SOLID WASTE MANAGEMENT FACILITY OPERATIONS

COVANTA NIAGARA, L.P.

SOLID WASTE

MANAGEMENT

FACILITY OPERATIONS

&

MAINTENANCE MANUAL

ADMINISTRATION PLAN

July 2014

TABLE OF CONTENTS

(Table of Contents Contains Clickable PDF Links to the Sections)

CERTIFICATION STATEMENT

May 2014

OM-1

INTRODUCTION

May 2014

OM-A

APPLICABLE REGULATIONS

March 2014

OM-2

ASH MANAGEMENT PLAN

March 2014

OM-3

WASTE CONTROL PLAN

July 2014

OM-4

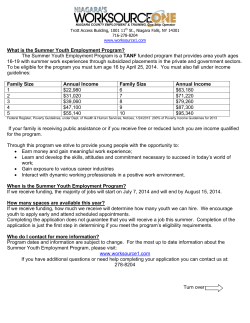

STAFFING PLAN

July 2014

OM-5

ASH SAMPLING & ANALYSIS PLAN

March 2014

OM-6

OPERATIONS & FACILITY

INSPECTION PLAN

May 2014

OM-7

MAINTENANCE PLAN

July 2014

OM-8

START-UP, SHUT-DOWN, &

MALFUNCTION PROCEDURES

May 2014

EMPLOYEE TRAINING PLAN

May 2014

MISCELLANEOUS OPERATIONAL

REQUIREMENTS

May 2014

CONTINGENCY PLAN

May 2014

CLOSURE PLAN

May 2014

OM-9

OM-10

COVANTA

Doc

PE Certification

Rev.

No. 2

COV ANT A NIAGARA

Revision Date: 5/8/1 4

O&M/ECOM Manual

Reviewed Date:S/811 4

Powering Today. Protecting Tomorrow.

COVANTA NIAGARA, L.P.

This O&M/ECOM Manual has been prepared under the supervision and direction of the below

certifying New York State registered Professional Engineer in accordance with 6NYCRR Part 3601.9(e ). All documents contained herein were prepared in conformance with the NYSDEC

requirements in 6NYCRR Part 360, the ECL, the current Part 360 permit and the proposed Part

360 Permit Modification Documents and all the information contained herein is believed to be true

and accurate. All engineering drawings included herewith were prepared under the supervision

and direction of another certifying New York State registered Professional Engineer.

'

\,

"I

~·

I

\

J •

\,

Chris Schifferli, PE

License 084525

Printed copies are not document controlled, refer to "S" drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 1of1

0

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

INTRODUCTION

The Covanta Niagara, L.P. facility, located on approximately 27 acres at 100 Energy

Boulevard at 56th Street in Niagara Falls, New York, combusts solid waste in two

Deutsche Babcock Anlagen (DBA) mass burn furnaces and boilers with associated

turbine/generators, flue gas cleaning systems, a refuse storage and feeding system, an

ash residue handling and processing system and a Rail-to-Truck Intermodal Facility

(RTIF). Waste is delivered to Covanta Niagara, L.P. either by over the road truck or by

rail via the operation of the RTIF.

In addition, there is an alternate fuel-fired furnace/boiler, that currently combusts waste

wood (e.g. pallets, construction/demolition wood, clean wood, creosote treated wood,

etc.), with associated alternate fuel storage and feeding system, lime injection system

for acid gas control, electrostatic precipitator, and an ash handling and processing

system. The solid waste and alternate fuels are the primary fuels used in Covanta

Niagara’s two solid waste-fired mass burn furnace/boilers and the alternate fuel-fired

furnace/boiler, respectively, to produce high pressure steam. As the solid waste and

alternate fuels are combusted in their respective furnace/boilers, the heat released is

recovered via the steam produced in the boilers. The steam produced will normally be

put through two extracting/condensing turbines to produce electricity and extracted

steam. Some of the electricity generated (approximately 17%) is used to power

equipment in the plant while the remainder is sold into the power grid. The steam that is

extracted is transported to six (6) neighboring manufacturing plants for use in their

processes.

PURPOSE OF THE MANUAL

This Operations and Maintenance manual is provided to comply with the requirements 6

NYCRR Part 360-1.14 and 360-3 and the requirements set forth in 40 CFR part 60,

Subpart Ea, section 60.56a(f)(6) – “procedures for operating the MWC unit within the

standards established under this subpart”. Detailed descriptions of the Covanta

Niagara processes are found in the Operation Manual's Systems Description book.

WASTE RECEIVING AND MANAGEMENT

Rail:

Delivery schedules of unit trains are established by CSXT and communicated to

Covanta Niagara. Unit train deliveries will be coordinated with the control room operator

to grant CSXT access to the RTIF rail sidings. Each unit train that arrives at the RTIF

includes 30-36 rail cars, each carrying 4 containers for a total of 120-144 sealed

intermodal containers per unit train which will be targeted to be unloaded over 36-48

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 1 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

hours. The net weight of each container is expected to be 20-22 tons. Based on this

expected net weight, each unit train will deliver approximately 2,400-3,200 tons of

MSW.

Prior to receipt by the RTIF, residential MSW is screened and is subsequently loaded

into sealed containers at the Department of Sanitation of New York (DSNY’s) North

Shore and East 91st Street converted Marine Transfer Stations (MTSs). Alternate

facilities are available for receipt of containerized waste from DSNY due to either an

emergency or for long term capacity and is addressed by the Waste Control Plan

(Section 3) of this manual.

Containerized waste received by the RTIF is screened for radiation prior to transport to

the tipping hall to verify radiation screening performed at the MTS to ensure only nonhazardous municipal solid waste is delivered to the Niagara RTIF. No hazardous

wastes will be transported to the RTIF. The Covanta Niagara EfW Facility will not

accept any hazardous wastes, either by rail or truck.

Radio Frequency Identification (RFID) technology is utilized to track container

movements and elapsed time from NYC to Niagara. Passive RFID technology captures

data entering and leaving the facility to assist in the management of containers.

After delivery of the railcars loaded with full containers, the RTIF Superintendent/Lead

Operator will review the RFID container data log, ensure that each container is in good

working order and discern any odors. Any discrepancies need to be immediately noted

and reported to the Rail Transportation Manager. The CSXT Bill of Lading is crosschecked with the RTIF schedule for receipt of containers. Any discrepancies are

immediately noted and immediately reported to the Rail Transportation Manager.

Intermodal containers will be offloaded from the railcars via a dedicated container

handler (Reach Stacker) designed specifically for intermodal container transfer

operations. Full intermodal containers will be lifted from the railcars and then loaded by

the container handler onto a yard tractor with tipping chassis. These tipping chassis will

be specifically designed for the transportation of intermodal containers. The yard tractor

units, with the full intermodal containers, will then proceed to the RTIF scale, or in the

event of an RTIF scale outage, to the EfW Facility scale.

At the scale house, the container identification is verified and container is scanned for

radiation after passing over the scale, the tractor trailer units with the full intermodal

containers will be directed to the tipping floor to be unloaded.

