Sample Furniture Inventory Tracking System MTS Seating 7100 Industrial Drive

Sample Furniture Inventory Tracking System

MTS Seating

7100 Industrial Drive

Temperance, MI 48182

Raymond Cata

Nathaniel Curtis

Jeffrey Hayton

Anthony Taylor

IS-421

Executive Summary .......................................................................................................... 3

Methodology/Tool Section................................................................................................ 4

Interviewees .................................................................................................................... 5

Websites.......................................................................................................................... 5

Software .......................................................................................................................... 5

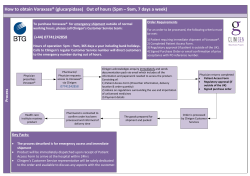

Organization and SWOT Analysis .................................................................................. 6

Strengths ......................................................................................................................... 8

Weaknesses ..................................................................................................................... 9

Opportunities................................................................................................................. 10

Threats........................................................................................................................... 10

History of the IT/IS & Database Development Projects ............................................. 11

Work Breakdown Structure (WBS).............................................................................. 13

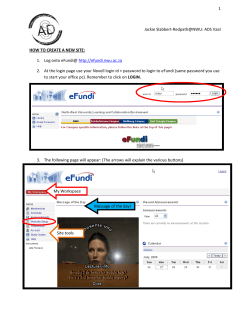

Database Development Process (SDLC) ....................................................................... 14

Plan ............................................................................................................................... 14

Analysis......................................................................................................................... 15

Entity Relationship Diagram for MTS Seating Sample Order Tracking.................. 15

Business Rules .......................................................................................................... 15

Business Rules .......................................................................................................... 16

Logical Design .............................................................................................................. 17

Relational Schema .................................................................................................... 17

Physical Design............................................................................................................. 21

Main Menu................................................................................................................ 21

Forms ........................................................................................................................ 22

Implementation ............................................................................................................. 29

Data ........................................................................................................................... 29

SQL statements ......................................................................................................... 34

Reports ...................................................................................................................... 48

Appendix.......................................................................................................................... 50

2

Executive Summary

MTS Seating is a small manufacturing company located in Temperance Michigan.

Profitability and growth has established the need for continued expansions in IT

resources. Information systems are tightly integrated within a number of its business

processes. Production planning, sales management and finance systems are a few

examples of IS employed. MTS has a firm understanding of the benefits that

information systems provide.

A Just In Time (JIT) inventory system for production is currently in place. Raw

materials for production are ordered as needed. By implementing a lean

manufacturing concept, MTS hasn’t had a need for an inventory tracking system.

MTS does however maintain a small stock of inventory. Sample furniture is kept on

hand as a means of providing customers a way to view product. The sample furniture

is also displayed in trade shows that MTS participates in throughout the year.

Due to the lean manufacturing philosophy in place, inventory tracking software is not

part of MTS’s information systems. We propose a simple, easy to use database to be

utilized for tracking the customer sample furniture. The use of automated tools is

essential in maintaining efficiencies in business operations.

3

Methodology/Tool Section

As part of the project requirements, a relational database will be used to input, store

and retrieve information for our database system. Oracle 9i will be the DBMS we will

be using. Oracle 9i will enable the creation of forms, queries, and reports that will be

associated with the database project. The Oracle software is also very powerful and

flexible. It is capable of growing, adapting, and changing along with needs of the

business. This is important because the enterprise we are focusing on is a growing

business with new customers being acquired frequently. We will also use software to

assist in the initial logical design phase the database. Software such as RF Flow and

Microsoft Project will be extremely useful in the completion of this project.

We will follow the Systems Development Life Cycle (SDLC) methodology. In the

planning phase we will gather information about the users and research possible

entities and attributes that we will use in the database. We may also possibly meet and

interview some employees of the company specifically in the IT department of MTS

Seating. In the analysis phase we will create an ERD and we will clearly define all

entities, attributes, and unique identifiers.

In the logical design phase we will develop the relational database model for the

business. In the physical design phase we will define technical specifications and

define the database to the DBMS. When we get to the implementation phase we will

enter all related data into our database. Finally in the maintenance phase we will test

the system and make any necessary changes to ensure easy adaptation by the users.

4

Interviewees

Nancy VanDevelde

Quality Assurance Manager

(734) 847-3875

Rodney Schell

IT Manager

(734) 847-3875

Websites

http://www.mtsseating.com

http://www.uscc.gov/

Software

Microsoft Project 2002

Oracle 9i database

Rfflow

5

Organization and SWOT Analysis

Mission Statement

"Our Goal is to provide all products and services in the committed time,

competitively priced, at the desired quality; costs effectively manufactured and

forever improve our performance."

MTS Seating is a privately owned and operated corporation. MTS is a manufacturer of

seating for the hospitality industry. With 325 employees MTS’s annual sales are $55

million.

MTS was started by Dean Curtis and Paul Swy who incorporated their business under a

small barn in Bedford, Michigan. At the time the company’s main business involved

strictly metal fabrication, production of steel chair and table legs, and other parts for the

automotive and aircraft markets.

In the early 1960s, finished chair and table frames became a major part of the company’s

product line, and by mid-decade MTS was assembling complete chairs. By the early

1970s, upholstery was done in house at the factory and no longer had to be outsourced.

This enabled the company to introduce the MTS seating line.

Today MTS has a 300,000 square foot, state-of-the-art, manufacturing facility located in

Temperance, Michigan. MTS has built a reputation for producing the best-built, best-

6

backed chairs in the industry. For over forty-five years MTS Seating has been a leading

provider of seats to the restaurant and hotel industry. MTS is committed to providing the

hospitality and food-service industry with total seating solutions. MTS can produce made

to order chairs, tables, and other furniture for its many customers in the hospitality

industry. Recent customers include City Grill, Quiznos Classic Subs, Newark

International Airport, Mancinos Pizza, and Denny’s.

