Technology Days Follow us – We are different!

Follow us – We are different! Technology Days 8th ASYS Group Technology Days | November 12 – 13, 2014 | 20 | | 24 | | 26-29 | INSIGNUM 4000 EKRA SERIO 4000 Networked and digitalized The marking system that uses SIMPLEX, the new user interface High-efficiency printing solution with integrated dual lane transport Interview with Werner Kreibl, Karin Walter and Erwin Beck Werner Jonke Vice President Sales Erwin Beck Director Product Management Karin Walter Director CI / Marketing Klaus Mang President ASYS Group Werner Kreibl President ASYS Group Jakob Szekeresch Managing Director EKRA I am convinced our customers are well aware of why we are different. We think outside the box, and incorporate trends and current issues. I need say no more than wearable electronics, renewable energies and e-mobility. The courage to act, the ability to respond promptly, and the willingness to make every effort to bring ideas quickly to fruition. That is ASYS! The history of our company is characterized by ideas and growth. We keep on growing and growing, yet still have our feet on the ground. Our products successfully live up to the trademark "Made in Germany", yet incorporate global trends at the same time. Because we are able to implement forward-looking projects very quickly and to keep on modifying designs until they perfectly match our customers' requirements. Why We Are Different: Ladies and gentlemen: This year, the motto of the ASYS Group Technology Days is "Follow us – We are different!" You might quite rightly say that every individual person, every company is unique. But ASYS is not just unique: we are simply different. The passionate commitment of a crowd of active people creates a very special blend that clearly sets us apart from the rest. Customized line solutions, for example, that we were only able to implement because of our broadly diverse portfolio and strong entrepreneurial spirit. Synergies Time and again, the synergies between our product areas produce new solutions. Product Diversity Our product portfolio encompasses different fields of technology and is unique. Follow us We would like to welcome you most warmly to our Technology Days in Dornstadt. We have put together a selection of fascinating new developments so you can see what we're capable of. Admittedly, it's a lot of stuff for two days. But Oliver Geisselhart, our keynote speaker, is here to help you. The memory coach will not only explain how you can easily retain the numerous impressions, but also how you can recollect them in detail. Maybe you have already noticed that this brochure is full of selfies, a special type of self-portrait and trend motif on the social web. These photos are sometime souvenirs of an event or a place we have been to. But their main purpose is always to share. These photos want to be remarked upon and distributed to others. Our message behind these selfies is: Join us in Dornstadt, talk to us to gain the most possible benefit from the fact that we are different. We look forward to welcoming you. Courageous Committed We embrace new ideas with enthusiasm. Regardless of the nature of the challenge: ASYS comes up with unique solutions. We owe our success to the professional competence and personal commitment of around 900 colleagues. Customer Orientation We develop efficient, next-generation products in close collaboration with our customers. 3 Jürgen Ries Managing Director Asys Group China Wolfgang Heinecke Director Sales and Service ASYS Group Asia Markus Wilkens President ASYS Group Americas Dr. Harald Wanka Senior Vice President Technology Wolfgang Müller Director Project Engineering and Services Wolfgang Pflum Director Production Every day, we manage to develop new solutions and processes for our customers thanks to the commitment of our team and the uniqueness of our product portfolio. "Not possible" is not an option. Even on the other side of the planet we remain close to our customers and provide them with the best possible support. ASYS Group, a global SME. At ASYS, we look far ahead, but without ever losing sight of our goal. ASYS has been supporting the solar industry right from the start, has made every effort to keep pace with developments and, as a result, is nowadays the world's leading metallization plant manufacturer in terms of engineering and technology. We often venture right up to the bound aries of feasibility, and offer our customers tailor-made solutions. First class engineering plays an enormous role at ASYS. We have top products; the competition first needs to catch up. Thursday, November 13, 2014 Wednesday, November 12, 2014 Welcome! 09:00 a.m. – 09:15 a.m. 09:15 a.m. – 10:45 a.m. "Head or slip of paper"? – Your memory can do much more than you think – With Oliver Geisselhart, Germany's premier memory coach, according to television broadcaster ZDF. The Geisselhart technique helps you to raise the performance capability of your memory easily, lastingly, and extensively. Tap your creative, imaginative and intelligent potential in a fun approach that is entirely effortless. 11:15 a.m. – 11:45 a.m. Martin Heinz, B. Eng. 10:15 a.m. – 10:45 a.m. Effective production and "real-time" monitoring are key steps for bringing production into the industrial era 4.0. 10:45 a.m. – 11:15 a.m. 11:45 a.m. – 12:15 p.m. Creating electric motors on 3-D screen printers? Is this economically feasible? Everyone is talking about three-dimensional printing at the moment. 3-D printers are, however, nowhere near suitable for the masses yet and their usability in widespread industrial applications is therefore limited. Dipl. Ing. Günter Lorenz 11:15 a.m. – 11:45 a.m. INVENTUS: Special processes and new fields of application for laser technologies. ASYS uses its INVENTUS machine platform to integrate highly complex processes in fully automated production plants for its customers. 11:45 a.m. – 01:15 p.m. 12:15 p.m. – 01:30 p.m. Tour of the Machine Park 09:15 a.m. – 10:15 a.m. General Manager, iTAC Software AG The OPAK research findings aim to enable simpler, faster and more cost-efficient development of complex processes for manufacturing automation systems. Dr.-Ing. Thomas Studnitzky Keynote Speaker, Prof. Dr.-Ing. Klaus Dietmayer Autonomous driving / Ulm university Just imagine, a car without driver picks you up on a request sent by your smartphone from wherever you are, takes you to wherever you want to go and then drives off again, without you having to do anything. 10:45 a.m. – 11:15 a.m. Dr. Sven Hermann 09:00 a.m. – 09:15 a.m. Thorsten Frenzel, Head of Sales D / A / CH & BeNeLux ASYS Group Werner Kreibl and Klaus Mang, Management Board, ASYS Group Keynote Speaker, Oliver Geisselhart Welcome! 01:30 p.m. – 05:00 p.m. Presentation of the lines Tour of the Machine Park 01:15 p.m. – 05:00 p.m. Presentation of the lines 05:00 p.m. Close Evening Event Starting at 06:30 p.m. With surprise guests, Shuttle service to the hotels 5 Packed venues and enthusiastic audiences Wednesday Oliver Geisselhart 09:15 Wednesday, 12 November Watch the video trailer now Oliver Geisselhart, Germany's Memory Coach Rated No.1 by ZDF "Head or Paper"? – Your Memory Can Do Much More Than You Think. Oliver Geisselhart (Bachelor of Business Administration) is one of Europe's most successful speakers and memory coaches. In 1983 at the age of 16, he was Europe's youngest memory coach. The bestselling author is a top 100 speaker and a visiting lecturer at the University of Economics in Seekirchen near Salzburg. His "Geisselhart memory and mental training technique" is considered by experts to be the most practical technique available. The "memory pope" (TV HH1) knows how to enthuse and motivate listeners like no other, with humor, charm and wit, earning him the title of "Memory trainer of the year" in 2000. Thanks to his superb performances as a speaker, he has been awarded the Conga Award three times in a row (from 2008) – the 'Oscar' of Germany's conference and events industry. He is sought after around the world for employee training sessions and customer events by recognized companies, such as Bosch, Telekom, TUI, Deutsche Bahn, Hewlett Packard, Deutsche Bank, RWE, Fujitsu-Siemens, DekaBank, BASF, LBS, Microsoft, AOK, Lufthansa, BMW, IBM, E-Plus, and many others. Oliver Geisselhart is a recognized face from countless appearances in newspapers, radio and television. "Germany's leading memory coach" (N24) fascinates countless thousands of enthusiastic participants every year with his almost comic presentation style. At ASYS Group Technology Days, he shows how you can change from someone with a memory to someone who uses their memory in a fun and stress-free way. 7 Thursday Prof. Dr.-Ing. Klaus Dietmayer 09:15 Thursday, 13 November Prof. Dr.-Ing. Klaus Dietmayer Drive as if by Magic Autonomous driving – a research project at Ulm University Just imagine, a car without driver picks you up on a request sent by your smartphone from wherever you are, takes you to wherever you want to go and then drives off again, without you having to do anything. That is the vision of future mobility of Ulm University's engineering researcher, Prof. Dr.