Structural and Interfacial Properties of Large Area n-a-Si:H/i-a-Si:H/p-c-Si Heterojunction Solar Cells

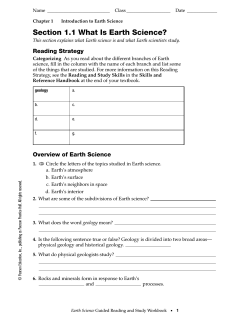

Structural and Interfacial Properties of Large Area n-a-Si:H/i-a-Si:H/p-c-Si Heterojunction Solar Cells Özlem Pehlivana, Deneb Mendab, Okan Yılmaza, Alp Osman Kodolbaşa, Orhan Özdemirb*, Özgür Duyguluc, Kubilay Kutlub and Mehmet Tomakd a) TUBİTAK, National Metrology Institute (UME), TR-41470, Gebze, Kocaeli, Turkey b) Yıldız Technical University, Department of Physics, Davutpasa Campus, TR-34210, Esenler, Istanbul, Turkey c) TUBITAK, Marmara Research Center (MAM), TR-41470, Gebze, Kocaeli, Turkey d) Middle East Technical University, Department of Physics, TR-06800, Ankara ABSTRACT Large area (72 cm2) doping inversed HIT solar cells (n-a-Si:H/i-a-Si:H/p-c-Si) were investigated by High Resolution Transmission Electron Microscopy (HR-TEM), Spectroscopic Ellipsometry (SE), Fourier Transform Infrared Attenuated Total Reflection spectroscopy (FTIR-ATR) and current-voltage (I-V) measurement. Mixture of microcrystalline and amorphous phase was identified via HR-TEM picture at the interface of i-a-Si:H/p-c-Si heterojunction. Using multilayer and Effective Medium Approximation (EMA) to the SE data, excellent fit was obtained, describing the evolution of microstructure of a-Si:H deposited at 225 °C on p-c-Si. Cody energy gap with combination of FTIR-ATR analyses were consistent with HRTEM and SE results in terms of mixture of microcrystalline and amorphous phase. Presence of such hetero-interface resulted poor open circuit voltage, Voc, of the fabricated solar cell devices, determined by I-V measurement under 1 sun. Moreover, Voc was also estimated from dark I-V analysis, revealing consistent Voc values. Efficiencies of fabricated cells over complete c-Si wafer (72 cm2) were calculated as 4.7 and 9.2 %. Improvement in efficiency was interpreted due to the back surface cleaning and selecting aluminum/silver alloy as front contact. Keywords: Doping inversed large area silicon heterojunction (SHJ), TEM, SE, epi-layer. 1. INTRODUCTION The a-Si:H/c-Si interface is the key factor to obtain efficient heterojunction solar cell and the performance of the cell depends on the recombination at the a-Si:H/c-Si interface (emitter-substrate) and substrate-rear contact. These losses can be prevented by a strong band bending in the crystal wafer which leads to an inversion layer at the interface or by a low density of interface states (Nss) at the junction. Not only Nss but also the optimum growth conditions of a-Si:H (optimum emitter thickness, optimum doping) as well as band offsets in a-Si:H/c-Si junction impact the properties of heterointerface, yielding better or worse cell properties. Nevertheless, the main challenge is on the suppression of recombination of the a-Si:H/c-Si interface. To accomplish this goal, density of states (DOS) shall be modified by a pretreatment of the Si wafers that results in reducing Nss at the amorphous/crystalline interface or by depositing a thin intrinsic a-Si:H buffer layer prior to the doped a-Si:H emitter layer, forming (p)a-Si:H/(i)a-si:H/(n)c-Si structure. Efficiency of such kind of cells, known as Silicon Heterojunction (SHJ) or Heterojunction with intrinsic thin layer (HIT), is reported over 23% by Sanyo group. Further improving of the efficiency of the solar cell structure is possible by focusing on either preventing the optical losses that limit the short circuit current density, J sc, or the resistance losses affecting the field factor, FF, or the recombination losses, impacting on the open-circuit voltage, Voc. *ozdemir@yildiz.edu.tr; phone 0090 212 383-4279; fax 0090 212 383-3254 Providing efficient light trapping by texturizing the wafers reduces optical losses. By decreasing the series resistance of the device with transparent conductive oxide (TCO) and good ohmic contacts leads to improve in the resistance losses. Efficient cleaning of the wafer surface before the a-Si:H deposition decreases the number of recombination centers and interface trap density, Nss. As Nss decreases from 1012 