to the manufacture of x-ray lenses

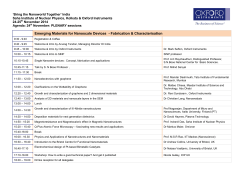

1114 PROCESSNEWS Follow us on... A Newsletter from Oxford Instruments Plasma Technology @oxinst /oxinst Welcome to this issue of PROCESSNEWS IN THIS ISSUE 2 Flexible high performance Siliconbased inorganic electronics Data storage, Atomic Layer Deposition, MEMS, Graphene and 2D materials have all been presented recently through our series of webinars 3 Watch again - Fascinating technical webinars – key expert guest speakers 4/5 Exploring Flatlands at Oxford Instruments 6/7 Atomic layer deposition of dielectric materials 8/9 The application of Bosch™ Deep Silicon Etch (DSiE) to the manufacture of X-Ray lenses 10 ICP plasma etching of tapered Via in Silicon for MEMS integration 11 Metallic nanoparticle formation by sputtering and annealing 12 2D plenary sessions attracted enormous interest at recent Beijing Nanotechnology Seminar 13 Nanoparticle and nanosphere mask for etching of ITO nanostructures and their reflection properties 13 University of Science and Technology of China orders an additional plasma etching system for quantum information processing 14/15 Dust management in silane PECVD systems 16 Introducing our new Service agent in Israel 16 Launching new training dates for 2015 We’ve been lucky that distinguished experts in each field have presented at these webinars. They are available to view again, just look inside this newsletter to find out more about them. www.oxford-instruments.com/plasma-videos PROCESSNEWS 1 Flexible high performance Silicon-based inorganic electronics Watch again 1114 Galo A. Torres Sevilla and Dr. Muhammad Mustafa Hussain / Integrated Nanotechnology Group, King Abdullah University of Science and Technology (KAUST) Fascinating technical webinars – key expert guest speakers Since the introduction of flexible electronics in 1969, many different approaches have been demonstrated to create high performance devices on flexible substrates. The most commonly known is the use of flexible organic substrates to fabricate devices using microfabrication processes. However, plastic semiconductors have many disadvantages when compared with inorganic ones. Plastic thermal instability together with their inherited low electron mobility hinder their potential for truly high performance flexible electronics. For this reason, alternate approaches have been followed to integrate the electrical advantages of inorganic substrates with the flexibility of organic semiconductors. These techniques are usually based on transfer of silicon nano-ribbons released from costly Si (111) substrates to plastic host substrates. However, the incompatibility between transfer techniques and industries’ processes along with the reduced integration density, hinder their potential for very large scale integration required for high performance electronics. Taking nano to the next level For these reasons, in recent years, we have demonstrated state of the art silicon devices on flexible platforms without the need of transfer processes or expensive substrates. Our process is based on etch-release-peel-reuse techniques. First, we fabricate our devices with state of the art industry compatible processes. Then, with the aid of BOSCH process (Oxford Instruments PlasmaPro 100) we etch deep trenches in the passive areas of the wafer. Depending on the etch depth, the final thickness of the substrate can be controlled. Next, we protect the lateral walls of the holes using ALD deposition. Finally, using isotropic etching of silicon (XeF2), we create caves at the bottom of the trenches, once these caves meet, the top silicon film can be easily peeled and flexed due to the extremely reduced thickness (1 to 20 µm). At this point, the remaining substrate can be polished and reused making our process industry compatible and cost effective at the same time. Figure 1 shows a released sample containing the most advanced transistor architecture (FinFET). The obtained film is only 1 µm thick exhibiting extremely high flexibility (5 mm minimum bending radius) and semitransparency due to the etch holes created for the peeling process. 2 PROCESSNEWS Figure 2 shows a comparison between the performance of released and unreleased samples. It can be seen that no degradation is introduced to the devices during peel-off process, hence making our technique suitable for state of the art devices. In summary, we have developed and presented a practical way to transform traditional high performance electronics into flexible ones without the need of expensive substrates or processes. We expect that in a close future, this technique may be used to fabricate high performance wearable and ultraportable electronics. Figure 1: Released sample containing FinFET transistors. Sample is 1µm thick allowing a minimum bending radius of 5 mm and exhibits semitransparency due to the etch holes introduced during the peel-off process. Focusing on recent advances in nanoscale etching and in atomic layer deposition (ALD), from research to manufacturing applications, this webinar was presented by leaders in their respective fields of research and production. Two