Document 162219

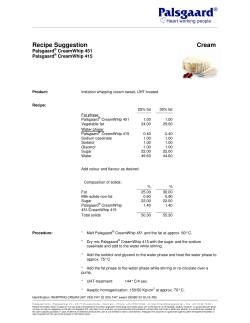

we are e x p e r t s in e mul s i f i e rs and stabilizers for bakery, confectionery, dairy, ice cream, margarine and fine foods - and we happy to share our expertise. our company values can be defined are in just three words : loyalty, responsibility and we aim to be the preferred partner commitment. and supplier of quality products, application service and knowhow to regional and m u l t i - n a t i o n a l food companies. to Palsgaard l o y a l t y means that we act as a reliable and honourable business partner for our customers. we treat information confidentially and know how to keep a business secret. to Palsgaard r e s p o n s i b i l i t y means caring about the environment and being aware of our corporate social responsibility; we have a goal to be CO 2 neutral by 2020 and are members of SEDEX and RSPO. to Palsgaard c o m m i t m e n t means we are dedicated to getting the best results for our customers’ products - to the benefit of their customers. we care about our employees and have a declared aim that Palsgaard must be a pleasant place to work. Palsgaard we know that our most important resource is the k n o w - h o w and d e d i c a t i o n found in our employees. we are committed to getting the best results with our products in our pilot plants and in your facilities. at Palsgaard we don’t sell standard solutions - we start with your needs. Palsgaard - Heart Working heart work is the best way to achieve success - let us help you get it. our products are produced according to the Heart Working People strictest quality criteria. we are experts in emulsifiers and stabilizers and we are happy to share our expertise with you. let our pilot plants help you shorten the step between idea and your new product. heart work is the best way to succeed - let us help you do so. Manufacturing delicious imitation whipping creams Palsgaard Technical Paper, October 2013 Over the past years imitation whipping creams have become increasingly popular due to a number of benefits, such as reduced fat content, better costin-use calculations and better foam stability which makes them easy to use and hence attractive bakers and caterers. However, producing successful imitation whipping creams requires not only the right fats but the right combination of emulsifiers and stabilizers. This article explains the science behind imitation whipped creams and the effect of the emulsifiers and stabilizers. By Hanne K. Ludvigsen, Product & Application Manager, Ice Cream and Dairy, Palsgaard A/S. Whipped creams Whipped creams are widely used for cooking in households and in the catering sector, especially for desserts and cake decorations. The whipped creams may be in the form of dairy whipping cream or imitation whipping cream. Dairy whipping cream with above 35% fat is the original product; however, nowadays creams based on vegetable fat are commonly seen. These vegetable fat based products are called e.g. imitation creams, non dairy creams, topping creams or confectionary creams. The whippability of dairy whipping cream depends on the fat content as well as on the fat globule structure. The fat content should be above 35%, as dairy creams with lower fat contents do not whip into a stable foam. Further, the original fat globule structure should be maintained, meaning that the cream, in contradiction to most other dairy products, are not homogenised. If high shear is applied during processing the whippability is diminished, which can, however, be re-established by application of emulsifiers. There are several advantages of using imitation whipping cream compared to dairy whipping cream: • Products with a fat content down to 20% can be whipped into a firm foam meaning that healthier products may be developed • Imitation whipping creams are less sensible to overwhipping and consequently more flexible in use Palsgaard Technical Paper - October 2013 Manufacturing delicious imitation whipping cream • Higher overrun can be obtained with imitation whipping cream compared to dairy whipping cream resulting in improved cost in use calculation • Vegetable fat is lower priced than butterfat also resulting in better cost in use calculation • Even though dairy proteins are commonly used in production of imitation whipping cream it is possible to produce 100% vegetable products avoiding allergens and supporting veganism. Production of imitation whipping cream Imitation whipping cream is a liquid oil in water emulsion, which is whipped into a stable foam. The foam is air bubbles dispersed in the serum phase stabilized by destabilized fat. Imitation whipping cream normally contains vegetable fat, milk proteins, sweeteners, water and emulsifiers and stabilizers. The milk protein is often sodium caseinate