design of a simple versatile apparatus (fixture) for small

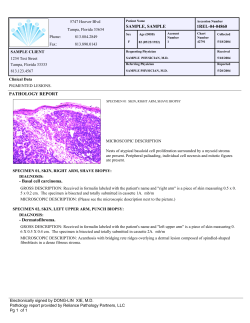

INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-5, MAY-2015 E-ISSN: 2349-7610 Design and Development of a Notched Ring Shaped Miniature Specimen and Its Test Setup to Study the Mechanical Behavior of Metals F.Hafeez1 and A.Husain2 1 Assistant Professor, 2Associate Professor 1 Department of Mechanical Engineering, College of Engineering, University of Shaqra, Saudi Arabia 1 farrukh6aug@gmail.com 2 Department of Civil Engineering, Jamia Millia Islamia, New Delhi,India – 25 2 asif_iitd@rediffmail.com ABSTRACT The paper presents in detail the design and development of a notched ring shaped miniature specimen as well as the experimental setup used for testing the miniature specimen. The experimental setup is simple and possesses salient features which help in meeting the desired objectives of miniature testing. In the present study, notched ring shape specimen are developed from cylindrical rods of different materials using minimum number of machining operations so that the test could be performed in tension mode without affecting its material properties and the proposed notched ring shaped miniature specimen can easily be modeled in plane stress condition in finite element method. The aim of this paper is to develop a methodology for determining mechanical and damage properties of metals from the resultant load displacement curve, obtained by means of a tension test on a Zwick-Z250 universal testing machine. Keywords: Miniature Tests, Mechanical Properties 1. INTRODUCTION The ball or spherical head punch test is the most studied The miniature specimen test is a very useful technique to method used to obtain several mechanical properties such as determine the mechanical properties of materials in those strength, ductility, ductile–brittle transition temperature, and situations where it is impossible to extract large volumes of fracture toughness with little volume of material [3] [4] [5]. material conventional The various shapes and dimensions of the punches, and specimens. Miniature specimen test technique has specifically circular disks have been used by various research groups [1] emerged to solve practical problem related to monitor the [6] [7] [8] [9] [12]. One of the limitations imposed on such test performance of components used in nuclear power generation is the accurate requirement of alignment through the guide systems, petroleum industry, chemical plants, thermal power cylinder of the axis of the punch, specimen and die. Manahan stations etc. Manahan et al [1] have successfully developed the et al. [5] discussed the reasons for this and suggested that the application of small specimen test technique for designing eccentricity of loading should not exceed ~ 0.025mm on large system and nuclear systems in particular. Lucas [2] has samples of 3mm in diameter. In most of the literature on such shown that miniature specimen test technique can be applied type of tests [7] [8] [10] [11] [12], the samples are clamped in successfully to obtain the mechanical properties of metals in place to minimize the misalignment of the miniature specimen the form of either tensile tests, micro hardness, creep, impact with respect to the axis of symmetry of the test rig. Although tests, bend tests, fracture toughness, or punch tests (ball, shear researchers have succeeded in accurately measuring the punch). mechanical properties of samples of various shapes and required for VOLUME-2, ISSUE-5, MAY-2015 standard/full-size COPYRIGHT © 2015 IJREST, ALL RIGHT RESERVED 16 INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-5, MAY-2015 E-ISSN: 2349-7610 thickness using various tests but due to several limitations from the same test. The procedure for making this specimen is placed over design of their test apparatus and specimen the easier as compared to that of making conventional sub size tests become complicated and uneconomical. Owing to the tension test specimens. The selected geometry has additional simplicity of tension test need arises to design a test apparatus advantage due to its convenience in finite element modeling and a simple miniature specimen that can be successfully used and economy in computation time. Fig. 1 shows the mode of to demonstrate and simulate the strength of miniature test failure of specimens prepared and tested as per testing technology in the laboratory. The paper presents the design of requirements. basic components of the experimental setup i.e. specimen holder, loading pin and miniature specimen that can be used on any universal testing