industry-leading speakers discussed their specialities: ALD and nanoscale-etch processing techniques and results from recent work carried out at the LBNL, Deirdre Olynick, Lawrence Berkeley National Laboratory (LBNL): Data storage - a technology area that is benefitting from advances in nanoscale fabrication, Kim Lee, Seagate • • Dr Deirdre Olynick, LBNL Exploring flatlands: fabrication technologies One of the key technical challenges when working towards the commercial realization of graphene and related 2D materials is the development of robust fabrication techniques for deposition, etching and integration with other processes in a device-fabrication facility. This webinar focussed on recent advances in research from academic speakers at the forefront of their fields, as well as from Oxford Instruments. What you will gain from this webinar: Understanding of the use of controlled etching processes for novel 2D heterostructures – by Dr Andrey V Kretinin (University of Manchester, UK) Growth and characterization of graphene and hexagonal boron nitride via CVD and plasma-enhanced CVD – by Dr Ravi Sundaram (Oxford Instruments, UK) Use of ALD in the deposition of low-resistance contacts and high-k dielectrics on graphene – by Dr A A Bol (Eindhoven University of Technology, Netherlands) • • • Kim Lee, Seagate Watch either of these webinars at: www.oxford-instruments.com/plasma-videos Figure 2: Transfer characteristics comparing released and unreleased samples showing no performance degradation due to peel-off process. Gate length (L) = 250nm and width (W) = 3.6 µm. Contact: MuhammadMustafa.Hussain@kaust.edu.sa Galo A. Torres Sevilla was a guest speaker at our spring seminar at IEMN, Lille, France Dr Andrey V Kretinin, University of Manchester Dr Ravi Sundaram, Oxford Instruments Dr A A Bol, Eindhoven University of Technology PROCESSNEWS 3 1114 Exploring Flatlands at Oxford Instruments Dr Ravi Sundaram, Development Scientist, Oxford Instruments 2000 Intensity (a.u.) We have been taking a close look at growth and characterisation of 2 dimensional materials. As the field moves beyond graphene, there is growing interest in studying atomic planes of other Van der Waals solids and heterostructures created by stacking layers with complementary characteristics to achieve novel functionality. One such material that serves as a high quality substrate for graphene is hexagonal Boron Nitride (hBN). 1800 Lorentz 1600 Position 1400 FWHM 1367.534 0.11898 21.413 0.37 1200 1000 800 600 400 200 0 1000 1100 1200 1300 1400 1500 1600 Raman Shift (cm-1) N 1s 3 x 10 B 1s N1s:398.4 3 x 10 B1s:191.03 22 60 20 18 50 16 40 CPS The process Standard semiconductor process gases, Diborane (B2H6) and Ammonia (NH3) were introduced in the right proportions over a nickel foil heated (~1000 ºC ) which were pre-treated in a reducing atmosphere. The reaction of these components catalysed by nickel resulted in the nucleation and growth of hBN islands. The load-locked sample transfer enabled quick sample exchange and also allowed us to precisely arrest the reaction to observe these growth fronts before the formation of a continuous film using an SEM and also on an Oxford Instruments Asylum Research MFP-3D Classic AFM CPS Chemical Vapour Deposition (CVD) has emerged as a workhorse for the preparation and production of graphene [1,2] and more recently applied in the synthesis of other 2D materials such as hexagonal Boron Nitride [3] and Molybdenum Disulphide [4]. We had previously demonstrated that the Oxford Instruments Nanofab Agile tool with the capability of both CVD and PECVD processes can be used for the growth of monolayer graphene and related graphene-like allotropes. Recently, we have developed a thermal CVD route to synthesize hexagonal Boron Nitride (hBN) using Nickel foils as catalyst in this tool. 30 14 12 10 8 20 6 10 4 408 404 400 Binding Energy (eV) 396 392 200 196 192 Binding Energy (eV) 188 184 Fig. 2. (a) Raman spectrum of hBN on Ni showing the characteristic peak ~1368 cm-1 (b)Zoomed in plot of Spectrum shown in (a) to elucidate the absence of non-hBN phase (c) XPS survey scan, (d) N1s(at 398.4 eV) and (e) B1s(at 191.03 eV) Fig. 1. (a) SEM image showing a triangular hBN island growing on a Nickel crystal face. (b)AFM topography and (c) AFM lateral force image of a growing edge. Film characterisation In order to confirm the deposition of hBN we used Raman spectroscopy and X-Ray Photoelectron Spectroscopy (XPS) (Figure 2). The presence of a sharp peak at ~1368 cm-1 (excitation at 532 nm) arises from the E2g phonon and is characteristic of the h-BN phase. On closer examination of the spectrum we did not see the presence of broad peaks which may arise due to unwanted co-deposition of the cubic phase, carbon contaminated phase or amorphous BN soot. 4 PROCESSNEWS Chemical structures are characterized by X-ray photoelectron spectroscopy (Oxford Instruments-Omicron ESCA+). XPS measurements were performed with an Al-Kα X-ray source on the samples. Fig. 2 shows the XPS spectrum for the transferred sample on Nickel, where two peaks at 191.03 eV and 398.4 eV are identified as the binding energies of the B 1s and N 1s electrons respectively. These energy values (and integrated intensity analysis) reaffirms the formation of hexagonal Boron Nitride presented in nearly equal stoichiometric ratio [7]. We have an extensive portfolio of deposition and characterization tools tailored towards research the field of graphene and 2 dimensional materials. References: [1]. Li, X et al; Science 324, 1312-1314 (2009) [2] Bae, S. et al; Nat Nanotech. 