Document 47249

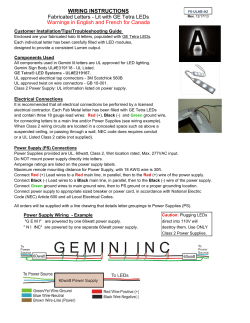

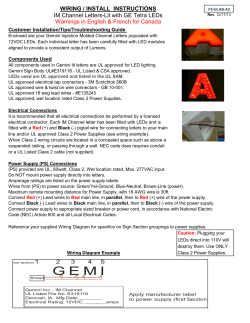

the new engineering contract USERS’ GROUP newsletter I S S U E N o . 1 5 • O C T O B E R 2 0 0 0 NEC Partnering Agreement now available by Martin Barnes, NEC Panel The NEC Panel has produced for consultation a simple new Partnering Agreement to link parties in one or more NEC-procured construction projects in a comprehensive partnering relationship. It is designed as an ‘umbrella’ agreement to be used alongside conventional NEC contracts, providing everything needed to create a full partnering process and culture around the designers, contractors, subcontractors and suppliers as well as the client and other key stakeholders. The original NEC contracts were designed to stimulate collaborative working between any two parties in a single project but this was some years before the modern concept of partnering was defined and then promoted by the Egan report Rethinking construction. However, because so much of what a partnering contract requires is already in the basic NEC contracts, the new agreement is very short and straightforward. It has been prepared in consultation with experts and is fully compatible with existing NEC standard contracts. The content is derived from the guide to project team partnering published by the Construction Industry Council (CIC). All requirements of the CIC document not already in the NEC bi-party contracts are covered. Going further than the CIC proposals, it allows for both multi-project and single-project partnering and enables the composition of the partnering team to be changed from time to time as projects evolve. C O N T E N T S ECC adapted by Yorkshire Water 2 Chairman’s message 3 Housing trust uses ECC 4 Using the target-cost option 4 ICE procedures questioned 6 Common problems 6 NEC diary 8 NEC USERS’ GROUP NEWSLETTER•No.15•OCTOBER 2000 What it contains The agreement follows the normal NEC structure in that it is made up of clauses, data and information but does not have options, as these are unnecessary. It does not duplicate provisions of the appropriate existing contracts in the NEC family, which should continue to be used for the individual contracts. The agreement includes agreements for joint pursuit of objectives, for working towards achievement of key performance indicators and for the work of the partners to be monitored by a core group of managers from the principal members of the team - all as recommended by the CIC. The most important performance indicator is perhaps achievement of the client’s objective. This is the objective for ‘the programme of projects’, if more than one, or for ‘the project’ if only one. The objective should be expressed quantitatively if possible (the business case) and should also include the partnering objectives. Just like works information in the Engineering and Construction Contract, the agreement includes partnering information. This comprises project-specific requirements for such things as ● use of common information systems, sharing of offices ● attendance at partners’ and core group meetings ● participation in partnering workshops ● arrangements for joint design development ● value engineering and value management ● risk management. How it can be used The document is intended to be used as a multiparty agreement supplementing the bi-party NEC contract which each party has with the body paying for its work. The parties to the agreement should be all the bodies that are intended to make up the project team. The agreement is given legal effect by including it in all appropriate bi-party contracts by means of an additional clause (for example as option X12 in the ECC). It is not a free-standing contract but a part of each bi-party contract that is common to all contracts in a project team. Because organisations will join the team at different times, the agreement does not have Wilmott Dixon, Chairman Sir Michael Latham unveils palque at Priory Court housing development in London – another ECC success (page 4) a date but an identifying number reference instead. The underlying bi-party NEC contract will be for a contribution as contractor or consultant, the work content of which is sufficiently defined to permit a conventional NEC contract to be signed. In the early stages, for example, it may be desirable to appoint a contractor on the Professional Services Contract with the partnering agreement to cover the contractor’s upfront advisory role before any physical work can be defined. An ECC can be substituted later. Similarly, many team members may have to be appointed under a time-based payment option in the early stages until the partners have worked out exactly what work has to be done and can make a price commitment to it. As with all NEC documents, the agreement is intended to have wide-ranging application. It can be used internationally, for projects of any technical composition and as far down the supply chain as required. It is also intended that the agreement should work with both common law and civil law systems and that it should be compliant with EU procurement regulations. It should prove to be a very effective and useful addition to the NEC family. Copies of the agreement can be obtained from John Hawkins at the ICE on 020 7665 2217 or john.hawkins@ice.org.uk ● 1 Yorkshire Water adapts ECC to suit rolling programme Graph showing how risk is narrowed during the three sections of each scheme By Richard Patterson, Mott MacDonald Yorkshire Water Services (YWS) has successfully used a simply modified version of the NEC Engineering and Construction Contract (ECC) to allow new parcels of a programme of work – from feasibility studies to construction at different sites – to be let on a reimbursable, lump sum or target-cost basis within a single contract. As part of its second asset management plan (AMP2) programme, YWS is upgrading service reservoirs at some 60 sites throughout Yorkshire. The company wanted to have feasibility studies and resulting new-build or refurbishment works procured by an ‘entity’ with single-point responsibility. In this respect the project was a test of the company’s plan to let the whole AMP3 programme to a series of contractor-consultant teams. Final details of each scheme would only be known as the feasibility studies carried out under the contract were completed. The client thus needed a form of contract that was flexible enough to deal with both the feasibility studies and the resulting construction work. It also wanted to use the knowledge and skills of the framework contractors and consultants with which it had been working for 3 years and, most importantly, to facilitate an early start and rapid delivery of the project. Procurement process The client selected three of its framework consultants with reservoir experience: RKL-Arup, EarthTech and my firm Mott MacDonald. Each consultant was asked to approach contractors to form three teams, each of which was assigned to one of three geographical regions in Yorkshire. We chose to work with Taylor Woodrow (TWC) and regional contractor J N Bentley (see chart). Structure chart of one of the three contractor/consultant teams ● each section could be reimbursable, target-cost or