as whey proteins tend to induce agglomeration in the liquid cream during storage. As the fatty acid composition of the vegetable fat influence the viscosity of the liquid cream as well as the 2 foam structure, firmness end eating properties, the manufacturer must ensure that the fat chosen is suitable for the application. Likewise the choice of emulsifier and stabilizer has great importance for the quality of the cream. Emulsifiers and stabilizers are important in the formation of a stable liquid emulsion and in the whipping process for formation of a stable foam with a high overrun. This will be described in more details below. Imitation whipping cream is commonly produced by means of the UHT-process as this ensures a long shelf life of the product. With the right choice of emulsifiers and stabilizers the cream may be stored at room temperature. The design of the UHT-plant should be downstream with 2 stage homogenisation ensuring the formation of a stable emulsion. The effect of emulsifiers on imitation whipping cream Emulsifiers are surface active ingredients due to their hydrophiliclipophilic properties. In competition with the proteins it locates in the interface between the oil droplets and the serum phase, or in the case of foam, in the air serum interface. Hereby it lowers the interfacial tension between two phases. Proteins and emulsifiers also interact altering the fat globule membrane and its emulsion stability and resistance towards mechanical interactions. The effect depends on the hydrophilic and lipophilic groups as well as the ionic properties. The main functionality of emulsifiers in imitation cream is to destabilize the fat globule membrane covering the fat globules formed during homogenisation of the cream. During storage of the liquid cream the proteins covering the fat globule are displaced by emulsifiers. Hereby agglomeration and partially coalescence of the fat globules is facilitated. This is important for the structure formation and air cell distribution formed during whipping. Further emulsifiers are important for the stability of the formed air cells i.e. the strength of the air cell walls. For imitation whipping cream there is a conflict between formation of a stable liquid emulsion with good storage stability and an easy whippable emulsion with good foam stability. During whipping the fat globules needs to be broken and release fat which then agglomerates and coats the air cells and thereby builds a stable foam skeleton. In production of imitation whipping cream several types of emulsifiers are used in combination: Lactic acid esters of mono- and diglycerides (Lactem) improves the whippability and overrun of the product due to it’s α-tending properties. α-tending emulsifiers strengthen the foam skeleton due to increased fat agglomeration. Lactem is often used in combination with mono- and diglycerides. Monoand diglycerides are added for its destabilizing effect on the emulsion improving the foam stiffness and stability, an effect increasing with increased iodine value of the emulsifier. The combination of the Palsgaard Technical Paper - October 2013 Manufacturing delicious imitation whipping cream high fat content in the cream and the fat destabilizing effect of the added mono- and diglycerides, leads to increased viscosity in the cream, sometimes to an extent so that the liquid cream is becoming a paste which isn’t attractive for the consumer. This viscosity increase may be inhibited by adding the more polar emulsifier lecithin, or an anionic emulsifier like diacetyl tartaric acid esters of mono- and diglycerides (Datem) or sodium stearolyl lactylate (SSL) acting as strong oil in water emulsifiers. They interact with proteins in the interphase by hydrophobic and electrostatic interactions forming an emulsifier/ protein film. Hereby the negative net charge of the fat globules is increased and the emulsion stability increased. The increased emulsion stability counteracts the whipping properties, which is why a balance in the use of different emulsifiers is important. The effect of stabilizers on imitation whipping cream Emulsifiers are used in combination with stabilizers. Stabilizers are hydrocolloids which bind and immobilise water. In imitation cream stabilizers are working in water phase improving the emulsion stability in the liquid cream, improving 3 • • • • • • 25% vegetable fat 0.8% sodium caseinate 10% sugar, 1% sorbitol 0.6% stabilizer – Palsgaard® CreamWhip 415 1% emulsifier – respectively Palsgaard® CreamWhip 440 or Palsgaard® CreamWhip 451. Both of the mentioned emulsifier blends include Lactem as the whipping agent. The cream was produced by means of UHT. After whipping in a Hobart whisper the hardness was analysed in a TaXT2 texture analyzer. From Figure 1 it can be seen that simply by changing the composition of emulsifier it is possible to influence the hardness of the foam giving the hardness/softness needed by the application or desired by the customers. This even at the same overrun in the cream as demonstrated in Figure 2. Hardness of whipped imitation cream Trial 1: Palsgaard® CreamWhip 451 Trial 2: Palsgaard® CreamWhip 440 800 600 400 Force [g] At Palsgaard’s application lab in Denmark creams were produced according to the following composition: Figure 1 Texture of 25% fat whipped imitation cream with 2 different emulsifiers: Palsgaard® CreamWhip 451 and Palsgaard® CreamWhip 440. 