How to Use the Design Process to Manage Risk: Why It Matters

environmental • failure analysis & prevention • health • technology development How to Use the Design Process to Manage Risk: Elements of Design Controls and Why It Matters Kevin L. Ong, Ph.D., P.E. Managing Engineer, Medical Device Consultant Exponent Inc., Philadelphia, PA A leading engineering & scientific consulting firm dedicated to helping our clients solve their technical problems. 2 “There’s never time to do it right, but there’s always time to do it over.” http://curiousphotos.blogspot.com/ http://curiousphotos.blogspot.com/ http://americancommondefencereview.wordpress.com/ 3 Overview Where do design controls fit in? Elements of design controls Design controls and the FDA ISO and Medical Devices Directive Managing risk against product liability claims http://www.endlessautumn.net/documentation/ 4 Medical Device Development Technology and Business Forecasting and Planning Design Control Safety/Efficacy Research, Development Production, Design Cycle, Performance Testing 5 Areas of Risk Risk to safety of patients, users, handlers Business Regulatory Product liability 6 Quality System Regulation QSR, 21 CFR Part 820 - 1996 (eff. 1997) replaced the 1978 Good Manufacturing Practices (GMP) for medical devices Ensure that good QA practices are used for medical device design and that they are consistent with quality system requirements worldwide Applies to finished medical devices intended to be commercially distributed for human use: some exemptions for Class I devices Harmonized with efforts by Global Harmonization Task Force 7 21 CFR Part 820 - Quality System Regulation Subpart A – General Provisions 820.1 Scope 820.3 Definitions 820.5 Quality System Subpart B – Quality System Requirements 820.20 Management Responsibility 820.22 Quality audit 820.25 Personnel Subpart C – Design controls 820.30 Design controls Subpart D – Document controls 820.40 Document controls Subpart E – Purchasing controls 820.50 Purchasing controls Subpart F – Identification and traceability 820.60 Identification 820.65 Traceability Subpart G – Production and process controls 820.70 Production and process controls 820.72 Inspection, measuring and test equipment 820.75 Process validation Subpart H – Acceptance activities 820.80 Receiving, in-process and finished device accept. 820.86 Acceptance status Subpart I – Nonconforming product 820.90 Nonconforming product Subpart J – Corrective and preventative action 820.100 Corrective and preventative action Subpart K – Labeling and packaging control 820.120 Device labeling 820.130 Device packaging Subpart L – Handling, storage, distribution and installation 820.140 Handling 820.150 Storage 820.160 Distribution 820.170 Installation Subpart M – Records 820.180 General requirements 820.181 Device master record 820.184 Device history record 820.186 Quality system record 820.198 Complaint files Subpart N – Servicing 820.200 Servicing Subpart O – Statistical techniques 820.250 Statistical techniques 8 Significance Of Design Controls “FDA found that approximately 44% of the quality problems that led to voluntary recall actions during this 6-year period were attributed to errors or deficiencies that were designed into particular devices and may have been prevented by adequate design controls.” Federal Register, October 7, 1996 21 CFR Parts 808, 812, and 820 Medical Devices; Current Good Manufacturing Practice (CGMP); Final Rule 9 2010 Warning Letters FDA issued 89 Warning Letters to medical device companies for QS/GMP deficiencies QS subsystem # warning letters with cite % warning letters with cite Corrective and 81 preventive actions 91 Production & process controls 69 78 Design controls 49 55 Management controls 43 48 Document controls 33 37 Source: CDRH http://www.fda.gov/downloads/AboutFDA/CentersOffices/CDRH/CDRHTransparency/UCM256354.pdf 10 Most Frequent Quality Systems Warning Letter Cites 2010 21 CFR 820.198(a) 42 21 CFR 820.100(a) 30 21 CFR 820.75(a) 28 21 CFR 820.22 26 21 CFR 820.184 21 21 CFR 820.20(c) 19 21 CFR 820.30(i) 18 21 CFR 820.90(a) 18 21 CFR 820.30(g) 17 21 CFR 820.50 (general) 17 Design changes Design validation Source: CDRH http://www.fda.gov/downloads/AboutFDA/CentersOffices/CDRH/CDRHTransparency/UCM256354.pdf 11 Design Control Warning Letter Cites 2010 21 CFR 820.30(i) - Design Changes 21 CFR 820.30(g) - Design Validation 21 CFR 820.30(a) - General 21 CFR 820.30(j) - Design History File 21 CFR 820.30(c) - Design Input 21 CFR 820.30(f) - Design Verification 21 CFR 820.30(e) - Design Review 21 CFR 820.30(d) - Design Output 21 CFR 820.30 21 CFR 820.30(b) - Design & Development Planning 18 17 14 6 4 4 3 3 2 1 12 FDA Design Control Guidance Assist manufacturers in understanding quality system requirements concerning design control Make systematic assessment of the design an integral part of development Increase the likelihood that the design transferred to production will translate into a device that is appropriate for its intended use Applies to the design of medical devices