lump sum. In addition ● ‘actual cost’ was redefined ● there was no ‘work’ to be priced at tender. The client’s main driver initially was to award a contract and begin building the team. Each consultant and contractor had a track record with the client and costs could be benchmarked against previous schemes. For this reason the client was able to invite tenders based on rates only. At the time of the tender there was no identified work to price and the contract became known by the implementation team as the ‘hollow’ contract. Projects divided into three sections Within the same contract, new sub-projects were added as new sections of the works, with separate sections at each site for ● feasibility ● defining the works sufficiently to price them ● detailed design and construction. This allowed sensible risk management with cost and time control and the need for employer authorisation before the commencement of each phase. The process is illustrated in the flow chart. Flow chart showing the authorisation process for each scheme Define problem Proposed compensation event for feasibility (reimbursable) Forecast acceptable Yes Carry out feasibility. Proposed compensation event for outline design (reimbursable) The consultants were asked to develop jointly a tender document reflecting our requirements. This work was co-ordinated by the contract advisors from each firm who, thanks to their role in the contracts task force within the framework, were already accustomed to working together. Mott MacDonald was responsible specifically for the modifications to the ECC conditions and the payment mechanism and Ove Arup led the preparation of the works information. The result was an identical tender document put out to the three contractor/consultant teams for three separate contracts, one for each area. The document was reviewed and ‘challenged’ by a fourth consultant, Montgomery Watson, which also carried out tender evaluations and subsequently audited the implementation of the contracts. Innovations with the ECC The principle when modifying any form of contract should be to work within its structure rather than to add to it. The clear and structured provisions of the NEC were used as far as possible and amended as little as possible. The best innovations are often the simplest. The key innovations with the ECC were ● treatment of work at new sites as new sections, each introduced as a compensation event 2 Forecast acceptable No Yes Carry out outline design. Proposed compensation event for detailed design and construction (large or lump sum) Target (or lump sum) acceptable ● on a new site ● with new site information ● as a new section. This new power was constrained by the requirement for specific authorisation by the employer. The fact that the work was identified as a new section automatically allowed data, such as completion dates and key people for that section, to be introduced. Selection and extension of the ECC’s secondary option L (sectional completion) allowed the ECC’s inherent procedures for dealing with sections to be automatically applied. Contract data items, specific to the section, were included in an ‘Appendix to Contract Data’ for each section. Perhaps most importantly, the new section was treated as a compensation event, the ECC’s mechanism for dealing with employer-initiated change and events at the employer’s risk. This automatically allowed and forced the use of the procedures for notifying, quoting for and implementing change that are key to the ECC. The works information at tender was generic in nature with specifics for each site introduced with the instructions for each new section. In this way the client was able to go to tender and sign contracts before the work was defined. Reimbursable, target and lump sum options No employer should make appropriate provision for them. Under the ECC, the project manager has the power to instruct a change to the works information. The required additional flexibility was achieved merely by extending the power of the project manager to introduce work Negotiate revise requirements or cancel scheme or, possibly, seek quotation from alternative team No Yes Carry out detailed design and construction The gradual effect of narrowing the necessary risk allowances in the cost estimates for construction at various stages is illustrated in the graph. At the time of setting the ‘total of the prices’ (the target-cost), risk must be discussed openly with those risks carried by the contractor included within the total. Those carried by the employer are outwith the target-cost but the The ECC is an excellent risk management tool allowing through its ‘main options’ for a contract to be let on either a reimbursable, remeasurement, target-cost or lump sum basis. However, without modification, all the works under a contract have to be under the same main option. For the service reservoirs contract, sensible risk management dictated that some sections should be reimbursable, some target-cost and others lump sum. The ECC option C (target contract with activity schedule) provides for interim payment based on a defined actual cost. Pre-defined share percentages set out the pain/gain mechanism to determine the contractor’s share – the share of any saving or overspend compared with the target. The flexibility of allowing individual sections to be effectively either reimbursable, target-cost or lump sum, was achieved simply by adopting the ECC option C, but defining the share percentages separately for each section. For each section, the share percentages could be either ● set at 0% to represent a reimbursable contract ● set at 100% to represent a lump sum contract ● set to achieve a true target-cost basis. The project manager, in consultation with the employer and the contractor, determined the appropriate option for each section. The corresponding share percentages were set, along with other section-specific information, in the appendix to contract. Redefining actual cost The ECC’s definition of actual cost was changed to tendered rates for resources. At the time of tender, the NEC USERS’ GROUP NEWSLETTER•No.15•OCTOBER 2000 volume of work to be carried out was not fixed so proposals and rates were included for the establishment and maintenance of the core team and its facilities and accommodation needed to manage the programme. This was based on the best estimate of the volume of work. On award, the first section of the works was to provide the core team and those facilities. The contractor was required to employ a stated framework consultant at stated rates. For all sections, the total of the prices was built up as the forecast actual cost as is the standard requirement for all compensation events with the ECC. As actual cost had been redefined as the tendered rates, it was these rates that were used to build up each quotation. Similarly, it was the redefined actual cost that was paid in interim payments and ultimately compared with the accepted quotation to determine any share at completion of each section. The contractor was required to code its actual costs separately to each section. Implementation and progress The nature of the works and the contract necessitated the establishment of a core team consisting