICS EXPRESS 18211 3.2 Center wavelength selection method and thickness design of the double-layer AR coating The center wavelength was selected by optimizing the thickness of a TiO2 single-layer AR coating on the GaAs substrate without a window layer. A single-layer AR coating of λ / 4n thick gives minimum reflectance at the center wavelength λ . After performing an optimization simulation by FDTD method, we found the best TiO2 thickness was 60 nm which corresponded to the center wavelength of 560nm. Under this circumstance the GaAs solar cell had a maximum LAE under AM1.5 solar spectrum (400 nm-860 nm), as shown in Fig. 5. Fig. 5. LAEs of the GaAs solar cells with TiO2 single-layer AR coatings of different thicknesses. LAE represents the photon number ratio of the light absorbed by the GaAs substrate to the light incident on the GaAs solar cell surface under AM1.5 solar spectrum (400 nm-860 nm), which is defined as LAE = 860 nm λ 400 nm hc AE (λ ) I AM 1.5 (λ )d λ 860 nm λ 400 nm hc . (2) I AM 1.5 (λ )d λ Here, h is Plank’s constant, c is the speed of light in the free space and I AM 1.5 is AM 1.5 solar spectrum. AE (λ ) is defined by AE (λ ) = Pabs (λ ) Pin (λ ) (3) where Pabs (λ ) and Pin (λ ) are the powers of the light absorbed by the GaAs substrate and the light incident on the GaAs solar cell surface at a wavelength λ , respectively. Therefore, we chose 560nm as the center wavelength for the thickness design of the double-layer AR coating. For double-layer AR coatings, two schemes are widely used to design the thickness of each layer [22]. One is to make each layer λ / 4n thick. Here, λ is the center wavelength, and n is the refractive index of each layer. This kind of double-layer AR coating is called a λ / 4n − λ / 4n AR coating or a v-shaped AR coating, because if the refractive indices of two layers satisfy #191494 - $15.00 USD (C) 2013 OSA Received 31 May 2013; revised 13 Jul 2013; accepted 15 Jul 2013; published 22 Jul 2013 29 July 2013 | Vol. 21, No. 15 | DOI:10.1364/OE.21.018207 | OPTICS EXPRESS 18212 n2 = n1 ng / n0 , (4) where n0 , n1 , n2 and ng are the refractive indices of air, layer1, layer2 and the substrate respectively, the reflectance at λ will be reduced to zero and the reflectance curve looks like a “v”. The other scheme is to make layer2 λ / 2n thick and layer1 λ / 4n thick, respectively. This kind of double-layer AR coating is called a λ / 4n − λ / 2n AR coating or a w-shaped AR coating because if the refractive indices of two layers match well the reflectance will be reduced in a broad band around λ and the reflectance curve looks like a “w”. In our work, we used TiO2 for layer2 and AAO for layer1 to design these two kinds of AR coatings. The effective refractive index of AAO was optimized to make the refractive indices of two layers more matching and to realize a maximum LAE of the GaAs solar cell. 4. Results and discussions Fig. 6. Results of AAO-TiO2 λ / 4n − λ / 4n AR coatings. (a) Reflectance curves of the GaAs solar cells with AAO-TiO2 double-layer AR coatings (colored solid lines with symbols, different colors stand for the AAO layers with different pore diameters) compared with a bare one (black solid line) and one with a TiO2 single-layer AR coating (red dash line). (b) LAEs of the GaAs solar cells with AAO-TiO2 double-layer AR coatings compared with one with a TiO2 single-layer AR coating. At first, we calculated the reflectance curves of the bare GaAs solar cell in Fig. 1 (which consists of a GaAs substrate and a thin window layer) and the same cell covered with a 60 nm TiO2 single-layer AR coating, respectively. LAE of the GaAs solar cell with the single-layer AR coating was also calculated, which is 90.2%. As shown in Fig. 6(a), the single-layer AR coating achieves a minimum reflectance at about 620 nm, which has a red shift from the center wavelength because of the existence of the thin window layer. Secondly, we calculated the reflectance curves and LAEs of GaAs solar cells with AAO-TiO2 λ / 4n − λ / 4n AR coatings. When the pore diameter of the AAO layer is 50 nm, the reflectance curve is quite close to the one of the GaAs solar cell with the TiO2 single-layer AR coating. This is because the fill factor of pores of the AAO layer approximately equals to 1 in this case, which makes the AAO layer almost not exist. The effective refractive index of the AAO layer is 1.22 when the pore diameter is 45nm, which basically satisfies Eq. (4) (the refractive index of GaAs is substituted for ng in Eq. (4)). In this case the reflectance is reduced to zero at about 640 nm, which also has a red shift from the center wavelength because of the existence of the thin window layer. As seen in Fig. 6(b), the results of the AAO-TiO2 double-layer AR coatings are all better than the TiO2 single-layer AR coating. Especially, when the pore diameter of the AAO layer is 40 nm, corresponding to the effective refractive index of 1.32, LAE of the GaAs solar