N-FLOW™ Breaker System Product Presentation

N-FLOW™ Delayed Action Filter Cake Breaker EXTERNAL SALES PRESENTATION Customer Challenge Producing the well at maximum potential © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 2 Customer Challenge Incomplete filter cake removal may result in: ▌ Formation damage ▌ Decreased production and injection rates Increased costs Increased rig time Chemical costs © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 3 Traditional Acid Breakers Traditional acid breakers can: ▌ Expose corrosive acids, which can lead to HSE issues ▌ Provide uncontrolled and localized reaction ▌ Increase the risk for wormholing ▌ Require specialized trucks, tanks and equipment © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 4 Baroid’s Solution – N-FLOW™ Filter Cake Breakers N-FLOW™ breakers offer a delayed reaction, providing uniform distribution, reducing the risk of ‘hot spots’, and preventing the risk of corrosion and formation damage. ▌ Oil and water-based filter cakes ▌ For formations with a wide range of temperatures and pressures © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 5 N-FLOW™ Filter Cake Breakers Value Proposition ▌ N-FLOW™ Delayed Action Filter Cake Breaker can effectively remove filter cake with an in-situ reaction, leading to reduced formation damage and increased production. © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 6 N-FLOW™ Filter Cake Breakers Applications ▌ Horizontal wells ▌ Open hole gravel pack ▌ Injector wells for filter cake removal ▌ Sandstone, dolomite, and limestone formations ▌ Deepwater applications ▌ Workover and completion © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 7 Key Features ▌ Neutral pH at surface ▌ In-situ reaction ▌ Uniform distribution for even removal ▌ No downhole “hot spots” ▌ Removes wormholing potential © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 8 Key Features ▌ Controlled corrosion risk ▌ Does not require special trucks, tanks or equipment ▌ All components are environmentally acceptable ▌ Can be mixed in the surface rig pit and pumped down-hole © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 9 Filter Cake Deposition and Removal Process one Deposit filter cake during drilling. © 2014 HALLIBURTON. ALL RIGHTS RESERVED. two Clean wellbore and prepare for filter cake removal. three Displace to wellbore fluid containing N-FLOW™ breaker. 10 four five Reaction takes place over the prescribed duration. After filter cake removal, the well begins to produce. Return Permeability – N-FLOW™ Breaker ▌ Berea sandstone core material exposed to 10.8 parts per gallon (ppg) NaCl/NaBr/BARADRIL-N™ fluid. Filter cake was exposed to N-FLOW breaker. © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 11 Customer Benefits ▌ Safer than conventional acid breakers - Excludes harsh chemicals - Safer for workers and environment ▌ Cost-efficient - Mixed at the surface rig pit and pumped down hole, leading to simplified operations ▌ Effective filter cake removal -Fully controlled, in-situ reaction ▌ Enhance production and injection quickly and efficiently by evenly removing the filter cake Helps increase production © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 12 BEFORE N-FLOWTM AFTER N-FLOWTM Create maximum production and injection potential by effectively removing filter cakes with N-FLOWTM breakers. © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 13 Case Study – N-FLOW™ 325 Filter Cake Breaker System Leads to Increased Production Rate Location: Kazakhstan, Mangistau Region CHALLENGE: Reducing formation damage in newly drilled 6” production intervals and in older wells during workover operations Increasing production rates Removing filter cake SOLUTION: BARADRIL-N® non-damaging drill-in fluid was used, providing a thin filter cake, and helping to prevent damage to the reservoir After extensive testing, the N-FLOW™ 325 system was customized for the operator’s well conditions and proposed as the filter cake breaking system Laboratory test results were reviewed by Baroid Global Technical Advisors and the program was implemented on 5 trial wells RESULT: After treatment of the wells with the N-FLOW 325 system, the operator’s production department measured an increase in the productivity index Averaged over the 5 wells, the increased production rate amounts to 86.2% improvement in produced oil volume CASE STUDY © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 14 Case Study – Engineered Baroid Fluid Systems Help Operator Exceed Predicted Production Rate in Tight Sandstone Reservoir Location: Central Saudi Arabia CHALLENGE: Minimize formation damage, and ultimately increase reservoir producibility while drilling a 1,660 ft 6 1/8-in reservoir section horizontally across sandstone formation Logging-while-drilling data also showed a major shale body on top of the sandstone reservoir section to be drilled SOLUTION: The interval was drilled with an 8.7 lb/gal (65 pcf) INVERMUL® oil-based mud The open hole section was then enlarged to 7-in and displaced to a customized 8.7 lb/gal (65 pcf) solids-free oilbased drill-in fluid (DIF) A 68-bbl N-FLOW™ treatment was placed inside and outside the screen using the rig pump at a rate of 250 gpm. The drillstring was then pulled to the top of the screen. After 1.5 hours, losses averaging 60 bph were observed. This indicated that the N-FLOW breaker delayed reaction had performed as planned. RESULT: After the well was brought on production, the operator reported oil flowing immediately upon submersible pump activation at a steady productive rate, significantly exceeding offset producers performance CASE STUDY © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 15 Case Study – Non-Damaging Water-Based Fluid and N-FLOW ™ 408 Breaker System Lead to Maximum Production Rates Location: United Kingdom CHALLENGE: Minimize formation damage Optimize production through removal of filter cake without inducing losses SOLUTION: BARADRIL-N® water-based drill-in fluid system was bridged with a blend of acid soluble calcium carbonate material specifically tailored to the porosity range of the reservoir N-FLOW™ 408 breaker was designed to remove the bridging material and filter cake Both fluids were tested against the reservoir core to ensure compatibility and minimal formation damage RESULT: The reservoir section was drilled successfully, ensuring minimal seepage losses and damage to the formation The N-FLOW 408 breaker successfully removed the filter cake from the wellbore, allowing the operator to successfully test and suspend the well After the N-FLOW 408 breaker was spotted and inhibited for 24 hours, the maximum constrained flow rate of 52 million scf per day was reached and was well within the anticipated range. CASE STUDY © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 16 Related Documents Data Sheets Technical Papers Customer Presentation Quicksheet Case Histories © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 17 Baroid Reservoir Fluid Solutions Reservoir Drilling Fluids Breaker Systems Completion Fluids Wellbore Clean-Up and Displacement Packages Breaker Systems for Click on image above to launch ecosystem,then click on Launch Interactive ► Polymer and Solids Removal Lost Circulation in the Reservoir www.halliburton.com/baroid © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 18 Who to Contact Alan Marr Product Manager, Completion Fluids Alan.marr@halliburton.com Phone: +44 1224 776785 http://www.halliburton.com/en-US/ps/baroid/fluid-services/fluidadditives/corrosion-control.page © 2014 HALLIBURTON. ALL RIGHTS RESERVED. 19

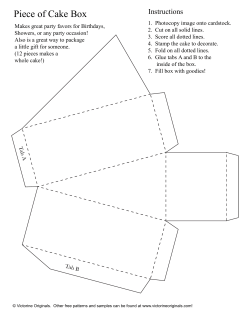

© Copyright 2025