5. Stability evaluation of vaccines for use in a CTC

1 2 WHO/CTC_FIRST DRAFT/19 December 2014 3 ENGLISH ONLY 4 5 6 Guidelines on the stability evaluation of vaccines for use in a controlled temperature chain 7 8 9 10 11 12 13 14 NOTE: This document has been prepared for the purpose of inviting comments and suggestions on the proposals contained therein, which will then be considered by the Expert Committee on Biological Standardization. Publication of this early draft is to provide information about the proposed WHO Guidelines on the stability evaluation of vaccines for use in a controlled temperature chain to a broad audience and to improve transparency of the consultation process. 15 16 17 18 19 20 21 The text in its present form does not necessarily represent an agreed formulation of the Expert Committee. Written comments proposing modifications to this text MUST be received by 30 January 2015 in the Comment Form available separately and should be addressed to the World Health Organization, 1211 Geneva 27, Switzerland, attention: Department of Essential Medicines and Health Products (EMP). Comments may also be submitted electronically to the Responsible Officer: Dr Jongwon Kim at email: kimjon@who.int. 22 23 24 25 The outcome of the deliberations of the Expert Committee will be published in the WHO Technical Report Series. The final agreed formulation of the document will be edited to be in conformity with the "WHO style guide" (WHO/IMD/PUB/04.1). 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 © World Health Organization 2014 All rights reserved. Publications of the World Health Organization can be obtained from WHO Press, World Health Organization, 20 Avenue Appia, 1211 Geneva 27, Switzerland (tel.: +41 22 791 3264; fax: +41 22 791 4857; e-mail: bookorders@who.int). Requests for permission to reproduce or translate WHO publications – whether for sale or for non-commercial distribution – should be addressed to WHO Press, at the above address (fax: +41 22 791 4806; e-mail: permissions@who.int). The designations employed and the presentation of the material in this publication do not imply the expression of any opinion whatsoever on the part of the World Health Organization concerning the legal status of any country, territory, city or area or of its authorities, or concerning the delimitation of its frontiers or boundaries. Dotted lines on maps represent approximate border lines for which there may not yet be full agreement. Page 2 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 The mention of specific companies or of certain manufacturers’ products does not imply that they are endorsed or recommended by the World Health Organization in preference to others of a similar nature that are not mentioned. Errors and omissions excepted, the names of proprietary products are distinguished by initial capital letters. All reasonable precautions have been taken by the World Health Organization to verify the information contained in this publication. However, the published material is being distributed without warranty of any kind, either expressed or implied. The responsibility for the interpretation and use of the material lies with the reader. In no event shall the World Health Organization be liable for damages arising from its use. The named authors [or editors as appropriate] alone are responsible for the views expressed in this publication. This document provides guidance to National Regulatory Authorities (NRAs) and manufacturers on scientific and regulatory issues to be considered in evaluating the stability of vaccines for use in a controlled temperature chain (CTC). It should be read in conjunction with the existing guidelines on the stability evaluation of vaccines published by the WHO. The following text is written in the form of WHO Guidelines rather than Recommendations because vaccines represent a heterogeneous class of agents and the stability testing programme will need to be adapted to suit the product in question. WHO Guidelines allow greater flexibility than Recommendations with respect to specific issues related to particular vaccines. 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 Page 3 1 Contents 2 3 1. INTRODUCTION ..................................................................................................................... 4 4 2. SCOPE........................................................................................................................................ 5 5 3. GLOSSARY ............................................................................................................................... 5 6 4. GENERAL CONSIDERATIONS FOR THE EVALUATION OF VACCINES FOR USE 7 IN A CTC ....................................................................................................................................... 7 8 5. STABILITY EVALUATION OF VACCINES FOR USE IN A CTC................................ 10 9 6. MONITORING TEMPERATURE CONDITIONS IN THE CONTEXT OF CTC ......... 14 10 7. SUGGESTED LABEL LANGUAGE FOR CTC INDICATIONS ..................................... 16 11 AUTHORS& ACKNOWLEDGMENTS .................................................................................. 18 12 REFERENCES ............................................................................................................................ 22 13 APPENDIX: PRODUCT SPECIFIC CTC EVALUATION OF A MODEL 14 MONOVALENT POLYSACCHARIDE CONJUGATE VACCINE..................................... 24 15 Page 4 1 1. Introduction 2 3 To meet the need identified by WHO to distribute vaccines to countries and areas where the cold 4 chain cannot be maintained (1-2), it is important to define key conditions (including temperature 5 and time limits) under which vaccines can be stored, distributed, and administered outside of the 6 cold chain (typically 2-8⁰C). Such conditions are referred to as a “Controlled Temperature 7 Chain” (CTC) (3). A CTC label indicates that sufficient information has been presented and 8 accepted by the appropriate regulatory authority(s) to permit the vaccine’s safe and effective use 9 under specified ambient conditions (e.g. maximum temperature and time). 10 11 The use of an approved CTC approach for the Meningitis A conjugate vaccine (MenAfriVac) 12 has been shown to effectively support vaccine distribution to populations that would otherwise 13 be difficult to vaccinate (4-5). CTC labelling can allow greater predictability in vaccination 14 campaigns and can save refrigeration and generator infrastructure costs, as well as address the 15 difficulties associated with the distribution of vaccines on wet ice. Additionally, this “on label” 16 approach avoids “off label” vaccine administration, which is inconsistent with official guidance 17 on best practice. 18 19 While not all vaccines are sufficiently stable to support such CTC labelling, vaccines that can be 20 safely and effectively used after a limited duration exposure to elevated temperatures (typically 21 up to 40⁰C) may be considered for a CTC label. Under some circumstances, a temperature lower 22 than 40°C may be considered for CTC applications depending on the vaccine’s stability. It is 23 anticipated that CTC labelling will be pursued for certain high priority vaccines that are already 24 known to be relatively stable outside of the normal cold chain. 25 26 As mentioned above, this guidance document arises from the urgent WHO immunization 27 programme requirements (1-2) and the resulting discussions held by an international group of 28 vaccine stability experts at WHO-sponsored consultations in Ottawa (6), Canada, and in Langen, 29 Germany (7). This CTC guidance is intended as a supplement to the broader existing WHO 30 “Guidelines on Stability Evaluation of Vaccines” (8), where this supplement will focus on CTC 31 specific issues not covered in the existing guidance with as little overlap as possible. The key 32 elements of this document are the application of the mathematical modeling and statistical 33 concepts described in the existing stability guidance (8), as well as in the related publications (9- 34 10), to address the unique needs imposed by the high temperature CTC requirements (6-7). As 35 described in the Ottawa and Langen CTC reports (6-7), whenever a vaccine is known to decay Page 5 1 over its approved shelf-life, it’s important to use appropriate statistical methods to establish 2 different release and end of shelf-life potency specifications. Given the dramatic potency 3 declines typically seen with vaccines under the high temperature associated with CTC conditions 4 (40⁰C), it is critical that this approach be applied for the stability analysis. A CTC label should 5 only be approved for a vaccine if the combined normal storage and planned CTC excursion 6 conditions are supported by statistical analysis of stability data as described in this document. 