to 1010 cm-2eV-1, Voc, increases from 600 to 680 mV; J sc, changes from 38 to 38.5 mA/cm2; efficiency increases from 18% to 22% according to the simulation study [1]. As shown, interface traps have dramatic influence on heterojunction, particularly on V oc. Moreover, deteriorating of Voc might also be caused owing to the epitaxial (epi) growth formation at the a-Si:H/c-Si heterojunction [2,3], leading highly defective region at the a-Si:H/c-Si interface. Epitaxial growth is often observed on <100> oriented p-type substrates, and at high temperatures on n-type substrates. The formation can be avoided by tuning proper deposition conditions [4]. Nevertheless, if exist, presence of such layer modifies the transport of carrier paths, affecting the solar cell performance under working condition. Although, large area silicon heterojunction (SHJ) is fabricated on n-type c-Si wafer, studies on large area over p-type cSi are rather limited [5]. In the present work, improvement of the efficiency of the solar cells built on 72 cm 2 over p-type c-Si wafer is presented. According to the recent studies, given in table 1, this is the largest active area SHJ solar cell study so far. Cell and interface properties are investigated in detail using HR-TEM, SE, FTIR, and IV measurement and we report improvement of the c-Si wafer surface passivation and of the electrodes on the cell performance. Table 1 Literature survey on p- type crystalline silicon wafer Voc Jsc FF A (%) (mV) (mA.cm-2) (%) (cm2) EPFL,Switzerland 19.7 717 37.9 72.7 4, FZ 2011 NREL, USA 19.3 678 36.2 78.6 0.9, FZ 2010 Titech, Japan 19.1 680 36.6 76.9 0.8, FZ 2011 HZB, Germany 18.5 633 36.8 79.1 1 2009 Univ. Stuttgart, Germany 18.1 670 35.7 75.6 2 2010 LPICM, France 17 662 33.0 77.6 25, CZ 2009 ENEA, Italy 17 601 37.1 76.3 2.25 2004 Univ. Hagen, Germany 16.6 655 31.0 81.6 FZ 2009 NCHU, Taiwan 16.4 645 34.8 73.0 1 2008 IMEC, Belgium 16.4 644 1, FZ 2005 Univ. of Valencia, Spain 15.2 591 33.8 77.6 1, CZ 2010 CAS, China 15.1 585 34.6 74.7 <1, CZ 2009 Ultrecht Univ., the Netherlands 14.9 571 33.3 78 1, FZ 2005 UPC, Spain 14.5 613 30.3 77.9 FZ 2008 SUNY, USA 10.6 550 30 64 0.03 1997 Affillation Year 2. EXPERIMENTAL <100> oriented boron doped p-type crystalline silicon wafers were used. Two sets of solar cells were fabricated and called as HIT 44 and 51. For both sets, prior to film deposition, substrates were cleaned through standard RCA cleaning procedure in wet processing bench in ISO 6 cleanroom environment. Afterwards, wafers were immersed into the H2SO4:H2O2 (1:1) solution for 10 minutes for chemical oxide growing and then after rinsing in de-ionized water, wafers were dipped into 1% HF 60 seconds for the etching of the native silicon oxide. In order to prevent the surface oxidation, cleaned substrates were introduced immediately into the chamber of plasma enhanced chemical vapor deposition (PECVD) system. Note that before deposition, the chamber was cleaned with a NF 3 gas. Doped and undoped a-Si:H films were grown in capacitive type 13.56 MHz, multi-chamber UHV-PECVD system at TUBITAK UME. Growth conditions were as follows: substrate temperature was held constant at 225°C, deposition pressure was adjusted to 0.6 Torr, RF power density was set to 12mW/cm2. For intrinsic a-Si:H, SiH4 flow rate was adjusted to 40 sccm. For n type doping, 20sccm PH3 was added to the silane. Aluminium (Al) busbars and fingers were deposited on the top of the cell using thermal evaporation. Before full back contact Al deposition, rear side of the wafer was flown over 2% HF solution for 1 minute and subsequently rinsed with DI water. For the second set (HIT 51), prior to back contact formation, the wafer was immersed into 2% HF solution till hydrophobic surface was achieved and thickness of front contacts has been increased as well as Al/Ag(silver) alloy was used instead of aluminium. In both sets, resume growth conditions were used. HRTEM (High Resolution Transmission Electron Microscopy) techniques were applied to investigate the a-Si:H/c-Si heterointerface formation on present sets with JEOL JEM 2100 at 200 kV. TEM samples were