Green Buildings – the future is here and MATTHIAS GELBER by

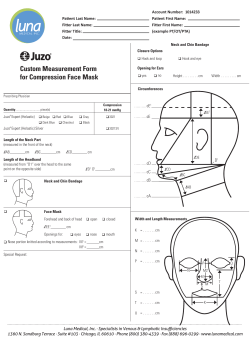

Green Buildings – the future is here and how to make it commercially work by MATTHIAS GELBER Office based in?? Arctic Polar Ice Melting International Geosphere-biosphere programme http://www.igbp.kva.se/ Science of Global Warming Green factor starts in your life and at home ! Recycling Rate now 2 times higher! Before Condo recycling implemented 1 July 2010 Maleki GmbH is a company dedicated to using technology to address global climate change by finding green solutions for building materials. Located in Osnabrück, Germany’s Green City of Peace, Maleki GmbH was established in 2007 by Hossein Maleki and Matthias Gelber. Production of conventional cement Local rock (limestone) and corrective minerals sourced from mining Raw mixture mill Crushing process Raw mixture silo Rotating kiln Clinker silo Additional filler material (fly ash, blast furnace slag etc.) Cement mill Packing and transport of cement to consumer Heating to 1300 – 1450 Celsius Production of conventional cement Cement production releases more CO2 than any other manufacturing process! OPC content 50% CO₂ from Limestone app. 70% CaCo₃ 18-25% SiO₂ 4-8% Al₂O₃ 2-4% Fe₂O₃ C3S (3CaO – SiO₂) C2S (2CaO – SiO₂) C3A (3CaO – Al2O₃) C4AF (4COO – Al₂O3 – Fe₂O₃) 6-7% of global CO2 emissions are derived from cement manufacturing! Production of Maleki Green Cement Industrial by-products OPC Compound Mixer Storage Silo Packing and transport of green cement to consumer Contract-based sourcing Blending process (low energy) The Maleki Triple-Benefit GREEN At Maleki, we replace cement with safe industrial byproducts and other alternative substances. This keeps us from tapping into natural resources while using materials which would have ended up in landfills. The end result is a greatly reduced carbon footprint of between 60 to 90% - even better than other competing green products. Case Studies Maleki Green Building Materials 1. Eco Binder System Cement is the binding component of concrete and mortar products. It contains three key ingredients: CaO Calcium Oxide SiO2 Silicon Dioxide • Obtained from limestone (CaCO3). • Extremely polluting & energy-intensive process involves extracting the limestone, transporting it and heating it to 1350oC. • 60% of the limestone’s mass is released into the atmosphere as CO2. Al2O3 Aluminium Oxide • Known as corrective minerals, these ingredients are mixed with Calcium Oxide to create OPC. CaO CaO Calcium Calcium Oxide Oxide SiO SiO22 Silicon Silicon Dioxide Dioxide Al2O3 Al2O3 Aluminium Aluminium Oxide Oxide Certain waste materials from other industrial processes also possess all three primary components of cement. However, activating these materials from their inert (non reactive) state and forcing them to react has always been a challenge. Maleki’s Eco Binder System utilizes advanced green chemistry to activate these by-products and turn them into cement. • These by-products undergo a stringent analysis for heavy metals and other toxic substances first. • Eco Binder cement and dry mortars are inherently stronger, have improved chemical resistance and better physical characteristics. • There is no longer any need to quarry limestone for OPC production. • Maleki Eco Binder cement and dry mortars are cost competitive, last longer, and do have minimal CO2 emissions! Eco Binder System Eco Binder System 77% CEMENT REDUCTION in concrete with Maleki Eco Binder System Eco Binder System 62% LESS CARBON EMISSIONS compared to normal concrete (Up to 90% less if compared to high cement concrete) Eco Binder System HIGHER COMPRESSIVE STRENGTH than normal concrete Eco Binder System BETTER STRENGTH CONSISTENCY – Maleki UHPC with Eco Binder System Statement from Masdar regarding Render “This product has a higher score under sustainability than others in the product range which we have evaluated so far” Quote from Masdar environmental product evaluation expert Rating: C−Excellent B−Good A−Average Eco Binder System Case Studies Duralite Building & Construction Material http://www.duralite.com.my/support.htm Case Studies Cold 22 Hydrocarbon Refrigerant (air-conditioning) Cold 22 Hydrocarbon Refrigerant (air-conditioning) Price is RM 0.30 cents per gram so example a 1HP would normally take in 1 KG of 22 (HCFC) but for COLD 22 is only 405 grams which comes up to RM121.50 Cold 22 Hydrocarbon Refrigerant (air-conditioning) Cold 22 Hydrocarbon Refrigerant (air-conditioning) VISTA BAY Butterworth Case Studies Case Studies Item G Block Cement Bricks Material 2.70 2.10 Lay 0.60 0.70 Mortar 0.15 0.40 Plaster 0.90 1.30 Internal Plaster 1.10 1.40 Exmet 0.05 0.15 Total Cost 5.50 6.05 Commercial Buildings - Problem 19% total energy consumption 70% used in HVAC systems So high HVAC consumption.. .. means high operating costs for you Eco Tower Solution No Risk Performance Contract No install costs Save up to 30% electricity Save up to 50% water Eliminate chemicals Example Eco Tower Savings 500t Chiller Eco Tower Case Study Annual Cos t of E nergy Annual Cos t of E nergy B efore Ins tallation: After Ins tallation: $245,800 $147,480 Total Annual S avings : $98,320 % s avings 40% Contacts resources • Lightweight blocks: Charles 0175099492 • http://www.greenmanspeaks.com/press/Hom efinder%20May%202011.pdf • Cool 22: Chris 0176999554 • Eco Tower: Dennis – 0169839715; dennis@gbjvt.com Outdoor Air Quality • Regulations say how much pollution is acceptable Indoor Air Quality • Not regulated Indoor Air Quality • Pollution inside the typical American home is 2 to 5 times worse than air outdoors • Indoor air pollution is one of the top 5 most-serious environmental risks to public health • 50% of all illnesses can be traced back to the home Personal Care/Cosmetics TVs & Computers Furniture An Ordinary House A Chemical House Automobile Carpeting Cleaning Products & Pesticides Furniture Flooring A Chemical House = Building Related/Sick Building Syndrome • • • • • • • • • Eye irritation Headache Upper respiratory Irritation Nausea, dizziness Fatigue, lethargy Sore/dry throat Odor Memory impairment Where does it come from ? • • • • • • • • Cleaning products Air flow and Air Conditioning Pesticides Vinyl Formaldehyde Volatile Organic Compounds (VOC) Mercury Mold For further information, kindly refer to: Speaker - http://www.greenmanspeaks.com Blog - http://greenmanplanet.blogspot.com/ Face book - http://www.facebook.com/matthiasgelber YouTube - http://www.youtube.com/matthiasgelber Press Download - http://www.greenmanspeaks.com/press.htm Eco-Inspirational Talk-Series on Facebook: http://www.facebook.com/pages/Eco-Inspiration-TalkSeries-by-Matthias-Gelber/208210252526310 E-mail: Office: matthiasgelber@gmail.com Bangunan SSA No.9, JalanBangsarUtama3 BangsarUtama 59000 Kuala Lumpur, Malaysia Phone: 603- 2282 2399 Fax: 603- 2283 1699 Business: www.malekigmbh.com

© Copyright 2025