7 During the Langen CTC consultation, it was (7) proposed that a CTC specific guidance be 8 developed and that the key concepts and principles be subsequently integrated into the next 9 revision of the existing WHO vaccine stability guidelines (8), to provide convenient and 10 consistent guidance with regard to stability of vaccines in general. 11 2. Scope 12 13 These guidelines cover vaccines intended for delivery and/or use outside the typical cold chain 14 for a single planned excursion immediately prior to the use of the product. 15 16 Inadvertent temperature excursions should be considered separately from the planned 17 temperature excursions, which are the focus of this CTC initiative, given the different 18 programme objectives and field conditions related to CTC applications. CTC labels are not 19 recommendations for shipping or storage, but may guide decisions for use in case of temporary 20 temperature excursions. 21 22 3. Glossary 23 24 The definitions given below apply to the terms used in these guidelines. They may have different 25 meanings in other contexts. 26 27 Cold chain: The system used for keeping and distributing vaccines in good condition consists of 28 a series of storage and transport links, all designed to keep vaccines within an acceptable 29 predefined temperature range until they are used, typically 2⁰-8⁰C but other approved 30 temperatures can be specified. 31 32 Controlled Temperature Chain (CTC): Temperature conditions encompassing thermal 33 storage, transportation, or use conditions that go beyond those previously defined for a given Page 6 1 product. The working definition of CTC, which may be dependent on the country in which 2 vaccine is approved, allows a specific vaccine to be kept and used at ambient temperatures, up to 3 40°C: 4 − 5 immediately preceding vaccine administration, but minimum 3 days; 6 − 7 extremely challenging; 8 − for vaccines meeting a number of pre-determined conditions; 9 − up until this excursion, the vaccine should continue to be kept in the traditional 2 - 10 for a limited period of time (length of time will vary with the product and setting) under circumstances where maintaining a 2 - 8°C cold chain is not possible or 8°C cold chain or other label conditions. 11 12 Real-time and real-condition stability studies: Studies on the physical, chemical, biological, 13 biopharmaceutical and microbiological characteristics of a vaccine, during and up to the 14 expected shelf-life and storage periods of samples under expected handling and storage 15 conditions. The results are used to recommend storage conditions, and to establish the shelf-life 16 and/or the release specifications. 17 18 Accelerated stability studies: Studies designed to determine the rate of change of vaccine 19 properties over time as a consequence of the exposure to temperatures higher than those 20 recommended for storage. These studies may provide useful data for the stability 21 characterization of a product but should not be used to forecast real-time, real-condition stability 22 of a vaccine. However, when the accelerated temperature conditions are equivalent to the CTC 23 condition under evaluation, the accelerated stability data can be considered real-time and real- 24 condition data. 25 26 Shelf-life: The period of time during which a vaccine, when is stored under approved conditions, 27 is expected to comply with the specification as determined by stability studies on a number of 28 batches of the product. The shelf-life is used to establish the expiry date of each batch of final 29 product. 30 31 Product Release Model: This defines the relationship between the minimum release potency 32 and shelf-life, given the decay rate of critical quality attributes under the approved storage 33 conditions, to ensure that the vaccine is above the established minimum potency at the end of 34 shelf-life. The potency decay rate and the associated confidence intervals (e.g. 95%) should be 35 based on an appropriate statistical analysis of multiple lots and should include assay variability. Page 7 1 The vaccine stability under the approved conditions and the minimum required potency are the 2 properties of the product, which in turn influence the options with regard to the minimum 3 required release potency to achieve a specific shelf-life or vice versa. The upper limits on the 4 release potency (for safety reasons, particularly for live vaccines) should be considered in the 5 model, in addition to the manufacturing capability. In the case of a CTC label, the release model 6 must consider the potency decay over the normal storage condition for the full shelf-life as well 7 as that under the planned CTC excursion (see also Figure 1, Section 4). 8 9 Stability indicating parameters: Quality parameters that are associated with vaccine efficacy or 10 safety demonstrated in clinical trials. They are used to assess product suitability throughout the 11 shelf-life. Determination of these parameters should result in quantitative values with the 12 detectable rate of change. Qualitative parameters such as sterility could also be considered but 13 cannot be included in the statistical analysis. 14 15 Stability of vaccines: The ability of a vaccine to retain its chemical, physical, microbiological 16 and biological properties within specified limits throughout its shelf-life. 17 18 19 4. General considerations for the evaluation of vaccines for use in a 20 CTC 21 Use of vaccine under CTC requires consideration of both appropriate vaccine stability 22 assessment and the feasibility of compliance with the resulting vaccine labelling in the field. 23 While the stability evaluation principles described here could potentially be applied to data to 24 support multiple temperature excursions for a vaccine, consideration needs to be given to how 25 such excursions would be tracked for specific vaccine vials. When contemplating the potential 26 difficulty in tracking multiple excursions and assuring that vials that have reached their limit are 27 discarded, it was concluded that, at this time, guidance for a CTC label should be limited to a 28 single planned excursion of specified duration prior to the labelled expiration date. Subsequent 29 return to normal storage (e.g. 2 - 8°C) will not be considered here, in order to prevent inadvertent 30 administration of subpotent vaccine. As experience with CTC stability assessment and 31 programme implementation expands, this could potentially be reconsidered. 32 Page 8 1 A central conclusion from the previous two WHO consultations (6-7) was that CTC labels could 2 potentially be approved based solely on product specific stability/quality data under the normal 3 and CTC storage conditions when the following conditions are met: 4 - the approved product specifications, supported by quality attributes of the clinical lots, 5 remain unchanged and the vaccine is expected to be compliant with these specifications 6 following the normal storage for the full shelf-life and the CTC excursion; 7 - a battery of tests, often including additional characterization tests, that are performed to 8 assess vaccine stability have the capacity to detect changes in antigen conformation 9 and/or immunogenicity that are predictive of vaccine’s clinical effectiveness; 10 - and that additional clinical studies would not be required. 11 12 Additionally, when a manufacturer has accelerated stability data, that brackets the intended CTC 13 excursion of 40°C (e.g. stability data at both 37°C and 42°C), the potential for interpellation of 14 the data to support a 40°C CTC label could be considered on a case by case basis. It is assumed 15 that the accelerated stability data are from lots that represent the current manufacturing process. 16 17 Vaccines used under CTC should be capable of withstanding the approved planned excursion 18 conditions regardless of the shelf-life remaining before expiry. These evaluations must involve 19 statistical analysis of stability data to determine the rates of decay under both the normal storage 20 conditions and those of a CTC excursion. It is essential that adequate potency be available to 21 compensate for any decay over the full approved shelf-life under normal storage conditions plus 22 under the worst temperatures and conditions for the planned CTC excursion (e.g. 40⁰C) to 23 address worst-case scenarios, where the planned excursion occurs at the end of shelf-life for a 24 vaccine lot that was filled at or near the minimum release potency. 