A customer can select from a wide range of seating designs and mix and match,

upholstery, finish, and materials. MTS’s online catalog makes it easy for a customer to

get an idea of possible matching combinations. On the company’s website,

mtsseating.com, a potential customer can see seating displays for restaurants,

bars/lounges, guest rooms, and banquets. Customers can also see pictures of MTS’s

products in restaurants and other businesses. MTS has forged itself into a leading

manufacturer and supplier of hospitality seating in Michigan and across the country. This

is primarily the reason we choose MTS for our project.

President

Vice President

General Mgr

Sales Dept

(hotels)

Sales Dept

(food service)

Chief Financial

Officer

VP Sales

(hotels)

VP Sales

(food service)

Manufacturing

Dept

Supporting

Operations

Information

Systems Dept

7

Strengths

1. Custom Made Products

The size of the company puts MTS at a distinct advantage. MTS possesses

the capability of producing custom made furniture. A majority of the

competition both large and small are unable to recreate such proficiency in a

large scale. MTS has a substantial selection of fabrics, frames, and other

materials that customers can choose from. The information entered into the

production system reflects customer preference.

2. Just In Time (JIT) inventory

Lean manufacturing is a management philosophy that centers on the idea of

eliminating waste. A JIT inventory system is one process that follows the lean

manufacturing concept. Customer orders are ran in the production schedule a

week following orders. This enables MTS to use JIT and eliminate costs

associated with maintaining inventory.

3. Product Warranties

MTS Seating strongly backs its products. Extensive stress testing is

conducted on all products offered. As a result, MTS has strong confidence in

the furniture that is sold to the customer. Warranties on products last up to 12

years. If a customer is not satisfied with their product, it can be returned.

4. Utilization of Information Systems

Many small firms do not utilize an Information Systems department. MTS is

profitable enough to justify an IT department. Information systems are

utilized to support a majority of the businesses functions.

8

Weaknesses

1. Employing Specialized Labor

Individuals possessing special trade skills are a human resources issue that can

be problematic. Specialized laborers command higher salaries and are

sometimes hard to find. MTS employs a number of specialized laborers such

as welders and fabricators. This is not a major issue for MTS; however the

usage of specialized labor creates a weakness for the company.

2. Aged Machine Presses

A large array of equipment is used in the manufacturing process. MTS

currently uses state of art equipment; such as an automated machine that

paints metal frames. Machinery of this caliber is easily justified by its ROI.

MTS also utilizes machine presses that are as old as the company. These

presses are not used very often so justifying the purchase of replacement

presses is an issue.

3. Tracking of Customer Sample Furniture

MTS has space set aside in its manufacturing area where sample furniture is

stored. These items represent some of the models that are produced. The

sample furniture is sent to trade shows that MTS participates in throughout the

year. MTS’s customers may also request sample furniture to determine if it

suits their needs. MTS currently lacks an automated process of tracking the

sample furniture. A customer may request a sample from a sales coordinator

who must physically walk out to the sample area to see if the item is in stock.

This manual process is time consuming and inefficient.

9

Opportunities

1. blabla

2. blabla

3. blabla

Threats

1. Energy Costs

Rising costs of energy is of concern to everybody and MTS is not an

exception. MTS is impacted as its expenses associated with running its

business increases along with the costs of energy.

2. Cheap overseas labor

Labor costs in some of the other parts of the world are substantially lower than

those in the U.S. Manufacturers overseas are then able to produce similar

products cheaper than their American counterpart.

3. Subsidized steel

For more than a couple of decades, discussion on imported steel has remained

a topic of debate. There is worldwide excess production capacity for steel.

Dumping and government subsidized steel sent overseas to exporting markets

consequently becomes an issue. An example includes China’s current

government subsidized steel exporting practices. U.S. steel producing firms

benefit in the short run from low costs and domestic production of steel is

harmed. In the long run, these same firms are

10

History of the IT/IS & Database Development Projects

Current IT Environment

MTS Seating utilizes UNIX based servers in order to ensure reliable service for their

production scheduling systems. Their database applications are written in COBOL and

accessed from Microsoft Windows based desktops via Telnet over a TCP/IP network.

Business Problem

The company possesses sample furniture which is allows potential buyers to examine the

product. Samples can be taken to trade shows, on sales presentations, sent to clients for

evaluation or stored in showroom in company’s main offices. Currently the inventory of

sample furniture is not tracked. Because the inventory is not tracked, MTS Seating

cannot easily determine what samples are in stock. If a client requests a sample,

employees must physically go to the showroom and try to locate the samples visually.

Proposed Solution

We propose to develop an inventory tracking system that will allow MTS Seating to keep

track of furniture samples. Tracking will include where the sample is located and if the

sample has been sent out. This new system will also allow samples to be reserved.

Reserving will allow sales associates to request that a sample be sent to a customer.

Reservations will assist the shipping department in planning shipments to trade shows.

11

The system shall generate a report of overdue samples. This will allow sales associates to

follow-up with their clients. This also allows time to resolve reservation issues when

needed furniture is not returned on time and thus unavailable to fill the reservation.

The system will track specific quantities of various models/variations of furniture as well

as the specific pieces of furniture. Periodic physical inventories can be taken of samples

located in the showroom and an exception report noting discrepancies with system

maintained inventory.

The system will allow the user to remove products from inventory. Some reasons for

removal may include: damaged, lost, sold, donation, discontinued, etc.