and associated manufacturing processes; new designs as well as modifications or improvements to existing device designs 13 Application of Design Controls User Needs Review Design Input Design Process Verification Requirements are fulfilled Validation Intended use is fulfilled Design Output Medical Device 14 Elements of Design Controls CFR 820.30 Establishment, maintenance, and documentation of: Design and Development Planning Design Input (Requirements) Design Output (Specifications) Design Review Design Verification (Meets specifications) Design Validation (Meets clinical needs) Design Transfer (Moves from design to manufacturing) Design Changes Design History File 15 Medical Device Classification Class I - General Controls Minimal potential harm to the user, e.g., elastic bandages, examination gloves Prohibit adulteration and misbranding; allow for bans and restriction of sale and distribution; notification of risk and of repair, replacement or refund; registration of manufacturers and listing of devices Most are exempt from the premarket notification and/or GMP regulation Class II – General Controls with Special Controls Those for which general controls alone are insufficient to assure safety and effectiveness, e.g. infusion pumps, surgical drapes Special controls may include special labeling requirements, mandatory performance standards, patient registries, postmarket surveillance Few Class II devices are exempt from the premarket notification Class III - General Controls and Pre-Market Approval Those for which insufficient information exists to assure safety and effectiveness solely through the general or special controls, e.g., implantable pacemaker, artificial disc replacement Pre-Market Approval (PMA) application – scientific review Clinical data may be necessary - IDE/HDE 16 Design Control – Scope § 820.30(a) Design control requirements apply to: All Class II and Class III devices The following class I devices: Devices automated with computer software Tracheobronchial suction catheters Surgeon's gloves Protective restraints Manual radionuclide applicator system Radionuclide teletherapy source 17 Design & Development Planning - § 820.30(b) Product concept is usually outlined in a set of marketing requirements and include the “wish list” for device features and functionality Is there a market opportunity for the device? Where will the new device be used and who will use it? How will the new device be used? How long will the new device be used? Once the project moves forward, a project plan is drawn up to guide and control the design and development of the device Implementation of design controls is initiated 18 Design & Development Planning - § 820.30(b) Establish and maintain plans that: Describe or reference design and development activities Define responsibility for implementation Identify or describe interfaces with different groups or activities Review, update and approve plans as design and development evolves 19 Design & Development Planning - § 820.30(b) Elements include: Major tasks Deliverables Responsible individuals/units, including interface with suppliers, contractors Resources Project timeline, milestones Major reviews and decision points Review teams Design documentation Planning method: Flow diagram or spreadsheet Gantt chart 20 Design Input - § 820.30(c) Design input means the physical and performance requirements of a device that are used as a basis for device design Establish and maintain procedures to assure that device design requirements: Are appropriate Address the intended use of the device Include in procedures a mechanism for addressing requirements that are: Incomplete Ambiguous Conflicting 21 Design Input - § 820.30(c) Starting point for product design Usually fall into three categories: Functional requirements specify what the device does, focusing on operational capabilities and processing of inputs and resultant outputs. Performance requirements specify how much or how well the device must perform, addressing speed, strength, response times, accuracy, limits of operation, etc. Also includes device reliability and safety requirements Interface requirements specify characteristics critical to compatibility with external systems; specifically, those characteristics which are mandated by external systems and outside the control of the developers. An example is important in every case is the user and/or patient interface 22 Types of Design Inputs Intended Use User Needs Physical/chemical characteristics Performance characteristics Safety Reliability Environmental limits User interfaces Regulatory requirements Labeling Human factors Maintenance Compatibility with other devices Sterilization Energy source Toxicity and biocompatibility 23 Sources of Design Inputs Customer input through focus Performance requirements groups, surveys, etc. stipulated by the FDA, voluntary standards, or other Comparison testing of competitor regulatory agencies product for specific performance criteria or other benchmarking Literature review activities Input