machine such as MTS, INSTRON and Zwick etc. Figure- 1: Specimen after Testing 2.2 Specimen Holder 2. DESIGN FEATURES OF MINIATURE The designed specimen holder is made from non shrinkable SPECIMEN TEST APPARATUS die steel having a diameter of 12mm at one end and 6mm The basic components of the experimental setup used in diameter at the other end with a gauge length of 125mm. The present work consist of specimen holder, loading pin, holder is provided with a 10 mm deep slit of 2mm width at miniature specimen, and Zwick/ Z250 universal testing one end (to hold the specimen with the help of a loading pin) machine. The specimen designed for the present investigation and the other end left for firm gripping. A through 2mm is ring shaped with a V notch added diametrically to the diameter hole, drilled laterally, at the depth of 3mm from the miniature specimen. To hold the above notched ring shaped top, is provided for holding the specimen with the help of specimen in the machine, versatile miniature specimen holder 2mm diameter loading pin, shown in Fig. 2. Special attention of die steel which is capable to accommodate different is given to ensure that the slit in the top and bottom holder lie thicknesses of specimens has been designed. The miniature along the same line when both holders are gripped in testing testing is tensile in nature. The miniature specimen machine along with the specimen through the loading pins. experiences tensile load through the loading pin, which holds The arm of the specimen holder is designed in such a way that the miniature specimen in specimen holder. The extension of it can accommodate different specimen thicknesses. After the specimen upon tensile load is recorded automatically with machining, the holders were austenitized at 1000°C for 30 the help of Test-Xpert software interfaced directly with the minutes, followed by air-cooling, and then tempering at 700°C Zwick machine. for an hour to achieve the final hardness of HRC 60. Loading pins used to fix the miniature specimen in the specimen 2.1 Specimens holders were made of martensitic steel so that they would not The miniature specimen in the present investigation has been bend when the tension force is applied. prepared in the following steps. Initially the samples of different materials were produced in the circular rods of 12mm diameter. A precise hole of 8mm diameter was drilled, along the axis of the circular rod, on each of them by marking the centre of the hole. The rings of 0.5mm, 0.8mm and 1.0mm thickness were sliced from these circular rods on EDM wire cut machines. A V-shaped notch of 1mm depth and 60o angle of cut was developed manually on all rings, along same diametrically opposite ends, using a fine grade triangular cross cut file. A V-notch is being added diametrically to obtain both the uniaxial mechanical properties and fracture properties VOLUME-2, ISSUE-5, MAY-2015 Figure 2. Ring specimen attached in the holder COPYRIGHT © 2015 IJREST, ALL RIGHT RESERVED 17 INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-5, MAY-2015 E-ISSN: 2349-7610 The test specimen is subjected to tensile loading through the deformable body with bonded strain gauges. Strain gauges are pin in the bottom holder. Fig. 2 shows a complete assembly of connected together to a measurement bridge. The value of the specimen holder, loading pins and ring specimen. At first the measurement voltage at the measuring bridge output is top specimen holder is gripped along with the specimen using analogous to the force to be measured. This force acts on the wedge grips. Then the specimen is attached with the bottom deformed body and on the entire sensor system. Fig. 3 shows holder by passing the pin through the hole provided in the the specimen in a holder attached on Zwick machine with a specimen and holder. As the bottom holder is gripped in the 5kN load cell used for measuring the force. lower wedge grip, it tries to push the holder along with the specimen and gets rotated. Now, when the tensile load is applied through the loading pin the lower cross head displaces itself and tries to become straight so that the specimen experiences tensile load uniformly. 