12

Work Breakdown Structure (WBS)

It is a listing of the works/tasks involved in the project

It defines the total scope of the project

It is the foundation document in project management because it provides the basis for

planning, managing schedules, costs and changes

Enter all tasks and schedule into MS Project ( a hardcopy required)

13

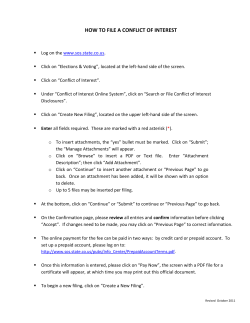

Database Development Process (SDLC)

Plan

14

ModelNum

Desc

Image

UnitPrice

Qoh

Inventory

ShipNum

ModelNum

QShip

ShipmentLine

OrderNum

ModelNum

QResv

ShipNum

OrderNum

CarrierId

Shipment

shipped

on

OrderNum

CustNum

EmpNum

shipped

Reserved

Returned

on

SampleOrder

ordered

for

ReturnItem

ReturnLine

OrderLine

Returns

ReturnNum

CustNum

OrderNum

ReturnNum

ModelNum

DateRet

QRet

Carrier

Employee

Customer

CarrierId

Company

AccountNum

EmpNum

FName

LName

Title

Ext

CustNum

BusName

Address

City

State

Zip

CustPhone

Analysis

Entity Relationship Diagram for MTS Seating Sample Order Tracking

15

Business Rules

1. An EMPLOYEE may reserve one or more SAMPLEORDER(s). A

SAMPLEORDER is reserved by one and only one EMPLOYEE.

2. A CUSTOMER may order one or more SAMPLEORDER(s). A

SAMPLEORDER is ordered for one and only one CUSTOMER.

3. A SHIPMENT is shipped for one and only one SAMPLEORDER. A

SAMPLEORDER is shipped on one or more SHIPMENT(s).

4. A SHIPMENT is shipped with one and only one CARRIER. A CARRIER

ships one or more SHIPMENTS.

5. INVENTORY may be a shipment line for one or more SHIPMENT(s). A

SHIPMENT contains shipment lines for one or more items in INVENTORY.

6. A SAMPLEORDER contains order lines for one or more items in

INVENTORY. INVENTORY may be an order line for one or more

SAMPLEORDER(s).

7. A RETURNITEM contains return lines for one or more INVENTORY items.

An INVENTORY item may be a return line for one or more

RETURNITEM(s).

8. A RETURNITEM is returned on only one SAMPLEORDER. A

SAMPLEORDER may be returned on one or more RETURNITEM(s).

9. A CUSTOMER may return one or more RETURNITEM(s). Each

RETURNITEM is returned by one and only one CUSTOMER.

16

Logical Design

Relational Schema

1. Structure

Carrier (CarrierId, Company, AccountNum)

Customer (CustNum, BusName, Address, City, State, Zip, CustPhone)

Employee (EmpNum, FName, LName, Title, Ext)

Inventory (ModelNum, Desc, Image, UnitPrice, Qoh)

ReturnItem (ReturnNum, CustNum, OrderNum)

ReturnLine (ReturnNum, ModelNum, DateRet, QRet)

SampleOrder (OrderNum, CustNum, EmpNum)

OrderLine (OrderNum, ModelNum, QResv)

Shipment (ShipNum, OrderNum, CarrierId)

ShipmentLine (ShipNum, ModelNum, QShip)

2. Domains

Attribute

Logical Domain

Physical Domain

AccountNum

Carrier Account Number

Character (7)

Address

Customer Address

Character (20)

BusName

Customer Business Name

Character (15)

CarrierId

Carrier Identification Number

Character (3)

City

Customer City

Character (15)

Company

Carrier Name

Character (10)

CustNum

Customer Identification Number

Character (7)

17

CustPhone

Customer Phone Number

Character (10)

DateRet

Date Sample Item is Returned

Character (8)

Desc

Brief Physical Description

Character (15)

EmpNum

Employee Identification Number

Character (7)

Ext

Employee Phone Extension

Character (4)

FName

Employee First Name

Character (10)

Image

Digital Image of Item

BLOB

LName

Employee Last Name

Character (15)

ModelNum

Inventory Item Model Number

Character (5)

OrderNum

Sample Order Number

Character (10)

Qoh

Inventory Quantity On-Hand

Integer (3)

QResv

Inventory Quantity Reserved

Integer (3)

QRet

Quantity of Items Returned

Integer (2)

QShip

Quantity of Items Shipped

Integer (2)

ReturnNum

Return Identification Number

Character (7)

ShipNum

Shipment Identification Number

Character (7)

State

Customer State

Character (2)

Title

Employee Job Title

Character (15)

UnitPrice

Inventory Item Unit Price

Integer (5)

Zip

Customer Zip Code

Character (5)

18

3. Constraints

a. Structural Constraints

i. Primary Keys

CarrierId in CARRIER may not be null.

CustNum in CUSTOMER may not be null.

EmpNum in EMPLOYEE may not be null.

ModelNum in INVENTORY may not be null.

ReturnNum in RETURNITEM may not be null.

OrderNum in SAMPLEORDER may not be null.

ShipNum in SHIPMENT may not be null.

ii. Cardinalities

Maximum Cardinalities

Each RETURNITEM is returned by only one CUSTOMER

Each RETURNITEM is returned on only one SAMPLEORDER

Each SAMPLEORDER is reserved by only one EMPLOYEE

Each SAMPLEORDER is ordered for only one CUSTOMER

Each SHIPMENT is shipped using only one CARRIER

Each SHIPMENT is shipped on only one SAMPLEORDER

Minimum Cardinalities

ModelNum in INVENTORY must exist in ModelNum in RETURNLINE

ModelNum in INVENTORY must exist in ModelNum in

SHIPMENTLINE

19

ModelNum in INVENTORY must exist in ModelNum in ORDERLINE

ReturnNum in RETURNITEM must exist in ReturnNum in

RETURNLINE

ShipNum in SHIPMENT must exist in ShipNum in SHIPMENTLINE

OrderNum in SAMPLEORDER must exist in OrderNum in ORDERLINE

iii. Referential Integrity

CarrierId in SHIPMENT must exist in CarrierNum in CARRIER

CustNum in RETURNITEM must exist in CustNum in CUSTOMER

CustNum in SAMPLEORDER must exist in CustNum in CUSTOMER

EmpNum in SAMPLEORDER must exist in EmpNum in EMPLOYEE

ModelNum in RETURNLINE must exist in ModelNum in INVENTORY

ModelNum in ORDERLINE must exist in ModelNum in INVENTORY

ModelNum in SHIPMENTLINE must exist in ModelNum in INVENTORY

OrderNum in RETURNITEM must exist in OrderNum in SAMPLEORDER

OrderNum in SHIPMENT must exist in OrderNum in SAMPLEORDER

OrderNum in ORDERLINE must exist in OrderNum in SAMPLEORDER

ReturnNum in RETURNLINE must exist in ReturnNum in RETURNITEM

ShipNum in SHIPMENTLINE must exist in ShipNum in SHIPMENT

b. Operational Constraints

An inventory item can not be reserved unless that model is in stock.