25 26 Calculations must be made based on an evaluation of decay rates, minimum release potencies, 27 and desired end-expiry potencies obtained from the manufacturer’s data. This is described in the 28 existing stability guidance and subsequent papers (9-10) and is critical for CTC applications, for 29 which the same principles apply. Studies to support CTC use should be performed by the 30 manufacturers because they have access to the validated assays, quality data and other essential 31 information necessary for assessing the robustness of the data in the context of the Product 32 Release Model (Figure 1). The need to label a vaccine for CTC use will of course require the 33 support of the manufacturer and the approval of the appropriate regulatory authority(s). 34 Page 9 Potency (EU: ELISA units) 80 70 Potency range at release 60 Release specification Potency range of clinical lots 50 2-8°C 40 Potency budget 40°C 30 End of shelf-life specification 0 -6 1 2 3 4 5 6 7 8 9 0 6 12 18 24 30 36 Shelf-life (months) Figure 1: Graphic representation of a “Product Release Model” for a CTC application. The figure illustrates the relationship between the minimum potency release specification (50 EU) and the shelf-life (24 months), given the rate of decay (slope) of the potency over both the normal storage temperature (28°C) and the maximum CTC temperature (40°C), to ensure that the vaccine is above the approved minimum potency (30 EU) at the end of shelf-life (supported by clinical lots). As noted in the guidance, the decay rate should be based on an appropriate statistical analysis, with a given degree of confidence (e.g. 95%), of multiple lots and should include assay variability. 10 For multivalent vaccines, CTC evaluation must consider all antigens in the product, although if 11 one antigen is known to be less stable than other antigens within a specific vaccine, the worst- 12 case may be considered. Potential interference among vaccine components may also need to be 13 considered. 14 15 The concept of a “Potency Budget” or the “available potency” to compensate for potency loss 16 over the shelf-life of a vaccine may be useful when considering CTC applications. During the 17 Ottawa and Langen CTC consultations (6-7), the term “Stability Budget” was also used in the 18 context of the discussions which could be applied to all quality attributes that change during 19 storage or use. However, the focus here will be on how to evaluate and manage within a potency 20 budget to simplify the discussion. At release, products must contain sufficient potency to ensure 21 clinical effectiveness, and to account for assay variability and product decay. If “excess 22 potency” is present, this could be used to permit CTC use, but if this is not the case, other 23 strategies could be considered to enhance the CTC potential of a vaccine. Under the “Potency 24 Budget” concept, additional potency could be identified by demonstrating that lower potencies 25 are effective (thus reducing the amount of potency “budgeted” to assure clinical effectiveness), 26 by improving assay variability (thus reducing the amount of potency “budgeted” to account for 27 potential errors in initial potency assignment), or by obtaining improved stability estimates 28 (which might show the product to be more stable than previously estimated, or this could reduce Page 10 1 the amount of potency that is budgeted to account for errors in stability estimates). Changes in 2 labelled storage conditions (for example, by reducing the shelf-life at the normal storage 3 temperature (e.g. 2-8⁰C)) could also potentially make available potency that could be “budgeted” 4 for CTC. In some cases, a manufacturer might choose to fill a vaccine for a CTC application at a 5 higher release potency in order to assure that the vaccine contains sufficient potency to allow for 6 the full shelf-life plus a CTC excursion, provided there are no safety implications. It may also be 7 possible, under well-defined circumstances, to consider CTC use of lots sufficiently in advance 8 of their expiration date to permit exposure to the CTC. 9 10 From a CTC programme implementation perspective, it is considered that a CTC excursion 11 potential at 40⁰C of less than three (3) days is of little value and that clearly the longer the 12 excursion provision, the better it would be for programme implementation. 13 14 Generally, additional clinical assessment for approved products for CTC applications should 15 only be required where a planned CTC excursion results in a change of product specifications 16 that requires further clinical evaluation (e.g. lower end of shelf-life potency or a higher release 17 potency beyond existing clinical experience). Field studies where the clinical evaluation of a 18 vaccine that has been exposed to higher than approved temperatures without direct involvement 19 of the manufacturer is not considered acceptable from a regulatory perspective. Clinical studies 20 that are intended to support CTC applications should be performed using a vaccine with known 21 (or modeled) potency at the time of delivery, as determined by the manufacturer’s validated 22 assays. Independently procured and characterized vaccines may not address worst-case scenarios 23 as described above, which is explicitly required for CTC applications. 24 25 5. Stability evaluation of vaccines for use in a CTC 26 27 The primary goal of stability evaluation of vaccines for use in CTC is to obtain sufficient data to 28 support labelling for such use. This requires assurance that there is sufficient potency available, 29 even with lots at end-expiry, to allow for an additional excursion under CTC conditions. Because 30 the best estimate of actual end-expiry potency of any given lot depends upon a variety of factors, 31 including release potency of the specific lot, accuracy and precision of the potency assay, as well 32 as the results of stability studies, statistical evaluation is needed in order to be able to state that, 33 with a given (usually 95%) degree of confidence, the potency after an end-expiry CTC excursion 34 will exceed a minimum threshold needed for product efficacy. It is only through the use of Page 11 1 statistical analysis that it is possible to obtain an indication of the level of confidence in reported 2 results or in actual potencies delivered to the vaccine recipient, and thus, statistical analysis is 3 required for complete analysis and review of vaccine delivery in a CTC context. Of course, there 4 may also be safety considerations, but in most cases, the major concern is that the temperature 5 excursion will reduce potency to unacceptable levels. Thus, this discussion will focus on 6 ensuring that the minimum required potency, recognizing that similar principles may be used to 7 assure that potentially unsafe degradation products do not exceed a safe threshold. 8 9 While it was noted previously that additional clinical studies should generally not be required for 10 a CTC label approval, the establishment of the minimum potency specification for a specific 11 vaccine, through the initial licensing studies is essential for all stability assessments. Thus, the 12 data package for CTC applications should include the initial clinical studies, including the 13 quality data of the clinical lots, to support the end of shelf-life potency specification as well as 14 stability studies that formally demonstrate that this minimum potency is exceeded throughout the 15 dating period, including the CTC excursion. Estimates of the rate (or slope) at which the potency 16 decays (“stability estimates”) at the normal and CTC temperatures, along with an understanding 17 of potential errors in those estimates, are the most important outcomes of these stability studies. 18 The reliability of these stability estimates, as well as the reliability with which the release 19 potency of any lot can be determined, depends in turn upon the potency assay. 