prepared with Gatan 691 Precision Ion Polishing System (PIPS). By Fourier Transform Infrared Attenuated Total Reflection spectroscopy (FTIRATR), the vibrational response of the Si-H bonds in the frequency range of 400-4000 cm-1 with a resolution of 4 cm-1 was studied. Structural and interface properties were analyzed with a variable angle spectroscopic ellipsometer (SA Jobin YvonHoriba) of the rotating analyzer type. All measurements were performed in the wavelength range of 245 to 1200 nm. Measurements were carried out at 70° angle of incidence. All data analyses were made using DeltaPsi II software. In the analysis of SE data, multilayer model was used. The surface roughness layer was modeled as a mixture of the bulk material and voids using the Bruggeman effective medium approximation. For electrical analysis, the current voltage characteristics of solar cell devices were measured within dark and light ambient by means of a computer controlled voltage-current Keithley 2600 source meter. Solar cell performance was determined at Standart Test Conditions (STC) with the help of calibrated reference cell from Fraunhofer ISE. 3. RESULTS AND DISCUSSION 3.1 (i) a-Si:H/c-Si Heterointerface Properties by HR-TEM and SE Analysis Figure 1-a depicted the cross-sectional TEM image of (i) a-Si:H film deposited onto c-Si substrate with the resumed growth condition of that of the HIT solar cells (44 and 51). ZnO:Al was deposited on the top of a-Si:H film to improve the quality of the TEM image. Obviously, co-existentence of epitaxial (epi) layer and the amorphous layer were shown within the deposited film. Furthermore, a transition layer showed pyramidical epi growth followed by amorphous silicon phase. Due to the changes in material properties like crystallinity and surface roughness, spectroscopic ellipsometry analysis was used as one more confirmation. The dielectric function reflects the main absorption in the film due to band to band transitions, while the evolution of the surface roughness yields information about nucleation process and surface mechanisms [6]. For instance, as shown in Figure 1-b, two sharp peaks at 3.5 eV and 4.2 eV corresponded to the direct optical transitions from the (valance band) to (conduction band) in the first Brillouin zone and transition in the Brillouin zone along the X and R directions [7-8], respectively. A broad peak around 3.6 eV indicated amorphous structure whilst narrower peak with a shoulder at smaller photon energies approved a mixture of crystallinity and amorphous phase like nanocrystalline (nc) or microcrystalline structure [8, 9, 10]. Particularly, c phase has an intermediate spectrum with a soft peak at 4.2 eV and a shoulder at low photon energies [10], whereas nc phase has a soft peak at 3.6 eV and a shoulder at low photon energies. (a) (b) Figure 1. (a) Cross-Sectional TEM image of (n)a-Si:H/(i)a-Si:H/)p)c-Si Heterostructure, (b) Photon Energy versus 2 graph for c-Si and 60s deposited intrinsic a-Si:H film For the surface roughness, top layer was defined as the composite structure including void and the bulk by using Bruggeman Effective Medium Approximation (EMA) method in which each component material was identified by its percentage of the overall volume of the relevant layer [8-10]. Effective medium approximation method based on the addition of the polarization effects, and given as: eff h h fi i eff 2 h i 2 h i (1) Where , , and fi were the effective medium dielectric function, the host dielectric function, and the dielectric function and volume fraction of the ith component, respectively. In the Bruggeman approximation (EMA), relation was hold and Eqn. 1 turned into [11-13]: f i i i h 0 i 2 h (2) Generally Tauc-Lorentz dispersion law was used to describe the a-Si:H thin film [14] and hence, imaginary part of the dielectric function was defined as: AE o C(E E g ) 2 ε 2 (E) E (E 2 E o2 ) 2 C 2 E 2 0 if E E g (3) if E E g where, Eg = optical band gap energy, Eo = energy of maximum absorption (peak transition energy), A = the amplitude factor proportional to the density of the material, C = the broadening parameter