20

Physical Design

Main Menu

21

Forms

22

23

24

25

26

27

28

Implementation

Data

Carrier

CarrierId

Fed

Ups

Yel

Rdw

Company

Federal Express

United Parcel Service

Yellow Truck

Roadway

AccountNum

1003214

1003215

1013216

1023218

Customer

CustNum

BusName

1007000

Applebees

1007001

Big Boys

1007002

Craker Barrel

1007003

Days Inn

2005000

Denny's

2005001

Chuck E Cheese

2005002

Chilis

2005003

Tavern on the Main

2006000

Butterfield

2006001

Marriot

Address

1156

Water St

2211 Pine

Dr

699

Belleville

Rd

987

Durham

Rd

8976 12

Mile Rd

7867 Bay

Ridge

73

Springfield

Rd

170

Walnut

Ridge

8109

Renfrew

Rd

52 Corning

St

City

State

Zip

CustPhone

Alpeena

MI

49707 7155558943

Ann Arbor

MI

48103 7343426689

Belleville

MI

48111 7345554978

West

Orange

NJ

17052 1236559090

Farmington

MI

Hills

48322 2488804322

Rochester

NH

3867 5679382214

Newport

NH

3773 9148760944

Atlanta

GA

31211 6562317632

Greensboro NC

27409 2345543098

Lock

Haven

17340 6178953333

PA

29

Employee

EmpNum

100998888

FName

Mark

Lname

Meyers

101223333

Shelia

Hernandez

102334444

103445555

104556666

105667777

105778888

105889999

Brian

Sarah

Ryan

Janet

Lisa

Edward

Zhang

Calson

Courtlandt

Park

Hummer

Cole

Inventory

ModelNum

210

211

311

315

CI17R4

1424base

808

808-30

813

813-30

814

814-30

933

933-30

941

941-30

Desc

Bumper Edge Table Tops

Bumper Edge Table Tops

Wood Edge Tops

Wood Edge Tops

Base, Cast Iron, round series

Base, Valencia

Chair, Design Classics

Barstool, model 808 matching item

Chair, Luckhardt, Design Classics

Barstool, Model 813 luckhardt

matching item

Chair, Loos, Design Classics, beige

Barstool, Model 814 Loos matching

item

Chair, Americana Collection, black,

stipes

Barstool, model 933 matching item

Chair, Americana Collection

Barstool, model 941 matching item

Title

Ext

President

3777

TradeShow

5261

Mgr

Salesperson

5788

Salesperson

8977

Salesperson

6722

Salesperson

8355

Production

8878

Programmer

2213

Image

UnitPrice

Qoh

210-top.jpg

2.25

211-top.jpg

4.75

311-top.jpg

7.25

315-top.jpg

6.50

CI_17R_2LS15.65

base.jpg

1424-base.jpg

14.50

808_Nouveau.jpg

10.75

808_30.jpg

12.50

813_Luckhardt.jpg

11.45

813_30.jpg

814_Loos.jpg

814_30.jpg

933.jpg

933_30

941.jpg

941_30.jpg

10

10

15

15

20

25

20

25

20

13.85

15

9.45

15

11.80

15

8.25

10

12.75

9.35

14.25

25

15

10

30

ReturnItem

ReturnNum

9999912

9999913

9999914

9999915

9999916

9999917

9999918

9999919

9999920

CustNum

1007000

2005001

2005001

1007002

2006001

1007001

2005003

1007003

1007000

OrderNum

ReturnLine

ReturnNum

9999912

9999912

9999912

9999913

9999914

9999915

9999915

9999916

9999917

9999917

9999918

9999919

9999920

9999920

ModelNum

210

808

808-30

933

941

210

808

941

210

814

933

941-30

210

814

DateRet

06141999

06141999

06141999

06171999

06171999

06201999

06201999

06201999

06221999

06221999

06221999

06251999

06251999

06251999

SampleOrder

OrderNum

888101

888102

888103

888104

888105

888106

888107

CustNum

1007000

2005001

2005001

1007002

2006001

1007001

2005003

888109

888103

888102

888104

888105

888106

888107

888108

888101

Qret

1

4

4

1

1

1

4

2

1

2

1

1

2

8

EmpNum

105778888

104556666

104556666

102334444

105667777

102334444

105889999

31

888108

888109

OrderLine

OrderNum

888101

888101

888102

888102

888102

888103

888104

888104

888105

888106

888106

888107

888108

888109

888109

888109

888110

888110

888110

888110

888110

888110

Shipment

ShipNum

7771234

7771235

7771236

7771237

7771238

7771239

7771240

7771241

7771242

1007003

1007000

ModelNum

814

210

941

CI17R4

808

933

210

808

941

210

814

933

941-30

210

808

808-30

311

808

808-30

933

933-30

1424base

OrderNum

888101

888102

888103

888104

888105

888106

888107

888108

888109

102334444

105778888

Qresv

8

2

1

1

4

1

1

4

2

1

2

1

1

1

4

4

2

2

2

2

2

2

CarrerId

Fed

Ups

Fed

Fed

Ups

Fed

Fed

Fed

Ups

32

ShipmentLine

ShipNum

7771234

7771234

7771235

7771235

7771235

7771236

7771237

7771237

7771238

7771239

7771239

7771240

7771241

7771242

7771242

7771242

7771243

7771243

7771243

7771243

7771243

7771243

ModelNum

814

210

941

CI17R4

808

933

210

808

941

210

814

933

941-30

210

808

808-30

311

808

808-30

933

933-30

1424base

Qship

8

2

1

1

4

1

1

4

2

1

2

1

1

1

4

4

2

2

2

2

2

2

33

SQL statements

applications, stored procedures, functions and triggers

DROP TABLE carrier CASCADE CONSTRAINTS;