20 21 As mentioned in Section 4, stability studies to support vaccine use in a CTC context should 22 employ the manufacturer’s validated potency assay, in order to preserve a connection between 23 the released product proposed for CTC use and the original clinical material used to support 24 product efficacy. Key parameters of this assay should already be known from assay validation, 25 including the assay accuracy and precision. It is critical that potency assays for all stability 26 assessments be validated as accurate, sensitive, robust and stability indicating and this is 27 particularly true for CTC evaluations given the likelihood of product failure under the high 28 temperatures. Considerable time was devoted to the sensitivity and stability indicating potential 29 of various potency assays during the WHO CTC consultations and it was clear that this should 30 not be taken for granted, even with some existing approved assays. Other assays, as are typically 31 performed during product stability testing, should also be considered for use in a CTC context. 32 This may include assays of qualities parameters that may themselves affect stability (e.g. 33 moisture, pH), as well as studies that support container integrity under the CTC conditions (e.g. 34 sterility, specific container integrity tests). 35 Page 12 1 Typically, the rate of decay of most biological substances does not follow linear kinetics. Log- 2 transformation of potency data is usually preferred, because it can allow the use of a linear model 3 and often has the advantage of greater biological relevance than direct analysis of non-log- 4 transformed potency data. In all cases, the decay model used should correspond to product decay 5 kinetics as observed in stability studies, which may support use of linear or other non-log- 6 transformed decay models, if these models can also be justified as biologically relevant. Thus, 7 log-transformation is not the best approach for all stability indicating assays, as will be evident in 8 product specific CTC stability evaluation in the Appendix. 9 10 Stability studies should include a sufficient number of time points to determine the adequacy of 11 the decay model, while also providing robust stability estimates. Decay rates may vary over the 12 shelf-life of the product and this should be assessed during the stability evaluation, as it can 13 influence the overall rate of change assigned over the normal shelf-life. Linearity (of log- 14 transformed potency) can be supported using a minimum of three time points, the starting point, 15 the ending point (desired CTC dating period) and ideally the midpoint. Use of additional time 16 points can increase the assurance that decay truly follows a linear model, information that is 17 needed to be able to obtain the best estimates of true rates of decay. Once linearity is established, 18 the most accurate estimates of decay rates are obtained by testing equal numbers of samples at 19 beginning and ending time points. It is often assumed that decay rates under CTC conditions will 20 be similar near the time of release and at expiry, but this assumption should be tested as with the 21 rate of decay over the normal storage period. If the rate of decay does not vary with the time 22 from release, vaccine potency is usually tested on recently produced material under CTC 23 conditions at at least three (3) time points, before exposure to the CTC conditions, after the 24 proposed CTC exposure, and at the midpoint, to simultaneously support linearity and to 25 maximize the precision of the CTC stability estimate. The midpoints can be omitted if existing 26 data already has demonstrated linear decay kinetics under the CTC conditions. If the decay rate 27 does vary depending on the time from release, this may need to be considered if the influence 28 substantially alters the assessment. Testing larger numbers of independent samples (lots) will 29 further improve this precision and increase the likelihood that these studies will support CTC 30 use, but in all cases, a minimum of three lots should be tested. When decay kinetics are non- 31 linear, if the absolute value of the decay slope (as observed at the proposed CTC or ending time 32 point) is less than the decay rate calculated using only starting and ending time points, a linear 33 model may be used, employing only starting and ending time points. In contrast, if the decay 34 slope appears to increase during exposure to CTC conditions, additional modeling, and likely 35 additional testing at time points beyond the proposed CTC conditions, must be performed to Page 13 1 assure reliable decay estimates. When decay kinetics are linear, testing at time points beyond the 2 proposed CTC use can also improve the precision of the stability estimate. 3 4 It is not possible to perform decay modeling on products with potency assays that have binary 5 outputs (e.g. pass/fail). In those cases, supplemental potency assays that are capable of showing 6 decay of the product’s active ingredient (or that can provide a worst-case estimate of that decay) 7 may be considered for use in CTC evaluation, recognizing the need for conservatism in 8 interpretation of the analysis and results. 9 10 Stability testing thus provides information on expected rates of decay (for the linear model, the 11 decay slope) and standard error of the decay slope at expected temperatures of product exposure 12 at “n” different temperatures of exposure (modeling storage, shipping, post-reconstitution, etc.), 13 plus under CTC conditions (for time TCTC with decay slope DCTC). Assay validation provides the 14 precision (standard error) of the potency assay. The product release model (Figure 1) defines the 15 known potency of the product at the time of release. From this information, it is possible to 16 calculate the 95% lower bound (LB) on mean potency of product that is released at the minimum 17 release potency, as follows1: 18 LB1-α= MRP + T1 DT1 + T2 DT2+…+ Tn DTn+ TCTC DCTC + U 19 20 21 Where MRP is minimum allowable release potency (where potency is log-transformed), Ti is 22 time at temperature i, DTi is decay slope (normally a negative number) at temperature I, and U is 23 the combined uncertainty associated with the independent calculation of the other numbers on 24 the right side of the equation, e.g. 25 U= z1- α x sqrt((sassay)2+( T1 sDT1) 2+( T2 sDT2) 2+…+( Tn sDTn) 2+ ( TCTC sDCTC) 2) 26 27 28 Where z1- α is the one sided z statistic, at the confidence level associated with the desired degree 29 of confidence (usually α=.05, for 95% confidence bounds, sassay is the assay precision (standard 30 error), and sDTi is the precision (standard error) of the decay slope at temperature i. Thus, the 31 expected end-expiry potency depends on the release potency, the actual stability of the product at 32 the various temperatures and times of exposure, and an error term. 1 As noted, the equations listed are for the general case that could inculde modeling storage, shipping, postreconstitution, etc.. However, when only considering the normal storage condition and a single CTC excursion, an example of a simplified form of the equations (which could be applied to each of the three presented) would be: LB1-α= MRP + T1 DT1 + TCTC DCTC + U Page 14 1 2 Without a CTC excursion and with omission of the CTC-associated terms, the above equation 3 yields the actual potency that a product is expected to maintain throughout its dating period, and 4 represents, for already licensed products, the potency that is assured using the already existing 5 release model. Inclusion of the CTC term allows a reviewer to determine the degree to which 6 that minimum assured potency is affected by the CTC excursion and can allow a determination 7 of whether or not that is acceptable. 8 9 A preferred approach is to first identify the minimum potency (LL) below which there is some 10 concern about product efficacy (ideally, based on the potency data of the clinical lots), and set 11 the 1-α confidence interval on the lower bound on allowable potency to that level and to 12 rearrange the terms of the above equation to determine the minimum release potency required to 13 maintain potency through expiry including the CTC excursion, conceptually describing the 14 amount of potency that must be added to that minimum potency in order to assure product 15 quality throughout the normal storage period plus CTC excursion: 16 17 MRP = LL + T1 DT1 + T2 DT2+…+ Tn DTn+ TCTC DCTC + U 18 19 This provides a convenient way to determine whether a release model will support CTC 20 labelling. If no CTC excursion potential is identified then several options could be considered as 21 outline in Section 4 (see also the “Product Release Model” definition in Section 3 and the related 22 Figure 1, in Section 4). It should be noted that the analytical principles represented in the 23 equations above are the same as those in the existing WHO vaccine stability guidance (8), but 24 the forms represented in this document are expanded versions and explicitly refer to a CTC 25 excursion. Additionally, the equations here are not the only ways to represent these calculations 26 and that other approaches that encompass the same principles could potentially be acceptable. 