-Ing. Klaus Dietmayer. His presentation will review the current status of the autonomous driving research project. The future project was started two years ago at Ulm University's Institute of Measurement, Control and Microtechnology. It is financed exclusively by research funds. The researchers equip a standard vehicle with a number of modules to make autonomous driving possible. Highly responsive sensors, laser scanners, radar units and numerous cameras scan the environment in front of and behind the vehicle. Each individual module supplies information and synchronizes with the other modules for safe driving. The system is in constant contact with the driver, who can intervene at any moment, if necessary. Prof. Dr.-Ing. Dietmayer explains the intelligent technology behind the autonomous vehicle of the future. Project Website 8 9 Wednesday Presentations Thursday Presentations Our Speakers Stand for New Ideas and Creative Solutions Martin Heinz Dr. Sven Hermann General Manager at Product Manager INVENTUS Process, ASYS The Future of Industrial Automation OPAK: An R&D Project for Industry 4.0 Wednesday 11:15 – 11:45 Dr. Sven Hermann presents the new OPAK research project, funded by the German Federal Government. A network of companies and institutes, including ASYS, are getting involved in the future project. The OPAK research aims to make development of complex processes for manufacturing automation systems simpler, faster and more cost-efficient. The project will create an innovative engineering platform with optimized autonomous mechatronic components. The components will significantly simplify systems development, with integrated control technology and intelligence, delivering true plug & produce functionality. Dr.-Ing. Thomas Studnitzky iTAC Software AG Thursday 10:15 – 10:45 Industry 4.0: Effective Production & Monitoring Effective production and real-time monitoring are key steps to bring production into the Industry 4.0 era. Direct integration and networking of different systems with the MES play a key role in this case and offer enormous added value to the customer. Martin Heinz will look at the innovative solutions that have already been found. Dipl.-Ing. Günter Lorenz Group Manager 3D-Metal Product Development Manager Printing, Fraunhofer Institute for Laser Systems, Solar and Manufacturing Technology and Advanced Materials (IFAM) in Dresden Wednesday 11:45 – 12:15 New Horizons for Screen Printing Create electric motors on 3D screen printers? Is it economically feasible? Everyone is talking about three-dimensional printing at the moment. But 3D printers are currently far from suitable for large-scale use as yet and their usability in widespread industrial applications is therefore limited. Traditional 2D screen printing, on the other hand, is already established as a manufacturing process in many areas of industry, despite limited print height. Further development of three-dimensional screen printing will open up the advantages of screen printing for complex components. Dr. Thomas Studnitzky from the Fraunhofer IFAM in Dresden will show how series components are produced economically using new 3D screen printing techniques. New Technologies, ASYS Thursday 11:15 – 11:45 INVENTUS: Special Processes and New Fields of Application for Laser Technologies ASYS uses the INVENTUS machine platform to integrate highly complex processes into fully automatic production systems for its customers. Frequent applications include surface cleaning, coating, complex joining processes and the test procedures required for quality assurance. The platform uses a large number of laser processes, such as hermetic-seal laser plastic welding and separation to separate panels without dust or stress. 11 es ri to ra bo La ASYS Group Product portfolio - b Co xhi e ito Presentations rs on an Area Measuring 1,000 sq.ft. Exhibition hall Live production SMT production line Watch your very own, personal PCB being produced! The entire SMT process will be demonstrated, including 03015: Laser marking, printing, solder paste inspection, picking and placing, soldering, assembly inspection and labeling. To enable the demonstration, systems from our partners PARMI, FUJI, Rehm and VISCOM have been integrated. The icing on the cake: The entire production line, including all partner systems, is being monitored by PULSE Mobile Line Assist. EKRA X5 Professional Redefining high end EKRA SERIO 4000 Dual Lane Printing Solution The next generation high performance printing system is now even more accurate. Not only have its functions and performance capabilities been improved; it has also been given a next generation design. A highly efficient printing solution based on the SERIO 4000 stencil printer will be on display. The redundant dual lane design increases line availability. It can even handle different line layouts, with one- or two-sided operation to support different pick and place machines. Catering We have improved the innovative CONEXIO line concept to bring it in line with customer and market requirements. 100% high speed oriented, minimum footprint, back to back capability and open interfaces are characteristic of the next generation standard for SMT manufacturing. ASYS laser applications Marking, scribing, depaneling We're opening our laser lab for you! The INSIGNUM experts will be demonstrating innovative new products, such as INSIGNUM Variety, the combined laser/label marking system, and INSIGNUM 4000, the high end marking system with SIMPLEX user interface. We will also be presenting fascinating applications, such as "Marking on the Fly" and 3-D lasers. Specialized processes, such as laser depaneling and scribing, will be demonstrated on the INVENTUS laser platform. EKRA HYCON Customized printing solutions The printing experts will demonstrate reel to reel processing solutions, together with a concept for gradually printing meter-long PCBs on a standard printer. Experience live the emergence of threedimensional structures from a screen printer. TECTON Tray handling in a "clean" environment from ASYS Prozess- und Reinraumtechnik ASYS is conquering new markets, such as Life-Science. We want to present a new solution for this field of application: a TECTON Tray Hand ling system with transfer line that is incorporated into a cleanroom environment from ASYS Prozess- und Reinraumtechnik. DIVISIO: "Optodrilling" PCBs equipped with LEDs ASYS offers a new standard procedure for processing LEDs. We will be demonstrating "optodrilling", the process of drilling into PCBs relative to the center of light emitted by LEDs or LED clusters, which allows accurate positioning of the optical components (lenses, reflectors). Cl ea nr oo m CONEXIO – the new generation Everything simply SIMPLEX – A new approach to machine operation using a multitouch user interface. Experience live how SIMPLEX works when marking, depaneling, screen printing and Tray Handling. INVENTUS Customized solutions ASYS Solar Metallization line OPAK – Next generation automation design INVENTUS is the crystallization point for innovations within ASYS Group. INVENTUS impressively demonstrates how ASYS is capable of com bining any manufacturing processes to create competitive system solutions: From automatic screwing, laser welding, and assembling, up to plasma cleaning. ASYS is a leading manufacturer of metallization lines for the production of solar cells. A complete production line will be set up in the exhibition hall, including two particular highlights: An integrated system for handling the laser contact opening process, and a Botest cell tester for innovative, high efficiency cell designs. Together with our partners, we are constantly striving to develop individual automation systems more simply, faster, and more cost efficiently. Allow us to present the automation concept of the future on our OPAK demonstrator. (OPAK = Open engineering platform for autonomous automation components) www.opak-projekt.de And much, much more ... 13 Customer testimonials Customer testimonials Udo Schulz Manufacturing Engineering Manager-Plant Electronic Controls Delphi Deutschland GmbH Jens Brennenstuhl Master of SMT Production Brose Fahrzeugteile GmbH & Co. KG Dirk Fricke Director Operations Diehl AKO Stiftung & Co. KG We Are Different: What Do You Think? Motivated, innovative and customer-focused team. ASYS reacts very quickly and directly to unforeseen challenges. Asys is different because the customer is more than just king. Georg Schafer Dirk Andreas Buddy Siegfried Alexander Member of Executive Board Jachemich Rehfuss Krämer Schmierer Wagner Head of Turn Key Electronics Head of Manufacturing Process Engineering Team Manager Production Planning – Process Engineering Dept. Manager Pre-Production Electronics Process Engineering Asetronics AG SERO GmbH Pilz GmbH & Co. KG Helbako GmbH Endress+Hauser GmbH & Co. KG ETL - Elektrotechnik Lauter GmbH Asys has a broad range of standard systems that can be customized and networked very cleverly. Asys is a supplier that really fits our motto: Leader in EMS – Next Level. We are increasing our quality and productivity by constantly developing and optimizing our processes and machines in collaboration with Asys. Working with Asys, customerspecific solutions can always be implemented. ASYS has its sight set to the future. We appreciate that. As a precision engineer, I often found mechanical engineers to be quite cautious. The world of electronics seems to me to be just one and the same big family. But Asys stands out thanks to its competent and less restrictive approach. ASYS/EKRA has been a reliable, flexible, innovative and thoroughly friendly partner for the ETL team, from the very inception of the two companies. 