DROP TABLE customer CASCADE CONSTRAINTS;

DROP TABLE employee CASCADE CONSTRAINTS;

DROP TABLE inventory CASCADE CONSTRAINTS;

DROP TABLE return_item CASCADE CONSTRAINTS;

DROP TABLE return_line CASCADE CONSTRAINTS;

DROP TABLE sample_order CASCADE CONSTRAINTS;

DROP TABLE order_line CASCADE CONSTRAINTS;

DROP TABLE shipment CASCADE CONSTRAINTS;

DROP TABLE shipment_line CASCADE CONSTRAINTS;

CREATE TABLE carrier

(carrier_id VARCHAR2(10),

company VARCHAR2(50),

account_num VARCHAR2(20),

CONSTRAINT carrier_carrier_id_pk PRIMARY KEY (carrier_id));

CREATE TABLE customer

(custnum NUMBER(10),

busname VARCHAR2(50),

address VARCHAR2(50),

city VARCHAR2(50),

state CHAR(2),

zip VARCHAR2(10),

custphone VARCHAR2(10),

CONSTRAINT customer_custnum_pk PRIMARY KEY(custnum));

CREATE TABLE employee

(emp_num NUMBER(10),

f_name VARCHAR2(50),

l_name VARCHAR2(50),

title VARCHAR2(50),

ext VARCHAR2(10),

CONSTRAINT employee_emp_num_pk PRIMARY KEY (emp_num));

CREATE TABLE sample_order

(order_num NUMBER(10),

custnum NUMBER(10),

emp_num NUMBER(10),

CONSTRAINT sample_order_order_num_pk PRIMARY KEY(order_num),

CONSTRAINT sample_order_custnum_fk FOREIGN KEY (custnum) REFERENCES

customer(custnum),

34

CONSTRAINT sample_emp_num_fk FOREIGN KEY (emp_num) REFERENCES

employee(emp_num));

CREATE TABLE inventory

(model_num VARCHAR2(10),

description VARCHAR2(200),

image VARCHAR2(50),

unit_price NUMBER(10,2),

qoh NUMBER(7),

CONSTRAINT inventory_model_num_pk PRIMARY KEY (model_num));

CREATE TABLE return_item

(return_num NUMBER(10),

custnum NUMBER(10),

order_num NUMBER(10),

CONSTRAINT return_item_return_num_pk PRIMARY KEY(return_num),

CONSTRAINT return_item_custnum_fk FOREIGN KEY (custnum) REFERENCES

customer(custnum),

CONSTRAINT return_item_order_num_fk FOREIGN KEY (order_num)

REFERENCES

sample_order(order_num));

CREATE TABLE shipment

(shipment_num NUMBER(10),

order_num NUMBER(10),

carrier_id VARCHAR2(10),

CONSTRAINT shipment_order_shipment_num_pk PRIMARY KEY(shipment_num),

CONSTRAINT shipment_carrier_id_fk FOREIGN KEY (carrier_id) REFERENCES

carrier(carrier_id),

CONSTRAINT shipment_order_num_fk FOREIGN KEY (order_num) REFERENCES

sample_order(order_num));

CREATE TABLE order_line

(order_num NUMBER(10),

model_num VARCHAR2(10),

q_resv NUMBER(10),

CONSTRAINT order_line_order_num_pk PRIMARY KEY(order_num, model_num),

CONSTRAINT order_line_model_num_fk FOREIGN KEY (model_num)

REFERENCES

inventory(model_num),

CONSTRAINT order_line_order_num_fk FOREIGN KEY (order_num) REFERENCES

sample_order(order_num));

CREATE TABLE return_line

(return_num NUMBER(10),

model_num VARCHAR2(10),

35

date_ret DATE,

q_ret NUMBER(10),

CONSTRAINT return_line_return_num_pk PRIMARY KEY(return_num, model_num),

CONSTRAINT return_line_model_num_fk FOREIGN KEY (model_num)

REFERENCES

inventory(model_num),

CONSTRAINT return_line_return_num_fk FOREIGN KEY (return_num)

REFERENCES

return_item(return_num));

CREATE TABLE shipment_line

(shipment_num NUMBER(10),

model_num VARCHAR2(10),

q_ship NUMBER(10),

CONSTRAINT shipment_line_shipment_num_pk PRIMARY KEY(shipment_num,

model_num),

CONSTRAINT shipment_line_model_num_fk FOREIGN KEY (model_num)

REFERENCES

inventory(model_num),

CONSTRAINT shipment_line_shipment_num_fk FOREIGN KEY (shipment_num)

REFERENCES

shipment(shipment_num));

--Populate data for table carrier(CarrierId, Company, AccountNum)

--dbms_output.put_line('Inserting Carrier...');

INSERT INTO carrier VALUES

('FED', 'FedEX','1003214' );

INSERT INTO carrier VALUES

('UPS','United Parcel Service','1003215');

INSERT INTO carrier VALUES

('YEL','Yellow Truck', '1023216');

INSERT INTO carrier VALUES

('RDW','Roadway', '1023218');

-- Populate data for table Customer(CustNum, BusName, Address, City, State, Zip,

CustPhone)

INSERT INTO customer VALUES

('1007000', 'Apple Bees', '1156 Water Street','Alpena', 'MI', '49707',

'7155558943');

INSERT INTO customer VALUES

36

('1007001', 'Big Boys', '2211 Pine Drive', ' Ann Arbor', 'MI', '48103',

'7343426689');

INSERT INTO customer VALUES

('1007002', 'Craker Barrel', '699 Belleville Rd', 'Belleville', 'MI', '48111',

'7345554978');