5, 574 (2010) [3] Ismach, A. et al; ACS Nano,6, 6378 (2012) [4] Zhan, Y et al; Small, 8, 966 (2012) [5] R. Gorbachev et al; Small , 7, 465,(2011) [6] Reich, S. et al; Phys. Rev. B, 71, 205201, (2005) [7] Lee, Yi-Hsien et al; RSC Adv., 2, 111(2012) Please contact us for more information on graphene and other 2 dimensional materials: nanotools@oxinst.com or visit www.oxford-instruments.com/graphene PROCESSNEWS 5 0614 Atomic layer deposition of dielectric materials Harm Knoops and Tom Sharp, Oxford Instruments Atomic layer deposition (ALD) is of interest for controlled deposition of dielectric materials in complex device structures. To serve the needs of the wide range of devices and applications fields which can benefit from these dielectric films, there is a constant drive towards new ALD processes and improved material properties (e.g., higher dielectric constant). Furthermore for many applications there is a desire to go towards lower temperatures, while maintaining high material quality. To this end, several oxidants can be applied in the ALD cycle such as water, ozone and oxygen plasma, which differ in oxidizing strength. Figure 1 shows an overview of common dielectric materials and whether they have been grown using Oxford Instrument systems (OpAL and/or FlexAL). The usage of oxygen plasma allows the deposition of the widest range of oxides and furthermore has been demonstrated to allow deposition at room temperature for some (Al2O3, SiO2, and TiO2 have been demonstrated by the Eindhoven University of Technology). Note that for deposition on sensitive substrates (such as III-V materials) a low power plasma or weaker oxidant could be desired. Besides binary oxides, also the desire to deposit multicomponent oxides using ALD is present. For instance stoichiometric strontium titanate oxide (STO) can have very high k values. The cycle wise nature of the ALD process and the recipe based software of the OpAL and FlexAL allows easy mixing of materials by alternating ALD cycles of the binary compounds. Figure 2 for instance shows how the optical properties of STO deposited on a FlexAL system can be tuned by varying the [SrO]/[TiO2] ALD cycle ratio. This example furthermore shows how in situ ellipsometry can be used to determine the stoichiometry for these materials. Postannealing at 600/650 °C for 10 min under N2 gas resulted in a crystallization into the high-k perovskite phase. The highest capacitance density has been demonstrated for 15 nm polycrystalline stoichiometric SrTiO3 films resulting in a capacitor equivalent thickness (CET) of about 0.7 nm. One of the main advantages of ALD is its inherent high conformality, which for instance can be used to deposit 6 PROCESSNEWS dielectric films for trench capacitors. Due to the self-limiting nature of the ALD surface reactions, complex 3D structures can be covered with films of equal thickness throughout the structure, as long as sufficient flux of precursor and oxidant has reached all surfaces. For thermal ALD processes conformal coating of extremely high aspect ratio (>1000:1) has been reported. In this case methods to enclose the precursor in the reactor chamber, such as the automatic pressure control valve (APC), are beneficial to limit the precursor usage per cycle (note that the APC which is standard on the FlexAL system is now also available as an option for the OpAL system). Due to recombination of plasma radicals at surfaces, conformality for plasma processes can be more challenging depending on radical type and surface material. Nonetheless, conformal coating of high aspect ratio structures is achievable by plasma deposition. For instance for plasma ALD of SiO2, conformal coating of 30:1 trenches using an OpAL has been reported. Also for plasma ALD of HfO2, high conformality can be obtained as shown in Fig. 3. Here 25:1 trenches are coated by 20 nm HfO2. In general Oxford Instruments ALD tools are equipped to deposit a wide range of dielectric materials under demanding conditions, such as room temperature deposition, stoichiometry control of ultrahigh k materials, and plasma deposition in 3D structures. Al2O3 HfO2 SiO2 Ta2O5 TiO2 ZrO2 SrTiO3 Water ✔ ✔ ✗ ✔ ✔ ✔ ✗ Ozone ✔ ✔ ✔ Plasma ✔ ✔ ✔ ✔ ✔ ✔ ✔ Room Temp. ✔ ✔ Figure 2 (a) Real and imaginary part of the dielectric functions ε1 (a) and ε2 (b), respectively, of as-deposited TiO2, SrO and of STO films. The corresponding [Sr]/([Sr]+[Ti]) content ratio from RBS and [SrO]/[TiO2] cycle ratio are indicated for the STO films. Figure 3 SEM image of Si trenches (AR = 25:1) with conformal coating by plasma ALD of HfO2 (20 nm) as shown by insets of SEM images on the right at the trench corner and the trench bottom. ✔ Figure 1 Common dielectric materials and possible oxidants by which they have been deposited. Materials that have been grown at room temperature are also indicated. Processes in blank spaces may have been demonstrated in literature but have not yet been directly demonstrated by Oxford Instruments. Material list is not exhaustive. Potts et al., Chem. Vap. Deposition, 19, 125 (2013) Aslam et al., Phys. Status Solidi A 211, 389 (2013) Dingemans et al., J. Electrochem. Soc. 159, H277 (2012) Longo et al., ECS Trans. 