In the event that full intermodal containers require the application of heat in order to

allow the municipal solid waste to be discharged, then the RTIF Superintedent will direct

the tractor driver to enter the thaw shed. The yard tractor units loaded with the full

intermodal container will remain inside the thaw shed for a time sufficient to allow the

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 2 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

outermost portion of municipal solid waste to de-ice and release from the interior walls

of the intermodal containers. The yard tractor units loaded with full intermodal

containers will then proceed to the EfW Facility tipping hall to discharge the municipal

solid waste.

OVER THE ROAD TRUCKS:

Over the road trucks (i.e., front and rear end loaders, rolloffs, transfer trailers, dump

trailers, van trailers, flat bed trailers, tank trailers, etc.) hauling solid waste enter the

facility grounds through a monitored entry gate off 56th street and proceed to the

scalehouse via Energy Boulevard where they are weighed on computerized scales for

record keeping and billing purposes. At the scalehouse, the load is identified. The

hauler/generator must have a contract with Covanta Niagara and be in the scalehouse

computer system, otherwise the load will be refused entry. If the generator/hauler is the

scalehouse computer system, this indicates that there is a contract in place, that the

waste type has been reviewed for suitability for acceptance and that the generator has

been informed as to what wastes are acceptable and what wastes are not acceptable.

As reflected in the facility's Waste Control Plan (Section 1) no hazardous waste,

radioactive waste, or regulated medical waste are accepted.

All solid waste unloading (with the exception of the tank trailers of liquid waste for the

liquid injection system), storage and handling are done inside buildings. Trucks with

acceptable loads proceed to either the tipping hall or the liquid waste unloading

(secondary containment) area. Inside the tipping floor, the transfer trailers and dump

trailers are normally backed up and unloaded directly into the large concrete refuse

bunker. The refuse bunker is designed to provide three to four days of storage

capacity. This storage capacity allows the facility to handle short term waste flow

fluctuations. The smaller waste delivery trucks (i.e. packers and rolloffs) are unloaded

on the tipping floor and then a payloader is used to push these loads into the refuse

bunker. Van trailers containing pallets of various wastes: drums (liquids and solids),

super sacks of powder and boxes of consumer packaged products, are unloaded by

forklift using a portable unloading dock. After the pallets of boxes are unloaded, they

are normally pushed (by the payloader) directly into the refuse bunker. Pallets of fiber

drums and super sacks containing powders are temporarily stored on the tipping floor

(either the south or north ends) and then put into the refuse bunker, one or two pallets

at a time, so that they can be picked up by the grapple crane and put directly into the

furnace hopper without breaking the container and creating a dust cloud. Most pallets

of drums (steel, plastic or fiber) and totes (plastic or mild steel) with liquids or solids are

temporarily stored in the drum storage area at the north end of the tipping floor until the

containers can be processed through the Komar shredder. After discharging their

loads, the trucks leave the tipping floor.

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 3 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

A Komar shredder (approved by the NYSDEC in October 2002) was installed on the

tipping floor to process drums (steel, plastic and fiber) and tote containers (mild steel

and plastic). The drums and totes can contain liquids, solids or semisolids. The drums

and totes are put into the shredder where an auger pushes the containers against a

shear plate which results in the container being torn apart. As the container gets torn

apart, the auger pushes the contents, as well as, pieces of the container out the

discharge chute and onto the solid waste in the refuse bunker.

The refuse bunker is completely enclosed and contains two full-span, overhead

traveling cranes. Grapples on the cranes are used to pick up the solid waste and put it

into the furnaces feed hoppers. The solid waste then slides by gravity into the refuse

chute, where it acts as an airlock to impede entry of air from the feeding system into the

furnace. A ram feeder pushes the solid waste from the bottom of the refuse chute onto

the boiler's uppermost roller grate. The feeder then retracts, ready to feed more solid

waste onto the grate. The rate at which solid waste is fed onto the grate depends on the

demand for steam, the heating value of the solid waste being fed, its moisture content,

and several other factors. The feed rate is altered by changing the cycle time of the ram

feeder. When a change in the feed rate is made, corresponding adjustments to roller

speeds and primary and secondary air flows are made to maintain combustion control.

Primary air distribution to individual rollers is controlled to ensure burnout of the waste.

Each crane is operated from a common air-conditioned pulpit, and each is able to

satisfy the fuel requirements for each of the two furnaces.

Bulk liquid wastes arrive at the facility in tank trailers (nominal size – 5,000 gallons). Most

of those tank trailers are staged in a concrete secondary containment dike on the north

side of the DBA boiler building and then the liquid is pumped from the trailer, through a

strainer and into a storage tank. Occasionally a tank trailer is taken to the tipping floor and

the liquid then sprayed from the tanker onto the solid waste in the refuse bunker.

A liquid waste injection system (approved by the NYSDEC in March 2003) is used to inject

the liquid waste directly into the combustion zone of the DBA boilers. Six permanent

storage tanks were installed in 2011 inside a concrete secondary containment dike. The

tanks have a total storage capacity of 300,000 gallons. From the tanker the liquid waste

flows through a strainer (to remove solids that would plug the injection nozzles), then into a

pump, through a grinder and then into one of the storage tanks. From the storage tank

the liquid waste directly (through spray nozzles) into the combustion zone of the DBA

boilers.

The direct injection liquids are the only wastes that are not put into the refuse bunker prior

to being put into the furnace.

The facility effectively controls odors; all refuse handling occurs in the enclosed tipping

hall and refuse bunker areas which are maintained under a slight negative air pressure.

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 4 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

Primary air for the furnace is drawn from the tipping hall and refuse bunker so that solid

waste odors, as well as truck exhaust fumes are swept into the furnace and combusted.

The liquid waste storage tanks are vented into the primary air ducts for each of the two

DBA boilers - thus there is slight negative pressure on the storage tanks and any air

venting from the tanks is burned in the boilers.

COMBUSTION PROCESS

The Deutsche Babcock Anlagen (DBA) Duesseldorf Roller Grate system technology,

developed in Germany and used throughout the world, is used at the Covanta Niagara

facility. Proper combustion of solid waste is based on three fundamentals: time,

temperature, and turbulence.

The Duesseldorf Roller Grate consists of six rotating rollers each approximately 5 feet in

diameter and made of ductile iron bars that extend the full width (approximately 22 feet)

of the furnace. The roller grates are installed on a 20% incline from the first to sixth

grate. Each roller is independently driven through a gear box that enables its rotational

speed to be varied from about 0.6 to 12 revolutions per hour. The solid waste tumbles

and mixes as it travels over the roller grates. The furnace walls are constructed of steel

tube panels of membrane construction. Water flows in the tubes and heat from the

combustion of the solid waste is transferred through the tubes into the water, and steam

is produced.

Primary air for combustion is blown into each of the roller grates, and spaces between

the bars allows the combustion air to penetrate the solid waste. As each roller rotates

forward, the solid waste slowly moves toward the next lower roller. Between each of the

rollers a transition piece causes the solid waste to tumble and roll, an action that

exposes previously unburned solid waste to the fire and air in the furnace. The

Duesseldorf Roller Grate system is designed in this manner to allow a through burnout

of solid waste.

