Sample Oxidizers Manual and Automatic Sample Preparation for Liquid Scintillation Counting

Sample Oxidizers Manual and Automatic Sample Preparation for Liquid Scintillation Counting System 387 Sample Oxidizer PerkinElmer’s System 387 – As Easy as ABC! For many years the PerkinElmer Model 307 Sample Oxidizer has been the gold standard for the Researchers around the world have been impressed with the performance of the System 387 and have commented: “The System 387 is reliable, dependable and has performed exceptionally well.” preparation of many biological sample types, such as animal and plant tissue and fluids, and for subse- “The System 387 sample oxidizer provides a powerful tool to process a diverse array of samples to a high degree of precision and accuracy.” quent measurement by liquid scintillation counting. For high throughput application situations, the Oximate 80 Robot converts the Model 307 Oxidizer into a fully automatic sample preparation station, known as the System 387, for preparing as many as 80 samples completely unattended. The two arm robotic system transports the sample-filled Combusto-Cone™ to the ignition basket and positions the LSC vials to collect the 14CO2 and 3H2O combustion products. Seven days a week, twenty-four hours a day. Now there is a way to eliminate the tedious work, the counting errors and the exposure to solvent fumes from your LSC sample preparation methods. PerkinElmer’s System 387 combines the Sample Oxidizer 307 with the OxiMate 80 robotic system to automatically prepare single and dual label 3H and 14C samples for liquid scintillation counting. “The System 387 has proven to be an excellent piece of equipment and has saved considerable time and manpower for our department in just a few short months.” If your work requires repetitive processing of multiple samples by sample oxidation, the System 387 is the solution you are looking for. It’s as easy as ABC!!! A Load 80 samples & LSC vials into the System 387 B Press the start button and WALK AWAY! C When you return, you’ll find all your samples in vials, capped and ready for counting in your LSC. What’s more, the System 387 prepares your samples by flame combustion, the absolute best method for LSC sample preparation: • • • • • 2 No No No No No color quenching chemiluminescence variable dual label ratios chemical quench variations sample self-absorption effects OxiMate 80 Plus Oxidizer 307 Equals System 387 Exclusive Features and Benefits of the System 387 OxiMate 80 Plus… Oxidizer 307 • 80 sample capacity • Samples up to 1.5 grams • 240 samples per day* throughput • Eliminates counting errors • Sensor controlled safety • • Limited exposure to hazardous materials Combusts dual label samples, collects single label 3H/14C • Pays for itself in less than two years • Wet, dry or freeze-dried samples • Eliminates solubilization • No catalyst required • Automatically adds cocktail • High temperature flame combustion (up to 1300°C) • Unique splash-free filling system • OxiMate 80 will indicate when maintenance is required • Upgrade Oxidizer 307 to a System 387 • Caps and uncaps vials • Automated Combustaid addition • Multiple combustions collected in the same vial Equals… System 387 *Based on an eight-hour work day. 3 Automate Your LSC Sample Preparation Why Automate? Expand Experimental Capabilities Reduce Labor and Avoid Hazardous Work • Processes sample weights up to 1.5 grams.* • Automates tedious sample preparation procedures. • Works with a wide variety of sample materials. • Separates 3H and materials. 14 C for dual label sample • Capable of combusting up to 15 grams of 3H labeled material and collecting into one counting vial.* • Processes up to 80 samples in one run; up to 240 samples per day. • Hands-off system reduces exposure to hazardous materials. *Depending upon sample type. 1 4 2 Cut Costs and Eliminate Solubilization Eliminate Counting and Preparation Errors • Pays for itself in less than two years. • Reduces the element of human error. • Reduces costs of specimens and consumables. • Eliminates errors caused by colored samples, sample self-adsorption, chemiluminescence, varying quench levels, and isotope spillover. • Eliminates costly and error-prone solubilization procedures. 