INSERT INTO customer VALUES

('1007003', 'Days Inn', '987 Durham Rd', 'West Orange', 'NJ', '07052',

'6559090');

INSERT INTO customer VALUES

('2005000', 'Denny''s', '8976 12 Mile Rd.', 'Farmington Hills', 'MI', '48322',

'2488804322');

INSERT INTO customer VALUES

('2005001', 'Chuck E Cheese', '7867 Bay Ridge', 'Rochester', 'NH', '03867',

'5679382214');

INSERT INTO customer VALUES

('2005002', 'Chilis', '73 Springfield Rd', 'Newport', 'NH', '03773',

'9148760944');

INSERT INTO customer VALUES

('2005003', 'Tavern on The Main', '170 Walnut Ridge', 'Atlanta', 'GA', '31211',

'6562317632');

INSERT INTO customer VALUES

('2006000', 'Butterfield', '8109 Renfrew Rd', 'Greensboro', 'NC', '27409',

'2345543098');

INSERT INTO customer VALUES

('2006001', 'Marriot', '52 Corning St', 'Lock Haven', 'PA', '17340',

'6178953333');

--Populate data for table Employee(EmpNum, FName, LName, Title, Ext)

INSERT INTO employee VALUES

('100998888', 'Mark', 'Myers', 'President', '3777');

INSERT INTO employee VALUES

('101223333', 'Shelia', 'Hernandez', 'TradeShow Mgr', '5261');

INSERT INTO employee VALUES

('102334444', 'Brian', 'Zhang', 'Salesperson', '5788');

37

INSERT INTO employee VALUES

('103445555', 'Sarah', 'Calson', 'Salesperson', '8977');

INSERT INTO employee VALUES

('104556666', 'Ryan', 'Courtlandt', 'Salesperson', '6722');

INSERT INTO employee VALUES

('105667777', 'Janet', 'Park', 'Salesperson', '8355');

INSERT INTO employee VALUES

('105778888', 'Lisa', 'Hummer', 'Production Clerk', '8878');

INSERT INTO employee VALUES

('105889999', 'Edward', 'Cole', 'Programmer', '2213');

--Populate data for table inventory(ModelNum, Desc, Image, UnitPrice, Qoh)

INSERT INTO inventory VALUES

('210', 'Bumper Edge Table Tops', '210-top.jpg', '2.25', '10');

INSERT INTO inventory VALUES

('211', 'Bumper Edge Table Tops', '211-top.jpg', '4.75', '10');

INSERT INTO inventory VALUES

('311', 'Wood Edge Tops', '311-top.jpg', '7.25', '15');

INSERT INTO inventory VALUES

('315', 'Wood Edge Tops', '315-top.jpg', '6.50', '15');

INSERT INTO inventory VALUES

('CI17R4', 'Base, Cast Iron, round series', 'CI_17R_2LS-base.jpg', '15.65',

'20');

INSERT INTO inventory VALUES

('1424base', 'Base, Valencia', '1424-base.jpg', '14.50', '25');

INSERT INTO inventory VALUES

('808', 'Chair, Design Classics', '808_Nouveau.jpg', '10.75', '20');

INSERT INTO inventory VALUES

('808-30', 'Barstool, model 808 matching item', '808_30.jpg', '12.50', '25');

INSERT INTO inventory VALUES

('813', 'Chair Luckhardt, Design Classics', '813_Luckhardt.jpg', '11.45', '20');

INSERT INTO inventory VALUES

38

('813-30', 'Barstool, model 813 Luckhardt matching item', '813_30.jpg', '13.85',

'15');

INSERT INTO inventory VALUES

('814', 'Chair, Loos, Design Classics, beige', '814_Loos.jpg', '9.45', '15');

INSERT INTO inventory VALUES

('814-30', 'Barstool, model 814 Loos matching item', '814_30.jpg', '11.80',

'15');

INSERT INTO inventory VALUES

('933', 'Chair, Americana Collection, black, striped', '933.jpg', '8.25', '10');

INSERT INTO inventory VALUES

('933-30', 'Barstool, model 933 matching item', '933_30.jpg', '12.75', '25');

INSERT INTO inventory VALUES

('941', 'Chair, Americana Collection', '941.jpg', '9.35', '15');

INSERT INTO inventory VALUES

('941-30', 'Barstool, model 941 matching item', '941_30.jpg', '14.25', '10');

--Populate data for table sample_order(OrderNum, CustNum, EmpNum)

INSERT INTO sample_order VALUES

('888101', '1007000', '105778888');

INSERT INTO sample_order VALUES

('888102', '2005001', '104556666');

INSERT INTO sample_order VALUES

('888103', '2005001', '104556666');

INSERT INTO sample_order VALUES

('888104', '1007002', '102334444');

INSERT INTO sample_order VALUES

('888105', '2006001', '105667777');

INSERT INTO sample_order VALUES

('888106', '1007001', '102334444');

INSERT INTO sample_order VALUES

('888107', '2005003', '105889999');

INSERT INTO sample_order VALUES

('888108', '1007003', '102334444');

39

INSERT INTO sample_order VALUES

('888109', '1007000', '105778888');

INSERT INTO sample_order VALUES

('888110', '2006000', '102334444');

--Populate data for table order_line(OrderNum, ModelNum, QResv)

INSERT INTO order_line VALUES

('888101', '814', '8');

INSERT INTO order_line VALUES

('888101', '210', '2');

INSERT INTO order_line VALUES

('888102', '941', '1');

INSERT INTO order_line VALUES

('888102', 'CI17R4', '1');

INSERT INTO order_line VALUES

('888102', '808', '4');

INSERT INTO order_line VALUES

('888103', '933', '1');

INSERT INTO order_line VALUES

('888104', '210', '1');

INSERT INTO order_line VALUES

('888104', '808', '4');

INSERT INTO order_line VALUES

('888105', '941', '2');

INSERT INTO order_line VALUES

('888106', '210', '1');