While on the first roller and at least part of the second roller, the solid waste is dried by

the hot combustion gases produced from the solid waste combustion on the lower roller

grates. The dried solid waste ignites as it crosses the second roller, and burns

thoroughly as it travels across the third and fourth rollers; occasionally, wet or low heat

content waste may continue to combust on the fifth roller grate as well. The burnout is

completed as the bottom ash passes over the sixth roller and ultimately falls off into the

water-impounded bottom ash extractor trough below.

The hot combustion gases from the combusted solid waste flow upward from the lower

furnace through the upper furnace, heating the water in the wall tubes. The combustion

gases then pass through the screen tube section and then through several passes

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 5 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

containing the superheater and economizer sections. In the upper sections of the

boiler, urea is injected through a series of nozzles for nitrogen oxides control. The urea

reacts with the nitrogen oxides to form nitrogen. After the economizer section, the

combustion gases flow into the boilers’ air pollution control system’s acid gas scrubber.

Steam is generated in the wall and screen tubes and flows through riser tubes into the

steam drum. In the steam drum, water and steam are separated. The water is returned

to the lower headers of the wall tubes, while the steam is piped through the boiler’s

superheater tubes to increase the steam’s temperature. Steam leaves the superheater

and enters the main steam header and is transported to the facility’s two turbine/

generators to produce electricity.

Each boiler is equipped with two ignition burners and two auxiliary burners that can fire

natural gas. The burners are operated at the following times to facilitate the combustion

process.

Furnace start-up prior to introduction of solid waste;

Furnace shut-down after solid waste feed has been discontinued until burnout of the

solid waste in the furnace has occurred; and

Other times as needed to ensure the combustion gases are subject to high

temperature residence time.

Basic Combustion Theory Applicable to a Municipal Waste Combustion (MWC) Unit

The following description is provided in accordance with 40 CFR Part 60, Subpart Ea,

section 60.56a (f) (2) - description of basic combustion theory applicable to MWC units.

The proper combustion of solid waste is based on three fundamentals: time,

temperature, and turbulence. The DBA boilers grates and furnace systems are

designed and constructed to obtain complete combustion of solid waste, a highly

variable fuel.

The combustion of any fuel requires a theoretical (stoichiometric) amount of oxygen

which is usually supplied from ambient air. In practical applications, because of the

incomplete mixing of the fuel and air, this stoichiometric amount of air is not enough to

complete the combustion of all the fuel. In order to complete the process and have no

unburned solid waste passing through the furnace, an extra amount of combustion air is

supplied above the stoichiometric amount. This extra air is called “excess air” and will

vary depending on the type of fuel being burned, but for solid waste will typically range

from 60 to 100% of the stoichiometric amount. As stated above, the DBA furnace’s

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 6 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

primary air fan pulls the combustion air from the solid waste bunker and tipping floor

area and directs it into the furnace through the roller grates.

As the solid waste burns on the rollers, its volume decreases. An adequate bed depth

of solid material on the surface of the rollers is maintained by adjusting relative

rotational speeds of the rollers. This bed of solid waste protects the grate bars from

intense heat in the furnace and provides a bed of combustible material deep enough to

make good contact with the primary air. The ability to independently adjust the rate at

which the solid waste passes across succeeding rollers in the grate as well as the

quantity of air flowing through the individual roller grates contributes to proper burnout

and a steady fire. In the DBA "parallel flow" design that is used at Covanta Niagara, the

flue gas generated during the combustion of fuel over the initial rollers is forced to flow

parallel to the remaining rollers. This increases the turbulence and the time that the flue

gas spends in the primary combustion zone. After leaving this zone, secondary air is

injected into the flue gas stream. Once again, further turbulence is created and the

additional air promotes the completion of combustion of any unburned organic

compounds and carbon monoxide remaining in the flue gas. By maintaining the proper

primary and secondary air flow, a constant feed of solid waste into the furnace, and

proper solid waste/ ash depth on the roller grates, a furnace temperature adequate for

good combustion can be maintained.

In summary the DBA furnace design incorporates the basic requirements of good

combustion by:

lengthening the time for combustion ( the time the solid waste is in the furnace)

using slowly rotating roller grates, by directing the combustion gases generated from

the solid waste on the first sets of roller grates over the remaining roller grates, and

adding secondary air after the initial combustion zone in order to complete the

combustion of volatiles in the flue gas.

maintaining sufficient temperature - typically 1800 to 2300 F in the primary

combustion zone.

creating a turbulent combustion zone through the combination of primary air injection

from the roller grates, forcing the flue gas initially generated to turn back and mix

with the combustion gases generated on the last roller grates, and finally injecting

secondary air into the furnace.

Procedure to Maintain Proper Combustion Air Supply Levels

The following description is provided in accordance with 40 CFR Part 60, Subpart Ea,

section 60.56a (f) (5) - procedures for maintaining proper combustion air supply levels.

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 7 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

As described above, air in excess of the stoichiometric quantity needed to combust the

solid waste is supplied to the DBA furnace. The air enters the furnace as primary air

through the roller grates and as secondary air through nozzles located above the

grates. The flue gas oxygen concentration and carbon monoxide concentration are

monitored in the boiler’s final flue gas pass, after all combustion has been completed.

In addition the operating conditions of the primary and secondary air fans are

monitored.

Plant operators, in particular the control room operators (CRO) who actually run the

DBA furnace/ boilers are trained and are aware of the requirements for proper

combustion, and the relationship between oxygen and carbon monoxide concentrations.

The typical range for flue gas oxygen concentration is 5 to 7 % with a carbon monoxide

concentration of less than 100 ppm corrected to seven (7) percent oxygen. Each unit

has a dedicated continuous emission monitoring system (CEMS). The CEMS data

acquisition system will collect and tabulate all the monitors outputs and will alarm in the

control room if a parameter, such as flue gas oxygen concentration, is out of the proper

range. The CROs monitor various parameters and make adjustments in the controls,

as necessary, to maintain proper combustion air levels and overall good combustion of

the solid waste.

ASH RESIDUE HANDLING

The solid waste combustion process results in two ash residue streams: the heavy

residue from the roller grates - bottom ash, and the lighter residues from the pollution

control system - flyash and scrubber salts. As the solid waste completes the burning

process on the roller grates, bottom ash falls through ash chutes into the water filled ash

extractor tank, entering below the water line. The water cools the ash and also serves

as a seal to prevent air leakage into the furnace. A hydraulic ram extractor, submerged

below the water level pushes the ash up an inclined chute (to allow free moisture to

drain back into the tank) and onto one of two vibratory slipstick conveyors. The

vibratory slipstick conveyors, common to both furnaces, transport the ash the width of

the boiler building, and discharge it onto belt conveyors that transport the ash to the ash

processing building. The belt conveyor is located inside an enclosed gallery.

AIR POLLUTION CONTROL SYSTEM

In addition to providing a general description of the air pollution control equipment, this

description is provided in accordance with 40 CFR Part 60, Subpart Ea section 60.56a

(f) (8) - procedures for minimizing the particulate matter carryover.