that is inversely related with the short range order of the material [15-18]. Keeping those in mind, we have successfully applied a multilayer model to fit the measured SE data and depicted in inset of Figure 2-a. In this model, a crystalline silicon wafer was a substrate, followed by two linearly graded breakdown layers (void on bottom and c-Si on top and a transition from crystal silicon at the bottom and amorphous silicon at the top). Subsequently, an amorphous layer itself and a layer constituted by amorphous silicon and void, which yielded a full history of the deposition, including the epitaxial layer thickness and the evolution of the breakdown into a-Si:H. Low 2, 0.066, indicated a good matching of model with the experimental data as shown by solid lines in Figure 3-a. Consequently, retrieved parameters as a result of fit were compared with that of the HRTEM results (given in Table 2), presenting a very good agreement in both film thickness and proposed composition for a-Si:H film. As partial conclusion, the model successfully described the evolution of microstructure of a-Si:H deposited at 225 °C on p-c-Si substrate. For the bandgap estimation, another clue for the existence of microcrystalline phase of present thin films, we determined Cody gap from the energy position of in the plot of versus En and obtained as 1.59 eV (see figure 2-b) [19]. Surface roughness analysis of the films, deposited at the same deposition conditions with different deposition times consisted also a mixed a-Si:H and c-Si:H phases together within the. Surface roughness a-Si:H layer was calculated to be 5.7 A. (a) (b) Fgiıre 2. (a) Matching of SE measurements (symbols) with model fitting (solid lines), for 120 s deposited sample. The inset shows multi layer model for 120 s deposited sample, representing the structure of the material as accurately as possible (b) Variation of dielectric function versus photon energy. Note that energy gap of the film was obtained as 1.59 eV from Cody analysis. 3.2 FTIR-ATR of (n)a-Si:H/(i)a-Si:H(p)c-Si Heterostructure Fourier Transform Infrared Attenuated Total Reflection spectroscopy (FTIR-ATR) technique was applied to measure the vibrational response of the Si-H bonds in the frequency range of 400-4000 cm-1 with a resolution of 4 cm-1. Figure 3 showed a typical IR spectrum in the domains of absorption coefficient with a spectral range of 1800-2300 cm-1 (denoted as symbol). Figure 3. Raw (symbol) and deconvoluted (solid line) FTIR-ATR spectrum of (n)a-Si:H/(i)a-Si:H/(p)c-Si heterostructure At priori, wavenumbers of Si-Hx stretching modes (SM) and their corresponding bond types on device grade a-Si:H films without microcrystalline phase were given in Table 3 for comparison purpose. Table 2, Silicon-hydrogen stretching modes for FTIR measurement, Surface Hydrogen Bulk Hydrogen Peak position (cm-1) Hydride Type References Peak position (cm-1) Hydride Type References 2070-2080 SiH [22, 23, 24] 1980-2010 (LSM) SiH vacancies [25, 26, 27, 23] 2095-2105 SiH [22, 23, 24] 2070-2100 (HSM) SiH clustered [27,28] 2110-2120 SiH2 [22, 23, 24] 2190-2210 SiHx(Oy) [23] 2135-2145 SiH3 [22, 23, 24] 2240-2260 SiH(O3) [23,26] 2255-2265 SiH(O2) [22] in As clear from TEM and SE analyses, microcrystalline phase existed at the interface. Solid line in figure 4 designated deconvolution process of the spectrum with Gaussian modes. The extreme low SM (ELSM: 1862, 1884, 1917, 1937, 1955 and 1964), the middle SM (MSM: 2024, 2041, 2055), the high SM (HSM: 2122, 2138, 2150, 2169) were attributed to microcrystalline phase. ELSM reflected thin hydride dense a-Si:H tissue, ascribed either passivates the crystalline grain boundaries or fills the small pores whereas MSM were associated with SiH x groups. HSM showed the contribution of mono-, di-, and trihydrides on crystalline surfaces, assigned to crystalline grain boundaries in the bulk. The wavenumber at 2000 cm−1 was attributed to the stretching mode (SM) of the Si-H bond whereas the wavenumber at 2090 cm-1 peak revealed the stretching mode of the Si-H2 bond, respectively. Presence of the Si-H2 stretching mode proved increase of a dangling bond in the film due to the microcrystallization. The intensity of the Si-H stretching mode on the other hand, indicated good quality a-Si:H thin films [20,21]. At last, wavenumber range of 2180-2250 is associated to oxygen related bonds: SiH2(O2) at 2185-2210 and SiH(O3) at 2250 cm-1 [1]. 