41, 63 (2011), and ECS J. Solid State Sci. Technol. 2, N15 (2013) PROCESSNEWS 7 The application of Bosch™ Deep Silicon Etch (DSiE) to the manufacture of x-ray lenses Katarzyna Korwin-Mikke a, Mark E McNie a, Lucia Alianelli b a Oxford Instruments Plasma Technology, Yatton, BS494AP, United Kingdom b STFC Diamond Light Source, Oxfordshire, OX11 0DE, United Kingdom The trend in X-Ray optical devices, such as refractive lenses, zone plates, curved mirrors, multilayers and multilayer Laue lenses, is towards shrinking dimensions and/or deeper optics. Due to excellent properties, such as thermal x-ray absorption, diamond is highly desirable material for use in many optical instruments, however, due to cost of manufacturing, extreme hardness and resistance to chemical attack, diamond is a difficult material to realize structures suitable for x-ray lenses and this is why silicon is the leading material for x-ray lens production. Nanofocusing silicon x-ray lenses require not only high quality material but also high aspect ratio with vertical sidewalls and controlled roughness on the sidewalls to minimize aberrations and parasitic scattering respectively. The focus of this work was to develop the process for etching silicon x-ray lenses with good profile control and smooth sidewalls using the Oxford Instruments PlasmaPro 100 Estrelas etch tool. To achieve high aspect ratio lenses with vertical profiles and smooth sidewalls, a short cycle time is used in conjunction with lower powers for less aggressive process conditions. The passivation is regularly refreshed to maintain sidewall integrity through rapid switching with controlled ion energies. Etching microstructures on the samples with a high silicon exposed area reduces the etch rate due to loading effects and may cause undercut of the mask as the result of sidewall plasma attack on isolated features (Fig.1) even when overpassivated. One of the solutions to reducing the negative impact of the ions on the 8 PROCESSNEWS etched lenses is to tune the process to operate at low pressures and a low (controllable) DC bias. The other is to reduce the number of ion impacts on the sidewalls by protecting the lenses with sacrificial features that can be removed after the process. In the Oxford Instruments Applications Laboratory, etch processes for each approach were developed (with and without compensating features – Fig.2). The results gave close to vertical lens profiles (89.90°) without compensating features etched to 50µm depth with no mask undercut and controlled scallops to below 50nm (Fig.3). This process was adapted and extended to the lenses with compensation features to achieve etch depths in excess of 70µm with smooth sidewalls (scallops <50nm), no mask undercut or sidewall damage, vertical profile (89.94°) and clean surfaces in open silicon areas (Fig.4). 1114 Figure 1. The negative impact of the ions on etched X-Ray lens structure. Figure 2. Device mask patterns. Left: Lens with compensation features; Right: Lens without compensation features. The X-Ray silicon lens etch processes were carried out in a PlasmaPro 100 Estrelas deep silicon etch tool (Fig.5). This latest generation deep silicon etch system can trade high rate performance for increased control to enable a very flexible set of processes from high etch rate applications (>25µm/min) to nanoscale etching. The lens processes are being transferred to a third party commercial supplier for production of the lenses going forwards. Adapted from work presented at the International Micro Nano Engineering (MNE) Conference, Sept. 2014 Figure 3. SEM of a lens without compensation features etched to 50µm depth. Figure 4. SEM of a lens with compensation features etched to 75µm depth. Figure5. PlasmaPro 100 Estrelas. PROCESSNEWS 9 ICP plasma etching of tapered vias in silicon for MEMS integration Metallic nanoparticle formation by sputtering and annealing Zhong Ren and Mark E McNie, Oxford Instruments Louise R. Bailey, Cigang Xu, Brodie Mackenzie & Gary Proudfoot, Oxford Instruments With extensive applications of CMOS in smart phone and other portable equipment there is demand for an increase of integrated component density to achieve large capacity memory and high processing speed. A proposed method for enhancing the efficiency of silicon solar cells is to incorporate nanoparticles of gold or aluminium for improved light capture. In order to develop practical nanoparticle optimisation criteria, equipment which is suitably scaled for research, but traceable to volume production is required. To synthesise nanoparticles, precise and repeatable deposition of thin metallic films is done using a multiple target magnetron sputtering tool and post-deposition with