3 4 5 The Oxidizer 307 Expands Experimental Capabilities From specimen to ready-to-count samples in vials, the System 387 has been designed to enhance your experimental results and to expand your experimental horizons. Larger Sample Size Improves Accuracy Sample sizes up to 1.5 grams can be processed with the System 387. This ten-fold increase over conventional sample preparation methods, such as solubilization, increases the total sample activity per vial. The result is increased counting accuracy, shorter counting times, and less radioactive material to store. Wider Variety of Specimens Extends Experimental Capabilities The System 387’s flame combustion technology allows you to process a variety of samples that extend far beyond the capabilities of any other liquid scintillation sample preparation technique. Wet, dry or freeze-dried samples of whole organs, soil, plant tissue, liver, spleen, skin, plasma, bone, egg shell, muscle, feces, kidney, brain, bladder, hair, whole blood, water, insects, lung, adipose, heart, fat, intestines, urine, bacteria, gels, plastics, filters, membrane, glands, crude oil, toluene, thin layer scrapes... Typical LS counting of dual label 3H/14C samples results in large 3H errors when samples are counted with excess 14C activity. Oxidation eliminates these because it physically separates 3H from 14C. 6 ...the list is endless. The System 387 clearly demonstrates that flame combustion can be an easy, reliable and universal sample preparation technique. Higher Dual Label Activity Ratios Let You Perform Two Experiments on One Sample With the System 387, there are no limitations to the activity ratio of 3H and 14C in dual label experiments. Minute quantities of one label can now be obtained in the presence of high concentrations of the second label. The System 387 physically separates both isotopes, thus allowing you to perform dual label metabolic and tracer studies with higher accuracy — i.e., you can do two experiments with one specimen! Low Level Tritium Counting of Solid Samples You can collect tritium activity for 10-15 grams of solid material in a single vial for environmental control, health physics studies and other low level tritium measurements. This increases the detection sensitivity for tritium in these materials by a factor of 10-100. The OxiMate 80 Reduces Labor and Avoids Hazardous Work The System 387 is the first commercial, stand-alone, hands-off sample preparation system for liquid scintillation counting. It features electronic sensor controls to allow complete walk-away operation. Reduces Labor By Automating Tedious Sample Preparation Procedures Are you tired of uncapping and recapping vials; manually dispensing cocktails; mixing; adding solubilizers, bleaching agents and acidifiers; incubating at elevated temperatures; and dark adaptation? All of these laborious, tedious and often hazardous procedures can be eliminated with the System 387. Just load samples and capped vials, and press the start button. Up to 80 samples can be prepared in one run, totally unattended, and are ready for counting after two to three hours. Simultaneous counting and automatic sample preparation with the System 387 allows you to process up to 240 samples per day*, with minimal user intervention, reducing labor up to 80%! Avoid Hazardous Work and Clean-Up Your Laboratory The System 387 is a hands-off, stand-alone, and compact system. Samples are processed automatically and unattended. Limit the amount of radiolabeled materials. Lessen the exposure to fumes, mess and the hazards of solvents, solubilizers and other toxic reagents. Self-Monitoring Insures Error-Free Sample Handling The System 387 monitors several procedural steps and will stop automatic processing when errors are detected. Sensors will stop operation if oxidation is not detected. Processing will be concluded if fluid delivery, sample movement, vial movement, and oxidation pressures are detected as abnormal. *Based on an eight-hour work day. Just load your samples, press the start button, and 80 samples are prepared for counting in two to three hours. 