of ● three staff from the contractor ● three full-time staff from our firm, supported by specialist resources including designers, planners and estimators. A series of key performance indicators was developed, allowing benchmarking by the auditing consultant with time and between teams. As part of the framework, the teams met regularly to share lessons learnt. The success of the project, the procurement route and the team is evidenced by the fact that ● 78 new sections have been introduced covering work on 26 sites ● of these, 20 were refurbishments and six were newbuild reservoirs ● the £3 million spent to date has been considerably under the employer’s budget for the works ● £1 million of additional new schemes has been allocated to the team. The contract included a dispute resolution ladder preceding adjudication, but there were no disputes. Lessons learnt The relatively simple modifications to the already flexible ECC successfully enabled the delivery of a varied programme of design and construction services. As ever there were lessons to be learnt. The need at tender for rates to allow comparisons to be made meant there was an inevitable gap between the ‘defined’ costs for which the contractor was paid and the ‘real’ costs seen through its management accounts. For the extended relationship facilitated by the contract, there may have been advantages in defining actual cost better to match the contractor’s real costs so that all the team could focus on a single stream of costs and on reducing those costs. A recently closed PFI contract in the health sector, with which we have been involved, used the NEC throughout for design and construction. The actual cost was redefined to be as the ‘contractor’s standard costing system’, after those systems had been audited by the client’s advisors. However, some defined and tendered actual cost is often required to allow meaningful competition. Various writers have stressed the need for adequate training for staff from all parties that are new to the ECC. When the structure of the contract is augmented in any way, additional training is required. With the benefit of hindsight, more training for staff on the innovations described here would have shortened the learning curve and been a worthwhile investment. The flexibility and structure of the ECC allowed the desired procurement strategy to be implemented; in no way did the ECC dictate strategy. The ECC is a contract for any project and is not limited to a particular discipline. We have already adapted the model for situations where some parts of the project can be identified and priced at tender and this has found favour with a number of our clients in sectors as diverse as water supply, wastewater and bridge repairs. It meets a common need to roll out a programme of work when, at the start, only a portion of the requirements is known in detail. Reimbursable payment, up to a point when a target contract price can be agreed, is a common scenario for novel and complex projects, especially when a rapid start is required. This has been facilitated using heavily modified IChemE ‘Green Book’ conditions, but the modified NEC model described here can also be adopted for such an approach. Outline design could be included as a reimbursable section awarded at tender. The subsequent target-cost section would be awarded only once an acceptable target-cost had been developed. The various stepwise innovations have other possible uses. The notion of different share percentages applying to different sections might facilitate sensible risk management under the same contract when different parts of a project would be best procured on a reimbursable, target or lump sum basis. The NEC can, once properly understood and in safe hands, be used or adapted to suit a client’s needs. It is more flexible than perhaps even its authors imagined. A more detailed version of this article will be published in the February 2001 issue of the ICE Civil Engineering journal. For further information please the author can be contacted on 01223 463606 or rlp@mm-camb.mottmac.com. ● Message from Users’ Group chairman By Graham Clarkson, NEC Users’ Group chairman Following my introduction as the new chairman of the NEC Users’ Group at this summer’s workshop, I would like to start by thanking my two predecessors David Williams of BAA and Richard Bliss at London Underground Limited for establishing the role and providing guidance to the group over the last few years. When Richard approached me earlier in the year about taking on the role I was a little unclear as to the aims and objectives of our group, which is, after all, run by us as users for our benefit. I was also unclear on how we interface with the NEC Panel, Thomas Telford Publishing and the ICE in the promotion and development of the suite of contracts through Haro Bedelian. As a result I proposed a set of aims and objectives at the summer workshop, on which I have received some feedback - albeit limited! I presume that on the basis of your response you are generally in agreement with our aims and objectives, which I thus set out as follows. ● Organise forums to bring NEC users together to exchange information and experience on the use of the NEC. ● Provide a regular newsletter which advises members of NEC developments and through which members can communicate information on their usage of the NEC. ● Provide a helpline facility to answer members’ questions. ● Provide free or discounted access for members to a range of NEC products and services. ● Act as a conduit whereby the views of members can be passed to the NEC Panel and vice versa. ● Provide presentations on the NEC for new or prospective users and consultancy services for existing users. ● Receive feedback from its members on their experience of using the NEC to enable continuous improvements to be made to the suite of contracts. ● Share ‘best practice’ on the use and application of the contracts within the NEC suite. The aims and objectives provide the framework in which the chairman can act. I thus believe my role is to ● act as a figurehead in representing the users in appropriate forums ● act as chairman in formal NEC Users’ Group seminars and workshops ● act as a liaison point between the Users’ Group and the NEC Panel on issues as they affect group members and the general development of the NEC ● provide an input into Thomas Telford on how the Users’ Group is run and managed and the services it provides ● promote where possible the wider use of the NEC. In respect of the last duty in the above list I have been actively involved since my appointment in June, through my project management organisation, on introducing the suite of contracts to a number of employers. For example, we are now using the Short Contract on a construction management procurement route on a new £6 million health and leisure club for Holmes Place plc. We have also introduced the Professional Services Contract to the directorate of estates and facilities management of Oxford Brookes University, which proposes to use option A for the appointment of consultants on its projects. This will bring about greater clarity and transparency with regards to the employment of its professional team. I am keen to