from cross-functional Review of similar product teams (R&D, Quality, histories to include production Regulatory, Marketing, data for scrap, rework, testing Manufacturing, etc.) Review of complaints, MDRs, FDA Enforcement Reports, recall of similar products or earlier generations of the product 24 Design Output - § 820.30(d) Design output means the results of a design effort at each design phase and at the end of the total design effort. The finished design output is the basis for the device master record. The total finished design output consists of the device, its packaging and labeling, and the device master record Establish and maintain procedures for… Defining and documenting design output in terms that allow an adequate evaluation of conformance to design input requirements Containing or referencing acceptance criteria Ensuring design outputs essential for the proper functioning of the device are identified 25 Design Output - § 820.30(d) Design output are the design specifications which should meet design input requirements, as confirmed during design verification and validation and ensured during design review The output includes the device, its labeling and packaging, associated specifications and drawings, and production and quality assurance specifications and procedures 26 Types of Design Output Production specifications and other descriptive materials that define and characterize the design Production specifications – used to procure components, fabricate, inspect, install, maintain and service the device Other materials that are necessary for establishing conformance, but are not used in device production: Biocompatibility test results Bio-burden test results 27 Design Review - § 820.30(e) Documented, comprehensive, systematic examination of a design to evaluate adequacy of requirements, capability of design to meet requirements, and to identify problems Establish and maintain procedures for design reviews Plan and conduct formal documented design reviews of the design results at appropriate stages Include at each design review Representatives of all functions concerned Independent reviewer for the stage being reviewed Any specialists needed 28 Considerations for Design Review Formal process to evaluate design, resolve concerns, and implementation of corrective actions Required for phase approval Formal design review prior to release for manufacture and distribution Responsibility and authority for decision-making Determine frequency of review and design phases for review Controlling documentation and record keeping Competency of reviewers in terms of background and experience 29 Design Verification §820.30(f) vs. Design Validation §820.30(g) Design Verification… Did I make the product right? i.e. specified requirements have been fulfilled Design Validation… Did I make the right product? i.e. device specifications conform with user needs and intended use(s) 30 Design Verification – § 820.30(f) Establish and maintain procedures for verifying the device design Confirm design output meets design input requirements Types of verification activities include: Inspections Tests Analyses 31 Examples of Design Verification Activities Evaluation of physical characteristics Mechanical/chemical/electrical testing Failure modes and effects analysis Package integrity testing Biocompatibility testing Sterility testing Comparison against predicate device with successful history 32 Design Validation – § 820.30(g) Establish and maintain procedures for validating the device design Perform design validation Conform to defined user needs and intended uses Under actual or simulated use conditions Under defined operating conditions On initial production units, lots, or batches or their equivalents Includes software validation and risk analysis, where appropriate 33 Examples of Design Validation Activities Clinical studies Consumer preference testing Bench testing under simulated use conditions Review of labeling and packaging Environmental testing (e.g. stress during shipping and installation) Testing that distinguishes between customers, users, and patients 34 Design Transfer – § 820.30(h) Establish and maintain procedures to ensure that the device design is correctly translated into production specifications Design moves from R&D to manufacturing Specifications ensure that manufactured devices are repeatedly and reliably produced within product and process capabilities 35 Types of Production Specifications Assembly drawings Component procurement specifications Workmanship standards Manufacturing instructions Inspection and test specifications Computer-aided manufacturing programming files Manufacturing jigs/fixtures 36 Design Transfer: Elements Product risk documentation shows what failure modes, components, parts, etc. should be monitored and trended Process validations indicate critical control points for manufacturing and design 37 Design Changes - § 820.30(i) Establish and maintain procedures for the identification, documentation, validation or where appropriate verification, review, and