27 28 6. Monitoring temperature conditions in the context of CTC 29 30 Vaccine manufacturers, distributors and users control, monitor and record the temperature during 31 storage, transportation and delivery to the end users in the cold-chain to ensure that all vials of 32 vaccines are kept in the recommended storage conditions. 33 Page 15 1 Vaccine administrators that use vaccines outside of the cold-chain, as in the CTC, should have 2 established formal procedures for the recording of use, transport containers, monitoring the 3 maximum temperatures and the discard of unused vaccines that have been exposed to the CTC 4 excursion. Examples are WHO Guidelines concerning the use of MenAfriVac™ (meningitis A 5 vaccine) in a controlled temperature chain (CTC) during campaigns (11-13). 6 7 These procedures are specific for each vaccine type, detailed by the immunization programme, 8 and should be considered by the regulatory authority when evaluating an application for CTC 9 labelling of a vaccine. CTC temperature monitoring systems need to be able to distinguish a 10 vaccine that is still appropriate for use from a vaccine that has exceeded the limits imposed by 11 the data supporting CTC use. Since vaccines for CTC use can only be considered for a single 12 CTC excursion, and in most cases will be discarded at the end of the excursion, the two most 13 important parameters to monitor are the maximum temperature to which vaccines are exposed 14 during a CTC excursion and the time that the vaccines have been exposed to the CTC 15 temperatures. 16 17 Assuring that vaccine containers are not exposed to temperatures that exceed a maximum 18 temperature during a CTC excursion requires suitable peak temperature threshold indicators (11- 19 13). Non-reversible indicators that indicate whether a given temperature has been exceeded are 20 widely available and can be packaged with vaccine intended for CTC administration. These peak 21 temperature indicators do not need to be incorporated in the vaccine vial, but should be an 22 important programmematic component to assure that excursions do not exceed the labelled 23 maximum temperatures. Ideally, one or more of these indicators will be located in boxes 24 containing vaccine vials, positioned in a location or locations that is both most vulnerable to 25 temperature excursions and where it will reflect temperatures that actual vaccine vials could be 26 exposed to. 27 28 A vaccine that has undergone a CTC excursion must be distinguishable from a vaccine that has 29 not and the time of exposure to a CTC excursion must also be monitored and recorded. In 30 vaccination campaigns where the vaccine will be discarded at the end of the CTC excursion, this 31 can be accomplished by marking vials each day of excursion, such that when a predefined 32 number of marks is exceeded, the vaccine should be discarded. This marking can be performed 33 on unopened boxes, but once a box is opened, it should be performed on unused individual vials 34 at the end of each day. While peak temperature threshold indicators could be used to identify a 35 vaccine that has undergone a CTC excursion, neither such indicators (nor vaccine vial monitors, Page 16 1 as currently manufactured) are able to measure the time of CTC temperature exposure, and thus, 2 some additional strategy to assure that vaccine vials do not exceed the labelled time for CTC 3 exposure is needed. Whatever strategy is used, it should include features that reduce the 4 likelihood of errors, such as requiring marking to be double-checked by a second person. It is 5 anticipated that improved monitors that could measure the time that a box or vial is exposed to a 6 CTC temperature may become available. Such devices could be considered for CTC use, in the 7 context of the product labels. 8 9 Most pre-qualified vaccines supplied through United Nations agencies will include a vaccine vial 10 monitor (VVM) which is a label containing a heat-sensitive material placed on the vaccine vial 11 to register cumulative heat exposure over time. Several different types of VVM are available and 12 the manufacturer should select a type suitable for their vaccine and provide evidence of 13 suitability from appropriate stability tests with the vaccine. The details and use of the VVM are 14 described in WHO/PQS/E06/IN05.2 (2011) (14) 15 16 However, the current available VVMs are not sufficient in monitoring the vaccines in the field in 17 a CTC context because they generally do not provide information that would allow readily 18 distinguishing a vaccine that has undergone a CTC excursion from a vaccine that has not and 19 also do not provide information that can distinguish between a vaccine that has undergone the 20 maximum CTC excursion from that which has not. Yet, unless stability or potency data indicate 21 a different course of action, vaccine vials provided with a VVM should be discarded if the VVM 22 indicates that the vaccine is not suitable for use. 23 24 25 7. Suggested label language for CTC indications 26 Information on CTC should be described in the product leaflet/package insert to provide 27 information for medical practitioners. The statement on CTC should be a separate paragraph, in 28 the ‘conditions of use’ section. No CTC statement should appear on the vial or syringe itself or 29 on the boxes. 30 31 The CTC information on the label should be clear, concise and specific. If the vaccine consists of 32 two or more components (e.g. lyophilised vaccine and diluent), CTC information should be 33 given for all components of a specific vaccine. 34 Page 17 1 Information to be included in CTC statements should consider the following, if applicable: 2 - maximum temperature; 3 - maximum time at a specific temperature; 4 - time after opening (or reconstitution or mixture), if applicable; 5 - advice on unopened vials exposed to CTC (e.g. discard); 6 - single excursion within the shelf-life. 7 8 Proposed text for single use alternate storage conditions 9 In situations where the 2-8oC cold chain cannot be maintained [immediately prior to 10 administration], the vaccine [and its diluent or other component] can be kept for a single period 11 of time of up to [x days or x weeks or x months] at temperatures of up to [xoC]. At the end of this 12 period, the vaccine [must be discarded]. [After opening [or reconstitution or mixture], the 13 vaccine can be kept for [x hours or x days] at temperatures of up to [xoC] at which point it must 14 be discarded]. 15 Page 18 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 Authors& acknowledgments The first draft of these guidelines was prepared by: Dr Christoph Conrad, Department of Virology, Paul-Ehrlich-Institut, Langen, Germany; Dr Elwyn Griffiths, WHO consultant, Surrey, UK; Mrs Teeranart Jivapaisarnpong, Institute of Biological Products, Department of Medical Sciences, Bangkok, Thailand; Dr Jongwon Kim,Technologies, Standards and Norms (TSN) Team, Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland; Dr Ivana Knezevic, Technologies, Standards and Norms (TSN) Team, Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland; Dr Phil Krause, Division of Viral Products, Office of Vaccines, Center for Biologics Evaluation and Research (CBER), Food and Drug Administration (FDA), Bethesda, Maryland, USA; Dr Jinho Shin, Expanded Programmeme on Immunization (EPI), Regional Office for the Western Pacific (WPRO), World Health Organization (WHO), Manilla, Philippines; Dr Dean Smith, Bacterial and Combination Vaccines Division, Centre for Biologics Evaluation, Health Canada(HC), Ottawa, Ontario, Canada; Dr James Southern, Adviser to Medicines Control Council of South Africa, Cape Town, South Africa; Dr Tong Wu, Bacterial and Combination Vaccines Division, Centre for Biologics Evaluation, Health Canada (HC), Ottawa, Ontario, Canada;taking into account comments received from: Dr Bartholomew Dicky Akanmori, Routine Immunization and New Vaccines (RIN), Regional