INSERT INTO order_line VALUES

('888106', '814', '2');

INSERT INTO order_line VALUES

('888107', '933', '1');

INSERT INTO order_line VALUES

40

('888108', '941-30', '1');

INSERT INTO order_line VALUES

('888109', '210', '1');

INSERT INTO order_line VALUES

('888109', '808', '4');

INSERT INTO order_line VALUES

('888109', '808-30', '4');

INSERT INTO order_line VALUES

('888110', '311', '2');

INSERT INTO order_line VALUES

('888110', '808', '2');

INSERT INTO order_line VALUES

('888110', '808-30', '2');

INSERT INTO order_line VALUES

('888110', '933', '2');

INSERT INTO order_line VALUES

('888110', '933-30', '2');

INSERT INTO order_line VALUES

('888110', '1424base', '2');

--Populate data for table return_item(ReturnNum, CustNum, OrderNum)

INSERT INTO return_item VALUES

('9999912', '1007000', '888109');

INSERT INTO return_item VALUES

('9999913', '2005001', '888103');

INSERT INTO return_item VALUES

('9999914', '2005001', '888102');

INSERT INTO return_item VALUES

('9999915', '1007002', '888104');

INSERT INTO return_item VALUES

('9999916', '2006001', '888105');

41

INSERT INTO return_item VALUES

('9999917', '1007001', '888106');

INSERT INTO return_item VALUES

('9999918', '2005003', '888107');

INSERT INTO return_item VALUES

('9999919', '1007003', '888108');

INSERT INTO return_item VALUES

('9999920', '1007000', '888101');

--Populate data for table return_line(ReturnNum, ModelNum, DateRet, QRet)

INSERT INTO return_line VALUES

('9999912', '210', TO_DATE('06/14/1999', 'MM/DD/YYYY'), '1');

INSERT INTO return_line VALUES

('9999912', '808', TO_DATE('06/14/1999', 'MM/DD/YYYY'), '4');

INSERT INTO return_line VALUES

('9999912', '808-30', TO_DATE('06/14/1999', 'MM/DD/YYYY'), '4');

INSERT INTO return_line VALUES

('9999913', '933', TO_DATE('06/17/1999', 'MM/DD/YYYY'), '1');

INSERT INTO return_line VALUES

('9999914', '941', TO_DATE('06/17/1999', 'MM/DD/YYYY'), '1');

INSERT INTO return_line VALUES

('9999915', '210', TO_DATE('06/20/1999', 'MM/DD/YYYY'), '1');

INSERT INTO return_line VALUES

('9999915', '808', TO_DATE('06/20/1999', 'MM/DD/YYYY'), '4');

INSERT INTO return_line VALUES

('9999916', '941', TO_DATE('06/20/1999', 'MM/DD/YYYY'), '2');

INSERT INTO return_line VALUES

('9999917', '210', TO_DATE('06/21/1999', 'MM/DD/YYYY'), '1');

INSERT INTO return_line VALUES

('9999917', '814', TO_DATE('06/22/1999', 'MM/DD/YYYY'), '2');

INSERT INTO return_line VALUES

42

('9999918', '933', TO_DATE('06/22/1999', 'MM/DD/YYYY'), '1');

INSERT INTO return_line VALUES

('9999919', '941-30', TO_DATE('06/25/1999', 'MM/DD/YYYY'), '1');

INSERT INTO return_line VALUES

('9999920', '210', TO_DATE('06/25/1999', 'MM/DD/YYYY'), '2');

INSERT INTO return_line VALUES

('9999920', '814', TO_DATE('06/25/1999', 'MM/DD/YYYY'), '8');

--Populate data for table shipment(ShipNum, OrderNum, CarrierId)

INSERT INTO shipment VALUES

('7771234', '888101', 'FED');

INSERT INTO shipment VALUES

('7771235', '888102', 'UPS');

INSERT INTO shipment VALUES

('7771236', '888103', 'FED');

INSERT INTO shipment VALUES

('7771237', '888104', 'FED');

INSERT INTO shipment VALUES

('7771238', '888105', 'UPS');

INSERT INTO shipment VALUES

('7771239', '888106', 'FED');

INSERT INTO shipment VALUES

('7771240', '888107', 'FED');

INSERT INTO shipment VALUES

('7771241', '888108', 'FED');

INSERT INTO shipment VALUES

('7771242', '888109', 'UPS');

INSERT INTO shipment VALUES

('7771243', '888110', 'YEL');

--Populate data for table shipment_line(ShipNum, ModelNum, QShip)

43

INSERT INTO shipment_line VALUES

('7771234', '814', '8');

INSERT INTO shipment_line VALUES

('7771234', '210', '2');

INSERT INTO shipment_line VALUES

('7771235', '941', '1');

INSERT INTO shipment_line VALUES

('7771235', 'CI17R4', '1');

INSERT INTO shipment_line VALUES

('7771235', '808', '4');

INSERT INTO shipment_line VALUES

('7771236', '933', '1');

INSERT INTO shipment_line VALUES

('7771237', '210', '1');

INSERT INTO shipment_line VALUES

('7771237', '808', '4');

INSERT INTO shipment_line VALUES

('7771238', '941', '2');

INSERT INTO shipment_line VALUES

('7771239', '210', '1');

INSERT INTO shipment_line VALUES

('7771239', '814', '2');

INSERT INTO shipment_line VALUES

('7771240', '933', '1');

INSERT INTO shipment_line VALUES

('7771241', '941-30', '1');

INSERT INTO shipment_line VALUES

('7771242', '210', '1');

INSERT INTO shipment_line VALUES

('7771242', '808', '4');

INSERT INTO shipment_line VALUES

44

('7771242', '808-30', '4');

INSERT INTO shipment_line VALUES

('7771243', '311', '2');

INSERT INTO shipment_line VALUES

('7771243', '808', '2');

INSERT INTO shipment_line VALUES

('7771243', '808-30', '2');

INSERT INTO shipment_line VALUES

('7771243', '933', '2');