broaden the level of promotion and would welcome the opportunity to talk to any other users who may need support in converting potential users. Changes in the engineering and construction industries are abound these days, which all help in breaking down traditional barriers and encouraging customers and their suppliers to look at ways of improving the process of delivering new facilities. I therefore look forward to working with members of the Users’ Group and acting as your figurehead over the next two years. Possible future applications The YWS service reservoirs project was a typical programme of works but procured in an innovative way that encouraged co-operation and continuous improvement. NEC USERS’ GROUP NEWSLETTER•No.15•OCTOBER 2000 For further information the author can be contacted at gclarkson@gdgmanagement.co.uk. ● 3 When and how to use the target-cost options Two of the main options of the NEC Engineering and Construction Contract (ECC) are the ‘target-cost’ options option C: target contract with activity schedule option D: target contract with bill of quantities. Target cost contracts are a development of costreimbursable contracts - option E of the ECC - where the contractor is reimbursed its costs plus a fee. The fee in the ECC is expressed as a percentage of actual costs and therefore covers anything not defined in the contract as actual cost. The development from cost-reimbursable contracts is that any cost over-run or under-run compared with the target is split in pre-agreed proportions. The principal difference between the two target-cost options is how the target is broken down at tender - either using activity schedules or bills of quantities. Whichever option is chosen, the contractor is reimbursed its actual costs plus fee as the contract progresses. When to use target-cost contracts Target-cost contracts are traditionally used in less extreme circumstances to pure cost-reimbursable contracts, such as in the following situations. ● When time or quality is more of a priority than minimum cost. This is because any cost under-run or over-run is shared and therefore affects the contractor’s profit less compared with a pricebased contract, so he is less motivated to concentrate on minimising cost. An example of this in construction could be on a prestige office block in a city: the works would be time and costdriven and, while the scope has to be sufficiently developed for the target to be agreed, details will change as construction proceeds. ● When there is a relatively high amount of unquantifiable risk: it simply is not known how much risk is involved. For instance, early contracts in the North Sea were let as cost-reimbursable contracts. As conditions became known and the technology developed, these contracts briefly became target contracts before becoming fixed-price contracts; ● When there is a relatively high risk, where the contractor may be best-placed to manage the risk, but not to carry it. The contractor would therefore include a high-risk premium in a pricebased contract. Some employers would be unwilling to pay this premium for risk that may not happen, recognising that in the long term they are obtaining poor value for money. Further, if the risk occurs, the risk premium would not cover the financial effects, leading to confrontation rather than good management of the risk. Therefore, the risk is shared in order reduce the 4 amount of risk premium the employer would otherwise pay. Various research projects up to the mid 1980s found two other benefits from using target-cost contracts. ● Providing good financial administration procedures were in place, then the open-book accounting procedure gave transparency of costs, which in turn led to openness in other areas. ● A higher degree of co-operation appeared to be present when compared with price-based contracts. This is due to the alignment of motivations from sharing of risk and reward. Unlike in a priced based contract, it is directly in the employer’s interests to contribute to cost reductions as he gains some of the benefit. More recently, with the rise of partnering, targetcost contracts have been used specifically because of these benefits. Usually, it is a combination of these factors that leads to their adoption. Having decided to use a target-cost contract, what are the key implementation points? Ensure the target is realistic The first is to make sure the target is realistic and both parties agree which risks are included in the target and what allowances are made for them. Past literature consistently states that it is important for the employer to evaluate and be satisfied with the realism of the target. If it is too low, then the contractor will be losing money from the outset and, rather than concentrating his efforts on decreasing costs, may turn his attention to increasing the target. If the target is too high, then the employer may feel aggrieved and stop co-operating. A comparatively new phenomenon is the holding of joint risk-management workshops prior to signing of the contract and / or employers asking how much the prices (in ECC terminology), be it on a price-based or target-cost contract, will increase if a specific risk is included within the prices. If the amount of the risk allowance and what it is specifically for are not understood, then it can lead to a deterioration in relationships once into the contract. Set share fractions with care Different share fractions for different degrees of cost over and under run combine to form a share profile for a particular contract. This share profile both affects the amount of risk premium included within the target and the motivations during the contract should a particular circumstance appear. It is worthwhile noting that the share fraction ● need not be split 50 : 50 ● need not be linear. By Jon Broome, University of Birmingham / JB Project Consulting Ltd For example, some employers take a much higher share of significant cost over-runs, while others tend the other way, including capping their commitment above a pre-determined over-run. These are somewhat misleadingly known as guaranteed maximum price contracts. Unfortunately for practitioners, there is currently no detailed guidance on this aspect, although some will be published by the author in late 2001. Greater employer involvement Greater involvement from the employer at a managerial level should be encouraged both during the construction and detailed design, if the contractor is primarily responsible for it. This is because the employer will be working together making decisions that trade time, cost and quality off with each other. It could be argued that if the contractor is not given any leeway to reduce costs in the design phase and the employer can contribute nothing to decreasing costs in the design (e.g. through taking part in value engineering exercises) and / or in the design construction phases (e.g. through helping gain early access to a working area), then it may be more appropriate to adopt a lump-sum approach. Operate a good financial administration system Robust, transparent and efficient financial administration systems are needed. Reports up to the early 1980s found that more time was needed to administrate cost-based