Office for Aftrica (AFRO), World Health Organization (WHO), Brazzaville, Congo; Dr Silmara Cristiane Da Silveira, Agencia Nacional da Vigilancia Sanitaria (ANVISA), Ministerio da Saude Esplanada dos Ministerios, Brasilia, Brazil; Ms Anna-Lea Kahn, Expanded Programmeme on Immunization (EPI), World Health Organization (WHO), Geneva, Switzerland; Dr Andrew Meek, Pre-Qualification Team (PQT), Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland; Dr Carmen A, Rodriguez Hernadez, PreQualification Team (PQT), Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland; Ms Simona Zipursky, Expanded Programmeme on Immunization (EPI), World Health Organization (WHO), Geneva, Switzerland. Acknowledgement is given to Dr Mike Walsh, Centre for Biologics Evaluation, Health Canada (HC), Ottawa, Ontario, Canada for providing expertise on the mathematical modelling and statistical approach of the section on product specific CTC evaluation of a model of monovalent polysaccharide conjugate vaccine. This first draft was based on the Ottawa and Langen CTC consultation reports prepared by: Dr Maria Baca-Estrada, Bacterial and Combination Vaccines Division, Centre for Biologics Evaluation, Health Canada (HC), Ottawa, Ontario, Canada; Dr Christoph Conrad, Department of Virology, Paul-Ehrlich-Institut, Langen, Germany; Dr Elwyn Griffiths, WHO consultant, Surrey, UK; Dr Jongwon Kim, Technologies Standards and Norms (TSN) Team (formerly Quality, Safety and Standards Team (QSS)), Department of Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland; Dr Ivana Knezevic, Technologies Standards and Norms (TSN) Team (formerly Quality, Safety and Standards Team (QSS)), Department of Essential Medicines and Health Products (EMP), World Health Page 19 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 Organization (WHO), Geneva, Switzerland; Dr Phil Krause, Division of Viral Products, Office of Vaccines, Center for Biologics Evaluation and Research (CBER), Food and Drug Administration (FDA), Bethesda, Maryland, USA; Dr Morag (Ferguson) Lennon, Horning, UK; Dr Heidi Meyer, Viral Vaccines Section, Paul-Ehrlich-Institute, Langen,Germany; Dr Volker Oeppling, Microbiological Vaccines, Paul-Ehrlich-Institute, Langen, Germany; Dr Michael Pfleiderer, Viral Vaccines Section, Paul-Ehrlich-Institute, Langen, Germany; Dr Jinho Shin, Technologies Standards and Norms (TSN) Team (formerly Quality, Safety and Standards Team (QSS)), Department of Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland (currently Expanded Programmeme on Immunization (EPI), Regional Office for the Western Pacific (WPRO), World Health Organization (WHO), Manilla, Philippines); Dr Dean Smith, Bacterial and Combination Vaccines Division, Centre for Biologics Evaluation, Health Canada(HC), Ottawa, Ontario, Canada; Dr Ralf Wagner, Viral Vaccines Section, Paul-Ehrlich-Institute, Langen, Germany; Dr Tong Wu, Bacterial and Combination Vaccines Division, Centre for Biologics Evaluation, Health Canada (HC), Ottawa, Ontario, Canada; Ms Simona Zipursky, Expanded Programmeme on Immunization (EPI), World Health Organization (WHO), Geneva, Switzerland. Acknowledgments are extended to the following participants dedicated to presentation and discussion at 1) Ottawa, Canda 4-6 December 2012 and 2) Langen, Germany 4-6 June 2013: 1) Ottawa consultation: Dr Maria Baca-Estrada, Bacterial and Combination Vaccines Division, Centre for Biologics Evaluation, Health Canada (HC), Ottawa, Ontario, Canada; Dr Miga Chultem, Office of Policy and International Collaboration, Biologics and Genetic Therapies Directorate, Health Canada (HC), Ottawa, Canada; Dr Christoph Conrad, Department of Virology, Paul-Ehrlich-Institute, Langen, Germany; Dr Silmara Cristiane Da Silveira, Agencia Nacional da Vigilancia Sanitaria, Ministerio da Saude Esplanada dos Ministerios, Brasilia, Brazil; Dr Lindsay Elmgren, Centre for Biologics Evaluation, Health Canada (HC), Ottawa, Ontario, Canada; Dr Diana Felnerova, Crucell, Berne, Switzerland; Dr Darcy Akemi Hokama, BioManguinhos, Rio de Janeiro, Brazil; Mrs Teeranart Jivapaisarnpong, Institute of Biological Products, Department of Medical Sciences, Bangkok, Thailand; Dr Jongwon Kim, Technologies Standards and Norms (TSN) Team (formerly Quality, Safety and Standards Team (QSS)), Department of Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland; Dr Ivana Knezevic, Technologies Standards and Norms (TSN) Team (formerly Quality, Safety and Standards Team (QSS)), Department of Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland; Dr Jehanara Korimbocus, Agence nationale de sécurité du médicament et des produits de santé (ANSM), Lyon, France; Dr Phil Krause, Division of Viral Products, Office of Vaccines, Center for Biologics Evaluation and Research (CBER), Food and Drug Administration (FDA), Bethesda, Maryland, USA; Dr Alda Laschi, Sanofi Pasteur, Lyon, France; Dr Corine Lecomte, GlaxoSmithKline Vaccines, Wavre, Belgium; Dr Morag (Ferguson) Lennon, Horning, UK; Dr Denis Georges Maire, Pre-Qualification Team (formerly Quality, Safety, and Standards Team(QSS)), Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland; Dr Heidi Meyer, Viral Vaccines Section, Paul-Ehrlich-Institute, Langen,Germany; Dr Bernardo Luiz Moraes Moreira, Agencia Nacional da Vigilancia Sanitaria Secretaria de Vigilancia Sanitaria, Brasilia, Brazil; Dr Kyung-Tak Nam, National Center for Lot Release, National Institute of Food & Drug Safety Evaluation(NIFDS), Ministry of Food and Page 20 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 Drug Safety (formerly Korea Food and Drug Administration (KFDA)), Cheongwon-gun, Republic of Korea; Dr Maria Luz Pombo, Biological Vaccines Office, Pan American Health Organization, (PAHO), World Health Organization (WHO), Washington DC, USA; Dr Jinho Shin, Technologies Standards and Norms (TSN) Team (formerly Quality, Safety and Standards Team (QSS)), Department of Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland (currently Expanded Programmeme on Immunization (EPI), Western Pacific Region Office (WPRO), World Health Organization (WHO), Manilla, Philippines); Dr Dean Smith, Bacterial and Combination Vaccines Division, Centre for Biologics Evaluation, Health Canada(HC), Ottawa, Ontario, Canada; Dr Tong Wu, Bacterial and Combination Vaccines Division, Centre for Biologics Evaluation, Health Canada (HC), Ottawa, Ontario, Canada; Dr Maribel Vega, Centre for Genetic Engineering and Biotechnology (CIGB), Havana, Cuba; Dr Ming Zeng, Institute for Biological Product Control, National Institutes for Food and Drug Control (NIFDC), Beijing, P. R. China; Ms Simona Zipursky, OPTIMIZE, C&o PATH, Ferney/Voltaire, France. 2) Langen consultation: Dr Marie-Christine Annequin, Agence nationale de sécurité du médicament et des produits de santé (ANSM), Saint-Denis, France; Dr Koen Brusselmans, Scientific Institute of Public Health, Brussels, Belgium; Dr Claus Cichutek, Paul-EhrlichInstitute, Langen, Germany; Mr William Conklin, Merck, Whitehouse Station, New Jersey, USA; Dr Christoph Conrad, Department of Virology, Paul-Ehrlich-Institute, Langen, Germany; Dr Silmara Cristiane Da Silveira, Agencia Nacional da Vigilancia Sanitaria (ANVISA), Ministerio da Saude Esplanada dos Ministerios, Brasilia, Brazil; Ms Diane Doucet, GlaxoSmithKline Biologicals SA, Bruxelles, Belgium; Dr William Egan, Novartis, Columbia, Maryland, USA; Dr Sunil Gairola, Serum Institute of India Ltd., Pune, India; Dr Elwyn Griffiths, WHO consultant, Surrey, UK; Dr Weidan Huang, Xiamen Innovax Biotech Co., Xiamen, China; Mrs Teeranart Jivapaisarnpong, Institute of Biological Products, Department of Medical Sciences, Bangkok, Thailand; Dr Jongwon Kim, Technologies Standards and Norms (TSN) Team (formerly Quality, Safety and Standards Team (QSS)), Department of Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland; Dr Phil Krause, Division of Viral Products, Office of Vaccines, Center for Biologics Evaluation and Research (CBER), Food and Drug Aministratiom (FDA), Bethesda, Maryland, USA; Dr Houda Langar, Regional Office for the Eastern Mediterranean (EMRO), World Health Organization (WHO), Cairo, Egypt; Dr Alda Laschi, Sanofi Pasteur, Lyon, France; Prof Henry Leng, Somerset West, South Africa; Ms Angelica Lopez, Biológicos y Reactivos de México S.A. de C.V. (BIRMEX), Col Popotla, Mexico; Dr Avril Luethi, Crucell Switzerland AG, Bern, Switzerland; Dr Walter Matheis, Microbiological Vaccines, Paul-Ehrlich-Institute, Langen, Germany; Dr Andreas Merkle, Microbiological Vaccines, Paul-Ehrlich-Institute, Langen, Germany; Dr