15 INVENTUS Customized Solutions Singulation Platform Assembly Platform INVENTUS Assembly Dr. Sven Hermann, Process Specialist INVENTUS Break Laser Platform INVENTUS Laser Test Handler Platform INVENTUS Test Process Development and Process Integration – Unique Among Customized Solutions Machines and platform technologies for selected applications With INVENTUS Customized Solutions, ASYS combines the wide range of base technologies in the Group with new, customized processes. Development and expertise ASYS has extensive expertise in interface technologies, measurement technology and image processing. That is one reason why the INVENTUS division is so successful, as our expertise means that almost every system can be integrated into a customized ASYS solution – and even complex processes can be implemented. With INVENTUS, ASYS also supplies machine platforms as stand-alone products, which can encompass various different processes. INVENTUS technologies are often a source of inspiration for standard ASYS Group products. One example is a special imaging and image processing technology that has been adopted for TECTON tray handling systems. The technology is used to monitor the tray handling system and check for errors, allocate the items error-free and maintain an uninterrupted flow of material. These are important functions, particularly in Life Science, which has high demands in terms of precision. Measurement Technology and Image Processing as Key Qualifications ASYS has many years of experience modifying complex measuring systems and integrating them into production lines. Some processes are so specific that new designs have to be developed. In this case, ASYS uses in-house developments that can be rapidly retrofitted. This helps particularly in projects that have to be completed very quickly. Growing Portfolio for Lighting Manufacturing ASYS has already supplied several different systems used to produce efficient LED-based lighting. Assembly of LED PCBs is one example. The positioning accuracy of no more than 10 micrometers was a particular challenge in this case. Measurement systems were also developed and produced for single LEDs or entire groups of LEDs. The systems measure the light emission characteristics and check light patterns. A highly flexible system was developed to produce LED fluorescent tubes. The system can produce more than 30 different form factors of fluorescent tubes and PCBs without refitting. Bionic Solutions for the Packaging Industry The brief was for a complex packaging assembly system. Adhesive tape, which is used to protect packaged goods from external stress, had to be applied to highly flexible surface areas. The tape is used with objects that have limited dimensional stability and are not solid. To solve these challenges, processes were used that apply bionic principles – to date, uniquely on the market. For example, finger movements were emulated to seal and fold corners and edges. › Integration & automation of complex measurement and test procedures (integrating sphere, helium leak test, and complex 3D analyses). trays with packages adhesive tape on objects with non-standard geometries and highly variable geometry on ceramics › High-current and high-voltage measurement technology › Optical test of LEDs › AOI for completeness and correct position for filling › Development of special cleaning processes › Cutting, folding and application technologies for › Micrometer-accurate curvature measurement › Marking and assembly of complex modules in any spatial configuration › Plasma applications 17 DIVISIO Depaneling ASYS depaneling systems are taking over LED production! Accurate Drilling – New Option for DIVISIO Depaneling Systems Left image: Measuring a straight line on a fiducial Right image: Drilling alignment ASYS offers a new standard procedure for processing PCBs with assembled LEDs. In the "optodrilling" process, holes are drilled to align and support optical components. The LED technology opens up a range of new possibilities for the automotive industry. The glare-free high beam is one innovation. It is no longer necessary to dip your lights, as the vehicle recognizes other vehicles and dims the applicable segments of the illuminated area. This is only possible because the new headlights use LED clusters that can be individually controlled and therefore provide complex beam geometries. But when producing LED boards, it means a higher demand for precision. The optical elements must be located with high accuracy for the beam angle to function correctly in the LED cluster. A camera system determines the centers of illumination of the LEDs and therefore the optimal hole position. The optics are positioned with low tolerance. The accuracy of 100 +/- 50 micrometers is double that of traditional procedures. The challenge for optodrilling is the positioning of the drill center point, as the drift of the cutter – the axial eccentricity – causes a mismatch. To minimize the drift, the axial eccentricity must be measured and an optimum basic run to the drill center must be defined. ASYS has integrated a highly accurate laser measuring station into the system for this purpose. To ensure long running times, we worked with tool manufacturers to develop special tools to dry-drill into aluminum. A Cpk (measure of process capability) of > 1.33 was achieved. Optodrilling is an option for the depaneling system in the DIVISIO series. it can be integrated into either inline systems or manual systems with automatic rotary table. Holes have to be drilled into the PCB to position the optical components accurately (such as mirror or lens). In traditional procedures, the holes are already defined before the PCBs are produced. However, when the PCBs pass through the oven, the LEDs float on the soldering paste. When "optodrilling", on the other hand, LEDs can be placed "freely" on a PCB. The holes are drilled immediately before the optical components are attached. 19 Insignum Marking INSIGNUM Variety Labeling and Laser Cutting in One System SIMPLEX User Interface – dynamic variable panel INSIGNUM 4000 – The Next Generation The product innovation, INSIGNUM Variety, is a flexible marking system for marking and cutting of labels using laser technology. The machine is designed specifically to mark a variety of materials and various component heights where direct marking reaches its limits. A special feature is the freely selectable label size. ASYS presents the INSIGNUM 4000 laser marking system with SIMPLEX, the new user interface with innovative control logic. With SIMPLEX, the system is easy and extremely fast to operate. The marking system is now noticeably easy to operate thanks to a re-structuring of the complex content and a clear layout. A large number of setup processes, such as marking detection, are completely automated. Visualization of Job and Production Information: An analysis tool displays incorrect or unrecognized codes directly, if necessary. Poor markings are therefore located immediately. The actual and target values of the applicable job can also be compared directly. SIMPLEX comes with many advantages for system operation: "When developing SIMPLEX, we placed a high value on reaching the target in just a few steps", emphasizes Swen Nothjunge, INSIGNUM Marking Systems Product Manager. "And we put more than 15 years of developer expertise and user experience into the system." Important Basic Functions Can Be Accessed Quickly: Applying complex, interdependent marking data requires a large number of coordinate operating steps. Application is now fast and does not take up valuable time thanks to the new structure and the clear navigation panel. Variables Can Be Created Easily By the Module Principle: Variables can be combined simply by tapping them, thanks to the modular structure. Combined variables are displayed in a dynamically adjustable sequence (see figure 2). Individual modules can therefore be changed, adapted or deleted with simple operating gestures. INSIGNUM 4000 with New OPTIMAP Option: The unique innovation provided by the OPTIMAP option is that the system can now mark AND verify multiple marking items in just one process step. It is a new procedure that is designed to mark and check codes with optimized cycle times. The marking area on the PCB can be significantly enlarged thanks to this latest development. The marking area is optimally utilized and the number of movements is reduced. In addition, the new marking system has a flexible nozzle quick-change system. This makes it possible to place different label sizes on a wide range of materials in one operation. The system automatically selects from a set of available nozzles the sizes that it needs to place different labels. Setup times for manual tool changes are eliminated. Automated placement of large labels next to small labels is therefore a matter of seconds. A servo-driven X/Y-axis system and a motorized Z-axis allow different component heights of up to 40 mm to be marked. This axis combination and the tool changing system greatly increase the flexibility and efficiency of the machine, giving it a peak cycle time of four seconds. The laser fulfills two tasks in this process: It labels the foil and cuts it to the required size in just one step. To achieve a high accuracy, a camera system measures the label. Finally, the label is positioned by a servo-driven axis system and is applied by a motorized adjustable Z-axis. 21 EKRA Screen and Stencil Printing EKRA Screen and Stencil Printing Printing solutions Focused on Niche Markets Layer by layer to 3D Structure From left to right: Erwin Beck (head of product management), Jakob Szekeresch (EKRA Management), Torsten Vegelahn (EKRA Product Manager) X5 Professional Flagship Revised The X5 Professional printing system is one of the world's most successful highperformance printers. The leading model has now been revised and adapted to meet In collaboration with the Fraunhofer IFAM, EKRA has developed a special printing system that can create three-dimensional structures in multiple printing steps up to a height of 200 millimeters. In contrast to the well-known "3D rapid prototyping" process, the new process is not designed to manufacture three-dimensional prototypes. 