contracts. With the advent of information technology, this can be much reduced, but it does take time for the parties to familiarise themselves with each other’s systems. However, numerous benefits flow from having such a system in place at the start of the contract. These include the following. ● The time taken to account for and agree what actual costs have been incurred on the contract is much reduced. ● Monitoring is much improved with, in some cases, planned progress and costs being compared with actual progress and costs on weekly basis. This leads to rapid intervention and correction of the root causes if a divergence starts to occur. ● The transparency aids the quick and amicable agreement of any adjustments to the target / prices due to compensation events. ● Risk allowances and base costs can separated. Risk management techniques can be jointly applied to the risk element and value engineering techniques to the base costs. In short, a good financial system administrated by good people can dramatically increase the benefits which both parties can gain from the use of targetcost contracts. NEC USERS’ GROUP NEWSLETTER•No.15•OCTOBER 2000 Don’t ignore ‘cultural’ issues As with ‘partnering’ generally and use of the NEC family of contracts, cultural and skills issues need to be addressed. It is not worthwhile doing something different unless people know and understand why it is different, so they have reasons for doing their ‘thing’ differently! Communication, training and involvement are key. In summary, target-cost contracts are suitable for use when time and quality are a greater priority compared with cost; when the contract contains higher than normal amounts of risk; and as the contractual framework which underpins partnering, both because of the manner in which objectives are aligned and the transparency and openness they engender. However, more time and thought is needed to set them up right - to evaluate the realism of the target, to set the share profile intelligently and to set up and establish the financial administration system. More employer involvement is also required during the contract. For this reason, they may not be worthwhile on small one-off projects. The advantages that flow from setting up the contract correctly can include ● a more pleasant working environment as both parties have the financial motivation to work together rather than against each other ● reduced overall project costs for the employer and increased profit to the contractor ● greater certainty and knowledge of the outcome at any point in the contract for both parties ● more rapid agreement of final account. The benefits are ones that the NEC family of documents tries to promote whatever contract or option is chosen through its clauses and procedures. Targetcost contracts add in the aligned motivations and transparency, which is why more experienced NEC users have progressively used them more and more. For more information, the author can be contacted on 07970 428 929 or via www.jb-projectconsulting.co.uk. ● Housing trust puts faith in NEC shared between the contracting parties. On the We recently used the NEC Engineering and Construction Contract (ECC) option C (target contract Priory Court project, significant savings have been made which have been reinvested to enhance the with activity schedule) for a £14 million refurbishoverall environment of the estate. This has clearly ment and new-build project at Priory Court, a been very much welcomed by the residents. London Borough of Waltham Forest 600-unit estate at Walthamstow, east London. We chose contractor Willmott Dixon, wholly on non-cost criteria, to be our project partner. ECC option C chosen for the £14 million From a client’s standpoint the NEC Priory Court housing project contract works much better than more traditional contracts such as JCT. It worked particularly well on Priory Court, and on the other projects in which Willmott Dixon are engaged with us, because of the nature of the working relationship we have developed with the company. This relationship has actually led to what we believe is the UK’s first strategic partnership between a housing trust and a contractor. The result of the approach is that both parties are completely open with each other on costs, together with the underlying assumptions being made to reach the cost build ups. As a consequence we both know what risks are being entered into and can manage the project together so much more effectively and efficiently. Payments based on activity NEC savings reinvested The NEC lends itself very well to the partnering approach because, amongst other things, it allows the allocation of risk to be varied. This is very important because it means we can take on more risk as a client, which I believe enables costs to be reduced. Under more traditional forms of contract we paid heavily for the contractor to take more of the risk. Another big advantage, which also supports the partnering approach, is the construction share provisions which allow savings, and overruns, to be NEC USERS’ GROUP NEWSLETTER•No.15•OCTOBER 2000 The main issue we faced with the ECC option C was the payment method, which didn’t really work. The form of contract requires actual costs to be paid on a monthly basis, but by the time costs are accounted for and invoiced, months can pass by which creates cash-flow difficulties for both the contractor and the sub-contractors. We have overcome this by paying against activity levels on a monthly basis. However, to ensure that actual costs are properly monitored and controlled, the contractor is obliged to track and report actual costs on an ongoing basis. By Graham Watson, Circle 33 The contractor finds the NEC requires much more work in administration than more traditional contracts - mainly because it calls for a complete re-working of the programme after each and every compensation event (client variation) with an obligation to report the revised cost and completion timing implications. This is a workload issue for the contractor and many sub-contractors are just beginning to gear up for the administrative requirements. A charter for partnering However, the contractor has found the NEC’s plain and simple language more user-friendly than traditional contracts such as JCT. It is also seen as more flexible, allowing use on many types of projects and, following the Egan principles for partnering throughout the supply chain, provides a family of contracts which also cover subcontractors and consultants. Supporting the projects we have undertaken with the contractor has been the development of a separate partnering charter which is jointly agreed and which lays out clearly the obligations of each party throughout the project. A special pre-construction agreement is also used on each project to identify all the activities and costs prior to start on site. Both documents are filed as an addendum to the formal contract. At the end of the day, because of the excellent working relationship we enjoy with Willmott Dixon and the positive attitude both sides bring to the table as a result of this, the form of contract has been a less important factor in the success of the projects on which we have worked with them. For