Heidi Meyer, Viral Vaccines Section, Paul-Ehrlich-Institute, Langen, Germany; Dr Bernardo Luiz Moraes Moreira, Agencia Nacional da Vigilancia Sanitaria Secretaria de Vigilancia Sanitaria (ANVISA), Brasilia, Brazil; Dr Kyung-Tak Nam, National Center for Lot Release, National Institute of Food & Drug Safety Evaluation(NIFDS), Ministry of Food and Drug Safety (formerly Korea Food and Drug Administration (KFDA)), Osong, Republic of Korea; Dr Ria Nibbeling, Institute for Translational Vaccinology, AL Bilthoven, Netherlands; Dr Volker Oeppling, Microbiological Vaccines, Paul-Ehrlich-Institute, Langen, Germany; Dr Danay Mora Pascual, Centro para el Control 27 Estatal de la Calidad de los Medicamentos (CECMED), Havana, Cuba; Dr Michael Pfleiderer, Viral Vaccines Section, Paul-Ehrlich-Institute, Langen, Page 21 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 Germany; Dr Thaddeus Prusk, Temptime Corporation, Morris Plains, New Jersey, USA; Dr Martin Reers, Biological E Ltd, Azamabad, Hyderabad, India; Dr Carmen Rodriguez, PreQualification Team (formerly Quality, Safety, and Standards Team(QSS)), Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland; Dr Timothy Schofield, Medimmune, Gaithersburg, Maryland, USA; Ms Fita Amalia Setyorini, Biofarma, Bandung, Indonesia; Dr Satyapal Shani, Central Drugs Standard Control Organisation, FDA, New Delhi, India; Dr In Soo Shin, National Institute of Food & Drug Safety Evaluation(NIFDS), Ministry of Food and Drug Safety (formerly Korea Food and Drug Administration (KFDA)), Osong, Republic of Korea; Dr Jinho Shin, Technologies Standards and Norms (TSN) Team (formerly Quality, Safety and Standards Team (QSS)), Department of Essential Medicines and Health Products (EMP), World Health Organization (WHO), Geneva, Switzerland (currently Expanded Programmeme on Immunization (EPI), Western Pacific Region Office (WPRO), World Health Organization (WHO), Manilla, Philippines); Dr Dean Smith, Bacterial and Combination Vaccines Division, Centre for Biologics Evaluation, Health Canada (HC), Ottawa, Ontario, Canada; Dr Ralf Wagner, Viral Vaccines Section, Paul-Ehrlich-Institute, Langen, Germany;Dr Tong Wu, Bacterial and Combination Vaccines Division, Centre for Biologics Evaluation, Health Canada (HC), Ottawa, Ontario, Canada; Ms Sally Wong, Vaccine and Biological Stability, Merck, Whitehouse Station, New Jersey, USA; Ms Simona Zipursky, Expanded Programmeme on Immunization (EPI), World Health Organization (WHO), Geneva, Switzerland. Page 22 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 References 1. WHO Strategic Advisory Group of Experts on Immunization (SAGE) April 2012 http://www.who.int/immunization/sage/meetings/2012/april/presentations_backgroun d_docs/en/index.html [access 24.04.14] 2. WHO Immunization Practices Advisory Committee (IPAC) 2012 http://www.who.int/immunization/policy/committees/IPAC_2012_April_report.pdf [access 24.04.14] 3. McCarney S, Zaffran M. Controlled Temperature Chain: the New Term for Out of the Cold Chain. Ferney: PATH; 2009. www.technet21.org/index.php/resources/documents/doc_download/725-controlled-temperaturechain-the-new-term-for-out-of-the-cold-chain [access 02.12.14] 4. D Butler. Vaccines endure African temperatures without damage: Anti-meningitis campaign in Benin delivers more than 150,000 doses with no losses from excess heat. http://www.nature.com/news/vaccines-endure-african-temperatures-without-damage1.14744#/ref-link-1 [access 02.12.14] 5. S Zipursky, M Djingarey, J-C Lodjo, L Olodo, S Tiendrebeogo, and Oliver Ronveaux. Benefits of using vaccines out of the cold chain: Delivering Meningitis A vaccine in a controlled temperature chain during the mass immunization campaign in Benin 2014 http://www.sciencedirect.com/science/article/pii/S0264410X14000723 [access 02.12.14] 6. Meeting report of WHO/Health Canada Drafting Group Meeting on Scientific and Regulatory Considerations on the Stability Evaluation of VAccines under controlled temperature Chain, Ottawa, Canada, 4-6 December 2012 http://who.int/biologicals/areas/vaccines/CTC_FINAL_OTTAWA_Web_Meeting_re port_25.11.2013.pdf?ua=1 [access 02.12.14] 7. Meeting report of WHO / Paul-Ehrlich-Institut Informal Consultation on Scientific and Regulatory Considerations on the Stability Evaluation of Vaccines under Controlled Temperature Chain, Paul-Ehrlich-Institut, Langen, Germany, 4-6 June 2013 http://who.int/biologicals/vaccines/CTC_Final_Mtg_Report_Langen.pdf [access 02.12.14] 8. Guidelines on stability evaluation of vaccines. Annex 3 in: WHO Expert Committee on Biological Standardization. Fifty-seventh report. Geneva, World Health Organization, 2011 (WHO Technical Report Series, No. 962). http://who.int/biologicals/vaccines/stability_of_vaccines_ref_mats/en/index.html [access 02.12.14] 9. Philip R. Krause. Goals of stability evaluation throughout the vaccine life cycle. Biologicals; 2009, 37: 369-378. 10. Timothy L. Schofield. Vaccine stability study design and analysis to support product licensure. Biologicals; 2009, 37: 387-396. 11. Use of MenAfriVac™ (meningitis A vaccine) in a controlled temperature chain (CTC) during campaigns: Guidance for immunization programmeme decision-makers and managers: http://apps.who.int/iris/bitstream/10665/86018/1/WHO_IVB_13.04_eng.pdf?ua=1 Page 23 1 2 3 4 5 6 7 8 9 10 11 12 12. Use of MenAfriVac™ (meningitis A vaccine) in a controlled temperature chain (CTC) during campaigns: Training module for organizing immunization sessions: http://apps.who.int/iris/bitstream/10665/86019/1/WHO_IVB_13.05_eng.pdf ?ua=1 [access 02.12.14] 13. Use of MenAfriVac™ (meningitis A vaccine) in a controlled temperature chain (CTC) during campaigns: Adaptation guide and Facilitators guide: http://apps.who.int/iris/bitstream/10665/86020/1/WHO_IVB_13.06_eng.pdf?ua=1 [access 02.12.14] 14. Guidelines for manufacturers of temperature monitoring devices, http://www.who.int/immunization_standards/vaccine_quality/WHO_PQS_E06_GUI DE_1.2.pdf [access 02.12.14] Page 24 1 2 3 Appendix: Product Specific CTC Evaluation of a Model Monovalent Polysaccharide Conjugate Vaccine 4 The model vaccine and the stability data presented in this section were developed based on 5 Health Canada’s overall experience with conjugate vaccines but do not represent characteristics 6 or data from any specific product. The vaccine example under evaluation is a monovalent 7 conjugate vaccine composed of purified capsular polysaccharide (PS) covalently attached to 8 diphtheria toxoid (DT) protein. The final vaccine product is non-adjuvanted and presented in 9 single-dose vials. The normal storage temperature recommended for this model conjugate 10 vaccine is 2-8ºC and the temperature under consideration for the CTC application is 40ºC. The 11 quality attributes monitored in routine stability studies included total PS, free PS, molecular size 12 distribution, free protein, pH and sterility. Free PS is generally considered a key stability 13 indicating attribute for polysaccharide conjugate vaccines. The specification for free PS for this 14 model conjugate vaccine was set as “Not More Than (NMT) 30%”, as vaccine lots containing 5- 15 30% free PS were shown to be safe and immunogenic in clinical studies. A review of 16 manufacturing data indicated that 90% of the commercial lots contained less than 10% of free PS 17 at release, while 10% of lots contained free PS in the range of 10-14% at release. 18 19 Stability data 20 Real time and real condition stability studies were conducted to establish the shelf life under 21 normal storage conditions (2-8ºC) and to support CTC application. Routine stability monitoring 22 tests were performed for 4 commercial vaccine lots stored at 2-8ºC and for an additional 4 23 commercial lots stored at 40ºC. In addition, O-acetyl content, NMR spectrum and 24 immunogenicity (rSBA and IgG) in a mouse model were also performed to characterize vaccine 25 lots stored under 40ºC condition. Analysis of routine monitoring data revealed that several 26 quality attributes, including total PS, molecular size distribution, free protein and pH, remained 27 stable for all lots stored under 2-8ºC and 40ºC condition. However, an increase of free PS was 28 observed for all lots as summarized in Tables 1 and 2. 29 Table 1: Summary of free PS content at 2-8ºC Free PS (NMT 30%) Lot # 0 3M 6M 9M 12M 18M 30 31 24M 30M 36M 1 7.53 9.58 10.73 11.17 12.54 16.22 18.99 ND* 19.75 2 7.01 9.36 10.77 10.32 10.59 11.92 14.60 14.56 15.03 3 2.38 6.01 8.13 7.46 8.94 9.37 10.08 11.09 10.88 5.71 6.15 7.85 7.77 4 NMT: not more than. M: month. NT: not tested. 