an in-situ heater. Compared to traditional wire-bonding methods, through silicon vias (TSVs) provide a short interconnect path with as high as possible density. Therefore, in recent years conductive TSVs have become one of the most important components for electrical connection of stacked devices in the semiconductor industry, to replace wire bonding. Moreover, usage of TSV techniques is able to connect and control stacked MEMS modules in order to save space [Figure 1]. For increased throughput and decreased fabrication difficulty, silicon wafers can be thinned to 50-100µm thickness with a handle wafer. This reduces the aspect ratio required to etch TSVs and subsequent thin film depositing steps. Therefore, the typical size of TSVs is 10-50µm in diameter and 50-100µm depth. State-of-the-art wafer-level bonding techniques are able to integrate heterogeneous materials (e.g. III-V compounds, ferroelectric, etc) on a silicon base chip with multiple functions. These pioneering ideas are also creating new research opportunities for MEMS and opto-electronic integration. This requires a controllable TSV (60-85º) technique with a wide material compatibility, in order to fill the via completely with contact metal. Using high density plasma technique, the Bosch process based on cycling deposition and etch steps is usually used to etch TSVs and provides a vertical profile (88-90º) with a high aspect ratio (AR). The achievable angular range is too limited to approach to a tapered profile. Through an isotropic etch, a tapered profile (<85º) can be achieved, but usually with overhang at top of via. This would result in void formation in subsequent seeding and filling steps. To realize a void-free via, this overhang may be removed by means of a subsequent maskless etch step. But it results in the loss of a few microns silicon on the surface and enlarges the critical dimension (CD) of the TSV. The approach may not be acceptable where there are device areas on the surface. This paper reports a technique to achieve variable tapered angle on an etched TSV profile by means of an ICP etch (PlasmaPro 100 Estrelas), based on a SF6-C4F8 chemistry. Monotonic profile angles in the range of 60-80º have been achieved on 10-50µm wide vias through adjustment of the C4F8/SF6 ratio (controlling F concentration in plasma) [Figure 2]. An etch rate of 10µm/min was obtained on 60º profile TSV etch, with sidewall roughness of <1µm. However, the sidewall became significantly rougher (3µm) when profile was more than 68º. This was due to a reduction of the isotropic etch in the lateral direction and a lack of ion bombardment to remove polymer at shadowing area from the undercutting mask. Profile curvature was dominated by vertical: lateral etch balance. As a result, a 72º profile via was successfully realized on 20-50µm wide vias with sidewall roughness of <300nm and no overhang at the top of via [Figure 3]. Figure 1. Illustration of MEMS 3D integration and wafer-level packaging with TSV technology Figure 2. Sidewall angle change on TSV profile with increase of C4F8 ratio Figure 3. Tapered via (72º profile): Roughness of 180nm on sidewall, without any overhang at top 10 PROCESSNEWS Magnetron sputtering is a well established large area technique for the deposition of metals. In this investigation we have prepared uniform sputtered films varying in thickness from 200nm to less than 10nm for nanoparticle seed layers. Deposition rates are high and result in short sputtering times for the film thickness required so a cyclical deposition mode is used with short deposition times and low discharge powers. Resistivity data from multilayers formed by successive passes beneath the deposition flux demonstrates the thickness control that can be met in this mode which mimics an in-line sputter configuration. When the substrate is oscillated beneath the target, a shaper is used to correct the arrival flux such that the sputtered thin films are uniform and thin. The shaper can be further refined to permit the use of a range of instantaneous deposition rates which may in turn influence the morphology of the thin film. When depositing thin films for short processing times there is a stringent need for process repeatability. Au film sputtered to date has been 4 nm thick, determined by measuring the resistivity with a four point probe. (a) (b) Figure 1 (a) SEM image of 10nm Al Film deposited at room temperature; (b) SEM image of Al NPs obtained by annealing Al film (a) at 600 °C Au and Al nanoparticles have been formed by sputtering and annealing. Future work will involve studying the size, shape and distribution as a function of film thickness and the temperature of the process and anneal. Other factors such as substrate orientation may also play a role in nanoparticle formation. Fabrication of metallic nanoparticles has been demonstrated in a combined sputtering and anealing tool using a low-cost method. This work was supported by FP7 project 246331nanoPV. We show examples of nanoparticle formation by post deposition annealing. These indicate that for successful aluminium nanoparticle formation, a full in vacuum process is necessary, while