200 0 0 2 4 6 8 10 12 -200 -400 -600 Time [sec.] Figure 2 Overrun of 25% fat whipped imitation cream with two different emulsifiers: Palsgaard® CreamWhip 451 and Palsgaard® CreamWhip 440. Trial 1: Palsgaard® CreamWhip 451 Trial 2: Palsgaard® CreamWhip 440 260% 240% Overrun [%] the foam stiffness and preventing drainage in the whipped cream. By combining the emulsifiers and stabilizers in different levels imitation whipping creams with good piping definition but different body and mouth feel but can be produced. 220% 200% 180% 160% 140% 0 50 100 Time @ Speed 3[ sec.] 150 200 From Figure 2 it is also evident that imitation creams with Palsgaard® CreamWhip 440 and Palsgaard®CreamWhip 451 have a good stability against overwhipping. After the maximum overrun is reached continuous whipping for 30 to 60 seconds won’t influence the overrun. This is an important parameter for employees in catering and bakeries as they are handling more tasks at the same time. Here flexibility is a must. Palsgaard Technical Paper - October 2013 Manufacturing delicious imitation whipping cream 4 In Figure 4 results of the hardness analysed by means of the TaXT2 texture analyzer are shown and it is evident that the measured hardness is at the same level for the standard and high overrun solution. This opens an opportunity for cost saving in e.g. bakeries. Figure 3. Comparison of overrun in 25% fat whipped imitation cream with two different emulsifier solutions. Trial 1: Palsgaard® CreamWhip 451 240% 220% 200% 180% 160% 140% 0 Protein free UHT imitation whipping creams In confectionary applications fruit or fruit flavoured ingredients are often mixed into the cream. If proteins are present the risk of denaturation of the proteins is present resulting in a separated product with texture and sensory properties which will not be accepted by the consumers. As the protein, when available, is an important functional ingredient in the emulsion formation and structure building, the types of emulsifiers and stabilizers have to be modified and other ingredients added in production of protein-free alternatives to obtain the same overrun and stability in the liquid cream as well as in the whipped product. 50 100 Time @ Speed 3[ sec.] 150 200 Figure 4. Comparison of hardness of standard and high overrun solution in a 25% fat whipped imitation cream. Hardness of whipped imitation cream Trial 1: Palsgaard® CreamWhip 451 Trial 3: Palsgaard® CreamWhip 451,PS,MDG 300 250 200 150 Force [g] Palsgaard® CreamWhip 440 and Palsgaard® CreamWhip 451 are applicable in imitation creams with protein in the water phase. However, sometimes a protein free product is requested either for nutritional or for technological reasons. As a technological advantage talking for protein free imitation cream it can be mentioned that the cream is pH stable. Trial 3: Palsgaard® CreamWhip 451, PS, MDG 260% Overrun [%] It’s important also to notice that by changing the emulsifier composition e.g. by addition of polysorbate (PS) or mono- and diglycerides (MDG) it is possible to obtain the higher overrun and still have a good foam structure and stability – see Figures 3 and 4. 100 50 0 -50 0 2 4 6 8 10 12 -100 -150 -200 Time [sec.] Palsgaard is now offering a solution for protein free whipping cream called Palsgaard® CreamWhip 453. This combined emulsifier and stabilizer solution makes it easy for the manufacturer to produce a high quality protein free UHT imitation whipping cream. The emulsifier uses polyglycerol esters of fatty acid (PGE) as the main emulsifier. PGE is a hydrophilic emulsifier improving whippability and foam stability of emulsions. Palsgaard Technical Paper - October 2013 Manufacturing delicious imitation whipping cream Conclusion As shown above emulsifiers and stabilizers play a big role in creating an imitation whipping cream with the qualities demanded by bakers, caterers and the end consumer. Should you like to know more about how Palsgaard can assist you in finding the emulsifier/stabilizer combination suited especially for your needs please contact Product & Application Manager Hanne K. Ludvigsen at hkl@palsgaard.dk or Tel: +45 7682 7682. 5

© Copyright 2025