more information, please contact the author on 0207 4473023 or Garry Hague at Willmott Dixon on 01462 671852. ● 5 ECC a review of frequent problems the situation that exists. The main contractor will include a subcontract price, inclusive of the subcontractor’s fee, and then apply its own fee percentage in addition. It should naturally follow that this also extends to compensation events, especially as this situation could already prevail if clause 63.9 is effected (agreements to use bills of quantities pricing in lieu of the schedule of cost components). The Institution of Civil Engineering Surveyors’ (ICES) commercial management practices committee recently decided to ask ICES members whether the NEC Engineering and Construction Contract (ECC) was fulfilling its stated aims and objectives. In advance of a questionnaire being sent to ICES members, an article was published in the institution’s journal Civil Engineering Surveyor highlighting six key problems that seemed to be common among ECC users. For the benefit of Users’ Group members, these are repeated here. Equipment charges for internally owned equipment Use of the term ‘Actual Cost’ The term ‘Actual Cost’, especially to those first using the ECC, can and does cause confusion because it is, quite naturally, aligned to the generally understood meaning of this phrase as representing the contractor’s actual cost (i.e. those costs which its internal reporting systems state that it has incurred on any particular project). However, ‘Actual Cost’ should be seen as no more than a defined term used in the contract in exactly the same way as other defined terms are used, for example a ‘Defect’ or the ‘Accepted Programme’. A scrutiny of the definition of ‘Actual Cost’ will show that the extent of this term is determined by the very detailed statements within the schedule of cost components, not all of which would constitute the normal understanding of actual cost. For instance ● rates for the contractor’s own equipment may not be the same as its own internal plant company charges the site ● overhead recovery (‘Working Area Overheads’) is normally made on a percentage basis in relation to the cost of ‘People’ - depending on the level of that percentage quoted by the contractor at time of tender, more or less recovery than actual cost may be achieved. The NEC Users’ Group has debated the use of an alternative terminology to ‘Actual Cost’ in an attempt to avoid the confusion. No firm conclusions have been reached, and I am sure the NEC Panel would welcome further suggestions from members. Different meaning of ‘Actual Cost’ within main options To compound the problem of the meaning of ‘Actual Cost’, the term also has different meanings within the various ECC main options. There are three definitions used within the options ● conventional contract (options A & B) ● target-cost / cost-reimbursable (options C, D & E) ● management contract (option F). While it is logical to have a different definition for option F, that same logic does not, and should not in 6 By Alan Bates, Carillion Engineering and Construction and ICES Project Management Committee my opinion apply to the other two categories. For those not familiar with the problem, the difference lies in the treatment of subcontractor charges and the resultant application of the fee percentage. Under options A and B, subcontracting is effectively not recognised and the subcontractor resources are dealt with in exactly the same way as the contractor’s under the definition of ‘People’. The contractor’s fee percentage is then added to this combined total. What this means in practice is that the contractor then passes to the subcontractor the relevant portion of the ‘net’ cost as per the schedule of cost components plus the subcontractor’s fee percentage which can only be paid out of the contractor’s fee. The consequence of the mechanism is that, at time of tender, the contractor has to second guess ● the predicted value of the compensation events for the whole of the contract ● which subcontract trades those compensation events will affect ● the level of the various subcontractors’ fee percentages. From these three assessments the contractor must then attempt to compile a weighted fee percentage that will be sufficient to satisfy its subcontractor’s requirements and also provide a mark up for itself. Such guesswork and risk should, I believe, play no part in a form of contract that purports to compensate the contractor fairly and in accordance with the rules of common law in the event that a compensation event arises. By contrast, under options C, D and E, the contractor is paid the full subcontractor’s account (which includes that subcontractor’s fee) plus its own fee It has been argued that the system under options A and B has been put in place to avoid the ‘fee on fee’ situation. However, within the pricing of the bills of quantities or activity schedules, this is precisely Equipment charges for internally owned equipment are set out at clause 22 of the schedule of cost components. While the principle behind the provisions is designed to prevent the contractor from gaining two mark ups - one for the internal plant company and the other through the fee percentage - the details that have to be produced are extensive. Taken to extremes the contractor would have to produce a calculation for every pump, compressor and dumper on site, giving rise to a variety of rates for similar items simply because of their age, initial purchase price and current condition. In my experience the terms of clause 22 have never been strictly followed and the parties have always agreed a schedule of plant rates, either based on some form of published list or by reference to market prices. If this situation is common throughout the industry then there is some justification for the NEC Panel to have a re-think on how contractors’ internal equipment should be realistically charged to the project. Agreeing the value of compensation events Irrespective of which main option is used, the underlying principle is that compensation events (CEs) should ● be evaluated and agreed before any work on the CE is undertaken or the contractor incurs any costs in relation to the CE ● not be revisited to adjust the agreed value once the actual circumstances and costs are known. There are exceptions, but the general rule is as stated above. From the contractor’s point of view it is therefore important to include, if any, the consequential delay, disruption and increased risk costs within the evaluation of the CE. Human nature being what it is, there will inevitably be differences of opinion as to the level of these allowances to be included. The unfortunate outcome being that CEs tend not to be agreed at the time and mount up to be addressed after the event, sometimes in a typical claims-type forum which the ECC so desperately tries to avoid. I believe that such a situation is not fundamentally the fault of the drafting of the ECC, but arises through different perceptions that both parties will NEC USERS’ GROUP NEWSLETTER•No.15•OCTOBER 2000 have of the ‘indirect’ costs. This situation will only get better as the parties become more familiar with the form of contract and with each other in