3D printing focuses on producing high-quality, complex components and components required in large quantities. For example, you can combine all types of metals only by using the screen printing process. The metals only have to be available in powder form with a binder. Hollow spaces and channels can also be freely integrated into the 3D structure. A 3D screen printing system that manufactures three-dimensional structures live will be displayed. the technological challenges of the future. Endurance Test for XXL PCCs – Passed In addition to a range of improvements in functionality and performance, the process capability and print repetition accuracy have been increased to 20µm at 6 Sigma. This 20% increase is indispensable for future miniaturization of components. Current component sizes such as 03015 (metric) require ever more accurate printing systems. The X5 Professional printer is already prepared for the next component generation 0201 (metric). More than eight modules have also been revised and optimized. A vacuum monitoring unit has been added to the iROCS stencil cleaning system to increase process reliability. The print specialists have also optimized the squeegee assembly so that the operator can replace a squeegee even more quickly. "Our customers are perfectly equipped to meet future application requirements and can look calmly into the future thanks to the further development of our high-end printer. The latest model, which includes an updated look and feel, underlines our efforts as a premium manufacturer to create sustainable products with leading technology," says Torsten Vegelahn, Product Manager. EKRA has also improved the glue deposit size of the dispenser, the iPAG Jet. The dispenser can now apply even smaller deposits. The number of different dispenser media has also been increased. These are just some of the improvements you can look forward to. Be excited! very expensive and, second, stretching occurs much more commonly during the PCB production process for large-format PCBs. As stretching cannot be compensated for in screen printing, fine pitch structures cannot be applied as required for the process. EKRA is presenting a new and patented solution that makes it possible for the first time to print XXL PCBs step by step using a standard system. In the process, a substrate is conveyed through a printer in stages and soldering paste is applied at each stage. A further special feature is that it is even possible to process PCBs with different layouts. It is not only the PCB that is moved stage by stage, but the stencil as well. A special stencil design also prevents the applied soldering paste from smearing. High accuracy for fine pitch structure can be achieved thanks to the segmented alignment and printing in sections, despite possible stretching overall. Any PCB manufacturer who wants to print large-format PCBs (larger than 1.20 meters) is faced with two challenges in particular. First, special printing systems for these sizes are NEW! The S10 select, the new automatic dispenser for consumables, designed to dispense soldering paste, adhesive and gloves as required in your process – in a traceable way. 3D structure, created with 300 screen-printed layers 23 VEGO Handling Speed your line New VEGO Dynamic Production Line Unloader The fully automatic AMS 03 Speed magazine station from the VEGO Handling line achieves an exceptionally low cycle time of less than 10 seconds. From left to right: Michael Schimpf and Torsten Vegelahn, Product Managers at EKRA Dual Lane SERIO 4000 Printer with New Option Since the launch of the SERIO 4000 printer platform, it has been constantly expanded with new models and features. The "dual lane transport" option has now been added to the range. "SERIO 4000 has been well-received on the market. We can meet a large proportion of our customers' requirements with the four models – the SERIO 4000, SERIO 4000 Compact, SERIO 4000 Volume and SERIO 4000 Speed. However, there have been an increasing number of inquiries for a solution that delivers even higher throughput without increasing the space that is needed. The PCBs in consumer electronics are typically small and require cycle times of less than 15 seconds. It was then that we started thinking about a dual lane solution," explains Michael Schimpf, Product Manager at EKRA. Side-by-Side Solution The new dual lane solution delivers significantly shorted cycle times and therefore throughput-optimized production. A range of layouts is possible with the option. For example, one singlelane and one dual-lane printer can be used on the same production line. This side-by-side solution is the more costeffective Dual Lane solution. The innovation: a vertically and horizontally mobile conveyor belt transfers incoming PCBs to fixed magazines. This has enormous benefits, particularly when sorting 'good' and 'bad' PCBs using an AOI. Cycle Time Reduced by Approx. 30% A shorter cycle time is an important factor in efficient production. The ASYS application and software team has managed to reduce the average cycle time of a line unloader to a minimum. The new magazine station, the VEGO Dynamic AMS 03 Speed, has reduced the cycle time by approx. 30% compared to the AMS 03D, significantly increasing the productivity of a production line. Perfect Accessibility to All Magazines In the new high-speed system, only the conveyor belt moves, not the magazines. As the conveyor belt is significantly lighter than in the previous system, higher speeds and acceleration are possible. The perfect accessibility to all magazines familiar from the AMS O3D has been fully retained in this system, as the rapid shuttle conveyor is completely enclosed and the magazines do not move. Side-by-Back Solution Alternatively, two dual-lane printers can be used in a side-byback solution. One of the printers is rotated 180°. In this case, the system can be operated from both sides of the production line. The printers can be selected and arranged in the way that is most rational for the applicable requirements. Formats from 80 x 50 mm to 400 x 253 mm can be printed with the two dual-lane printers. The option can be integrated into all four models. Top: Clever solution – the shuttle conveyor belt travels up, down, right and left in a matter of seconds Right: VEGO Dynamic AMS 03 Speed, with a platform for max. three magazines Advantages at a glance: › Low cycle time < 10 seconds › Perfect accessibility to all magazines › Ergonomic working position › Platform for three magazines › Dual Lane capable › Automatic good/bad sorting Interview digitized and networked New Product Concepts, Digitized and Networked The internet of things is now considered a driver of innovation and is compelling industry to change established ways of thinking. Smart homes, autonomous driving and Industry 4.0 are the buzzwords in this field. Find out how ASYS is exploiting the potential in an interview with Werner Kreibl, the Managing Director, Karin Walter, Director of Marketing/CI, and Erwin Beck, Director of Product Management. How is ASYS preparing for the predicted changes? Werner Kreibl: The internet of things, or Industry 4.0 derived from it, is currently on everyone's lips. There is a dramatically growing volume of information behind it that should improve our everyday lives, if used effectively. For production, this means upgrading machines with technical intelligence, by which I mean sensors, and interpreting data in meaningful ways. Machines are being networked and are becoming more autonomous at the same time. At ASYS, we started looking at Industry 4.0 early on and have developed some ideas for products from it. We see it as a change to differentiate ourselves. We would like to benefit from the change from the start. Karin Walter: I am seeing a lot of new ideas in the mobile sector in particular. For example, new wearable devices, such as wristwatches and smart glasses, that have a lot of meaningful potential uses in day-to-day