Document 374184

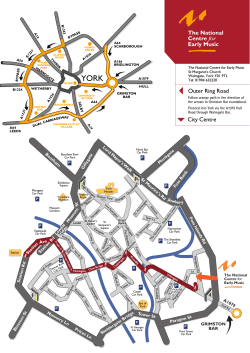

NOV. 4, 1952 v F. L. VAN WEENEN ETAL 2,616,668 REGENERATOR Filed April 22, 1948 GZASS‘ WOOL l0 // MEfALL/C Fl 6 | PART/61.66’ GLASS WOOL 37m FIG, 2 WIRE STEEL WIRE INVENTORJ FPANC/SZ‘US' 'MMBEPTUS V/W WffA/EA/ BY AGE/V7 2,616,668 Patented Nov. 4, 1952 uNrrEo STA-ms PATENT OFFICE 2,616,668 REGENERATOR Franciscus Lambertus van Weenen, Gerhart Wolfgang Rathenau, and Arie Koelewijn, Eind hoven, Netherlands, assignors to Hartford Na ~ tional Bank and Trust Company, Hartford, Conn., as trustee Application April 22, 1948, Serial No. 22,606 In the Netherlands May 30, 1947 1 Claim. (Cl. 257-6) l Regenerators as used, for example, in hot-gas engines and in refrigerating apparatus operating according to the reversed hot-gas principle have for their purpose to reduce the temperature of 'the medium ?owing from the hot side to the 2 contained‘ in the ?lling mass and having a co e?icient of heat-conduction 'higher than 0.03 gram calories per square centimeter per second per degree centigrade are substantially transverse to the direction in which the medium ?ows through the regenerator. In a further embodi ment of the invention the metal parts may be constituted by metallic strips or wires included cold side of the engine and to accumulate the amount of heat thus liberated to be given off again to the medium ?owing back through the in the ?lling mass. regenerator from the cold side to the hot side In order that the invention may be more clearly of the engine. It is common practice to utilise 10 understood and readily carried into e?ect, it will metal, for example in the form of metal wire, now be described more fully by reference to the such as a coil of wire or a clew of wire, as a ?lling mass for such regenerators. In some cases accompanying drawing wherein Figure l is a vertical cross-sectional view of one it would for certain reasons be preferred in con structing such regenerators to utilise as a ?lling 15 form of construction of a regenerator in accord mass, instead of metal, a material having a much ' ance with the invention; Figure 2, is a similar cross-sectional view of lower coe?icient of heat-conduction. Applicant another embodiment of the invention; and has found that this kind of ?lling materials also Figure 3 is a horizontal cross-sectional view of permit of obtaining very satisfactory results, Figure 2 taken on the section line III—III thereof. while there is the advantage that the thermal Figure 1 is a cross-sectional view of one form conduction through the material of the ?lling of construction of the regenerator according to mass from the hot side to the cold side of the the invention. It comprises a housing I0 con regenerator is in practice negligible. Further taining the ?lling mass H, which in this case is more the manufacturing cost of such ?lling ma an amonut of compressed glass wool. In order terials is, as a rule, materially lower than with to ensure the correct position of the ?lling mass the use of a ?lling mass of metal. ' I I in the housing l0, apertured plate members l2 According to the invention, it is now suggested and I3 are provided at the top and bottom of the that in a regenerator in which the ?lling mass, ?lling mass, said plate members ?tting in the which exhibits a large number of channels for housing in a clamping manner. The glass wool the medium flowing through, consists of mate constituting the ?lling mass exhibits a coefficient rial having a coef?cient of heat-conduction lower of heat-conduction of 0.0015 gram calories per than 0.005 gram calories per square centimeter square centimeter per second per degree centi per second per degree centigrade, the ?lling mass grade. In this construction the thermal capacity should be. composed so as to locally comprise parts, for example metallic parts, having a co 35 of the ?lling mass is increased by including in the glass wool a large number of metallic snips [4 of efficient of heat-conduction higher than 0.03 aluminum having a coefficient of heat-conduction gram calories per square centimeter per second of 0.7 gram calories per square centimeter per per degree centigrade. ' second per degree centigrade. It is thus possible for the thermal capacity of ,In the construction shown in Figures 2 and 3 the ?lling mass to be adjusted by varying the in which Fig. 3 is a cross-sectional view of Fig. 2 amount of material having the higher coe?icient taken on the line III—III, the ?lling mass 20 hav of heat-conduction, On the other hand, it may ing a coe?icient of heat-conduction of 0.02 gram be ensured that the temperature of various re .calories per square centimeters per second per generator parts which are equidistant from the hot side or the cold side of the regenerator is at 45 degree eentigrade contains a number of metal helices 2|, the location of which follows more least approximately the same, which is advanta particularly from Fig. 3. The said metal wires geous for satisfactory operation of the regenera tor. > consist, for example, of steel wire having a co emcient of heat-conduction of 0.1 gram calories different form. Thus, it is possible to provide 50. per; square centimeter per second per degree The metal parts in the ?lling mass may be of in the ?lling mass a number of metallic particles, such as metal scales, metal snips, extremities of wire, or the like. In the embodiment of the in vention, in order to ensure uniform distribution centigrade, and are spaced out of thermal con ,tact' with housing Ill. In addition to the advan tagesafforded by the inclusion of the said metal ~ parts‘ in regard to the increase in thermal capac of temperature, it is advisable that the parts 55 ity of the ?lling mass, their presence in the ?lling 2,616,668 4. mass offers the further advantage that the dis tribution of temperature in the ?lling mass is UNITED STATES PATENTS Number rendered as uniform as possible. What we claim is: Name 1,460,677 A regenerator comprising a housingv having an 5 1,716,333 ‘1307,5212 inlet and an outlet through which a medium flows, 2. ?lling mass of glass Wool in said housing " and contacting the wall of said housing, and ,a . Date ' Lundguard ________ __ July 3, 1923 Vuilleumier _______ __ June 4, 1929 Foulk __.._,1._v_>__‘_____ May 26, 1931 ' FOREIGN PATENTS Country Date plurality of spiral-shaped steel wires embedded 531,112 Great Britain _____ __ Dec. 30, 1940 in said glass wool in spaced apart planes, each 10 111,737 Australia _________ __ Oct. 11, 1940 of said wires extending in a plane perpendicular OTHER ,REFERENCES to the ?ow of said medium and adjacent wires being separated by layers of said mass of mate "Chemicai Engineers Handbook,” by John H, rial, said wires being spaced from the walls'of Perry, McGraw-Hill Book ‘00., 1941, pages 948 said housing. Number 15 FRANCISCUS LAMBERTUS ,VAN WEENEN. , GERHART WOLFGANG RATHESNAU. , ARIE KOELEWIJN. REFERENCES CITED 20 The following references are of record in the ?le of this patent: 954i - M “Handbook of Plastics," by H. R. Limonds, D. Van Nosti‘a-nd (36., 1943, pages 33 to 52.

© Copyright 2025