7 System 387 Cuts Costs and Eliminates Complicated Sample Preparation Considering the time saved by the System 387, The Solubilizer Case Study it can pay for itself in less than two years. The preparation of biological samples labeled with tritium presents a difficult challenge to investigators using liquid scintillation. While adding the sample to the cocktail may be adequate for simple aqueous samples with neutral pH, direct sampling is not recommended for biological samples. Biological samples such as plant or animal tissues, TLC scrappings, filter papers, protein precipitates, DNA/RNA blots and electrophoresis gels must be completely dissolved in the scintillation cocktail to prevent 3H self-adsorption. Cuts Costs of Labor and Consumables The System 387 enhances productivity by allowing more experiments to be run at existing staff levels. It functions overnight without supervision, and it doesn’t require any special skills. Another key benefit is that the System 387 allows increased sample sizes. The larger sample size can reduce the number of vials per experiment and reduce the radioisotope tracer material required. The System 387 eliminates the use of solubilizers, bleaching agents and chemiluminescence inhibitors. By physically separating 3H and 14C labeled material, the System 387 allows two experiments to be performed on a single specimen, reducing specimen costs! Automated oxidation reduces costs of labor and consumables, and eliminates interference from color quenching and chemiluminescence. AUTOMATED OXIDATION Depending on the material, there are various ways of dissolving the sample. The most common methodology is solubilization which requires incubation to reduce the processing time. The solubilization process often produces large errors in counting data. The counting errors can be attributed to self-adsorption and/or chemiluminescence. Automatic flame combustion with the System 387 provides a known technique that improves the sample preparation efficiency and the quality of experimental results. Samples are ready for counting in minutes instead of hours, and over 200 samples can be processed daily versus the 80 samples that typically can be processed through manual solubilization methods. SOLUBILIZATION SAMPLE SAMPLE COMBUSTO CONE COUTING VIAL AUTOMATIC COMBUSTION SOLUBILIZE (30 min. - 18 hours) BLEACHING? (color quenching) NEUTRALIZE pH? (chemiluminescence) 3 14 H C ADD COCKTAIL COUNTING (variable quench) CAP DARK ADAPT 3 14 H C (varying ratios) COUNTING 8 Eliminates Counting and Preparation Errors People make mistakes - that’s human nature. Many sample preparation methods may introduce interferences. The System 387 is the only automated sample preparation system that can reduce counting errors and human mistakes. Its automation technology performs the sample preparation tasks identically, without procedural mistakes. The oxidation technology prepares samples — large or small, wet or dry — without introducing counting interferences. Automation Reduces Preparation Errors Test results are only as accurate as the samples that are prepared. Manual sample preparation is prone to errors. Different samples require different procedures. A step may be skipped, a reagent may be delivered incorrectly, the wrong cocktail may be used. Flame oxidized samples allow the same liquid scintillation counting conditions for a variety of sample types. The only variable is the counting time. Automation allows tasks to be performed without procedural mistakes. The System 387 eliminates sample preparation errors. Oxidation Reduces Counting Errors Many errors, often unsuspected, have plagued LSC users for over 30 years. Colored samples, self-adsorption, chemiluminescence, varying quench levels, and isotope spillover are all well-known problems resulting from conventional sample preparation procedures. The flame oxidation principle yields samples that are uniform. The products of combustion are in the form of water and/or carbon dioxide. The oxidation of the organic substance in the sample eliminates color quenching, chemiluminescence and self-adsorption. Oxidation is the only technique that, prior to counting, physically separates 3H from 14C eliminating many errors associated with the counting of dual labeled samples. The System 387 reduces procedural mistakes. Sample combustion uses a field proven sample preparation methodology. System 387 delivers capped, ready-to-count vials. All procedural samples preparation mistakes are eliminated by total automation. 