for gold ex-situ annealing may be practical. This is an important factor in enabling research into the impact of particle size and distribution to the silicon solar cell efficiency. Here we demonstrate the formation of aluminium nanoparticles from a 10nm thick aluminium film. Figure 6 shows SEM images of film deposited at room temperature and annealed at 600 °C in the same chamber, using a high temperature substrate table. The images of before and after annealing clearly show the presence of nanoparticles. PROCESSNEWS 11 2D plenary sessions attracted enormous interest at recent Beijing Nanotechnology Seminar •Superconductors and Spin-Based Quantum Processors Prof. David Cory, University of Waterloo, Canada •Exchange Induced Interfacial Field from Magnetic Insulators Prof. Guoxing MIAO, Institute for Quantum Computing, University of Waterloo, Canada Leading high level international speakers •TEM studies of Nano Core/Shell Hetero structures EDS mapping at the atomic level dominated the Oxford Instruments two day Prof. Robert Klie, University of Illinois Chicago technical seminar hosted at the prestigious Institute •Fabrication of dielectric coatings using Optofab3000 Ion Beam of Physics in Beijing recently. This event focused sputtering deposition system on practical applications, techniques and advances Dr. Xiaodong WANG, Institute of Semiconductors, CAS during a half day ‘2D materials’ plenary session, •Structure and properties of graphene and graphene-like 2D materials by STM and many other applications areas. Expert speakers from key establishments in China, Europe and the USA gave talks, as did Oxford Instruments specialists, keeping participants abreast of the latest technologies and trends in many current and future industry research topics, including: • Recent Advancements in 2D Materials at Manchester, Dr. Aravind Vijayaraghavan, National Graphene Institute in Manchester, UK •ALD applications for power semi and advanced materials Prof. Erwin Kessels, Tue Eindhoven, NL •Nanoscale Terahertz Imaging and Spectroscopy of 2D Materials, Prof. Yukio Kawano, Quantum Nanoelectronics Research Center, Tokyo Institute of Technology, Japan Prof. Yeliang WANG, Institute of Physics, CAS •Nano-structure fabrication by ICP-RIE for optical devices Dr. Zhe LIU, Institute of Physics, CAS It was great to host such high calibre speakers and attendance at the IOP. This event showcased the breadth and diversity of Oxford Instruments tools and applications, and also it offered a good opportunity for the wider Nanotechnology research and fabrication community to meet and share their experiences and vision for the future of this exciting area. Nanoparticle and nanosphere mask for etching of ITO nanostructures and their reflection properties Cigang Xu*1, Ligang Deng1, Adam Holder1, Louise R. Bailey1, Caspar Leendertz2, Joachim Bergmann3, Gary Proudfoot1, Owain Thomas1, Robert Gunn1 Au nanoparticles and polystyrene nanospheres were used as a mask for plasma etching of an indium tin oxide (ITO) layer. By reactive ion etching (RIE) processes, the morphology of polystyrene nanospheres can be tuned through chemical or physical etching, and an Au nanoparticle mask can result in ITO nanostructures with larger aspect ratio than a nanosphere mask. During inductively coupled plasma (ICP) processes, Au nanoparticle mask was not affected by the thermal effect of plasma, whereas temperature of the substrate was essential to protect nanospheres from the damaging effect of plasma. Physical bombardment in the plasma can also modify the nanospheres. It was observed that under the same process conditions, the ratio of CH4 and H2 in the process gas can affect the etching rate of ITO without completely etching the nanospheres. The morphology of ITO nanostructures also depends on process conditions. The resulting ITO nanostructures show lower reflection in a spectral range of 400–1000nm than c-Si and conventional antireflection layer of SiNx film. An additional Oxford Instruments PlasmaPro 100 plasma etch system was recently ordered by the Center for Micro and Nanoscale Research and Fabrication at the University of Science and Technology of China (USTC) Hefei city, Anhui Province, adding to their already significant installed base of our leading etch and deposition systems. The systems are installed in USTC’s newly opened cleanroom and will be used for fundamental research into the increasingly important field of quantum information processing. Multiple Oxford Instruments plasma systems, including a PlasmaPro 100 ICP380 and PlasmaPro NGP 80 RIE, and PlasmaPro 100 PECVD deposition tools were already installed in USTC’s new facility during the past year. To find out about our forthcoming seminars: www.oxford-instruments.com ITO nanostructures obtained after etching (scale bar = 200 nm) 1Oxford Instruments Plasma Technology, North End Road, Yatton, Bristol BS49 4AP, UK 2Helmholtz-Zentrum Berlin für Materialien und Energie, Institut für Silizium Photovoltaik, Kekuléstr. 