In the air pollution control system, the light flyash residue that is entrained in the flue

gas during the combustion process as well as the acid gases produced during the

combustion process are removed. After leaving the boiler, the flue gas passes through

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 8 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

a flue gas cleaning system which consists of a dry scrubber followed by a reverse air

baghouse. In the scrubber, a lime slurry is injected into the flue gas stream using rotary

atomizers (which create a very fine mist.) When the mist contacts the flue gas, the

water evaporates which cools the flue gas while the lime particles react with the

hydrochloric acid, sulfur dioxide, hydrofluoric acid, etc. removing those pollutants as

calcium salts. The water content of the lime slurry can be adjusted to control the

temperature of the flue gas existing the scrubber while the lime content of the slurry can

be varied to achieve the required sulfur dioxide removal. Activated carbon, for mercury

control, is injected into the flue gas duct between the scrubber and the baghouse.

Exiting the scrubber, the flue gas flows through duct work into an eight module reverse

air, fabric filter baghouse. In the flue gas duct just upstream of the baghouse activated

carbon, for mercury control, is injected. In the baghouse the fine particulate flyash,

scrubber salts and activated carbon are removed. The reverse air baghouse has a

lower air-to-cloth ratio (more cloth for filtering the flue gas) than the typical pulse jet

baghouse and significantly lower emissions are expected. The baghouse will utilize

woven fiberglass bags with an acid resistant finish. The flow of flue gas is upward and

from inside to the outside of bags. When accumulated on the inside of the bags, flyash

scrubber salts /unreacted lime and activated carbon create an additional filtering

substrate to provide additional removal of unreacted acid gases, as well as very efficient

removal of particulates, metals, mercury and trace organics. Each module is equipped

with isolation dampers that allows the bag cleaning cycle to cascade from module to

module. During the cleaning cycles, the reverse air fan gently blows air in the reverse

direction from the flue gas flow and dislodges some of the flyash/ scrubber salts built up

on the inside of the bags. The dislodged ash is collected in the baghouse ash hoppers,

and then transported in sealed conveyors to the ash processing building where it is

wetted with water in a plugmill to prevent fugitive dust emissions, and then discharged

onto the loadout belt with the bottom ash for loadout into trucks for transport to the

landfill. The fabric filter baghouse is designed to limit particulate emissions from each

boiler to 0.01 grains per dry standard cubic foot corrected to 7% oxygen.

From the baghouse the flue gas is pulled into the induced draft (ID) fan and then

discharged out the stack. The flue gas continuous emission monitoring system is

located in the flue gas duct after the baghouse upstream of the ID fan.

CONTINUOUS EMISSION MONITORING SYSTEM

In addition to providing a general description of the facility's continuous emission

monitoring system (CEMS), this description is provided to comply with 40 CFR Part 60,

Subpart Ea, section 60.56a (f) (11) - procedures for monitoring MWC unit emissions.

Each of the two DBA combustion units is equipped with a dedicated CEMS to measure

various constituents of the flue gas exiting each boiler and each pollution control

system. Each CEM system includes both extractive and in situ components.

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 9 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

The extraction system component uses a dilution probe for sample handling and is an

integrated system purchased from Enviroplan, Inc. It includes sample probe, sample

transport, analyzers, and support hardware. The data acquisition, storage, calculations,

and reporting is done by a system purchased from Trace Environmental Systems,

Incorporated. Components of the Trace system will also control the sequencing of the

automatic calibration feature of the CEMS. Most of the components of the extractive

system and the data reporting system are in the CEMS shelter which is located at

grade, between the two DBA boiler trains, beneath the scrubbers. Flue gas

components measured by analyzers located in the CEMS shelter are: Sulfur Dioxide

(SO2), nitrogen oxides (NOX), carbon monoxide (CO), and carbon dioxide (CO2). An

extraction dilution probe is located in the flue gas duct just upstream (boiler outlet) of the

acid gas scrubber. SO2 and CO2 are analyzed in the flue gas from this sampling point.

After the scrubber and baghouse a second extraction dilution probe is located in the flue

gas duct just upstream of the ID fan. SO2, NOx, CO and CO2 are measured in the flue

gas from this sampling point.

Flue gas oxygen (O2) concentration (measured for boiler control purposes only),

opacity, furnace temperature, and scrubber outlet temperature are also measured by insitu devices. Measurement signals from in-situ analyzers are transmitted to the data

acquisition system (DAS) that is housed in the CEMS shelter. The O2 analyzers are

located in the flue gas duct adjacent to the extraction systems' dilution probes, while the

opacity analyzers are located in each flue gas duct upstream of the inlet to the ID fan.

The furnace temperature thermocouples are installed at the top of the section of the

boiler's first pass, two on each side. The scrubber outlet instrumentation is installed in

the scrubber outlet duct. Measurement data from the in situ analyzers are transmitted

to the Trace system housed in the CEMS shelter.

Flow monitors have now been installed in the flue gas duct at the ID fan to measure the

flue gas flow rate for each of the DBA boilers. The signal from each flow monitor is

transmitted to the DAS and is used in calculating the mass emissions – CO2.

The data reporting system is integrated with emissions measurement equipment to

digitize, record, and present CEM data. The system also controls the calibration and

sample system automation. The system continuously acquires data values and status

information from pollutant and process measurements, computes emission, forms

averages, detects alarms, provides emission summary reports in hard copy, and allows

for easy preparation of regulatory reports.

The Trace computer system also receives the analog values from the analyzers and

calculates three different averages, forms calibration results and performs data validity

checking. The data recording system consists of a personal computer (PC) running

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 10 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

Trace’s software. It features menu selections for most data entries. It can detect alarm

conditions based upon status inputs. The software can calculate such things as:

Emissions on a lb/hr basis,

Removal efficiency,

Combustion efficiency,

Boiler operating days,

Excess emission alarms, and

Analog alarms in bar chart or strip chart display.

Data are collected in monthly data files located in the computer's hard disk drive. The

Trace system produces a variety or reports, including data, calibration, and alarm logs.

Daily and monthly summary data reports are also available on demand. The Trace

system is also helpful in supporting daily quality assurance activities. Routine reports

and other procedures can be executed with a single command.

The alarm workstation is located in main control room. This PC provides the control

room operator with a real-time display of current data, trends and alarm conditions.

Alarms will be configured to detect emission exceedances. Normally the operator will

receive a warning alarm that a parameter is nearing a permit limit. This alarm will allow

the operator time to react and take actions to prevent the excursion. Any permit limit,

such as hourly, daily averages, may be checked.

FERROUS/NON-FERROUS METAL RECOVERY

The DBA facility will recover both ferrous and nonferrous metals from the bottom ash

residue and recycle those metals. At this time there are no components in the flyash

stream that can be economically recovered. The ferrous/nonferrous metal recovery

processes are located in the ash processing building.

As discussed previously, the bottom ash is transported from the boilers’ ash extractors

to the ash processing building by vibratory conveyors and belt conveyors. In the ash

processing building the bottom ash residue is discharged onto a finger sizer to separate

bulky items greater than 6 inch size from the ash (less than 6 inch size). The bulky

items are conveyed over a drum magnet to recover the ferrous metal, while the

undersized ash is conveyed under a second drum magnet to remove the smaller ferrous

metals. Both ferrous metal streams from the magnets discharge into a common pile for

subsequent loadout and transport to a scrap mill.