9 OxiMate 80 Automation to Increase Productivity The System 387 doesn’t make mistakes, even when working in the dark. OxiMate 80 Is Easy to Use PerkinElmer designed the System 387 to simplify sample preparation. Just load your samples and vials, press a button and walk away. Return later to collect your capped, ready-tocount vials. • Nitrogen and oxygen pressure • The back pressure during combustion • The sample ignition • End of combustion • Presence of vials — capped and uncapped Safety First With the OxiMate 80 • Position of caps The System 387 has been designed to avoid human mistakes. The nitrogen and oxygen sources are continuously monitored for potential system leaks. The integrity of the flame combustion system is insured by monitoring back pressure, the sample ignition, the presence of vials, and the liquid level in the vials. The System 387 is capable of working around the clock. • Reagents in vials • Sample presence • System leak tightness • Positioning of vials in vial carriage The pre-programmed System 387 requires no computer expertise and no supervision. The sample flame combustion system does not require the use of a catalyst. 10 The System 387 Automatically Monitors: Oxidizer 307 Flame Combustion to Improve Results The insolubility, or quenching, of many samples in Proven Oxidation Technology...30 Years Experience liquid scintillation systems has stimulated the search The flame combustion technology has proven to be a simple and reliable means of sample preparation. The combustion section, the trapping section, and the collection section are integral parts of the combustion device. for better techniques for sample preparation. The flame oxidation of labeled organic materials producing 3 H2O and 14 CO2 provides solutions to many sample preparation problems. Automatic Flame Combustion For over 25 years, PerkinElmer’s flame oxidation technology has been used to accurately combust 3H and 14C labeled samples which, otherwise, would be very difficult to assay. The products of combustion are trapped at ambient temperature, minimizing cross contamination. Only simple maintenance and cleaning procedures are needed. Up to 500 samples can be processed without refilling reagent containers. Non-catalytic flame combustion makes the Oxidizer 307 the best performing sample preparation system ever. Automation makes the System 387 the most efficient. The principle drawback of the oxidation technique was the lack of automation. The PerkinElmer Oxidizers, prior to System 387, manually processed one sample at a time. With the System 387, the entire procedure can now be automated to process up to 80 samples per run automatically, without supervision. Automating the flame combustion technique allows the investigator to exploit superior sample preparation by oxidation for a wide variety of samples. The non-catalytic combustion of organic samples by flame oxidation to 3H2O and 14 CO2 provides solutions to many sample preparation problems. 11 Flame Oxidation: The Preferred Way to Prepare Your Samples for LSC The non-catalytic combustion technology eliminates the use of a catalyst. A great variety of sample material can be processed in the PerkinElmer Sample Oxidizers. Examples of these materials are liver, kidney, heart, skin, plasma, urine, whole blood, bone, hair, fat, gels, whole insects, plants, soil, thin layer scrappings, and small amounts of aromatic solvents. “Open-Closed” Flame Combustion Technology The combustion section, the trapping section, and the collection section are all an integral part of each other and are “open” to the atmosphere, so combustion takes place in an “open” system. This will prevent excessive build-up of pressure during combustion. The system is “closed” to the products of interest: the tritiated water vapor (3H2O) and/or the radioactive carbon dioxide (14CO2). Simple, Fast and Hands-off Operation Once the program has started, the system initiates a highly reproducible cycle, which includes automatic: • Oxygen injection Flame oxidation with PerkinElmer’s Model 307 provides the following benefits. • Complete combustion of the sample material eliminating the need for time consuming, chemical solubilization. • The recovery of the radionuclide for both 3H and is >97% with close to zero cross contamination. 