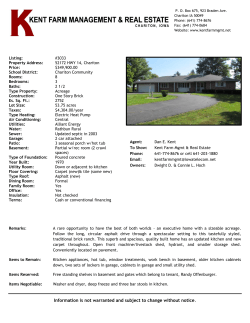

Catalogue