05/2015 - Gov.mt

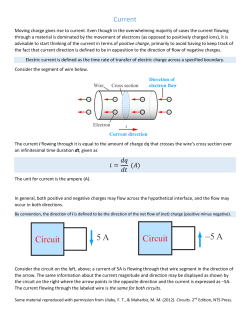

Marine Safety Investigation Unit SIMPLIFIED SAFETY INVESTIGATION REPORT 201403/019 The Merchant Shipping (Accident and Incident Safety Investigation) Regulations, 2011 prescribe that the sole objective of marine safety investigations carried out in accordance with the regulations, including analysis, conclusions, and recommendations, which either result from them or are part of the process thereof, shall be the prevention of future marine accidents and incidents through the ascertainment of causes, contributing factors and circumstances. Moreover, it is not the purpose of marine safety investigations carried out in accordance with these regulations to apportion blame or determine civil and criminal liabilities. REPORT NO.: 05/2015 MV MEIN SCHIFF 2 Damage to lifeboat’s davits travelling wire ropes in St. Georges, Grenada 13 March 2014 Course of events During the month of May 2011, all the wire ropes on Mein Schiff 2 lifeboats were replaced by a firm specialising in the supply and rigging of steel wire ropes. On 04 December 2013, the first of a series of wire rope failures was detected (Figure 1). NOTE This report is not written with litigation in mind and pursuant to Regulation 13(7) of the Merchant Shipping (Accident and Incident Safety Investigation) Regulations, 2011, shall be inadmissible in any judicial proceedings whose purpose or one of whose purposes is to attribute or apportion liability or blame, unless, under prescribed conditions, a Court determines otherwise. The report may therefore be misleading if used for purposes other than the promulgation of safety lessons. © Copyright TM, 2015. This document/publication (excluding the logos) may be re-used free of charge in any format or medium for education purposes. It may be only reused accurately and not in a misleading context. The material must be acknowledged as TM copyright. The document/publication shall be cited and properly referenced. Where the MSIU would have identified any third party copyright, permission must be obtained from the copyright holders concerned. MV Mein Schiff 2 March 2015 part of the lifeboats’ arrangement and are used to extend and retract the telescopic under deck stored power (UDSP) davits housed in the deck ceiling (Figure 2). No weight is taken by the travelling wire when the lifeboats are in the stowed position. Figure 1: Broken wire rope strands (travelling wire rope no. 7) On 13 March 2014, while the vessel was at St. Georges, Grenada, the crew members were carrying out a routine inspection of tender boat no. 12. During the inspection, a wire strand in the aft travelling wire rope was found broken. The travelling wire ropes are 1 Figure 2: UDSP davits extended out Pending wire rope replacement, the damaged strand was temporarily secured by the crew 201403/019 to prevent it from spinning and opening up. lifeboat no. 5. On further examination, three strands from the forward travelling wire rope were found severely damaged (Figure 5). It was also noticed that the wire rope was rigid and difficult to pull through the davits sheave. Tender boat no. 12 was inspected again on 26 March 2014, at Castries in St. Lucia. While extending out the UDSP davit, a cracking sound was heard. The crew detected three damaged strands from the forward travelling wire rope. The damaged section of the wire rope was intractable and strained to pass through the davit sheaves (Figures 3 and 4). Figure 5: Damaged travelling wire rope on lifeboat davits no. 5 Following the incident, the travelling wires of all the lifeboats and tender boats were examined by a certified shore contractor at La Romana, Dominica on 04 April 2014. The examination revealed four broken wire rope strands on the aft travelling wire of lifeboat no. 11. A recommendation was made to replace all lifeboat davits’ travelling wires. Figure 3 & 4: Damaged travelling wire on lifeboat no. 12 Planned maintenance and inspections Pursuant to SOLAS regulation III/20 and III/36, and MSC.1/Circ.1206/Rev.1 on Measures to Prevent Accidents with Lifeboats, the Company’s safety management system (SMS) provided guidance to the crew members on the operational readiness, maintenance and inspections of lifeboats, davits, winches and wire falls. An LA4E Type Test Certificate, issued by a firm authorised by DNV GL, confirmed that the wire rope was a 22 mm 32 x 7 Soliflex, rotation resistance, steel core (IWRC), right hand ordinary lay (sZ) with a breaking load of 380 kN and tensile strength grade of 1960 Nmm-2. The travelling wires on lifeboat no. 12 were