5, 12489 Berlin, Germany 3Leibniz Institute of Photonic Technology, Albert-Einstein-Str. 9, 07745 Jena, Germany The full article appeared in PSSA Journal DOI:10.1002/ pssa.201431228(2014) 12 PROCESSNEWS University of Science and Technology of China orders an additional plasma etching system for quantum information processing “Our latest Oxford Instruments plasma etching system will enhance the cutting edge research capabilities in Quantum Information Processing, currently being undertaken at our excellent new facility.” Said Prof Zhu, from USTC, “We chose Oxford Instruments systems as we have found that they offer extensive process capabilities, and great flexibility, backed by excellent support and service packages. These tools will allow our researchers to push the limits in micro- and nanoscale fundamental research.” Prof Zhu continued, “USTC has a very strong background in both nanoscale science and engineering, and this new stateof-the-art nanofabrication facility aims to drive collaborative, interdisciplinary, and fundamental research in the micro- and nano-scale.” PROCESSNEWS 13 1114 Dust management in silane PECVD systems Dr Mike Cooke, CTO, Oxford Instruments Plasma Technology Dust creation in plasma enhanced chemical vapour deposition (PECVD) tools can affect user safety, system reliability, and process quality. There are two main issues: -Upstream dust creation, from homogeneous gas reactions in mixtures of silane and oxidising gases. This can add particles to wafers, and in the worst case block a gas entry line. -Downstream dust accumulation of partially reacted silane. This rarely affects process quality, but can be a serious safety concern. Both are made worse the more intensively the tool is used, and the higher quantity of silane used. We have seen a steady increase in the total silane flow in PECVD processes, as higher rate processes are introduced. ICPCVD processes are also becoming more widely used, and such processes normally use 100% silane. Regrettably, there have been very serious silane incidents across the semiconductor industry, almost all involving the silane gas cylinder or gas delivery. PECVD processes themselves have been in Issue Silane – oxidiser reaction upstream Worst case fault Gas line blocks Mitigations Mix silane and oxidiser at the lowest possible pressure, close to the process chamber Use N2O oxidiser not oxygen Worse for silicon dioxide PECVD Use dilute silane, not 100% silane Perform regular checks for signs of lines blocking Investigate if there is an increase in particles on the wafer Pump and purge lines between gas box and chamber thoroughly before venting Partially reacted powder downstream, building up in the vacuum line to the pump Dust explosion Worse for amorphous silicon or silicon nitride PECVD 14 PROCESSNEWS Perform regular plasma cleaning Inspect vacuum line regularly regular, safe use for decades. This article is not concerned with safe delivery of silane to the gas box, nor with management of effluent out of the tool, but only with good practice in managing the PECVD tool. Upstream powder Oxford Instruments assesses the likelihood of upstream powder formation when a tool is ordered or upgraded. We strongly recommend that changes to the gases used or increases in maximum flow rates are only done in consultation with Oxford Instruments. For example, we may recommend splitting the gas manifold, so that gases mix closer to the process chamber, or adding upstream pressure monitoring devices to alert the user to potential line blockages. Silane reacts far more readily with oxygen than with nitrous oxide, so we recommend avoiding having oxygen and silane in the same gas box where possible. We have developed and recommend plasma cleaning processes using CF4 and N2O rather than the CF4/O2 mixture used historically. Good practice Where oxygen and silane share some common pipe work, but are not used together: Flush the line, preferably with an inert gas, between silane and oxygen use • At least 5 minutes, at least 100 sccm flow Pump the line thoroughly before first use of silane and before first use of oxygen •At least 20 minutes pumping for a gas box up to 5 metres from the chamber Venting. Use the same procedure before and after venting a chamber, to prevent air and silane meeting. • • • The same advice applies to gas delivery lines both to downstream injection points in ICPCVD (‘gas rings’) and to PECVD showerhead entry points. Diagnostics The wafer is a good indicator that powder is forming upstream, because it is often visible to the naked eye. Inspect the wafer under a bright light for signs of roughness, especially in a pattern matching the showerhead holes. Such powder might be formed at the showerhead itself, and eliminated by process changes or by renewing the showerhead. Run a test wafer and a high flow (>500sccm) of gas and no plasma to detect if powder is blowing down the line. Irregular mass flow controller (MFC) behaviour, such as long stabilisation time or failure to achieve higher flow, could be an indication of powder. (Inadequate upstream pressure or a faulty MFC should also be considered). If a line is contaminated, repeated partial venting with inert gas and pumping out can sometimes clear powder. Heavy contamination might need partial disassembly and blowing through to