the ongoing development of the ‘mutual trust and cooperation’ philosophy. Cash-flow problems – options C and D Under clause 11.2 (23) the contractor receives the ‘Actual Cost‘ ‘which the contractor has paid’. This indicates that the contractor must have paid out for all the resources used in the month prior to being eligible to submit an application for payment. Thus the contractor will always be in a negative cash flow situation (not accounting for the fee). The application of retention also exacerbates the problem. It is acknowledged that financing charges form a legitimate part of reimbursement under the schedule of cost components but, in contractor organisations, financing is usually provided for and controlled centrally and is not normally allocated to individual projects other than perhaps on some notional basis. Thus it is usually impossible for contractors to conclusively demonstrate the actual cost of finance on a project by project basis with the result that no recompense is generally made. A simple solution to the problem would be to pay the contractor for projected liabilities to the extent that a neutral cash position is generated -a forward projection of some 2-3 weeks beyond the month end should suffice. Option B – are the quantities remeasurable? The answer to whether quantities are remeasurable under option B will obviously depend on any specific statements regarding the status of the bills of quantities within any project. Assuming that no such statements are made then the normal ECC provisions apply. Clauses 60.4 to 60.6 detail circumstances where a change in quantities shown in the bills of quantities may become a compensation event. It should be noted that there is no ‘carte blanche’ authority for remeasurement as, for example, under the ICE Conditions of Contract (clause 56 (1)). However, if reference is made to the definition of the ‘Price for Work Done to Date’ (clause 11.2 (25)) it will be seen that payment is made for ‘the quantity of work that the contractor has completed” indicating that payment is made against actual, as opposed to bills of quantities, quantities - that is a remeasured contract. This is especially so when the phrase under clause 11.2 (21) ‘unless later changed in accordance with this contract’ is read in the context of clause 11.2 (25). For such a simple matter as ‘is the contract subject to remeasurement or not’ the wording is somewhat ambiguous and certainly less than clear. For further information, the author can be contacted at ajbates@carillionplc.com. Based on an article in Civil Engineering Surveyor, July/August 2000. ● Case studies By Rekha Thawrani, NEC Manager Due to the rapid expansion in usage of the NEC family of contracts, the Users’ Group has decided to produce selected case studies of NEC projects to promote the contract to potential clients as well as to provide a database for users. The case studies will be included within the NEC corporate brochure for marketing nationally and internationally as well as on the NEC website. Case studies proformas will be sent out shortly to the Users’ Group members. It is hoped that each member will be able to provide at least one case study. ICE procedures called into question By Drick Vernon, NEC Panel secretary The widely accepted procedures in ICE contracts that require parties to establish and identify matters in dispute have been questioned by a UK Technology and Construction Court judge. In John Mowlem v Hydra Tight Ltd, JudgeToulmin QC commented on the dissatisfaction procedure contained in clauses 90.1 to 90.4 of the NEC Engineering and Construction Contract option Y(UK)2. He said in an ‘obiter dictum’ (passing comment) that clause 90.5 conformed to the UK Housing Grants, Construction and Regeneration Act 1996 if taken on its own but not if taken in conjunction with clause 90.4. As far as the parties were concerned this was not the issue before the court as they both had agreed previously to disregard the Y(UK)2 option, meaning that the Construction Act’s statutory scheme for construction contracts would apply. The option starts with clause 90.1 by stating that the purpose of the dissatisfaction procedure is ‘for the avoidance and settlement of disputes’. Further clauses state that within 2 weeks of a notification of dissatisfaction, the parties and the project manager should attend a meeting to discuss and seek to resolve the matter. The procedure is considered to be good practice by both the industry and the courts. The ACA Project Partnering Contract launched earlier this month under the chairmanship of Sir John Egan has provisions for pre-adjudication dispute avoidance between NEC USERS’ GROUP NEWSLETTER•No.15•OCTOBER 2000 partners, presumably believing it not to be good partnering practice to go straight to adjudication. The Construction Industry Council is also considering adding a ‘pre-adjudication’ notice to its model adjudication procedure. The Pre-Action Protocol for Construction and Engineering Disputes has a general aim ‘to ensure that before court proceedings commence: ii each party has had an opportunity to consider the other’s case, and to accept or reject all or any part of the case made against him at the earliest possible stage; vi the parties have met formally on at least one occasion with a view to • Defining and agreeing the issues between them; and • Exploring possible ways by which the claim may be resolved; The expression ‘at the earliest possible stage’ is not accidental and presumably does not mean at the court steps. It would appear that the intention of this protocol is the clear identification of that which is in dispute and, if possible, its resolution without course to litigation. Compare this with clause 90.1. Section 108(1) of the Construction Act sets out that a party has a right to refer a dispute under the contract to adjudication. Furthermore it states: ‘For this purpose ‘dispute’ includes any difference.’ The Act is silent on whether the parties to a contract may or may not agree as to what constitutes a ‘dispute’ or ‘difference’ between them . In effect it is therefore the responsibility of a party to decide when it is in dispute with the other party and exercise its right to go to adjudication to resolve the issue. The ICE procedures are intended to assist this process of identifying what is in dispute and the redress sought. The parties accept this on signing the contract. The ICE has developed, over several decades, procedures for identifying, defining and resolving disputes and these have been accepted as good practice. In a recent article, a Technology and Construction Court judge acknowledged that the courts may have to give guidance on what constitutes a ‘dispute’.. This was stated in the context of the private finance initiative but it is difficult to believe such guidance would not affect a contract between two parties. The ICE will await such guidance from or decision of the court on this issue before considering amendments to its contracts in the belief that good engineering practice should prevail. It should be remembered that during the case of Trafalgar House v General Surety, the ICE was urged to change its form of bond. Successive courts reversed decisions of a lower court