14 C • No self-absorption; no optical or color quench; no chemical quench due to solubilizers, bleaching agents, etc. • Low initial start-up temperature to avoid loss of the sample due to evaporation. • No need for a recovery correction factor, such as is necessary for a catalytic combustion device. The Model 307 Oxidizer can accommodate sample material in liquid, wet, dried, or freeze-dried form with a sample weight up to 1.5 grams (up to 40 millimoles of CO2 and up to 85 millimoles of H2O). The products of the combustion are trapped at ambient temperature and thus, minimize cross contamination and reduce mechanical wear. The Model 307 uses standard 20 mL glass or polyethylene vials. It can process up to 500 samples without refilling reagent reservoirs. And, maintenance and cleaning of the Model 307 are simple. • Sample ignition • Vial positioning • Dispensing of reagents • Steam and water cleaning Fast, Precise and Reliable Results Isotopes in dual label mode are physically separated. There is no spectrum overlap and counting times are reduced drastically. Up to 60 samples can be processed per hour for each isotope. Results You Can Count On With flame oxidation of sample material, there is: • No self-absorption • No color quench • No optical quench • No spectrum overlap • No variable chemical quench • No need for solubilization • No need for replacement of catalyst Flame combustion eliminates the use of a catalyst for sample oxidation. This avoids loss of recovery with, for example, liquid samples or after prolonged use of the system. 12 The Flame Oxidation Advantage 1 Operating Controls 6 “Program Start” initiates automatic loading of sample, ignition of sample, programmed oxygen flow injection, dispensing of reagents, cleaning of total system, and pneumatic positioning of counting vials and ignition basket. 7 2 Distilled Water Reservoir 8 Combustion Flask Enclosure 9 Quick Remove Ignition Basket Pressure Regulators Factory set, built-in regulators with in-line filters improve reliability. They are mounted in a convenient location for easy and fast checking of pressure. A specially designed, durable platinum/rhodium basket for high recovery (and isotope separation) for dual labeled samples. It accommodates a wide variety of biological sample materials, independent of size or shape. 5 Reagent Storage Tanks Each has a five liter capacity with built-in, automatic dispenser and multiple dial settings from 0-18 mL. The tanks allow the user to optimize the amount of fluid dispensed. This was designed for easy and rapid maintenance, and has a built-in steam generator and temperature controlled heater for low memory and high recovery. 4 Timer Adjustable combustion time (zero to five minutes) allows maximization of the number of samples processed in a given time. The reservoir has a five liter capacity. It is used for the steam injection and cleaning cycle to achieve low memory and high recovery, and to constrain back pressure. 3 Vial Carriage Fits all standard counting vials (glass and/or plastic) with neck openings of 22-24 mm. Automatic positioning provides convenient and rapid loading and unloading of counting vials. 10 Override Button By pushing this button, the user can override the remaining combustion time. This allows maximum sample throughput. Trapping and Collection Section Isotope separation and trapping occur in this section at ambient temperature (there are no moving parts). 11 Reset Button Allows the user to reset the timer so that the sample can be completely combusted without restarting the system before preset time runs out. 9 5 3 7 1 4 10 11 8 8 8 2 13 PerkinElmer — The Only Complete LSC Systems Supplier PerkinElmer offers solutions to the most demanding problems in environmental, toxicological, and metabolic studies: • Sample preparation chemicals and consumables • Automatic sample preparation robotics • Liquid scintillation counters, flow scintillation analyzers, and direct imaging quantifiers • Worldwide applications support The times have changed. Maybe your sample analysis should, too. Call on PerkinElmer — you can expect more from us. 14 Americas: PerkinElmer Life and Analytical Sciences, 710 Bridgeport Avenue, Shelton, CT 06484-4794 USA (800) 762-4000 Europe: PerkinElmer Life and Analytical Sciences, Imperiastraat 8, B-1930 Zaventem Belgium Technical Support: in Europe: techsupport.europe@perkinelmer.com in US and Rest of World: techsupport@perkinelmer.com Belgium: Tel: 0800 94 540 • France: Tel: 0800 90 77 62 • Netherlands: Tel: 0800 02 23 042 • Germany: Tel: 0800 1 81 00 32 • United Kingdom: Tel: 0800 89 60 46 Switzerland: Tel: 0800 55 50 27 • Italy: Tel: 800 79 03 10 • Sweden: Tel: 020 79 07 35 • Norway: Tel: 800 11 947 • Denmark: Tel: 80 88 3477 • Spain: Tel: 900 973 255 All trademarks or registered trademarks are the property of PerkinElmer, Inc. and/or its subsidiaries. 006853_01 © 2003 PerkinElmer, Inc. www.perkinelmer.com

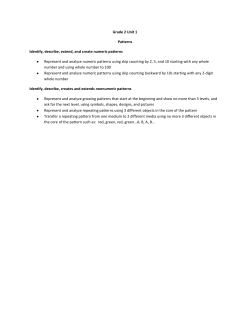

© Copyright 2025