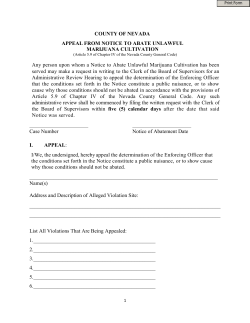

Nevada T Center University of Nevada, Reno/0257 Reno, NV 89557-0257