life. At ASYS, we have set ourselves the goal of using these innovations, where applicable, in the sectors of industry we serve. Marketing is working closely with product development and product management in this area, and Werner Kreibl provides us with valuable support in this field as well. The Integrated Design group, for example, is developing completely new designs for human-machine interaction, to keep the rapidly growing complexity and dataflow under control. Machines are becoming more intelligent and more autonomous – what does that mean for product development at ASYS? What concepts are coming out of this? Karin Walter: From my point of view, this means it is necessary to look more carefully at the human factor and human needs, in addition to mastering the technology. So, how can these innovations support and improve the work done by people. When machines control themselves, they require fewer, but more complex interventions by operators. The operator's level of education and training should therefore be considered more carefully in future. What I mean is that we have to provide inexpert operators with different tools than we would give an expert. We have been working on this for some years. Our SIMPLEX operating concept, for example, gained recognition within a very short period. We are also one of the first in the industry to exploit multi-touch technology for production. That was something new and trend-setting! Werner Kreibl: SIMPLEX quickly told us that we are on the right path, and we have experimented with transferring SIMPLEX to mobile devices. At the SMT 2013, for example, we operated one of our laser marking systems and a stencil printer from a mobile device. We used the contact with our customers at the trade fair to discuss the added value of mobile operation. The next step was the 'connected' app – the preliminary stage to our first mobile product, the PULSE Mobile Line Assist. Visitors to the trade fair could connect to our machines with their own smartphones and access useful information. The concept was new for the industry. The approach at the time was to exploit the potential of smartphones for production. The ASYS PULSE was the result. We are continuing this approach. Erwin Beck: If I can comment from the product management perspective (Erwin Beck laughs). When defining a product, I always come back to my guiding principle – "keep the line running". As machine availability of >99% has now been reached, it is not enough anymore for the individual machine to function flawlessly and use innovative technology. The box-tobox view of individual process that is still commonplace is necessary to be successful, but it is no longer sufficient. We have to help the customer optimize its production solutions as a whole. Nonetheless, I was initially critical of Industry 4.0. Could it be just another flash in the pan that will go out quickly "SIMPLEX quickly told us that we are on the right path." and would activity by ASYS in this direction just irritate customers? But on closer analysis and after seeing the product ideas we have developed from Industry 4.0 in a very short time, I was all for it in no time. I saw the potential – the benefit – for our customers. A tour of our customers before the product launch to present our ideas strengthened my opinion even further. As a side product, ASYS PULSE not only means that we can connect the machines in our portfolio on a central mobile devices, but also that our VEGO PCB handling modules contribute to energy savings as hardware components such as warning lights and control panels are no longer required. Werner Kreibl: That's right, PULSE was so convincing that we have our partner companies got on board straightaway. We have now also integrated SPI, AOI, loading, reflow over and cleaning systems into PULSE. So we already have a complete production line, which we will present at our Technology Days. Enthusiastic customers who encourage other suppliers to make the move to our PULSE platform are also a real support. That is also why my concern that the route to Industry 4.0 will be held back in particular by the lack of willingness among firms to cooperate is gradually subsiding. 27 Interview digitized and networked Erwin Beck: Yes. I keep on repeating – "Knowledge doesn't grow by hoarding, but by sharing" – and that seems finally to have found a sympathetic ear. And this is where inter connectedness comes in again. It is not very easy to establish new business models and to accept new transparent structures. Data security plays a major role here and a new legal framework has to be created. The entire industry has barely started on this. Technologies change, as do people. How is ASYS prepared for constant change in technology? Erwin Beck: That is very simple. ASYS makes it simple! For example, why wait for the Industry 4.0 interface standards a lot of people are asking for? We simply go a few steps ahead and take the people with us who want to come with us. For me, that was also one reason to switch to the ASYS Group three years ago. I got to know and appreciate this trial and error approach at ASYS and its high rate of success many years ago working on joint projects. In this environment, I can contribute my ideas directly. Karin Walter: That's right, but every new idea also brings a lot of unknowns into the equation and therefore uncertainty with it. Designers are 'why' thinkers and engineers are 'how' thinkers. Bringing both together is not always easy, but we have found a way. The courage to act, the ability to respond promptly, and the willingness to make every effort to bring ideas quickly to fruition. That is ASYS! Interview digitized and networked "We simply go a few steps ahead and take the people with us who want to come with us." Erwin Beck: When I first joined the ASYS Group, I was able to design and run with the CONEXIO project, which is our innovative line solution that splits the handling section from the process section and therefore guarantees fast set-up times. A pretty wide-ranging concept, which was still not completely backed up by analysis of market potential. Werner Kreibl: We heard from our key accounts that they really wanted a solution like that and we obviously thought about how we could meet that demand. Erwin Beck: That's right. The way we did the first version, unfortunately, it was not the perfect product for the target market. We learn from our mistakes and see them as opportunities. Sometimes, we go three steps forward and two back. But that's why we are always one step ahead of the others. That is ASYS. Werner Kreibl: This is the way I see it. It's called the concept car in the automotive industry, which is a product that is technologically very far out front – a kind of feasibility study directly with the customer. Prototype concepts such as CONEXIO or the Connected App were opportunities for us not just to talk to our customer about the future, but to test it directly. That requires courage, belief in something and openmindedness to the unknown and new. From left to right: Karin Walter, Werner Kreibl, Erwin Beck The interview was conducted by Katinka Eberl, Marketing/CI and Belma Gül, Marketing/CI. 29 ASYS GROUP Operating Concepts ASYS Group Usability Concepts for the machine operation of tomorrow Human-machine interfaces (HMI) have a major impact on quality and efficiency in production. They can increase productivity and reduce the costs of training and operating errors. The ASYS Group has been working in this field for several years and constantly brings new operating concepts onto the market. The right HMI for each machine As a producer of automated production lines, ASYS has an interest in testing innovative concepts and assessing with our customers what technology is best suited for what application. New solutions for different applications are constantly being developed by our in-house team, which includes product developers, programmers and interaction designers. The team focuses on applying interaction logic to various end devices. A uniform look and feel is intended to help the HMI user find his or her way around the machines on the production line quickly. End devices are very varied. The external workstation with desktop computer, mouse and keyboard – used, for example, to monitor the production line with OIC (Overall Inline Communication) – is one example. Cost-effective control panels are used for ASYS handling modules. The ASYS Group process machines are operated via large-format multi-touch screens. A software product for tablet PCs – PULSE – is supplied to control and monitor entire production lines. Hands-free technologies put to the test Hands-free technologies are also on the rise at ASYS. Smartwatches are the first product to be tested for use in a production environment. The argument for doing so is that, in the modern Industry 4.0 production environment, the human is increasingly an additional "sensor" and situational decisionmaker. The human grasps situations and solves conflicts instantly. Rapid reactions are therefore in demand. Presented data must therefore be filtered and made available in real time and directly. Wearables – wearable computer systems such as smartwatches – are perfectly suited to meet this challenge, because