3.3 Electrical Properties of of (n)a-Si:H/(i)a-Si:H(p)c-Si Heterostructure (a) (b) Figure 4. (a) Isc-Voc variation of fabricated solar cells under 1 sun illumination. (b) Dark I-V characteristics for the present cells. Figure 4 showed Isc-Voc curve under 1-sun illumination of solar cells (HIT 44 and 51), built over 72 cm2 on p-c-Si. The only difference between HIT44 and 51 were the back surface cleaning of the c-Si wafer and usage of Al/Ag as top electrode instead of sole Al. As a consequence of that V oc was changed from 410 mV to 430 mV while I sc was altered from 0.9 to 2.6 Amperes. In light of structural and heterointerface analyses carried out via HR-TEM, SE and FTIR-ATR measurements, such poor Voc was expected due to the microcrystalline phase formation at the interface of i-a-Si:H/p-c-Si heterojunction. Since Voc was directly related with surface passivation of p-c-Si wafer. On the other side, dark current-voltage curves were used to investigate the fundamental characteristics of solar cell device, particularly to extract Voc without the need of a solar simulator. For the two-diode equivalent circuit models, forward current would be [1] (4) In there, was the photo-induced current, V was the applied bias voltage, I0,1(I0,2) represented the saturation current, n1 was the diode ideality factor for the high-forward bias region, A was the temperature (in)dependent factor for the low-forward bias region, Rs was the series resistance, Rp was the parallel or shunt resistance, k was Boltzman constant and T was the temperature. Avoiding the series resistance region simplified the relation 4 into an analytical expression as (5) where the first terms corresponded to high forward bias region and the second term denoted to low bias voltage region. Under high forward bias within dark condition, setting I F=0 and solving the equation leaded an oppurtunity to estimate the Voc from dark I-V characteristic as, (6) The estimated Voc values (538 mV For HIT 44 and 458 for HIT 51) were in agreement with the actual V oc (410 mV For HIT 44 and 430 for HIT 51). On the other side, short circuit current increased due to improvement of the front contacts. As a result of better back surface cleaning of the c-Si wafer and improvement of top electrodes, solar cell efficiency has been increased from 4.7% to 9.2%. 4. CONCLUSION Two sets of doping inversed HIT solar cells were fabricated over the largest area so far on p-c-Si wafers (72 cm2). Owing to the resumed growth conditions, similar structural and heterointerface formation was observed for the two sets. Drastic difference in between fabricated solar cells in terms of efficiency was find out the largest studied area (4.7% and 9.2%) on p type c-Si wafer. The reasons behind were due to better back surface cleaning of the c-Si wafer and choosing alloys as top electrodes rather than aluminium. REFERENCES [1] Van Sark G.J.H.M., Korte L., Roca F., Physics and Technology of Amorphous-Crystalline Heterostructure Silicon Solar Cells, Springer 2012. [2] Fujiwara H., Kondo M., Impact of Epitaxial Growth of the Heterointerface of a-Si:H/c-Si Solar Cells, Appl. Phys. Lett., 90, 013503 (2007) [3] Fujiwara H., Kondo M., Real time Monitoring and Process Control in Amorphous/Crystalline Silicon Heterojunction Solar Cells by Spectroscopic Ellipsometry and Infrared Spectroscopy, Appl. Phys. Lett., 86, 032112 (2005) [4] Wang, T.H., Iwaniczko, E., Page, M.R., Effective Interfaces in Silicon Heterojunction Solar Cells, Proceedings of the 31st IEEE Photovoltaic Specialists Conference, Orlando, FL, USA, 95, 2005. [5] De Wolf S., Kondo M., Nature of Doped a-Si:H/c-Si Interface Recombination, Journal of Applied Physics, 105, 103707,2009. [6] Peng W., Zeng X., Liu S., Xiao H., Kong G., Yu Y., Xianbo L., Study of Microstructure and Defects in