eventually replaced on 22 and 28 March 2014. The Company operated an Asset Management Operating System (AMOS), which provided information on the required inspection and maintenance. All routine inspections and maintenance undertaken by the crew were logged in the AMOS. On 30 March 2014, at Rousseau, Dominica, the crew heard a cracking sound upon extending out the UDSP davit arms of MV Mein Schiff 2 2 201403/019 Inspections on Mein Schiff 2 were carried out by the chief mate – safety, the staff chief engineer and the chief electrical engineer. Inspections were supervised by the staff captain. Extensive visual inspections were normally done on a monthly basis and the davits wire falls were lubricated every three months. approximately 20 m to the sea. One crew member was thrown from the lifeboat as it entered the water and two crew members managed to escape from the upturned lifeboat by their own efforts. The remaining five crew members were subsequently declared deceased. The MSIU safety investigation found that: Since AMOS did not specifically make reference to inspection and lubrication of davit’s travelling wires, the master reported that the travelling wires were inspected and maintained at the same time as the lifeboat’s wire falls. the wire rope fall had parted near or around the forward davit’s upper sheave; the wire rope had parted at a site of preexisting corrosion wastage and that it appeared dry and void of lubricant; the cause of the corrosion was due to the wire rope strands opening up under tension, allowing seawater and other contaminants to penetrate the inner core and corrode the strands; The master confirmed that the travelling wire ropes were maintained by the application of lubricant - Fluid Film WRO EP - after the old grease would have been removed. However, due to restriction of space in the under deck area, the travelling wires were lubricated by hand instead of a grease machine. the wire rope fitted was not in accordance with the manufacturer’s recommended specifications; and the grease with the incorrect specifications had been used to lubricate the wire rope during periodic maintenance. Annual inspection of lifeboats All the lifeboats / tender boats were satisfactorily inspected and serviced by an approved shore company on 22 November 2013, in accordance with SOLAS regulations III/20.3, II/20.11 and MSC Circ. 1206 / Rev.1. On 26 February 2013 at 0545(LT), Celebrity Century2 was anchored in Kailua Kona, Hawaii, ready to commence tender boat operations. When tender boat no. 10 was extended out, and before lowering it, the forward wire rope fall parted, causing the tender boat to swivel on the aft hook. The tender boat remained hanging from the aft hook, which then ripped off its base, causing the boat to fall into the water, bow first, at an approximate angle of 45° and a height of 15 m. Similar accidents investigated by the MSIU On 10 February 2013, the Maltese registered passenger vessel Thomson Majesty1 was alongside in Santa Crux de La Palma when a lifeboat carrying eight crew members dropped to the sea and turned upside down. The forward wire rope had parted, causing the lifeboat to swivel on the aft hook. The safety investigation had found that: the wire rope had parted at a site of severe pre-existing corrosion wastage, As the lifeboat reached an angle of approximately 45° to the horizontal, its end and the hook failed and the lifeboat dropped 1 2 Vide MSIU Safety Investigation Report 05/2014 at http://mti.gov.mt/en/Pages/MSIU/SafetyInvestigations-2013.aspx MV Mein Schiff 2 3 Vide MSIU Safety Investigation Report 08/2014 at http://mti.gov.mt/en/Pages/MSIU/SafetyInvestigations-2013.aspx 201403/019 Cause of the travelling wire rope failure4 A thorough examination and laboratory test on the damaged forward and damaged aft travelling wire rope of tender boat no. 12, together with the undamaged aft wire rope section were conducted in a specialised engineering laboratory by the MSIU. which reduced the wire rope’s crosssection and load carrying capacity; it required Scanning Electron Microscope (SEM) and Energy Dispersive X-ray spectroscopy (EDS) analysis to determine that the wire ropes crowns exhibited severe corrosion attack representing as much as 50% reduction in its cross-section. Therefore, a change in the internal cross-section of the wire rope would not have been evident by visual examination such as that performed by either the ship’s crew or the contracted external technicians; Micro-hardness The micro hardness tests and measurements on the wire samples confirmed that the steel used for the