After the drum magnet, the bulky material not pulled out by the magnet is discharged

into a truck for subsequent transport back to the refuse bunker or, if necessary,

transport to a landfill, while the remainder of the undersized ash is conveyed to a set of

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 11 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

vibratory screens where material greater than 3/8 inch is separated and conveyed over

an eddy current system to remove nonferrous metals. The less than 3/8 inch ash that

goes through the screen is conveyed to a second eddy current system in order to

remove the smaller nonferrous metals. The remaining ash from both eddy current

systems is discharged on to conveyor belts, mixed with flyash/scrubber salt and loaded

out in trucks for transport to the landfill.

RECORDKEEPING AND REPORTING REQUIREMENTS FOR SOLID WASTE FIRED

BOILERS

This description is provided to comply with 40 CFR Part 60, Subpart Ea, section 60.56a

(f) (12) – reporting and recordkeeping procedures.

The following information must be recorded in computer readable format and on paper:

all 6-minute average opacity levels

all 1-hour average sulfur dioxide emission rate s at the outlet of the acid gas

control device ( inlet as well if compliance is to be based on percent reduction)

all 1-hour nitrogen oxides emission rates

all 1-hour carbon monoxide emission rates

all 1-hour steam load measurements

all 1-hour particulate matter control device inlet temperatures

The following average rates must be computed and recorded:

All 24-hour daily geometric average sulfur dioxide emission rates (percent

reduction , if used)

All 24-hour daily arithmetic average nitrogen oxides emission rates

All 4-hour block arithmetic average carbon monoxide

All 4-hour block arithmetic average steam load levels

All 4-hour block arithmetic average particulate matter control device inlet

temperatures

The following information must be identified:

Operating days when any of the average emission rates (percent reduction, if

applicable) or operating parameters, specified above, or the 6-minute opacity

average exceeds the applicable limit. Also include the reasons for the

exceedance and a description of the corrective actions taken.

Operating days for which the minimum number of hours of sulfur dioxide or

nitrogen oxides emissions or operational data (carbon monoxide, steam load,

particulate matter control device temperature) have not been obtained. Also

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 12 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

include the reasons for the exceedance and a description of the corrective

actions taken.

Times when sulfur dioxide or nitrogen oxides emission or operational data

(carbon monoxide, steam load, particulate matter control device temperature)

have been excluded from the calculation of average emission rates or

parameters and the reasons for excluding data.

The results of the daily sulfur dioxide, nitrogen oxides and carbon monoxide CEMS drift

tests and the accuracy assessment must be recorded.

The results of all annual performance tests conducted to determine compliance with

particulate matter, dioxin/furan and hydrogen chloride limits must be recorded. Also for

all the dioxin/furan tests, the maximum demonstrated steam load and maximum

demonstrated particulate matter control device temperature must be recorded.

Semiannually, compliance reports for sulfur dioxide, nitrogen oxide, carbon monoxide,

steam load and particulate matter control device temperature must be submitted to EPA

and NYSDEC. The report must include: dates, 24-hour block data, 4-hour block data,

identification of days when the minimum number of hours was not obtained,

identification of times when data was excluded and results of the CEMS daily calibration

drift check (only days when drift was excessive). Note Niagara submits this report on a

quarterly basis – “Excess Emissions Report”.

Semiannually, a report must be submitted for any pollutant or parameter that does not

comply with the specified limits. Note Niagara submits this report on a quarterly basis –

“Excess Emissions Report”.

The annual compliance stack test report must be submitted to the EPA and NYSDEC.

ALTERNATE FUELED-FIRED FURNACE/BOILER PROCESS

The alternate fuels (i.e. waste wood) are received into the facility and weighed through

the scalehouse in the same manner as the solid waste. Waste wood is received either

as whole / semi whole pieces (unprocessed) or already shredded. After being weighed

in, the trucks with the unprocessed waste wood then proceed to “C” building storage

area.

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 13 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

On an “as needed basis” the waste wood that is shredded on site is transported from

the storage pile to the “C” building storage area. The shredded wood is unloaded and

then pushed up into a pile using a bulldozer.

“C” building has storage capacity for several thousand tons of alternate fuels. In this

storage area, parascrews on either side of an A-frame traverse, under the piled

alternate fuels, the length of the building and push the fuel onto a transport system,

consisting of two parallel conveyor belt systems (each has three belts in series), that

transport the fuel to a surge bin at the top of alternate fuels furnace/boiler.

From each surge bin, which can store approximately 20 minutes of alternate fuels at

normal boiler feed rates, screws on the bottom of each bin push the fuel down chutes

into the furnace.

Combustion Process

As the alternate fuels enter the furnace, air swept distributor spouts at the bottom of the

chutes help propel the alternate fuels into the furnace; the less dense particles burn in

suspension and the denser material falls to and burns on the grates.

The alternate fuel-fired furnace grate system, rotograte stokers, consists of four parallel

trains of traveling grates each carried on two chains which are driven from the rear of

the furnace toward the front by a drive and sprocket assembly. Primary air would be

introduced below the grates providing the air required for combustion of the alternate

fuels on the grate. Holes in the bars allow the proper distribution of primary air to the

unburned fuel on the grates. By the time the grate traverses the bottom of the furnace,

the combustion process of the alternate fuels on the grate is completed. The ash which

remains drops off the grate, through the ash chutes. The siftings ash which falls

through he grates passes through the sifting hopper into the same quench tank.

Secondary air admitted above the grate would provide additional air for turbulence and

combustion of the suspended material as well as the volatile gases from partially

combusted material from the grate.

The rate at which alternate fuels would be fed to the grate would depend on the demand

for steam, the healing value of the fuel being fed, its moisture content, and several other

factors. Changes in the feed rate would result in corresponding adjustments to grate

speed and air flow to maintain combustion control. Air distribution to the grates and

secondary air nozzles would be controlled to ensure burnout of the alternate fuels.

Auxiliary burners would be operated as necessary at the following times:

(1)

furnace start-up prior to introduction of alternate fuels;

(2)

furnace shut-down;

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 14 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

(3)

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

During periods of malfunction.

Air Pollution Control

To control acid gases (sulfur dioxide and hydrochloric acid) hydrated lime is injected

directly into the furnace. Urea is also injected into the furnace in order to control

nitrogen oxide emissions. In addition activated carbon is injected into the flue gas at the

outlet of the economizer in order to control trace organic compounds. The calcium salts

of the acid gases and the activated carbon, as well as, the flyash produced during the

combustion process are removed in the electrostatic precipitator on collector plates.

Periodically, the collector plates are rapped and the flyash falls down into the flyash

hoppers and into sealed drag chain conveyors which transport the flyash to an ash silo.

Ash Residue Handling and Disposal

In the bottom ash quench tank, a drag chain pulls the bottom ash out of the tank and

discharges it into the ash hopper. When the ash hopper is full, it is taken to the tipping

floor and dumped into the DBA refuse bunker. This ash is then processed through the

DBA furnaces. From the ash silo, the flyash goes through a rotary feeder into a pugmill

where the flyash is wetted to prevent dusting. From the pugmill the wetted flyash drops

into the ash truck that transports the ash to the landfill.