they are worn on the body and have a strict limit on the data that can be displayed. Smart control panels for VEGO handling modules All VEGO handling modules are equipped with high-resolution control panels. All the panels come with a clear, reduced design and color display at the best possible price. Modules with limited operating demands, such as conveyor systems, are operated via the T350 panel, which has a small display and a set of hardware keys. Modules with more complex operating processes, such as buffers, are controlled via the T570 panel, which has a large touch display. SIMPLEX multi-touch operation Reduced to the Essential The navigation through menu items is highly original and is one reason SIMPLEX is unique. Anyone who has ever operated a complex production machine knows that simple navigation is important if you are to manage complex and extensive information quickly and effectively. Technological development means that adequate assistance systems are becoming increasingly important when it comes to machine operation. SIMPLEX therefore summarizes functions and creates user scenarios that are reflected in the navigation. The main menu, for example, has different use cases, such as production and program, i.e. for whether a machine is simple in production or a new program is being created for a change of production. The main menu items are clearly distinguished by color. An operator therefore can see at a distance the machine's status at any time. Intuitive Thanks to Visualization Images and 3D visualization are becoming increasingly important to support operators effectively, in particular when it comes to activities such as refitting or troubleshooting. Clear analogies to objects from the physical world make it possible to guide the operator through the required user actions in an intuitive way. That is why each input value with SIMPLEX is visualized by a simple illustrated icon. The interface is therefore multi-user ready and can be operated by personnel speaking different languages. The in-house design department has developed a uniform icon system for the entire ASYS Group machine portfolio, which guides international users to their goals. PULSE team SIMPLEX team SIMPLEX user interface for process machines The ASYS Group process machines have step for step been fitted with the award-winning SIMPLEX user interface over the past few years. Complex input tasks can be completed intuitively on large multi-touch displays. The multi-touch technology makes it possible, for example, to zoom in on a PCB view and place markings by simply tapping the screen. Status information is always available at the same point and displayed for rapid comprehension. This clarity is similar to that found in assistance systems in the automotive industry. Manual functions are always accessed at the same point. Start and stop are now so clearly indicated and color-coded that they have easily replaced traditional hardware buttons. SIMPLEX and PULSE 31 ASYS GROUP Operating Concepts ASYS GROUP Operating Concepts 2010 2014 SIMPLEX for screen printing systems VEGO Control Panel T350 badmarks is also an important new tool. The SIMPLEX menu structure means that operators can move very easily back and forth between operating steps. As creating of complex marking data requires a large number of coordinated single steps, jumping back and forth is often the way to get an overview. Variables can be created with a modular approach. The result is simply displayed in a line at the top of the screen. Another new feature is the simple visualized statistics tool for actual and target marking values. PULSE Mobile Line Assist Applied to Process Machines, Step for Step SIMPLEX was introduced in 2011 for the EKRA screen and stencil printing systems and won an NPI Award. SIMPLEX multi-touch interactions speed up marking setup by 15%. It was possible to reduce the time to set up inspection areas by 10 minutes. The DIVISIO series depaneling systems were next in 2013, including integration of new drag & drop features to load programs and manage tools. The INSIGNUM series marking systems are following in 2014. Direct teaching of fiducials and 5 6 SIMPLEX for tray handling systems 4 SIMPLEX depaneling systems 3 SIMPLEX for marking systems 2 VEGO Control Panel T570 1 In 2014, ASYS also began adapting the SIMPLEX operating concept to the tray handling systems of its TECTON subsidiary. The convenience of operation with SIMPLEX was transferred to smaller screens to ensure the machines were cost-effective. New programs and new cavity positions are created with the support of simple visualizations. The developers have also integrated a 3D live view that support operators during troubleshooting. PULSE: Keep the Line Running! Central operator to-do list with error messages, warning messages and pre-warnings for the entire line. Central status overview for the entire line. 1 VEGO HANDLING 2 3 INSIGNUM MARKING 1 4 EKRA SERIO PRINTING Connection to partner system 1 Connection to partner system 1 Connection to partner system 2 Connection to partner system PULSE Mobile Line Assist Human-machine interfaces are no longer restricted to controlling machine functions. Networking and visualization of entire production chains is of growing significance. The result is greater production flexibility, but also increased complexity when defining suitable human-machine interactions. Thanks to smart devices, the operator becomes an observer, viewing all the important information in a structured way on his or her table or smartphone. ASYS has developed PULSE for this use case. The mobile assistance system provides an overview of a complete machine line and displays status information and to-do items. PULSE Mobile Line Assist is a product that has developed from the VEGO handling range. Handling modules, as the connecting elements in production, are the perfect point to provide an overview. When PULSE is used, operating panels are no longer required at the individual handling modules. All functions can be controlled and activated via PULSE. 1 5 DIVISIO DEPANELING 6 TECTON TRAY HANDLING 33 Interview Life Science & Solar Well-Positioned with Life Science and Solar Oliver Bleher, Director Life Science "We can exploit the synergies and many years of experience from other business segments." The ASYS Group has a unique product portfolio covering various fields of technology. In addition to the two permanent pillars of Electronics and Solar, the Group is also currently establishing itself in the field of life science. Here is an interview with the new Director of Life Science, Oliver Bleher, and Dr. Harald Wanka, Senior Vice President Technology. The ASYS Group has many years of experience in Electronics and Solar. What synergies can be exploited from that experience for the life science segment? Oliver Bleher: The ASYS Group, in particular our companies ASYS TECTON and ASYS Prozess- und Reinraumtechnik, have been active in Life Science for years. Primarily we have supplied tray handling, tray loading, logistics, handling and cleanroom solutions. In the future, we will also be looking at assembly, packaging and laser marking in Life Science (pharma, diagnostics, medical devices, medical technology, etc.). We can exploit the synergies and many years of experience from other business segments where we have developed a lot of expertise that really drives our performance. Workpiece detection is one example, as shape and position detection play a major role when assembling medical devices. Dr. Harald Wanka: In Solar, detection solutions have been used extensively for many years, including solutions with cameras. Wafers are aligned accurately a number of times and print quality is constantly inspected within one metallization line. If necessary, the process is readjusted. These inspection solutions meet high demands in terms of line throughput and accuracy. They can therefore be transferred to other processes in electronics or even in Life Science with few adaptations. There are similar synergies, for example, with our laser processes. ASYS has been developing and producing laser systems for more than 15 years. A separate division, INVENTUS Laser, has now been established alongside our laser marking systems product division. The new division handles diverse materials and applies numerous material processing methods. Dr. Harald Wanka: The fact the we have been able to build up the INVENTUS Laser product division, i.e. customer-specific laser solutions, so quickly, is partly due to our successful experience in Solar. ASYS has supplied more than 100 solar lasers around the world. We are in a position to supply a solution for all the laser processes in solar cell production, including for new solar cell designs currently in transition from pilot production to line production. Oliver Bleher: In the Life Science industries, application and readout of codes is an important process step. The codes typically contain 2D or datamatrix codes, the serial numbers, expiration dates and/or track & trace functions. These are products where the smallest error can truly be a case of life or death. It has to be possible to trace the products all the way to the customer. Take pacemakers as an example. They have to be identifiable