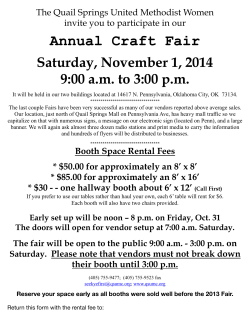

Advancing Technology Through Sample Preparation