Continuous Emission Monitoring System – Alternate Fuel Fired Furnace/Boiler

The alternate fuel -fired furnace/boiler system is equipped with a dedicated CEMS. The

CEMS sampling system is an extractive type, located in the stack, and the monitors

include carbon monoxide, sulfur dioxide, nitrogen oxides, and oxygen. In addition, there

is an in situ stack flue gas opacity monitor. A Trace Environmental System data

acquisition system (DAS) is integrated with the emissions measurement equipment to

digitize, record, present CEM data. The system also controls the daily calibration

checks, and sampling systems purges and sampling.

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 15 of 29

Doc

OM-1

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

COVANTA NIAGARA

O&M Manual/ECOM

Major Modifications to the Introduction

March 2009

The “Recordkeeping and Reporting” section on page 12 was revised to reflect the type

of data that is recorded in the computer

March 2011

The “Continuous Emission Monitoring System” section on page 8 was revised to include

the DBA boilers’ new flue gas flow monitors.

March 2012

The “Solid Waste Receiving, Storage and Handling” section, on page 3, was revised to

reflect the changes made to the liquid waste storage tanks and pumping system.

Appendix 1 was added

Combustion Unit

- Basic Combustion Theory Applicable to a Municipal Waste

April 2013

The “ferrous / nonferrous metal recovery” was modified to reflect the new nonferrous

process for recovering the less than 3/8 inch metal.

March 2014

The system description for the RTIF was added. Wood staging area text was removed

as that area is no longer used.

May 2014

Minor QA/QC updates.

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 16 of 29

Doc

OM-1

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

COVANTA NIAGARA

O&M Manual/ECOM

APPENDIX 1

COMBUSTION THEORY

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 17 of 29

Doc

OM-1

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

COVANTA NIAGARA

O&M Manual/ECOM

Basic Combustion Theory Applicable to a Municipal Waste Combustor Unit

THE FUEL - Municipal Solid Waste (MSW)

Combustion is a process in which fuel combines rapidly with oxygen to produce heat

and product gases. Figure 1 illustrates the process.

Fuel

Flue Gas

Carbon,

Hydrogen,

Oxygen

Nitrogen

Carbon Dioxide

Water

Combustion

Air

Nitrogen

Oxygen

Heat

The fuel is municipal waste, which contains a mixture of paper, plastics, wood, yard

waste, food, textiles, and various other materials. The combustible part of these

materials consists primarily of carbon and hydrogen. Most of these materials also

contain oxygen. MSW is composed of volatile fractions - which burn as a gas, and fixed

carbon - which burns as a solid.

Most of the materials in MSW are mixtures of many different chemical compounds. For

example, wood contains thousands of different chemical substances. However, most of

the important combustion reactions can be understood by just considering a few of the

major compounds in the waste stream. By far, the most important elements involved in

MSW combustion are

C – Carbon

H – Hydrogen

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 18 of 29

Doc

OM-1

Revision Date: 5/8/14

Review Date: 5/8/14

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

O – Oxygen

These elements are combined in many different compounds which are termed

hydrocarbons, because they contain large amounts of hydrogen and carbon. These

hydrocarbons are the primary sources of energy in the fuel. When carbon or hydrogen

reacts with oxygen, the reaction is called exothermic, meaning that heat is produced by

the reaction.

Two primary reactions occur during combustion of any hydrocarbon fuel:

carbon combines chemically with oxygen to produce carbon dioxide and heat

C + O2 CO2 + heat

hydrogen combines with oxygen to produce water vapor and heat.

4H + O2 2H2O + heat

The carbon dioxide and water vapor leave the furnace as flue gas.

In addition to carbon, oxygen, and hydrogen, MSW contains a number of other

elements including

Chlorine and Sulfur

Much of the chlorine combines with hydrogen to produce hydrogen chloride, a

highly reactive chemical which becomes hydrochloric acid when combined

with water.

2Cl + H2 2HCl

Sulfur combines with oxygen to form sulfur dioxide, which dissolves in water

to form sulfuric acid.

S + O2 SO2

Alkaline metals

These materials - which include sodium, potassium, calcium, and magnesium

- are present in many waste materials including wood and wood products.

They occasionally show up in a pure form. They are highly reactive and

combine readily with oxygen to form solid particles, but also with chlorine to

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 19 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

form salts which melt or vaporize in the high temperature combustion regions.

These salts can also exist as corrosive liquids on boiler tube surfaces. In

pure form, they are extremely combustible, easily ignited, and can react with

water or steam to produce hydrogen.

Heavy metals

These elements, such as lead, zinc, and cadmium, are present in a variety of

materials including electronic equipment, paints, and tires. These metals

react with chlorine to form metallic salts which are corrosive to boiler tubes.

In addition to the materials described above, trash also contains some things that don’t

burn, such as water, glass, metal, and dirt. These materials absorb heat from the

burning refuse and are known as heat sinks. Water is the most important of these

materials for two reasons:

1. There can be a lot of water in waste. MSW is typically about 15% water, but

after a lot of rain that value can be much higher, and

2. Water absorbs a lot of energy as it heats up and turns to steam. When a

pound of water and a pound of metal enter the furnace in the fuel, the water

takes with it about 30 times as much heat as the metal when it leaves the

boiler.

THE STAGES OF COMBUSTION FOR MSW

Most fuels are relatively pure materials, and burn in a consistent and repeatable

manner. Unlike these fuels, MSW is a mixture of many different materials and each of

these affects the overall combustion process. Some important aspects of MSW

combustion are:

1.

2.

3.

Moisture content and fuel drying

Volatile content and devolatization

Fixed carbon combustion, or burnout

MSW combustion involves all the mechanisms described above, and occurs in several

stages, with the duration of each stage depending on the particular fuel. These stages

include:

Heating and drying. The fuel must be heated and dried before it can burn. The heat is

supplied by the active combustion of nearby fuel, and in some cases by preheated

primary combustion air. Clearly, fuels with higher water content require more energy to

dry.

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 20 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

Devolatization. As the fuel heats up, it begins to break down chemically. During this

process the volatile fraction of the waste is released into the gas stream. These volatile

materials include the hydrogen and some of the carbon contained in the fuel. They are

emitted as heat vaporizes the lighter compounds, and breaks apart the chemical bonds

within heavier hydrocarbon molecules to release combustible gases. The gases

evolved from the waste include a wide range of light hydrocarbons, including methane,

ethane, and numerous other compounds.

Ignition. The light, flammable gases evolved from the heating waste move into the

primary air streaming through the bed, and are ignited when they reach sufficient

temperature or contact an existing flame.

Burnout. The remaining char burns slowly in the bed as the surface is exposed to

oxygen in the primary air.

Different components of the waste stream behave differently. For example, most light

plastics such as ethylene are completely volatile, so that the entire combustion process

occurs in the gas stream above the bed and no char or ash is left behind. Other

materials such as wood have a high percentage of both volatile materials and char,

meaning that significant combustion occurs both above and within the bed.

THE COMBUSTION PROCESS

Burning MSW is more complicated than burning traditional fuels for several reasons,

which will be described shortly. For combustion to take place, there are three

requirements:

Fuel - a combustible material

Heat, or a source of ignition

Oxygen, typically provided by air

If any one of the three is removed, the combustion process stops.