right down to the single components, so that it is possible to discover whether the error occurred along the production chain, in case of emergency. Markings are also important when it comes to preventing counterfeiting. Viagra is a good example. There is currently only one official manufacturer of the drug at the moment. However, there are a lot of counterfeits on the market, coming in particular from Asia. Protection against counterfeiting and the traceability of the logistics chain are challenges that can be solved by markings. Operating SMT production without clever systems for tracing electronic components is now unthinkable. What role does traceability play in Solar and Life Science? Oliver Bleher: A lot of work is done on traceability in Life Science. Traceability used to be a matter of paperwork. Electronic processes are now playing a bigger and bigger role. Batch numbers, batch sizes and expiration dates are applied in production, checked and recorded using appropriate systems and transferred via interfaces to line management. A keyword 35 Interview Life Science & Solar "We are very proud that almost 40% of the solar cells currently produced around the world run through ASYS systems." parity means that producing solar power is already more costeffective than conventional generation. We have now already passed that threshold in many regions of the world. This has been possible thanks to a massive reduction in production costs in the solar industry and because the processes for conventional energy production (such as fracking) are becoming more and more costly. Dr. Harald Wanka, Senior Vice President Technology in this area is definitely "CFR 21 Part 11", an FDA directive for electronic records and signatures that is designed to guarantee the accuracy and security of transferred data. Dr. Harald Wanka: Traceability plays a big role in solar for statistical production reasons. We supply a software and hardware solution for batch traceability, which is popular with our customers. It provides almost complete detection of the individual unmarked wafers. A cassette fitted with a transponder (RFID) is assigned to a batch. The wafers loaded to the line from the cassette are given an ID number. The number is applied virtually along the entire line. It is therefore possible at all times to find out where the applicable wafer is located on the metallization line. The art is to maintain batch integrity over approx. 40 meters of production line with a range of different buffers. Wafers can be traced almost 100% with our system. And that's why we're market-leading! What do the markets for Solar and Life Science look like? What experience do we have? Dr. Harald Wanka: The solar market that has grown at breakneck speed over the last 15 years is currently exposed to short-term, cyclical variation. The solar industry has developed in the same period from a niche supported by subsidy to a mature major industry. Around the globe, a little more than 50 gigawatts of production capacity (the total capacity of all modules that can be produced per year) is installed with the latest technical production methods and operational. Cumulatively, modules with output of around 170 gigawatts are installed. The driver for the industry is no longer state subsidy, but grid parity. Grid ASYS has supported the solar industry from the start and has developed consistently with the industry and is therefore the leading systems manufacturer globally in metallization – for the techniques and technology. Most of our customers in the solar industry are now based in Asia. We are very proud that almost 40% of the solar cells currently produced around the world run through ASYS systems. We are particularly pleased that the share of the market held by our new, technically advanced Alignus Dual-Lane line is continuing to rise. For new business, it currently has a market share of significantly above 50%. You might say that, if someone wants to expand or build an economically successful solar production system, ASYS is a guarantee that they will succeed. Oliver Bleher: The Asian market will also play a major role for us in Life Science in the medium term. We can benefit there from the strong ASYS sales and service network that has been built up massively for the solar market. Local support is particularly important for pharma. China is currently the largest growth market for medical and pharmaceutical products. As a result of internationalization and the growth in disposable income, the population's food consumption patterns are changing. Fastfood, for example, is growing very fast, so civilization diseases such as diabetes are also increasing fast, which is reflected in growing local demand for relevant medication. Production of pharmaceuticals is now also largely based in Asia, in particular when it comes to high-volume standard drugs, such as aspirin or Ibuprofen. The production costs are simply much lower in Asia. The costs of logistics also play a role, of course. But you are talking about fractions of a euro cent per tablet. APIs – active pharmaceutical ingredients – are produced to a large extent in India. Newly developed or highly complex products, however, are still largely produced in Europe or the US. Mr. Bleher, what challenges do you see for the Life Science segment? Dr. Wanka, can you round off by telling us what will happen in Solar? Oliver Bleher: The planning phases in this segment are very long. Projects run in some cases for 12 to 18 months before a decision. Approval of our customers' products by relevant authorities often takes a long time. So customers put off decisions on new systems for as long as possible. But then everything has to happen very quickly, so that production systems can be brought on line as soon as possible. The patent protection periods of our customers' products are limited and the return on the products falls dramatically once the patent has expired. So, the product has to be out for sale with no delay on the day of approval. There are also quite a few regulations that have to be followed and that requires a large volume of documentation. I can give you a few examples. There is the GMP (Good Manufacturing Practice) directive, which is designed to guarantee quality assurance for production processes; there are also several automation directives for pharma and other directives from the FDA (Food and Drug Administration), as well as the CRF (Code of Federal Regulations), in particular, as mentioned above, "CRF 21 Part 11". In general, materials and hygiene are important in the life science segment. That also means that specific qualification and validation documentation has to be supplied for each machine in the system. We are already well-placed with ASYS TECTON. We are currently looking more intensively for qualified employees for validation and qualification, so that we can serve our customers even better in this segment. Dr. Harald Wanka: We have a comprehensive technological solution for cost-effective solar cell production for all modern cell designs and we are constantly developing our solar products. The key question, however, is what direction the solar market will take in the long and medium term. Why should ASYS continue on this path when here in Germany, for example, we have seen one failure in the solar sector after another? Producers and systems manufacturers have been equally affected. ASYS has always been aware of the risk of market volatility and has acted to counter it with diversification. That is why we can wait calmly for the next major global upswing in solar power. We are very well prepared for it, in terms of technology, strategy and production engineering. The next solar wave will come, will be bigger and more powerful than everything we have seen so far, but will not be as steep as in 2010/2011. That sounds somewhat enthusiastic, and I would agree. Solar makes up 6% of the energy market in Germany, when averaged out, and is reaching a meaningful degree of saturation so slowly because of technical issues on the grid and general economic conditions. Overall energy consumption is also stagnating. But viewed globally, the situation looks very different. Still less than 1% of power is generated with solar technology and energy consumption per capita is increasing dramatically in the emerging markets and third world countries with constant growth in population. What enormous market potential! We therefore believe that the solar age has only really just started, viewed from a longer-term perspective. The interview was conducted by Katinka Eberl, Marketing/CI and Belma Gül, Marketing/CI. 37 ASYS Tecton Tray Handling & Transfer Systems Tray Handling & Transfer Systems New, Full-Surface Logistics Modules The PARIO machine series tray handling systems cover all applications, from the smallest trays to the Euro pallet. The PARIO 3000 high-end tray handling system provides the shortest possible tray changing times – in less than four seconds. Thanks to new extension packages, such as FDA conformity or ESD protection, and a modular basic design, the tray handling system can be adapted to any requirements. New full-surface logistics modules mean that all known tray formats can be processed, even trays with little stability. The