Hydrogenated Microcrystalline Silicon Films, IEEE Proceeding, (001029-001033), 2009. [7] Kageyama S., Akagawa M., Fujiwara H., Dielectric Function of a-Si:H based on Local Network Structures, Physical Review B, 83, 195205, 2011. [8] Yuguchi T., Kanie Y., Matsuki N., Fujiwara H, Complete Parametrization of the Dielectric Function of Microcrystalline Silicon Fabricated by Plasma-Enhanced Chemical Vapor Deposition, Journal of Applied Physics, 111, 083509, 2012. [9] Meijun L, Silicon Heterojunction Solar Cell and Crystallization of Amorphous Silicon, PhD Thesis, University of Delaware, 2008 [10] Cervantes, D. M., Silicon Heterojunction Solar Cells Obtained by Hot Wire CVD, PhD Thesis, Universitat Politecnika de Catalunya, 2008. [11] Stoke J. A , Spectroscopic Ellipsometry Analysis of the Component Layers of Hydrogenated Amorphous Silicon Triple Junction Solar Cells, Master of Science, University of Toledo, 2008. [12] Aspnes D.E., Optical Properties of Thin Films, Thin Solid Films, 89, 249-2621982. [13] Fujiwara, H.; Koh, J.; Rovira, P.I.; Collins, R.W, Assessment of Effective-Medium Theories in the Analysis of Nucleation and Microscopic Surface Roughness Evolution for Semiconductor Thin Films, Physical Review B, 61(16), 10832(13), 2000. [14] Ferlauto, A. S., Ferreira, G.M., Pearce, J.M., Wronski, C.R., Collins, R. W, Analytical Model for the Optical Functions of Amorphous Semiconductors from the Near-Infrared to Ultraviolet: Applications in Thin Film Photovoltaics, Journal of Applied Physics, 92(5), 2424, 2002 [15] Teplin, C.W., Levi, D.H., Iwaniczko, E., Jones, K.M., Perkins, J. D, Monitoring and Modeling Silicon Homoepitaxy Breakdown with Real-Time Spectroscopic Ellipsometry, Journal of Applied Physics, 97, 103536, 2005. [16] Morral, A.F., Cabarrocas, P.R, Structure and Hydrogen Content of Polymorphous Silicon Thin Films Studied by Spectroscopic Ellipsometry and Nuclear Measurements, Physical Review B, 69, 125307, 2004 [17] Pereira, L., Aguas, H.; Fortunato, E.; Martins, R., Nanostructure Characterization of High k Materials by Spectroscopic Ellipsometry, Applied Surface Science, 253, 339-343, 2006. [18] Feng, G.F., Zallen, R., Optical Properties of Ion-Implanted GaAs: The Observation of Finite-Size Effects in GaAs Microcrystals, Physical Review B, 40, 10641989. [19] Fujiwara H., Kaneko t., Kondo M., Application of Hydrogenated Amorphous Silicon Oxide Layers to c-Si Heterojunction Solar Cells, Applied Physics Letters, 91, 133508, 2007. [20] Okazaki Y., Miyazaki S., Hirose M., Infrared Attenuated Total Reflection Spectroscopy of Microcrystalline Silicon Growth, Jour. Non-Cryst. Sol., 266-269, 54-58, 2000. [21] Pehlivan Ö., PhD Dissertation, Metu, Turkey, 2013. [22] Van den Oever, P.J., In Situ Studies of Silicon-Based Thin Film Growth for Crystalline Silicon Solar Cells, Eindhoven: Technische Universiteit, 2007. [23] Smets A.H.M., Growth Related Material Properties of Hydrogenated Amorphous silicon, Eindhoven: Eindhoven University of Technology, 2002. [24] Peng, W., Zeng, X., Liu, S., Xiao, H.; Kong, G., Yu, Y., Liao, X., Study of Microstructure and Defects in Hydrogenated Microcrystalline Silicon Films, Photovoltaic Specialists Conference, 34th IEEE, 001029-001033, 2009. [25] Schulze T. M., Structural, Electronic and Transport Properties of Amorphous/Crystalline Silicon Heterojunctions, PhD Thesis, Institut für Silizium-Photovoltaik E-I1, Helmholtz Centre Berlin, 2011. [26] Kroely L., Process and Material Challenges in the High Rate Deposition of Microcrystalline Silicon Thin Films and Solar Cells by Matrix Distributed Electron Cyclotron Resonance Plasma, PhD Thesis, Ecole Polytechnique, Paris, 2010. [27] Vavrunkova V., Mullerova, J., Sutta, P., Microstructure Related Characterization of a-Si:H Thin Films PECVD Deposited Under Varied Hydrogen Dilution, Advances in Electrical and Electronic Engineering, 2007. [28] Wang Y.H. , Lina J., Huana C.H.A., Structural and Optical Properties of a-Si:H/nc-Si:H Thin Films Grown from Ar–H2–SiH4 Mixture by Plasma-Enhanced Chemical Vapor Deposition, Materials Science and Engineering, B104, 80– 87, 2003.

© Copyright 2025