Solid business cases for optimization tools Simple

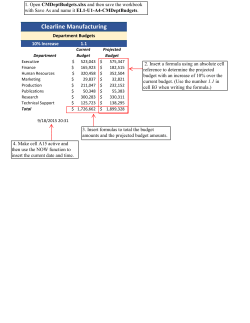

Solid business cases for optimization tools Simple – Smart – Swift © TBA 2015 / Dr. Yvo Saanen / San Francisco CONNECT. COLLABORATE. INNOVATE. INSERT PARTNER LOGO Overview 1. Superb planning practices (find and release them) 2. Get the most out of TOS (as-is) 3. Yard Crane Scheduling (unexplored territory) 4. Intelligent app platform (what we always wanted) 2 1. Superb Planning practices Quiz INSERT PARTNER LOGO What is the potential impact of superb vessel & yard planning on berth productivity? A. Insignificant (<1%) B. Small (<5%) C. Substantial (5 – 15%) D. Large (>15%) 3 INSERT PARTNER LOGO RTG / TT operation - Distributed imports 4 Better work distribution over RTG’s Higher performance during discharge Less concentration during import delivery Lower truck turn time No housekeeping required More reliance on the TOS – less planning Only possible during dense operations More equipment required for import delivery INSERT PARTNER LOGO RTG/TT operation – Distributed Exports 5 Real-time concentration of VVD combinations Stack (pile) based grounding INSERT PARTNER LOGO RTG / TT operation – Twin-carry 6 INSERT PARTNER LOGO Straddle carrier operation – 1 over 2 / 1 over 3 Pile based grounding for export For each pile: • 1 Size • 1 Vessel-voyage • 1 Destination • 1 Weight class 7 Better work distribution over SC’s Allows for highest yard density (>90%) Higher performance discharge & loading Less concentration during import delivery Lower truck turn time No housekeeping required Dispersed grounding for import For each pile: • 1 Size • 1 Mode INSERT PARTNER LOGO 1. Superb Planning practices Potential result Improvement PTO Deployments Average QC GMPH Improvement 30.0 bx/h 150% 135% 124% 25.0 bx/h Productivity 100% 20.0 bx/h 100% 15.0 bx/h 75% 10.0 bx/h 50% 5.0 bx/h 25% 0.0 bx/h 19.4 bx/h 24.1 bx/h 0% First Plan Second Plan More than 125 planners improved on average by 35%. Just by better planning 8 26.2 bx/h Third Plan Improvement compared to first plan 125% INSERT PARTNER LOGO Plan Verification Tool Plan verification reduces the amount of ‘simple’ errors to virtually ZERO 9 2. Get the most out of TOS (as-is) Test Tune Train Dual cycling Double cycling Twin-carry twin-lift Dynamic yard strategies Equipment pooling Automated container decking Automated vessel planning Distributed workflow ………. Double & dual cycling Prime mover pooling Twin-carry & twin-lift Many terminals have licensed modules they do not use 10 INSERT PARTNER LOGO INSERT PARTNER LOGO 1. Get the most out of your TOS Quiz QC productivity while active (bx/hr) / time (minutes) What kind of productivity improvement you think is feasible with implementing best TOS practices? Zeebrugge - SENSITIVITY varying STRNJP (nearby job priority) QC productivity (bx/hr) Truck turn around time 45 40 40.5 40.4 40.2 40.1 39.6 38.8 38.7 37.7 35 30 30.7 30.3 27.8 25 23.6 20 18.3 16.8 15 14.1 13.3 10 5 0 0 1 3 10 25 50 100 200 STRNJP (nearby job priority) - penalty per second driving TSI Primeroute tuning: with or without dual cycling Avg Net QC productivity 10 9 DG - waiting to receive 8 7 Time (minutes) A. Insignificant (<1%) B. Small (<1-5%) C. Substantial (5 – 15%) D. Large (>15%) DG - waiting to deliver 6 5.3 5 4 3.6 3 LD - waiting to receive 2.7 2.3 2.1 2.0 2 1.3 1.2 LD - waiting to deliver 1 0 TSI 1 / dual cycling TSI 1 / no dualcycling Scenario / setting TSI Primeroute tuning: dedicated versus pooling Relative QC productivity and Performance-cost-ratio compared to dedicated dispatching with 8 TTs per QC 120% 150% 110% 102% Relative QC Productivity 100% 140% 104% 93% 97% 90% 105% QC productivity dedicated 100% 92% 80% 60% 130% Reference point: dedicated with 8 TTs per QC 124% 70% 120% 117% QC productivity waterside pooling new settings 50% 40% 110% 105% 30% PCR neutral 20% 100% 10% 0% 90% 5 6 7 8 9 (average) number of TTs working for quay cranes 11 10 Estimated PCR new settings versus dedicated 8 TTs 2. Get the most out of TOS (as-is) Test Tune Train EMULATION: performance improvement & risk reduction around TOS implementation 12 INSERT PARTNER LOGO 3. Yard Crane Scheduler Quiz INSERT PARTNER LOGO What is the potential saving when 15% less RTG’s can be deployed (average) in a 1 M TEU operation @20 USD labour cost per hour? A. Insignificant (<100k USD) B. Small (<500k USD) C. Substantial (500K – 2M USD) D. Large (>2M USD) 13 INSERT PARTNER LOGO 3. Yard Crane Scheduler Potential savings Operational cost per year @1.0 M TEU/a QC $30.0M $25.0M RTG TT 6% -$1,7M $5.8M $5.8M $20.0M $13.2M $11.4M $15.0M $10.0M $5.0M $7.7M $7.7M Before After $0.0M 14 3. Yard Crane Scheduler Getting more out of your yard YCS: 15% less RTG’s required 15 INSERT PARTNER LOGO 4. Intelligent App Platform The functionality we always wanted 16 Timely reefer operation Chimney stacks Intelligent Housekeeping Pooling automated INSERT PARTNER LOGO INSERT PARTNER LOGO The improvement matrix: App ideas 17 INSERT PARTNER LOGO Contact Details TBA b.v. Company registration number NL27197330 Karrepad 2A 2623 AP Delft The Netherlands Internet www.tba.nl 18 Company board: Ir. Martijn Coeveld – CEO / Managing Director Dr. ir. Yvo Saanen – COO / Managing Director Office +31 (0) 15 3805775 Fax +31 (0) 15 3805763 info@tba.nl

© Copyright 2025