system is also now easier to service and maintain – something TECTON values in particular. PARIO 3000 high-end tray handling system: for the shortest possible tray changing times ASYS Tecton - A Member of the ASYS Group The handling specialists, ASYS TECTON, have been developing and producing high-quality tray handling and transfer systems for more than 20 years. ASYS TECTON stands for highest quality, innovative and detailed product solutions and maximum efficiency. These properties have their roots in many years of experience and tradition of the company. For more than 20 years, ASYS TECTON has been partner of major companies in the Life Science, automotive and electronics industries. As part of the ASYS Group and its agile production network, TECTON is exceptionally flexible and innovative. The company supplies innovative handling and transfer systems that deliver maximum utilization with the shortest possible cycle times. The handling experts do much more than simply loading and unloading of products and trays. Full-service performance is a matter of course at TECTON, from joint creation of a performance specification through product-specific special design to inhouse tray development. MOTUS Transfer Systems – Infinitely Expandable As varied are the tasks, as different are the solutions from ASYS TECTON. Under the MOTUS product range, TECTON produces and sells highly efficient, modular and extremely space-saving transfer and puck systems for fully automated large scale assembly systems. The MOTUS transfer sections consist of standard modules, so even complex requirements, even in the smallest production areas, can be optimally implemented. All of the system's modules are available in FDA-certified design. PARIO 3000: New Interface for High-End Tray Handling System New User Interface with Innovative Control Logic In further developing the tray handling system, TECTON thinks not only of new technologies, but keeps the operator in mind. The system is monitored and controlled from a new user interface with innovative control logic. Until now, the operator had to identify the important data from a wealth of available information. SIMPLEX presents this information in a clear and context-sensitive manner. The unique SIMPLEX humanmachine interface (HMI) can control and monitor highly complex machines. ASYS TECTON is associated with the ASYS Technology Group, where the user interface has been successfully in use for more than several years. With SIMPLEX, TECTON has been able to develop the high-end tray handling system even further. SIMPLEX – the Operator Is the Focus It is clear from the first glance that the human operator and his needs are the focus. The SIMPLEX screen buttons are optimized for accelerated touch input and the requirements of a production environment. Clear hierarchies and intuitive operating procedures on multi-touch screens are distinct usability benefits for the user. Input panels that are static in conventional solutions behave dynamically in the SIMPLEX operating context. Strict color coding increases the ergonomics of operating the system and contributes to the prevention of errors. Visualization in 3D Thanks to 3D animation in real time, the production process can be monitored live on the terminal screen. The 3D visualization directly displays affected components or assemblies when needed. So faults can be located immediately and then quickly eliminated. 39 ASYS Cleanroom Technology ASYS Cleanroom Technology CONSIDUS Dry Storage – Innovation in dry storage technology The economical dry storage system from the CONSIDUS range offers optimum protection for highly sensitive components and assemblies. It is used when storage under defined conditions of humidity or active component drying is required. Karl Goll, Managing Director ASYS Prozess- und Reinraumtechnik Front top left to bottom right: Dynamic storage systems, economical dry storage systems, flexible cleanroom booths, custom cleanroom solutions 15 Years of Expertise in Process and Cleanroom Technology As an independent company within the ASYS Group, ASYS Prozess- und Reinraumtechnik has been developing and producing solutions for more than 15 years in cleanroom technology, laminar flow systems, dry storage systems, storage lift systems, and special solutions. The company constantly invests in research and development. The aim is to advance technology for the benefit of the customer. Customers include internationally recognized companies and research institutes from microelectronics, semiconductor manufacturing, precision engineering, optics, biotechnology and Life Science. New Solutions in the ASYS Group The ASYS group of companies supplies a globally unique product portfolio covering various fields of technology. Synergies between the ASYS Prozess- und Reinraumtechnik and ASYS TECTON companies, for example, produce a combination of modular transfer section and a cleanroom booth. The mobile cabinet can be positioned flexibly along the transfer section, with FDA approval of ASYS TECTON. It is therefore possible to work under constantly clean conditions. Versatile CONSIDUS can be used for a variety of storage products such as electronic components, partially assembled electronic modules, circuit boards, foils, wafers and components with oxidation-sensitive surfaces. Three different dehumidification technologies are available to achieve the stable and dry atmosphere in CONSIDUS Dry Storage: 1. Adsorption Dehumidification › Controlled drying and circulation of air with a powerful adsorption drier › Closed recirculation system with high air circulation rates. › Additional option of installing a heating module to heat the cabinet up to 40 °C for stress-free component drying. 2. Nitrogen Dehumidification Controlled supply of nitrogen. 3. Compressed-Air Dehumidification Controlled supply of compressed air. Storage and Active Drying in One System The CONSIDUS Dry Storage cabinet will be presented at the ASYS Group Technology Days in combination with a heating oven. The special feature in this case is that the oven can be integrated directly into the system and can reach temperatures of up to 125 °C. A heating oven is used to actively dry components whose floor life time has expired and can be operated inside or outside the cabinet, as the customer prefers. Compared to the heated storage cabinet, the heating oven can save a large amount of energy, as not all of the cabinet's storage shelves are heated, but only the specially insulated heating oven. Advantages at a Glance: › Innovative drying technology with adsorption dehumidification or nitrogen/compressed air flushing › Temperature and humidity regulation for economical drying › Achieves a target value of <3% relative humidity less than one minute after door has been closed › Allows humidity-sensitive components in accordance with IPC/JEDEC-STD-033 to be stored indefinitely › Modular cabinet design with useful equipment options, e.g. drawer slide › Custom and customer-specific dimensions and equipment is available 41 Legal Notice Event Website Publisher ASYS Automatisierungssysteme GmbH Benzstrasse 10, 89160 Dornstadt, Germany www.asys-group.com Managing Directors: Werner Kreibl & Klaus Mang www.asys.de/tt2014 Project Manager Karin Walter Editor Belma Gül Graphics & Layout Johanna Boos Interviews Katinka Eber & Belma Gül Authors Johanna Boos, Katinka Eberl, and Pamela Kurz Photography Michael Stajer Image source ASYS Group Other image sources Teamgeisselhart GmbH, Universität Ulm, Institut für Mess-, Regel- und Mikrotechnik, Fraunhofer IFAM Dresden, and iTAC Software AG Subject to change All the information provided consists of general descriptions and features that do not always apply in a specific use case in the way described here or which may change due to ongoing product development. Only the performance agreed in a contract is binding. Printed in Germany The images may include options, extras, accessories and other elements that are not part of the standard scope of delivery and services. These are available for an additional charge. © Copyright 2014 by ASYS GmbH, subject to technical modifications. Contacts Co-exhibitors and Hotel Reservation Press Planning and Coordination Nicole Egle Belma Gül Karin Walter Phone +49 7348 9855 190 Fax +49 7348 9855 93 E-mail nicole.egle@asys.de Phone +49 7348 9855 412 Fax +49 7348 9855 93 E-mail belma.guel@asys.de Phone +49 7348 9855 0 E-mail karin.walter@asys.de ASYS Automatisierungssysteme GmbH Benzstrasse 10, 89160 Dornstadt Germany Partners | Sponsors › ASYS Solar › ASYS TECTON GmbH › ASYS Prozess- und Reinraumtechnik GmbH › EKRA Automatisierungssysteme GmbH › BOTEST Systems GmbH Event Location › Christian Koenen GmbH › DEPRAG SCHULZ GmbH & Co. › FUJI Machine MFG. (Europe) GmbH › Heraeus Materials Technology GmbH & Co. KG › Jenaer Leiterplatten GmbH › KIRRON light components GmbH & Co. KG › KVT-Fastening GmbH › Limtronik GmbH › Multi-Components GmbH › Parmi Europe GmbH › RAFI GmbH & Co. KG › Rehm Thermal Systems › Stüwer GmbH › Viscom AG Head office Phone +49 (0) 7348 9855 00 Fax +49 (0) 7348 9855 91 E-mail info@asys.de B 10 Dornstadt exit Dornstadt A8 Stuttgart ASYS A8 Munich 43 Follow us www.asys.de/tt2014/en

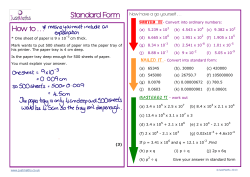

© Copyright 2025