2.3 Testing Machine In the present investigation Zwick/ Z250 universal testing machine is used for applying the load, as shown in Figure 3. The basic unit of the Z250 material testing machine consists of a load frame and an electronic control console, for testing varieties of materials. The material testing machine is Figure 3. Photograph of specimen in a holder attached on designed for quasi static loading with continuous, pulsating or Zwick Machine cyclic sequences. It has been designed for tensile, compressive and flexural tests. The machine is a floor model where the 3. CONCLUSION load frame basically consists of a base with lead screw drive, The complete apparatus for testing miniature specimen is guide columns, ball lead screws, and a height adjustable and described in this paper. The apparatus includes the description movable crosshead. The base consists of a base plate with lead of designed miniature specimen, specimen holder, and pins. screw bearings and column clamps, the lead screw drive and The results revealed the potential of simple tension test on shock absorbing elements. The base plate and each crosshead designed test apparatus used successfully to simulate the contain a central hole of 70 mm diameter as well as 8 strength of miniature test technology in the laboratory and coaxially arranged M16 threaded holes of radius 110 mm and hence to assess the mechanical properties of metals. 8 coaxially arranged M8 threaded holes of radius 57.5 mm. REFERENCES They serve for moving load cells and specimen grip mounting studs, and diverse supplementary devices such as [1] Manahan, M. P., Argon, A. S., and Harling, O. K., “The extensometers. Development of Miniaturized Disk Bend Test for the The moving cross head is guided on the columns by guide Determination sleeves with two adjustable PTFE friction rings. The basic Properties”, Journal of Nuclear Materials, Vol.103 and setting of adjustable crosshead can be made at a short distance Vol. 104, 1981, pp. 1545. below the head plate, on the columns through clamps. The [2] of Post Irradiation Mechanical Lucas, G. E., “Review of Small Specimen Test maximum test load is 250 kN and the crosshead speed varies Technique from 0.001 to 600 mm/min for the machine used in the present Transaction A, Vol. 21A, May 1990, pp. 1105 – 1119. study. The accuracy of the set speed is 1%. Different load cells [3] for Irradiation Testing”, Metallurgical Baik, J. M., Kameda, J. and Buck, O., “Small Punch Test are available according to the type of test and test materials. Evaluation O Inter-granular Embrittlement of an Alloy Load cells convert the physical quantity of force to an Steel”, Scripta Metallurgica, Vol. 17, 1983, pp.1443– electrically measurable current. It consists of a mechanically 1447. VOLUME-2, ISSUE-5, MAY-2015 COPYRIGHT © 2015 IJREST, ALL RIGHT RESERVED 18 INTERNATIONAL JOURNAL FOR RESEARCH IN EMERGING SCIENCE AND TECHNOLOGY, VOLUME-2, ISSUE-5, MAY-2015 [4] E-ISSN: 2349-7610 Manahan, M. P., “A New Post-irradiation Mechanical Engineering Education, Volume 15, No 1, 2013, pp 48- Behavior Test: The Miniature Disk Bend Test”, Nuclear 53. Technology, Vol. 63, 1983, pp. 275 – 295. [5] Manahan, M. P., Browning, A. E., Argon, A. S., and Harling, O. K., “Miniaturized Disk Bend Test Technique Development and Application”, The use of Small – Scale Specimen for Testing Irradiated Material, STP 888, American Society for Testing and Materials, Philadelphia, 1986, pp. 17 – 49. [6] Huang, F. M., Hanilton, M. L., and Wire, G. L., “Bend Testing for Miniature Disks”, Nuclear Technology, Vol. 57, 1982, pp. 234. [7] Baik, J. M., Kameda, J. and Buck, O., “Development of Small Punch Test for Ductile – Brittle Transition Temperature Measurement of Temper Embrittled Ni – Cr Steel”, In the use of Small – Scale Specimen for Testing Irradiated Material, STP 888, American Society for Testing and Materials, Philadelphia, 1986, pp. 92 – 111. [8] Takahashi, H., Shoji, T., Mao, X., Hamaguchi, Y., Misawa, T., Saito, M., Oku, T., Kodaira, T., Fukaya Kiyoshi, F., Nishi, H., and Suzuki, M., “Recommended Practice For Small Punch (SP) Testing of Metallic Materials (Draft)”, Japan Atomic Energy Research Institute, JAERI – M 88-172 (Report), September 1988, pp. 1-19. [9] Mao, X., Takahashi, H., and Kodaira, T., “Estimation of Mechanical Properties of Irradiated Nuclear Pressure Vessel Steel by use of Sub-sized CT Specimen and Small Punch Specimen”, Scripta Metallurgica, Vol. 25, 1991, pp. 2487 – 2490. [10] Foulds, J. R., Woytowitz, P. J., Parnell, T. K., and Jewell, C. W., “Fracture Toughness by Small Punch Testing”, Journal of Testing and Evaluation, JTEVA, Vol. 23, No.1, January 1995, pp. 3 – 10. [11] Li, H., Chen, F. C., Ardell, A. J., “A Simple Versatile Miniaturized Quantitative Disk Yield – Bend – Test Stress Apparatus for Measurements”, Metallurgical Transaction A, Vol. 22A, Sep. 1991, pp. 2061 – 2068. [12] Lim, W., Kim, H.K., “Design and development of a miniaturised tensile testing machine”, Global Journal of VOLUME-2, ISSUE-5, MAY-2015 COPYRIGHT © 2015 IJREST, ALL RIGHT RESERVED 19

© Copyright 2025