The three requirements for combustion are often illustrated using the well-known

combustion triangle

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 21 of 29

Doc

OM-1

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

COVANTA NIAGARA

O&M Manual/ECOM

Heat

Oxygen

Fuel

Changing any component of the combustion triangle can have an effect on one or both

of the other components. For example, adjusting the fuel OR oxygen (air) side of the

combustion triangle will affect the heat produced. It’s important to not only know what is

needed for combustion to take place, but also how they interact.

Providing sufficient air, heat, and fuel will allow combustion to take place. However, the

operator must ensure that combustion is proper and environmentally compliant as well.

Three things help ensure proper combustion: Time, Temperature, and Turbulence –

often described as the “three T’s”. These factors work together, to ensure that

combustion is complete:

Time: All chemical reactions take time to occur. Enough time must pass to

allow the chemical reactions to complete.

Temperature: Chemical reactions proceed faster at higher temperatures,

therefore the temperature must be hot enough to ensure their completion.

Turbulence: Fuel and air must be well-mixed to ensure that all the fuel is

burned.

How can the operator use and adjust the 3 T’s to aid in burning MSW? By looking at

each on a basic level, relating to the primary and secondary combustion:

Time: Give the solid fuel enough time in the primary combustion zone. The more

retention, the better chance the surface area of the fuel will be exposed to

oxygen. If the fuel moves through the primary combustion zone too quickly, the

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 22 of 29

Doc

OM-1

Revision Date: 5/8/14

Review Date: 5/8/14

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

likelihood of incomplete combustion increases. In the secondary zone, residence

time is primarily established by the boiler design.

Temperature: The fire must be hot – not only to sustain its own combustion, but

to aid in the drying out and ignition of new fuel, and to ensure that all reactions

are completed in the furnace volume above the grate.

Turbulence: Turbulence is needed on the primary combustion level to properly

mix and agitate the fuel, continually exposing the surface area to oxygen. On the

secondary combustion level, proper secondary air penetration is needed to

promote better mixing for the chemical reactions to complete.

Much like the three sides of the combustion triangle, the 3 T’s also interact. For

example, if the turbulence is insufficient, it would be difficult to adjust the time and

temperature to compensate.

A good operator not only understands the individual elements of the Combustion

Triangle and the “3 T’s”, but also understands collectively how each piece affects and

interacts with the others.

COMBUSTION AIR

A good combustion process requires that the fuel interact closely with the oxygen at a

molecular level. Because of the nature of MSW, it is very difficult to ensure this fuel-toair contact, and it is also very difficult to achieve good air/fuel mixing. The air delivered

to the furnace doesn’t readily mix with the fuel, as it would in a gas- or oil-fired boiler.

Referring again to the combustion triangle, to burn MSW we control the “heat” part of

the triangle (the output) by adjusting the “air” and “fuel” (the inputs):

HEAT

AIR

FUEL

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 23 of 29

Doc

OM-1

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

COVANTA NIAGARA

O&M Manual/ECOM

Excess Air The amount of air supplied to the combustion process is critical. For any

amount of fuel, the amount of air required for complete combustion, with no fuel or

oxygen left over is call the theoretical air rate. This would be 0% excess air. Combustion

normally occurs with excess air, meaning more air is supplied than is chemically

necessary to burn all of the fuel. Thus, oxygen is left over in the flue gas. If a

combustion process has insufficient air to completely burn the fuel, there would be fuel

left in the flue gas stream, in the form of CO, soot (carbon particles), and hydrocarbons.

The next figure illustrates an important point regarding air and fuel:

The flame temperature depends on the air ratio.

With insufficient air there is not enough oxygen to burn all the fuel and this limits

the temperature.

With excess air heat is carried away by the surplus air, cooling the flame.

At the stoichiometric point, the maximum flame temperature is reached because

there is exactly enough air to burn all the fuel without any excess. Again, this is

the theoretical air rate, or 0% excess air.

Stoichiometric

Combustion

Flame Temperature

Maximum temperature

occurs when there is

Temperature

Temperature is

is limited

limited

because

because

there is not

energy is used

enough air to

to heat up

burn all the

Insufficient Theoretical

Excess Air

Air

Air

Air Flow

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 24 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

The figure above again illustrates the interactions of different sides of the combustion

triangle – in this case, air affecting heat.

MSW combustion always utilizes excess air. Clearly, the diverse nature of MSW

presents an extreme challenge in mixing all of the combustible materials with the

oxygen. We must add extra air to compensate for this inability to obtain “the perfect

mix”.

However, simply adding additional air to ensure that all of the combustible materials are

adequately exposed to oxygen is generally not sufficient. The above figure illustrates

this as well. Combusting fuel with just a small amount of excess air results in extremely

high temperatures. These temperatures would be above the melting point of many

materials in the bed, which results in excessive furnace slag and bed clinkering.

This is also an illustration of how air can be a heat sink. Unlike moisture or noncombustible materials in the fuel, this is a heat sink that the operator can control.

Air is a mixture of many different gases, but is mostly nitrogen and oxygen. Combustion

requires oxygen, which is about 21% of the air. The rest of the air is not part of the

combustion process, but merely passes through the furnace and carries heat away as it

leaves. This excess combustion air is that heat sink.

The excess air rate can also affect emissions rates for carbon monoxide (CO) and

nitrogen oxides (NOx).

Carbon monoxide (CO) is a toxic pollutant known as a product of incomplete

combustion because it is a partially oxidized form of carbon. This compound is

produced under two conditions:

In a fuel-rich combustion zone where there is not enough oxygen to combine with

all the carbon (sometimes referred to as hot CO)

In a low temperature area where the combustion temperature is too low to

complete the chemical reactions (sometimes referred to as cold CO).

NOx (a general description for two similar compounds – NO and NO2) is an oxidized

form of nitrogen, which contributes to acid rain and ground-level ozone. It is formed

when nitrogen combines with oxygen at high temperatures in the combustion process.

Depending on the primary source of the nitrogen, it is described as either

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 25 of 29

Doc

OM-1

Revision Date: 5/8/14

Review Date: 5/8/14

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Fuel NOx, in which the primary source of the nitrogen is the fuel itself, especially

at certain times of the year. Green wastes such as grass clippings, Christmas

trees, and yard waste are high in nitrogen.

Thermal NOx, in which the primary source of nitrogen is the combustion air.

Relative Emissions Rate

The following figure illustrates the impact of temperature and excess air rate on

emissions of CO and NOx. The NOx emissions in a Municipal Waste Combustor

generally don’t vary as much with temperature as this graph illustrates, because virtually

all NOx formed in a waste combustion process is fuel NO x. This is because

temperatures are generally not high enough to produce significant amounts of thermal

NOx.

CO is high

because

there is not

enough

oxygen to

completely

burn the

fuel

NOx is high

because of the

high combustion

temperature

CO is high because the

excess air cools the flame

and stops combustion

before it is complete

CO

NOx

NOx is low

because the

temperature

is low

Insufficient

Air

CO is low

because enough

air is supplied to

completely burn

the fuel, but

without

excessive

cooling

Theoretical Air

NOx is low because

the temperature is low

Excess Air

Air Flow

Combustion air is typically provided in two forms: primary air and secondary air.