construction of the wire rope was within the industry’s norm. The poor performance of the wire rope under tensile load was therefore related to its deterioration during service rather than to a sub-standard grade of metal. the laboratory analysis of the grease from the failed wire rope revealed that it was contaminated with high concentrations of the elemental components of sea water as well as metals, including iron and zinc, thus precluding it from serving as an anticorrosive protection; The tensile testing of wire rope sections with no significant deterioration indicated that the tensile properties had remained virtually unchanged since the original tests on the wire rope, which were carried out in 2011. the Company’s processes for ordering, supplying, maintaining and inspecting the wire ropes were not integrated as an overall safety system to manage the long term integrity of the wire ropes. Corrosion damage Both damaged and undamaged sections of the wire rope showed general signs of corrosion. However, the degree of corrosion damage varied between the wire rope sections and within the same undamaged section. The tests indicated that a section of the undamaged aft wire had signs of advanced corrosion and was void of surface lubrication. Another section of the same was found in good condition. The zinc plating on the wires was intact and clearly visible through the lubricant. MSIU Safety Alert As a result of the safety investigation into the lifeboat accident on board Thomson Majesty, MSIU Safety Alert 01/2013 was issued and published in February 2013. The MSIU Safety Alert made several recommendations regarding the potential hazards, wire rope lubrication, and inspection of wire ropes3. The examination and tests concluded that the wires in the wire rope strand parted at a site of very severe corrosion wastage. 4 3 Vide MSIU Safety Alert 01/2013 at http://mti.gov.mt/en/Pages/MSIU/SafetyAlerts.aspx MV Mein Schiff 2 4 The purpose of a marine safety investigation is to determine the circumstances and safety factors of the accident as a basis for making recommendations, and to prevent further marine casualties and incidents from occurring in the future. 201403/019 There was an evident failure to maintain a suitably protective level of lubricant at sheave locations where the wire rope rested when the lifeboat was in stowed position. There was also an apparent failure to detect the wire rope’s deteriorating condition at periodic inspections (Figures 6a and 6b). Figure 7: Details of damaged aft rope, showing extensive corrosion reaching the inner lays, broken wires and strands. Broken wires All the three available wire rope samples had broken wires in the outer lay with the ends protruding from the wire rope. Figure 6a: Detail of damaged forward wire rope section showing onset of degradation of galvanised layer of outer lay, The damaged forward and undamaged aft sections contained several broken wires. It was observed that where the sections were not heavily corroded, the wire breaks were scattered and few in number. This was attributed to mechanical and / or corrosion fatigue. The degradation was linked to corrosion dynamic loading and from repeated bending and vibration. The damaged aft section of the sample had several wires and an entire strand broken and separated from the wire rope due to very severe corrosion attack (Figures 8 and 9). Figure 6b: Detail of damaged aft wire rope strand showing extensive corrosion. Figure 8: Detail of a broken outer lay strands of undamaged aft section (insert showing corrosion induced necking) MV Mein Schiff 2 5 201403/019 grease contaminated with salt particles, fine debris, dry corrosion products, and paint residues rubbing of the rope against the metal structure (Figure 11). There was also evidence of abrasion wear. Figure 9: Detail of a single broken wire of the damaged forward section (insert showing fracture morphology) Rope measurements and deformation The rope diameter measurements were checked at multiple locations along all undamaged sections of the wire rope. Figure 11: Paint flakes found amongst other debris around the wire rope sections The results confirmed a marginally thinner rope of 21.65 mm compared to the original specified 22 mm wire rope. The reduction was well within the range acceptable for multi-strand wire ropes. However, the corroded regions showed 19.2 mm; a significant reduction in the wire rope size. Tensile strength Several strands from the outer and inner lay of the different three sections were tested as single wire could not be individually gripped and loaded due to