INSERT INTO shipment_line VALUES

('7771243', '933-30', '2');

INSERT INTO shipment_line VALUES

('7771243', '1424base', '2');

COMMIT;

45

--Packing slip SQL

SELECT ALL CUSTOMER.CUSTNUM, CUSTOMER.BUSNAME,

CUSTOMER.ADDRESS, CUSTOMER.CITY,

CUSTOMER.STATE, CUSTOMER.ZIP, SAMPLE_ORDER.ORDER_NUM,

SHIPMENT_LINE.MODEL_NUM,

SHIPMENT_LINE.Q_SHIP, SHIPMENT_LINE.SHIPMENT_NUM,

EMPLOYEE.F_NAME, EMPLOYEE.L_NAME, EMPLOYEE.EMP_NUM,

EMPLOYEE.EXT

FROM CUSTOMER, EMPLOYEE, SAMPLE_ORDER, SHIPMENT_LINE,

SHIPMENT

WHERE SAMPLE_ORDER.ORDER_NUM = :Order_desc

AND ((CUSTOMER.CUSTNUM = SAMPLE_ORDER.CUSTNUM)

AND (SAMPLE_ORDER.ORDER_NUM = SHIPMENT.ORDER_NUM)

AND (SHIPMENT_LINE.SHIPMENT_NUM = SHIPMENT.SHIPMENT_NUM)

AND (EMPLOYEE.EMP_NUM = SAMPLE_ORDER.EMP_NUM))

--User Defined Perameters

SELECT sample_order.order_num

FROM sample_order

--Unreturned Orders SQL

SELECT ALL SHIPMENT.SHIPMENT_NUM, CUSTOMER.CUSTNUM,

EMPLOYEE.EMP_NUM, RETURN_LINE.RETURN_NUM,

RETURN_LINE.MODEL_NUM,

RETURN_LINE.Q_RET, SHIPMENT_LINE.Q_SHIP,

SAMPLE_ORDER.ORDER_NUM,

CUSTOMER.BUSNAME, CUSTOMER.CUSTPHONE, EMPLOYEE.EXT,

EMPLOYEE.L_NAME

FROM CUSTOMER, EMPLOYEE, SHIPMENT, SHIPMENT_LINE,

SAMPLE_ORDER, RETURN_ITEM, RETURN_LINE

WHERE ((RETURN_ITEM.ORDER_NUM = SAMPLE_ORDER.ORDER_NUM)

AND (RETURN_ITEM.RETURN_NUM = RETURN_LINE.RETURN_NUM)

AND (CUSTOMER.CUSTNUM = SAMPLE_ORDER.CUSTNUM)

AND (EMPLOYEE.EMP_NUM = SAMPLE_ORDER.EMP_NUM)

AND (SHIPMENT.ORDER_NUM = SAMPLE_ORDER.ORDER_NUM)

AND (SHIPMENT.SHIPMENT_NUM = SHIPMENT_LINE.SHIPMENT_NUM)

AND NOT (RETURN_LINE.Q_RET = SHIPMENT_LINE.Q_SHIP))

--PL/SQL

function CF_items_outstandingFormula return Number is

outstanding NUMBER;

begin

outstanding := :q_ship - :q_ret;

return(outstanding);

end;

46

--Inventory Count List SQL

SELECT model_num, description, unit_price, qoh

FROM inventory

--Inventory SQL

SELECT model_num, description, unit_price, qoh

FROM inventory

47

Reports

48

49

Appendix

Note: CD and student evaluations in sleeve of project binder

Meeting Minutes

Meeting 2-17-2006 7:00 pm

IS 421 Project meeting

Agenda

Decide what case to do.

Present

Jeff Hayton

Nathaniel Curtis

Ray Cata

Tony Taylor

Absent

None

Discussion to pursue MTS Seating Inc. case if possible, otherwise come up with some

alternatives before 3-10-2006.

Set next meeting for 3-10-2006.

Adjourned

Meeting 3-10-2006 7:00 pm

IS 421 Project meeting

Agenda

Discuses the case

Discus proposal

Decide which system we want to develop

Divide the work for the proposal

Present

Jeff Hayton

Nathaniel Curtis

Ray Cata

Tony Taylor

Absent

50

None

Discussion of the case that we had selected.

Decided to develop an inventory tracking system for MTS Seating Inc.

Project introduction

Current IT environment

Business Problem/Solution

Methodologies and tools/sources

Users involved

Ray

Jeff

Jeff

Nathan

Tony

Adjourned

Meeting 3-24-2006 7:00 pm

IS 421 Project meeting

Agenda

Talk about answers to questions from vender?

Dividing the first faze of the project

1. ERD

2. Swat analysis

3. Business Rules

Discuss ERD

Present

Jeff Hayton

Nathaniel Curtis

Ray Cata

Tony Taylor

Absent

None

Talked about answers

Discussed ERD

Divided the work

1. ERD

2. Swat analysis

3. Business rules

Every One

Tony

Every One

Adjourned

51

Meeting 3-31-2006 7:00 pm

IS 421 Project meeting

Agenda

Discuss ERD

1. Finalizing schema

Present

Jeff Hayton

Nathaniel Curtis

Ray Cata

Tony Taylor

Absent

None

Discussed ERD

Divided the work

4. Finalizing schema

Adjourned

Meeting 4-7-2006 7:00 pm

IS 421 Project meeting

Agenda

4. Talk about

a. Forms

b. Tables

c. Reports

5. Dividing the SQL coding

6. What we have left to do

Present

Jeff Hayton

Nathaniel Curtis

Ray Cata

Tony Taylor

Absent

None

52

1. Talk about

a. Forms

i. Enter Inventory Adjust

ii. Lookup

iii. Create order

iv. View Orders

v. Create shipment

vi. Return Items

b. Tables

c. Reports

i. Physical inventory Count sheet

ii. Over due Samples

iii. Packing List

2. Dividing the SQL coding

Adjourned

53

© Copyright 2025