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 26 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

Primary Combustion Air

Proper flow and distribution of Primary Combustion Air is critical to maintaining boiler

load, firebox temperatures, emissions, and complete combustion.

Primary air is supplied below the fuel bed, and passes through the burning fuel. The

distribution of this air below the bed is very important to the combustion process.

Depending on the combustion technology being used, the operator may be able to

adjust the primary air distribution, while in other cases it is established during startup or

tuning of the boiler.

As the fuel goes through the combustion stages, it also moves along the grate from the

feeding area to the ash discharge area. With some technologies the motion of the

refuse bed is very uniform, with fuel fed at one end, and moved steadily toward the

discharge end. With most technologies, however, the bed does not move through

distinctive stages because either the new fuel gets distributed over a wide area of the

bed, or grate motion causes continuous mixing of new fuel with material that has been

in the bed for some time. In all cases, however, there is a general trend for newer fuel

to be near one end of the bed and burned out ash to be at the other end.

With this distribution of the combustion stages, the goal is to match the primary

combustion air to the combustion process occurring in each region. The amount of air

in each zone affects the combustion rate and gas velocity. Velocity, in turn, affects

particulate carryover from the bed.

Primary Air Flow in the Combustion Regions. Combustion within the primary

combustion regions can generally be described as follows. Note that there is no clear

line between regions, but instead a continuous transition from drying to combustion to

burnout. Furthermore, the transitions between zones vary depending on fuel conditions

and combustion settings.

Drying region. Within this region, the fuel is heated and dried to drive out

moisture. With high moisture content fuels, this region may be very apparent

when looking at the grate, with little combustion taking place. With very dry

fuels, it may be difficult to even detect, as the fuel begins burning almost

immediately upon entering the furnace.

If moisture is low or airflow is too high, the fuel will quickly ignite and burn

intensely, quickly releasing much of its heat within a very small volume.

This leads to excessive slagging of the furnace and may damage the

stoker and feeding equipment.

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 27 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

If the airflow is too low, or moisture very high, the fuel will not adequately

dry out, preventing ignition. This situation may ultimately require manual

intervention to agitate and expose air to the fuel. Eventually the fuel will

ignite, but combustion intensity may be extremely high when this finally

occurs.

Main Combustion Zone. In this region, the volatile fraction of the fuel is driven

into the gas stream where it rapidly burns, using up the available oxygen. Gases

leaving this region of the bed have little to no oxygen, and very high contents of

combustible gases, including light hydrocarbons and CO.

Excessive airflow will cause rapid combustion within a small region,

leading to excessive temperatures. It is also likely to cause thin refuse

beds, which leads to high flue gas velocities and increased particulate

carryover.

Insufficient airflow will not allow complete combustion within the region,

causing long fires, high unburned content in the ash, and increased

likelihood of ash discharger pluggage.

Burnout Zone. Primary combustion is slow in this zone, as the fixed carbon

burns off. Most of the combustion is complete well before the solids leave the

grate, but sufficient air must be provided to ensure that any remaining carbon is

completely burned. Thus, the gases leaving this region are relatively high in

oxygen content.

Excessive airflow will cool the fire in this zone, causing high CO levels.

Insufficient airflow will not allow the combustion to complete, resulting in

high unburned content in the ash and may lead to ash discharger

pluggage.

Proper primary air flow and distribution is achieved by taking many things into

consideration, including but not limited to:

CO and NOx emissions

Combustion/furnace temperatures

Appearance of the fuel bed ( thick or thin, lumpy or uneven)

Appearance of the fire (bright or dull, proper fire line)

Unburned combustibles

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 28 of 29

Doc

OM-1

COVANTA NIAGARA

O&M Manual/ECOM

Rev.

No. 8

Revision Date: 5/8/14

Review Date: 5/8/14

Secondary Combustion Air

Proper Secondary Air flow, or Overfire Air flow, is critical for emissions and control of

the fire. As noted earlier, gases coming from the combusting refuse bed are highly

stratified:

Gases leaving the drying zone are very high in moisture content, and may

contain high levels of oxygen and low levels of combustible gases - particularly

with wetter fuels.

Gases leaving the main combustion zone form a reducing environment with

virtually no oxygen and very high concentrations of combustible gases. All

available oxygen has been consumed in the primary combustion process,

Gases leaving the burnout zone are high in oxygen.

Secondary air creates a very turbulent mixing zone to thoroughly mix together these

stratified streams leaving the refuse bed. It also provides additional oxygen to ensure

that all combustible gases released by the fuel are completely burned before leaving

the furnace.

In order to be effective, secondary air must be introduced to the furnace at a high

velocity. This gives the air enough momentum to penetrate deeply into the furnace,

ensuring that the reacting gases are thoroughly mixed.

By completing combustion of these rising gases, the overfire helps control flame tip

height, which can reduce corrosion rates in the boiler.

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 29 of 29

Doc

OM-A

Rev.

No. 4

Revision Date: 3/3/14

COVANTA NIAGARA

O&M/ECOM Manual

SECTION A

COVANTA NIAGARA, L.P.

NIAGARA RESOURCE RECOVERY FACILITY

APPLICABLE REGULATIONS

MUNICIPAL SOLID WASTE COMBUSTION UNITS

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 1 of 11

Doc

OM-A

Rev.

No. 4

Revision Date: 3/3/14

COVANTA NIAGARA

O&M/ECOM Manual

SECTION A

COVANTA NIAGARA

APPLICABLE REGULATIONS

A.1

EMISSION STANDARDS AND GUIDELINES

A.1.1

DBA UNITS

A.1.2

NEW SOURCE PERFORMANCE STANDARDS

A.1.3

EFW BOILER #1 / EFW BOILER #2

A.1.4

MISCELLANEOUS PERMITS

A. 1.5

MAJOR REVISIONS TO SECTION A

Printed copies are not document controlled, refer to “S” drive, ISO 14001 Environmental Management Systems file

for latest approved version

Page 2 of 11

Doc

OM-A

COVANTA NIAGARA

O&M/ECOM Manual

A.1

Rev.

No. 4

Revision Date: 3/3/14

EMISSION STANDARDS AND GUIDELINES

The U.S. EPA has established emission standards (regulations, codified as 40 CFR 60, Subpart Ea,

as well as guidelines, codified at 40 CFR 60, Subpart Cb – Maximum Achievable Control Technology

(MACT) requirements) that are applicable to sources combusting municipal solid waste and nonhazardous industrial waste (NHIW). The NYSDEC has taken the MACT guidelines and incorporated

those guidelines into a State Implementation Plan (SIP). U.S. EPA has approved New York’s SIP.

The emission standards applicable to the DBA furnace/boilers at the Covanta Niagara facility are

presented below. This description is provided in accordance with 40 CFR Part 60, Subpart Cb

Section 60.56a (f) (1) - pursuant to the Clean Air Act Amendments of 1977 and 1990. All federal

emission standards and NYSDEC requirements are consolidated in the Title V Air permit and the

Solid Waste Facility Part 360 permit.

In Section 111 of the Clear Air Act Amendments of 1977 (PL 05-11), the U.S. EPA Administrator was