approval of design changes before their implementation Establish design change control procedures, determine the risk presented by the change and implement design control requirements to the extent appropriate for that risk 38 Considerations for Document Control Enumeration of design documents, and tracking their status and revision history Maintain master list or document index to define product and/or process Maintain history of document revisions Periodically inventory controlled documents to confirm that contents are up to date Develop procedure for removal and deletion of obsolete documents 39 Considerations for Change Control Document decisions for change requests – identifies possible design matter which the requester believes should be corrected Document change order following acceptance of change request – identifies relevant document(s) and revision of document content May also include assignment to designers to further evaluate the problem and develop corrective action Review and assess impact of design change on design input requirements and intended uses 40 Design Change Review The effect of the changes on products already in commercial or clinical use Whether prior design verification or validation results are impacted Changes are implemented in such a manner that the original problem is resolved and no new problems are created; or if new problems are created, they are also tracked to resolution 41 Design History File - § 820.30(j) Establish and maintain a design history file for each type of device Include in the DHF or reference records necessary to demonstrate that the design was developed in accordance with the design plan and CFR 820 requirements Design history file (DHF) means a compilation of records which describes the design history of a finished device 42 Design History File Tells the story of a device or device family’s development from beginning to end Contains the documentation necessary to assure changes to design or process for manufacture of the device do not adversely impact the device design and lead to improvement in design and process Maintains knowledge base after design decisions have been made, employees leave, company reorganizes, or subcontractors unavailable etc. 43 Elements of Design History File Design and development plan Design input documents Risk analyses documents Design output Pre-production design change control records Engineering/laboratory notebooks V&V protocols and results Design review records Design transfer records Copies of controlled documents used during the design process, e.g. SOPs etc. Initial DMR 44 Benefits of Design Controls Improve the product development process by producing higher quality devices Reduce liability exposure Reduce design related product recalls Shorten development time Recognize problems earlier and make corrections Lower manufacturing costs Meet customer expectations (user and patient needs) 45 Other Quality System Requirements Medical Devices Directive (MDD 93/42/EEC): developed in 1993; lists requirements regarding medical device design within EU Revised in 2007 (2007/47/EC) Compliance became mandatory in March, 2010 46 Medical Devices Directive All devices require clinical data Of the actual device or a similar device Scientific literature of a similar device Human factors considered a key factor 47 ISO Standards on Quality ISO 13485 (Medical devices - Quality management systems - Requirements for regulatory purposes): standard that recommends procedures in order to have a quality system that complies with Medical Devices Directive (MDD 93/42/EEC) Based on ISO 9001, but excludes some of the requirements that are not appropriate for regulatory requirements 48 ISO 13485 Similar elements to § 820.30 ISO 13485 Section 7.3 Design and development Design and development planning Design and development inputs Design and development outputs Design and development review Design and development verification Design and development validation Control of design and development changes 49 ISO 14971 Provide framework within which experience, insight and judgment are applied systematically to manage the risks Risk management is the systematic application of Management policies Procedures and practices for analyzing, evaluating, and controlling risk 50 ISO 14971 Specifies process through which the manufacturer can identify hazards associated with a medical device, estimate and evaluate the risks associated with these hazards, control these risks, and monitor the effectiveness of that control 51 Quality System Inspection Technique (QSIT) Guidance for auditing medical device manufacturers against QS Regulation (21 CFR Part 820) and related regulations Focuses on four major subsystems that are the basic foundation of the QS to evaluate and states the purpose and importance of each subsystem http://www.fda.gov/downloads/ICECI/Inspections/I nspectionGuides/UCM085938.pdf 52 What are the four main subsystems? Design Controls Corrective & Preventive Actions Production & Process Controls Management Material Controls Records, Documents, & Change Controls Equipment & Facility Controls 53 What does FDA look for in the Design Control Subsystem? Design procedures and plan established? Design inputs or requirements for device identified? Design outputs or specifications for device identified? Design verification conducted? Design validation conducted? Software validation completed? Risk analysis carried out? Design reviews conducted? Design transfer to manufacturing completed successfully? 