clear powder, or even renewal of pipe sections. Downstream powder This problem is rare, but is also less well known. Type ‘dust explosion’ into a search engine if you are unfamiliar with the issue. White downstream dust from silicon dioxide PECVD is only a problem to mechanical components (pumps and valves) and rarely travels back to the process chamber unless a vacuum joint is opened without first venting the chamber.. Orange or red dusts in exhaust lines of PECVD tools used for silicon nitride or amorphous silicon deposition are potentially hazardous, as well as giving rise to mechanical troubles. If such powder builds up to more than a millimetre or so, then it can be dislodged and create a dust cloud in the pipe. If this happens when pumping down a chamber full of air, the conditions are satisfied for a dust explosion. A bulletin highlighting this hazard has been written and is available on request. Contact ptsupport@oxinst.com Use of atomic layer deposition for MEMS & NEMS applications Watch again Webinar hosted by the MEMS Industry Group Atomic layer deposition (ALD) with its growth control and unique properties can be used to grow an increasing variety of films in complex structures. As MEMS and NEMS applications are becoming more advanced, this webinar discussed important aspects of ALD and how they can be applied to MEMS. Mechanical properties that are important for MEMS, such as stress, were discussed for thermal and plasma ALD. Several examples from the literature of how ALD films can be used in MEMS applications were demonstrated and discussed. Presented by Oxford Instruments’ ALD Technical Sales Specialist Dr. Harm Knoops. Before his current position, Harm investigated the fundamentals and applications of atomic layer deposition (ALD) at the Eindhoven University of Technology. Good practice Plasma clean the chamber as recommended by Oxford Instruments. This will help to oxidise downstream dust, as well as clean the process chamber. Inspect the vacuum line regularly. Make the first inspection after 3 months use, then adjust the interval based on the amount and type of dust seen. Avoid building up more than 1mm thickness of dust on the pipe wall. As with all safety matters which depend on how the tool is used, it is the user’s responsibility to ensure safe operation - Oxford Instruments are not safety consultants, but will share our own best practice with our customers. To view this webinar: www.oxford-instruments.com/aldformems PROCESSNEWS 15 Oxford Instruments Plasma Technology focuses for the future Introducing our new service agent in Israel We recently signed an agreement with Asher Sonego to provide comprehensive service support to our customers in Israel. For more information please email: plasma@oxinst.com UK Yatton Tel: +44 (0) 1934 837000 Germany Wiesbaden Tel: +49 (0) 6122 937 161 India Mumbai Tel: +91 22 4253 5100 Asher just finished an intensive training course at Oxford Instruments Plasma Technology’s UK manufacturing facility. “I am extremely impressed by Oxford Instruments leading edge products and commitment to their customers, to provide the very best tools and world-class service and support”, said Asher, “I am excited to be a part of the team and represent the company in Israel.” Oxford Instruments Plasma Technology Mike Smyth, EMEA Business Manager, Oxford Instruments Plasma Technology and Asher Sonego, shake hands while exchanging the signed Agency agreement Japan Tokyo Tel: +81 3 5245 3261 PR China Shanghai Tel: +86 21 6132 9688 Beijing Tel: +86 10 6518 8160/1/2 Launching new training dates for 2015 Singapore Tel: +65 6337 6848 Our courses are designed to improve system maintenance and process techniques for engineers and technicians. We ensure our customers get the most from their Oxford Instruments system. Taiwan Tel: +886 3 5788696 US, Canada & Latin America Concord, MA TOLLFREE: +1 800 447 4717 Benefits Courses are run by our dedicated training officer supported by our experienced process and system engineers, who know the systems and understand your individual requirements We aim to provide the very best training, tailored to meet with your individual needs We limit numbers on each course, to ensure best training possible • • • Book early to ensure your place for 2015 training For more information: www.oxford-instruments.com/training Email: plasmacs@oxinst.com www.oxford-instruments.com/plasma for more information or scan the code... This publication is the copyright of Oxford Instruments plc and provides outline information only, which (unless agreed by the company in writing) may not be used, applied or reproduced for any purpose or form part of any order or contract or regarded as the representation relating to the products or services concerned. Oxford Instruments’ policy is one of continued improvement. The company reserves the right to alter, without notice the specification, design or conditions of supply of any product or service. Oxford Instruments acknowledges all trademarks and registrations. © Oxford Instruments plc, 2014. All rights reserved. Ref: OIPT/ProcessNews/2014/02 16 PROCESSNEWS www.oxford-instruments.com

© Copyright 2025