9.02 10.87 13.92 14.84 16.90 Page 25 1 Table 2: Summary of free PS content at 40ºC Free PS (NMT 30%) Lot # 0 1W 2W 3W 4W 6W 2.01 2.38 4.81 6.18 9.39 11.39 5 8W 13.55 10W 13.67 12W 13.88 6 1.74 5.71 4.64 3.48 5.89 6.65 6.79 6.92 9.26 7 5.43 10.48 10.49 10.59 13.94 15.35 15.66 15.57 16.88 5.21 8.05 9.45 8 NMT: not more than. W: week. 9.05 12.71 15.10 15.72 15.73 17.26 2 3 4 Statistical analysis 5 Statistical analysis was performed to estimate the increase of free PS over time under both the 2– 6 8°C and 40°C storage condition. Both log-transformed and non-transformed data were analyzed 7 and neither fit a linear model with high precision, likely due to varying decay rates over the 8 storage times being evaluated. A comparison of graphical representations of the analysis 9 indicated that the non-transformed data was a better fit with a linear model and therefore the 10 results from the analysis of the free PS data are presented below in Tables 3 and 4. 11 Table 3: Summary of statistical analysis of free PS data under 2-8°C condition Slope (free PS increase per month, %) Estimated free PS increase (%)* Data Set Mean STD 95% percentile 24M 36M 0.330 0.085 0.469 13.71 4 lots (0-24 M) 0.269 0.079 0.398 17.42 4 lots (0-36 M) STD: standard deviation. *The estimated free PS increase = T1 DT1 + U (described in section 5 of this document). 12 13 14 15 16 17 18 19 20 21 22 23 Table 4: Summary of statistical analysis of free PS data under 2-8°C and 40°C Slope (free PS increase per Estimated accumulated free PS after 24 week, %) at 40°C month at 2-8ºC plus CTC duration (%)* Data Set 95% 3 days of CTC 4 days of CTC Mean STD percentile (40°C) (40°C) 1.444 0.378 2.066 15.30 15.60 4 lots (0-4W) 0.803 0.225 1.172 4 lots (0-15W) STD: standard deviation. *The estimate increase = T1 DT1 + TCTC DCTC + U (described in section 5 of this document). When a change is observed for a key stability indicating parameter during a stability study (e.g. an increase of free PS or decrease of potency), statistical analysis should be used to determine the rate of change with a specified confidence (typically 95%) of this parameter. This may be performed by linear regression or other appropriate techniques using log transformed or non-transformed data. 24 25 Under the 2-8°C condition, it was noted that the estimated rates of free PS increase (95% 26 percentile of slope) was higher over the 24 months (0.469%/month) relative to that over 36 27 months (0.398%/month) as shown in Table 3. Since differences in rates of change for key quality 28 attributes over a product’s shelf-life are not uncommon, this highlights the need to characterize 29 trends when modeling the data and the need to estimate the rate of change based on real time Page 26 1 data over the full shelf-life. In this case, the statistical analysis summarised in Table 3 revealed 2 an increase of free PS of 13.71% after 24 months storage and 17.42% after 36 months storage. 3 4 Similarly, analysis of the data under the 40°C condition indicated that the rate of free PS increase 5 was higher during the first 4 weeks (2.066%/week) than that estimated for 15 weeks 6 (1.230%/week) as shown in Table 4. Given the rapid increase in free PS at 40°C, additional data 7 points during the first week would have aided the precision of the estimate. Although the data set 8 is not ideal, what is presented in this example is representative of what could be submitted to a 9 NRA. Due to the limited test points as well as limited number of lots tested, data up to the 4- 10 week test point was used to calculate the rate of free PS increase for the initial phase. The 11 statistical analysis summarized in Table 4 revealed an increase of free PS of 2.066% (or 12 0.295%/day) after one week of storage. As additional information, the 4 vaccine lots studied for 13 the CTC application had been previously stored at 2-8ºC for variable lengths of time, from 14 shortly after release to 20 months post-release, and an analysis of the available data suggested 15 that the duration of vaccine storage at 2-8°C did not impact the rate of free PS increase at 40°C. 16 Since the age of the lots when exposed to 40°C is less of an impact than the total storage time at 17 the 2-8°C on the free PS increase, the latter is considered the worst case scenario. 18 19 Following the methodology described in section 5 of this document, the total increase of free PS 20 after a 24 months storage at 2-8°C followed by a 3-day or 4-day storage at 40ºC was calculated 21 as 15.30% or 15.60% respectively (Table 4). 22 23 Conclusion 24 Based on principles of the “product release model” discussed in this document, different 25 specifications for release and at end of shelf-life should be established for free PS for this model 26 conjugate vaccine. The specification at the end of the shelf-life should not generally exceed 30%, 27 supported by clinical lots shown to be safe and immunogenic in clinical studies. Considering the 28 following: 29 - 30 31 an increase of free PS under the 2-8ºC condition is 13.71% after 24 months storage and 17.42% after 36 months storage, based on statistical analysis, - all commercial lots contain less than 15% free PS at release (manufacturing capacity), 32 a release specification of NMT 15% free PS and a 24-month shelf-life were determined to be 33 appropriate for this model conjugate vaccine. This conclusion ensures that “worst case lots” in 34 which contains the highest level of free PS permitted by the specification (NMT 15%) at release, 35 plus the accumulation of free PS during the storage period (13.71% with 95% percentile) comply Page 27 1 with the end of shelf life specification (NMT 30%). On the other hand, if the rate of 2 accumulation of free PS is not considered and only the reported free PS levels at each of the test 3 points are verified against the specification (NMT 30%), a minimum of 36-month shelf-life 4 would be accepted since all stability lots met the end of shelf life specification (NMT 30%) at 5 36-month test point. From this example it can be seen that if the accumulation of free PS and 6 worst case factors are not taken into account, this can result in an over-estimate of the shelf-life. 7 Also, the difference between worst case accumulation of free PS at 24 months and the end of 8 shelf-life specification of NMT 30% free PS approximately defines the available “free PS 9 budget” for the CTC excursion. Given that the estimated free PS increase after 24 month storage 10 at 2-8°C followed by a 3-day storage at 40ºC is 15.30%, the worst case lot (containing 15% free 11 PS at release) would contain 30.30% free PS at the end of CTC excursion, which slightly 12 exceeds the specification (NMT 30%). Considering the likelihood of an over-estimate of free PS 13 increase due to limited data set, the conservative approach in mathematical modelling and the 14 fact that the highest free PS content leading to unsatisfactory clinical performance has not been 15 established, it is considered acceptable that the free PS of the worst case lots slightly exceeds the 16 limit at the end of shelf-life. Therefore, a single storage period of 3 days at 40ºC, prior to 17 immunization, was considered acceptable. 18 19 Discussion 20 As explained in section 4 of this document, clinical testing of a vaccine stored under CTC 21 conditions might not be necessary as long as a battery of stability monitoring tests provides 22 sufficient assurance that the critical quality attributes (e.g. potency) of the vaccine meet the 23 specifications established in clinical studies. The following key quality attributes related to 24 vaccine clinical performance were assessed for this model conjugate vaccine: 1) Total PS and O- 25 acetyl content remained stable. 2) PS structure was confirmed using nuclear magnetic resonance 26 (NMR); 3) The specification for free PS at the end of shelf life (NMT 30%) was within the limit 27 showed to be safe and immunogenic in clinical studies; and 4) Carrier protein integrity was 28 supported by the results of an in vivo immunogenicity test. It was noted that the antigen dose 29 used to immunize the mice was within the dose response curve, indicating that the in vivo test 30 was of acceptable sensitivity. In conclusion, the available stability data sets assessing critical 31 quality attributes are considered sufficient to support the a 3-day CTC application of this model 32 conjugate vaccine.

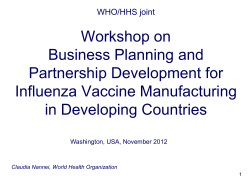

© Copyright 2025