54 Warning Letters - Examples “do not have design control procedures” “no documentation of design validation or design change controls” “no documentation of risk analysis or structural (b)(4) testing of the embedded software” 55 Warning Letters - Examples “unable to demonstrate that the validation for the … redesign project … was validated using initial production units” “the verification study for the … coating which is applied to the … was conducted after the validation study was completed” “failed to demonstrate bench testing of the [X] had been completed, prior to their installation into [Y] for design validation studies” “failed to establish acceptance specifications … prior to conducting verification and validation studies” 56 Warning Letters - Examples “Design validation was not executed or documented in order to ensure that the devices conform to defined user needs and intended uses” “A design and development plan … that describes or references the design and development activities and define responsibility for implementation was not established or maintained” “A design history file was not established or maintained by your firm” 57 Warning Letters - Examples “… Design Input for [X] contains no inputs for the [Y] which are to be used with the [X]” “Because you did not include [Y] inputs in your [X] design verification/validation, your [X] Risk Analysis/Failure Modes and Criticality Analysis, document (b)(4) is incomplete in that you failed to identify and evaluate potential hazards involved with use of the [Y] …” 58 Product Liability/Negligence Claims – Design Defects Foreseeable risks? Could have been reduced or avoided? Omission of reasonable, safer, and technologically feasible alternative design? Risks outweigh benefits? 59 Key Documents to Consider During Litigation DHF Regulatory documents (510(k), memo to file, PMA) DFMEA PFMEA Specifications Lot/device history records Manufacturing procedures Design drawings CAPA reports MDR/complaint files IFU Surgical brochures Marketing brochures/documents Audit reports 60 Impact on Litigation Design changes Design controls for line extensions Memo to file justification Questions to consider: After a design change or line extension, are there additional risks for the device? Is additional design verification or validation needed? Are the specifications clinically relevant? How were they developed? Are the specifications consistent? Were the inputs translated from marketing inputs into engineering inputs? Were finished products considered? Was validation completed before verification? Was there compliance with own requirements/procedures? 61 Final Thoughts The design control regulations provide a comprehensive and systematic framework for device development The design control process is iterative Design control regulations are a regulatory requirement, but when used properly serve as good business practice 62 “Design control does not end with the transfer of a design to production. Design control applies to all changes to the device or manufacturing process design, including those occurring long after a device has been introduced to the market. This includes evolutionary changes such as performance enhancements as well as revolutionary changes such as corrective actions resulting from the analysis of failed product. The changes are part of a continuous, ongoing effort to design and develop a device that meets the needs of the user and/or patient. Thus, the design control process is revisited many times during the life of a product.” Design Control Guidance for Medical Device Manufacturers; March 11, 1997; FDA, CDRH 63 Reading Materials FDA Guidance Document (http://www.fda.gov/downloads/MedicalDevices/DeviceRegulationandGuidance/ GuidanceDocuments/ucm070642.pdf) Medical Devices Directive (http://eurlex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2007:247:0021:0055:en:PDF) ISO 13485 (http://www.iso.org/iso/catalogue_detail?csnumber=36786) ISO 14971 (http://www.iso.org/iso/catalogue_detail.htm?csnumber=38193) Quality System Inspection Techniques (http://www.fda.gov/downloads/ICECI/Inspections/InspectionGuides/UCM08593 8.pdf) AdvaMed – Points to consider when preparing for an FDA inspection under the QSIT design controls subsystem (http://www.compliance-alliance.com/wpcontent/uploads/2010/05/points-design.pdf) 64 Thank you! Questions? Kevin Ong, Ph.D., P.E. kong@exponent.com 215-594-8874

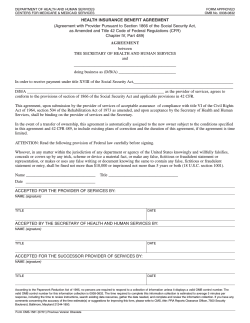

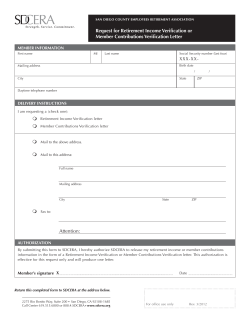

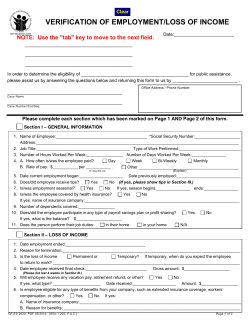

© Copyright 2025