and the final outcome was, in effect, that the status quo before all the court cases still existed. For further information, the author can be contacted at drick.Vernon@ice.org.uk ● 7 NEC Users’ Group workshop 23 OCTOBER 2000 By Kelvin Hughes, NEC Users’ Group secretary The next NEC Users’ Group workshop will be taking place at the Institution of Civil Engineers in London on Monday 23 October 2000. As stated in the last edition of the newsletter, the success of the Users’ Group workshops has prompted the planning of a series of smaller, more focused workshops in order to maintain the invaluable interactive nature of the first two events. It is clear from Users’ Group queries received through the fax helpline that a number of members are experiencing some difficulty in managing and pricing compensation events. The morning session of the forthcoming event will thus mainly consist of interactive discussion on compensation event management and evaluation. The morning will conclude with an open discussion forum, where members will have the opportunity to air views on any NEC topic of their choosing. The afternoon session has been allocated for discussion and consultation with the NEC Panel on the following ECC 3 rd edition matters ● ● ● ● ● ● The cost of the workshop is £295 + VAT. Gold members are entitled to three free delegates and a 25% discount for additional delegates. Silver members are entitled to one free delegate place and a 25% discount on additional delegates. Bronze members receive a 25% discount for one delegate. To book places on the workshop, please contact NEC manager Rekha Thawrani on 020 7665 2446 or rekha.thawrani@thomastelford.com. ● schedule of cost components simplification compensation events process risks and insurance application to the building sector NEC as a management process general brainstorming – use of IT. PROGRAMME 9.15 – 9.30 9.30 – 9.45 9.45 – 11.00 11.00 – 11.20 11.20 – 12.15 12.15 – 13.00 13.00 – 14.15 14.15 – 16.00 Registration and coffee Welcome and introduction Notification, pricing and assessment of compensation events under the NEC family of contracts Notification procedures, use of the schedules of cost components, quotations – basis and preparation, assessing compensation events Coffee Notification, pricing and assessment of compensation events under the NEC family of contracts (contd) Open discussion forum Buffet lunch NEC Panel consultation on ECC 3rd edition matters SCC simplification, compensation events process, risks and insurance, application to the building sector, NEC as a management process, general brainstorming – use of IT NECDIARY Date Event Venue 23 October NEC Users' Group Workshop ICE, London 1 November 6 November 8 November ECC introductory training course ECC compensation events training course ECC post-contract training course Ascot Altrincham Ascot 5 December 6 December 13 December Professional Services and Adjudicators Contracts training course ECC pre-contract training course ECC introductory training course Watford Ascot Cardiff 11 January ECC introductory training course Sutton Coldfield 7 February 7 February 20 February 27-28 February ECC introductory training course ECC pre-contract workshop Short Contract training course ECC for contractors and subcontractors (NEW) Falkirk Sutton Coldfield Ascot Ascot 6 March 7 March 13 March ECC pre-contract training course ECC post-contract training course ECC introductory training course Falkirk Sutton Coldfield Altrincham 4 April 10 April 24 April 26 April ECC compensation events training course ECC introductory training course Short Contract training course ECC pre-contract training course Sutton Coldfield Ascot Bristol Altrincham NEC Users’ Group members New members shown in bold A B Rhead & Associate Limited AEA Technology plc AMEC Civil Engineering Ltd Amec Utilities Ltd Anglian Water Services Ltd Ashridge Construction Limited BAA plc Balfour Beatty Major Projects, Channel Tunnel Rail Link Barton Plant Ltd Bayfield Associates Berkeley M.S. Ltd BG TransCo Plc Birse Construction Limited BNFL Engineering Limited Breach Associates British Waterways BT plc Bullen Consutlants Limited Cammell Laird (Tyneside) Carillion Plc ChandlerKBS Circle 33 Housing Trust Limited City of Glasgow Council Comhairle Nan Ellean Siar Contracts Consultancy Limited Cornwall County Council Currie and Brown Cyril Sweet Limited Dean and Dyball Construction Limited Debevoise & Plimpton Solicitors Department for International Development (DFID) Department for Regional Development Roads Service DLA Solicitors DOE (NI)Water Service Doig & Smith Doncaster Metropolitan Borough Council Earth Tech Engineering EC Harris Edmund Nuttall Limited – Newcastle upon Tyne Edmund Nuttall Ltd – Camberley Electricity Supply Board Emirates Telecommunications Corporation Environment Agency – Cheshire Environment Agency – Peterborough Ernest J Bayton ESKOM Faithful & Gould Forsters Forward Consult Limited Frank Griffiths Associates Limited Franklin & Andrews Galliford Northern GDG Management Ltd Gleeds Halcrow Group Limited Hannah Reed and Associates Ltd Hanson Construction Projects Harbour & General Works Limited JMP Consultants K Home Engineering Ltd Kilroot Power Limited Kirkham Board Associates Laing Limited Lancashire County Council Lincolnshire County Council London Underground Limited London Underground Limited – Crossrail Projects Lovell White Durrant M J Gleeson Group Plc Mabey Construction Company Limited Mansell plc Masons Solicitors Miller Civil Engineering Ltd MK International Ltd Montgomery Watson Ltd Morrison Construction Ltd Mott MacDonald Mouchel Consulting Ltd National Power plc Needlemans Ltd North Lincolnshire Council Neath Port Talbot County Borough Council Northumbrian Water Limited One North East Oval (717) Ltd Ove Arup & Partners Pell Frischmann Consultants Ltd Peter Brett Associates Railtrack Rock DCM Roger Lewendon Assoc. Royal Hong Kong Jockey Club Sainsbury's Supermarkets Ltd Scott Wilson Kirkpatrick Shawater Limited Shepherd Construction Ltd South African NEC Users Group Association Staffordshire Engineering Consultants Suffolk Waste Disposal Co. Ltd Symonds Travers Morgan The Nottingham Trent University Thurlow Associates – South Africa TPS Consult Trett Consulting UK Nirex Ltd UKAEA Union Railways Limited University of Hong Kong W S Atkins Walter Lawrence Civil & Mechanical Limited Webfell Group Limited West Lothian Council Wheeler Group Consultancy Wiggins Gee Construction Ltd Wrekin Construction Company Limited Yorkshire Water Services Ltd Constructive contributions to the newsletter are always welcomed and should be emailed to the editor Simon Fullalove at simon@fullalove.com (telephone +44 (0)20 8744 2028, fax +44 (0)20 8891 2462). The current issue of the newsletter is also available on the NEC web site at www.newengineeringcontract.com. All other enquires should be made to the NEC manager Rekha Thawrani, Thomas Telford Ltd, 1 Heron Quay, London, E14 4JD, +44 (0) 7665 2446, fax +44 (0)20 7538 2847, e-mail rekha.thawrani@thomastelford.com ● For further details of courses, please see the Thomas Telford web site at www.thomastelford.com or contact Diane Lewis on +44(0)20 7665 2457. 8 NEC USERS’ GROUP NEWSLETTER•No.15•OCTOBER 2000

© Copyright 2025