the very fragile condition. The damaged forward section of the wire rope showed localised signs of deformation with the onset of ‘birdcage’ or basket deformation (Figure 10). The outer lay wires appeared longer, exposing the core lay to the environment. These results clearly showed that for wire rope segments with no significant deterioration, tensile properties remained virtually unchanged since the test certification, originally carried out in 2011. Tests were performed on damaged strands, taken from the aft and forward wire rope section. A significant reduction in load bearing capacity, largely due to corrosion, was measured. Tensile tests showed that the mean breaking load of ten strands was only 6.2 ± 1.7 kN, with a recorded minimum breaking load amongst the strands tested as low as 3.4 kN. Inner strands composed of ~1.3 mm wires were also tested from different rope sections. Tensile specimens obtained from the aft sections showed the largest drop with a breaking load of 15.1 ± 0.7 kN. Figure 10: Onset of birdcage deformation Lubrication During the laboratory examination, all of the wire rope sections appeared dry and grainy. The damaged forward wire rope was covered in a thin coat of grease but the aft sections showed a very inhomogeneous cover of MV Mein Schiff 2 6 201403/019 For the inner strands, the measured reduction in breaking force was around 26% compared to almost 50% for outer layer strands due to the protection provided by the outer wires. Nevertheless, the entire wire rope section had suffered sufficient damage such that the resultant breaking force of the rope was 341.5 kN. The cumulative strength of the wire rope was much lower than 2011, when the rope was newly constructed. RECOMMENDATIONS In view of the recommendations made to Transport Malta’s Merchant Shipping Directorate in safety investigation report 05/2014, no further safety recommendations have been issued to the flag State Administration in this safety investigation report. Celebrity Cruises Inc. is recommended to: CONCLUSIONS 1. The damaged wire ropes were heavily corroded with several outer lay wires broken and protruding out from the wire rope; 2. The outer lay wires of one of the damaged wire rope section had basket deformation; 3. The wire ropes’ deteriorating condition was not detected during inspections by the shore-based competent company; 4. Due to the location and design of the davits, inspecting the wire rope for any signs of damage was difficult; 5. The level of knowledge and experience of the crew members was inadequate to recognise corrosion damage; 6. The crew suspected wire damage when they heard the wires cracking and visually noted the broken strands; 7. The wire rope was unevenly lubricated around the davits sheaves. 8. The steel used for the wire rope construction was within the industry’s norm; 9. The laboratory tests of undamaged sections of the wire rope showed that the tensile properties had remained virtually unchanged since the original tests in 2011. MV Mein Schiff 2 05/2015_R1 amend its safety management system manuals to specifically address the inspection and maintenance of lifeboat’s travelling wires; 05/2015_R2 provide training on inspection and maintenance of wire ropes to crew members, with particular emphasis on early detection of defects including corrosion damage; 05/2015_R3 raise awareness on the importance of wire rope maintenance and discuss with the relevant crew members the findings of safety investigation reports 05/2014, 08/2014 and this safety investigation report during safety management meetings. 7 201403/019 SHIP PARTICULARS Vessel Name: Mein Schiff 2 Flag: Malta Classification Society: Lloyd’s Register IMO Number: 9106302 Type: Passenger Registered Owner: Tui Cruises Ms Main Schiff Ltd. Managers: Celebrity Cruises Inc. Construction: Steel Length Overall: 262.51 m Registered Length: 227.25 m Gross Tonnage: 77302 Minimum Safe Manning: 21 Authorised Cargo: Not Applicable VOYAGE PARTICULARS Port of Departure: St. Georges Port of Arrival: St. Maarten Type of Voyage: International Cargo Information: Not Applicable Manning: 807 MARINE OCCURRENCE INFORMATION Date and Time: 13 March 2014 at 1030 Classification of Occurrence: Marine Incident Location of Occurrence: Coastal waters Place on Board Boat deck Injuries / Fatalities: None Damage / Environmental Impact: Not Applicable Ship Operation: On anchor Voyage Segment: Arrival External & Internal Environment: Calm seas with a Northeasterly fresh breeze. Air temperature was recorded at 28°C. Persons on board: 2719 MV Mein Schiff 2 8 201403/019

© Copyright 2025