ME 200 - HOMEWORK #8 – FALL 2014 8.1

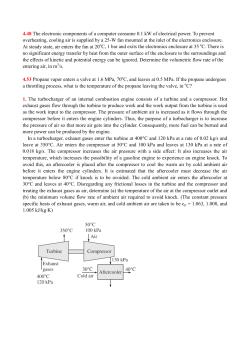

ME 200 - HOMEWORK #8 – FALL 2014 DUE: FRIDAY, NOVEMBER 14, 2014 8.1 Air at 300 kPa, 63oC, and a velocity of 423 m/s enters an insulated duct of varying cross-sectional area. The air exits at 150 kPa, 88oC. At the inlet, the cross-sectional area is 6.57 cm2. Assuming the ideal gas model for the air and variable specific heats, determine: (a) the exit velocity, in m/s, and (b) the rate of entropy production within the duct, in kW/K if the mass flow rate of air is 0.5 kg/s. 8.2 Steam at 550 lbf/in.2, 700oF enters a turbine operating at steady state and exits at 1 lbf/in.2. The turbine produces 500 hp. For the turbine, heat transfer is negligible as are kinetic and potential energy effects. (a) Determine the quality of the steam at the turbine exit, the mass flow rate, in lb/s, and the entropy production rate, in Btu/s.oR, if the turbine operates without internal irreversibilities. (b) Plot the mass flow rate, in lb/s, and the entropy production rate, in Btu/s.oR, for exit qualities ranging from the value calculated in part (a) to 1. 8.3 Air contained in a rigid, insulated tank fitted with a paddle wheel, initially at 4 bar, 40 oC and volume of 0.2 m3, is stirred until its temperature is 500 K. Assuming the ideal gas model for the air, determine the amount of entropy produced, in kJ/K. Assume variable specific heats (data from Table A-22). 8.4 Water initially exists as a saturated liquid at 186oC is contained in a piston-cylinder assembly. The water undergoes a process to the corresponding saturated vapor state, during which the piston moves freely in the cylinder. There is no heat transfer with the surroundings. If the change of state is brought about by the action of a paddle wheel, determine the net work per unit mass, in kJ/kg, and the amount of entropy produced per unit mass, in kJ/kg.K. 8.5 A 1.2-lb metal bar initially at 2100oR is removed from an oven and quenched by immersing it in a closed tank containing 28 lb of water initially at 620oR. Each substance can be modeled as incompressible. An appropriate constant specific heat value for the water is c w = 1.0 Btu/lb.oR, and an approximate value for the metal is cm = 0.1 Btu/lb.oR. Heat transfer from the tank contents can be neglected. Determine: (a) the final equilibrium temperature of the metal bar and the water, in oR (b) the amount of entropy produced, in Btu/oR 8.6 During steady-state operation, a gearbox receives 75 kW through the input shaft and delivers power through the output shaft. For the gearbox as the system, the rate of heat transfer by convection is Q = - hA(Tb – Tf), where h = 0.171 kW/m2.K is the convective heat transfer coefficient. A = 1.6 m2 is the outer surface area of the gearbox, Tb = 310 K (37oC) is the temperature at the outer surface, and Tf = 298 K (25oC) is the temperature of the surrounding air away from the immediate vicinity of the gearbox. (a) Evaluate the rate of entropy production, in kW/K for the gearbox (b) Evaluate the rate of entropy production (in kW/K) for an enlarged system consisting of the gearbox and enough of its surroundings that heat transfer occurs at the temperature of the surroundings away from the vicinity of the gearbox, Tf = 298K (25oC) 8.7 Consider an adiabatic mixing chamber operating at steady state into which steam enters with quality of 0.9. Water enters through a separate inlet at 300C. At the exit the temperature is 1500C and mass flow rate is 2 kg/s. The pressure in the mixing chamber is 800 kPa. Determine the entropy production for the mixing process, in kW/K. 8.8 Air enters the evaporator section of an air-conditioner at 100 kPa, 27oC with a volumetric flow rate of 6 m3/min. R-134a enters the evaporator at 120 kPa with a quality of 0.3 and rate of 2 kg/min and it leaves as a saturated vapor at the same pressure. Determine (a) the exit temperature of the air (oC) and (b) the rate of entropy production (kW/K) for the process in two ways: (i) Assume the outer surface of the evaporator is insulated. (ii) Assume the outer surface is not insulated and heat is transferred from the surrounding medium which is at 32oC to the evaporator at a rate of 30 kJ/min. Air at 100 kPa, 27oC Sat. vapor R-134a, 120 kPa, x = 0.3 Air

© Copyright 2024