cell reaches a maximum value of 96.8%, which has a 6.6% increase to the TiO2 #191494 - $15.00 USD (C) 2013 OSA Received 31 May 2013; revised 13 Jul 2013; accepted 15 Jul 2013; published 22 Jul 2013 29 July 2013 | Vol. 21, No. 15 | DOI:10.1364/OE.21.018207 | OPTICS EXPRESS 18213 single-layer AR coating. In this case the reflectance is reduced in a broad band and has a minimum total value, as shown in Fig. 6(a). In this optimized double-layer AR coating the thicknesses of TiO2 and AAO are 60 nm and 106 nm, respectively. This thickness of AAO is achievable in experiments. Ultrathin AAO template around 50 nm thick has been realized to fabricate nanodot arrays [23]. Growing a TiO2 layer of a specified thickness is a more ordinary technology. So this optimized AAO-TiO2 double-layer AR coating for GaAs solar cells can be realized in experiments. Fig. 7. Results of AAO-TiO2 λ / 4n − λ / 2n AR coatings. (a) Reflectance curves of the GaAs solar cells with AAO-TiO2 double-layer AR coatings (colored solid lines with symbols, different colors stand for the AAO layers with different pore diameters) compared with a bare one (black solid line) and one with a TiO2 single-layer AR coating (red dash line). (b) LAEs of the GaAs solar cells with AAO-TiO2 double-layer AR coatings compared with one with a TiO2 single-layer AR coating. Thirdly, we calculated the reflectance curves and LAEs of GaAs solar cells with AAOTiO2 λ / 4n − λ / 2n AR coatings. We can find that most of the AAO-TiO2 double-layer AR coatings basically realize a broad band reduction of reflectance, especially in the short wavelengths range from 400 nm to 450 nm, as shown in Fig. 7(a). But around the center wavelength the reduction result is much poorer than the TiO2 single-layer AR coating. Therefore LAEs of the GaAs solar cells with the double-layer AR coatings are lower, as shown in Fig. 7(b). In addition to the work above, we have also tried using SiO2 for layer2 and AAO for layer1 to design λ / 4n − λ / 4n and λ / 4n − λ / 2n AR coatings. Both results of the two kinds of AR coatings are poorer than the SiO2 single-layer AR coating. Especially, for the AAOSiO2 λ / 4n − λ / 4n AR coating, the refractive index of SiO2 is so low that the matching refractive index of layer1 derived from Eq. (4) is out of the effective refractive indices range of AAO. That is the reason why however the pore diameter of AAO changes, the doublelayer AR coating always works poorly. From all the results above, we can basically conclude some design principles of the double-layer AR coating containing an AAO layer for GaAs solar cells. For the λ / 4n − λ / 2n AR coating, we need to find a more proper material for layer2 to achieve a better result. For the λ / 4n − λ / 4n AR coating, the material of layer2 must be chosen properly to make sure the refractive index of layer1 derived from Eq. (4) is within the tuning range of AAO effective refractive indices. The reflectance will be reduced to zero around the center wavelength when the refractive indices of the two layers satisfy Eq. (4). However, it doesn’t mean that LAE of the GaAs solar cell will have a maximum value at the same time. We need to optimize the effective refractive index of AAO around this value to obtain the highest LAE of the GaAs solar cell. #191494 - $15.00 USD (C) 2013 OSA Received 31 May 2013; revised 13 Jul 2013; accepted 15 Jul 2013; published 22 Jul 2013 29 July 2013 | Vol. 21, No. 15 | DOI:10.1364/OE.21.018207 | OPTICS EXPRESS 18214 5. Conclusion As the effective refractive index of AAO can be tuned within a certain range, we used AAO templates as optical thin films to design λ / 4n − λ / 4n and λ / 4n − λ / 2n double-layer AR coatings for GaAs solar cells by FDTD method. TiO2 was used for the bottom layer and AAO for the top layer in the AR coatings. The effective refractive index of AAO was optimized by tuning the fill factor of pores to realize a maximum LAE of the GaAs solar cell. The results of the double-layer AR coatings have been analyzed and compared with the conventional TiO2 single-layer AR coating. We demonstrate that a λ / 4n − λ / 4n double-layer AR coating consisting of a TiO2 layer and an AAO layer whose effective refractive index is 1.32 realizes a 96.8% LAE of the GaAs solar cell under AM1.5 solar spectrum (400 nm-860 nm), which has a 6.6% increase to the TiO2 single-layer AR coating. We also have concluded some design principles of the double-layer AR coating containing an AAO layer for GaAs solar cells. Acknowledgments The authors greatly acknowledge the support from the National Basic Research Program of China (973 Program) under grant number 2012CB934204 and the National Natural Science Foundation of China under grant numbers 61076077, 61274066. #191494 - $15.00 USD (C) 2013 OSA Received 31 May 2013; revised 13 Jul 2013; accepted 15 Jul 2013; published 22 Jul 2013 29 July 2013 | Vol. 21, No. 15 | DOI:10.1364/OE.21.018207 | OPTICS EXPRESS 18215

© Copyright 2025