Document 7468

Travers Aviation has been developing special

relationships with Beech customers for the past 47 years.

Our ability to provide personal service and attention sets

us apart from the rest of the field . We realize that our

customers' time is valuable, so we make our aircraft

insurance simple. Our friendly and efficient staff is

always available to answer your questions.

1-800-888-9859

•

Traverst.:;>t'fT ssoclates

AVIATION INSURANCE NATIONWIDE

Successfully Combining Business and Pleasure

Glen Travers

SINCE 1950

Darla Sanford

"Not for one single tenth of a tach hour has there been any regrets with buying NIYR. The

Bonanza is the most superior all-around aircraft ill its class that I've flown." -Bill Lavellder

Bonanza

of the

Month

N1YR

1975 V35B

eneral aviation can often spur a

young person to greater heights.

In the case of our son, Graham,

it has done just that. He was raised in an

aviation community. Shortly after birth,

I took him spraying in my Ayres Turbo

Thrush, a large agricu ltural aircraft powered by a single PT6A-II turboprop.

It was only natural for Graham to solo

on his sixteenth birthday. The aircraft was

a 150HP Citabria that we had flown crosscountry from northern California six

months before.

Six years ago, our company, AgAir

Update , an intern ational agricultural

aviation publication, established an annual event called "AgAir Update's Annual Excursion." Each year, Graham and

I have spent a week to I0 days journeying across America writing ag aviation

G

1975 V35B Bonanza (SI N 0-9797)

articles using various forms of transportation, including a C-1 82 and a Citabria.

Graham received his Pri vate Pilot 's

licen e shortly after his eventeenth birthday. In the summer of 1996, we bought

IYR, a 1975 V35 B Bonanza with 3161

IT and 700 SFRM. Graham "officially"

had logged about 75 hours , mos tl y

tailwheel time. The checkout in the Bonanza went smoothly and within a few

hours, Graham soloed N I YR. Today, at

19, Graham has more than 100 hours

logged in NI YR, including two 25-hour

cross-country excursions west from

Georgia to Colorado, north to Canada,

east through North and South Dakota,

Minnesota and back to Georgia.

Wi thin a week of bringing N I YR

home from Memphis, Tennessee, the aircraft was put in the paint shop. The ugly

chocolate and taD colors were changed

to today's Air Tech Coaling 100 percent

polyurethane Glare Whi te paint. In the

summer of 1997, th e accents were

painted over by AeroPaint Il with metallic Winfield Bronze and Harvest Gold.

The metall ic accents add a nice touch to

Comilllled 011 page 5535

BONANZA OF THE MONTH

Cover: Th is 1975 V35B belongs to Bi ll Lavender of Perry, Georgia. ""

55 20

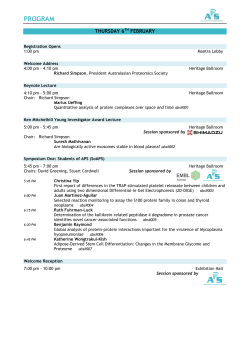

FEATURES

(lSSN 01 61 -35 45)

Publ;shed by

AME RICAN BONANZA SOCI ETY

Orga nized Ja n uary 1967

GUEST EDITORIAL

By Steve YOllng, Raytheon Aircraft Company . ............•......... 5522

ROCKIN'THROUGH THE ROCKIES

By Charlie Gibbs . ...................•...... _ ... . .. .. ... . ..... 5523

SEALING THE GAPS

By Geo rge Wilh elmsen ....... . ..... , ........... . ........ . ..... 553 1

AEROMEDICAL CERTIFICATION

By Jack Hastings, M.D.

5533

O XYGEN ALERT

By Itzhak Jacoby

ASS EXECUTIVE D IRECTOR

ED ITOR IN CHIEF

Nancy Jo hnson

PU BLI CATION O FFICE

192 2 M;df;eld Road

P.O. Box 1288B

Wichita, KS 67277

316-945- 1700

° Fax 316-945- 17 10

ABS web si te: http://www, bo na nza.org

ABS e-mai l : bonanza2@bonanza.org

Send articles/letters to the

above address/fax/e-mail.

ED ITOR

Betty Rowley

ASSOCIATE EDITOR

Tom Hutchinson

.... , ' . . . . . .... 5536

A TRIPTO ALASKA AND NORTHWEST TERRITORIES

By David Davidson ...

. ......... . .... . . . .. .. . ... . ... . " .... 5542

DEPARTMENTS

COLVIN'S CORNER .. . . . ... 5525

by Neil Pobanz alld Arl.·J FOlllk

INSU RANCE , .. , .. ,., .... 5537

Illduslry calls/or cautioll

by John Allen, Falcon Illsurallce

SHOPTAL K ....

by Lynn Jenkins

5538

AVION ICS, ..... , ...

.5540

Autopilots, comilllled

FORUM ...

5544

CU RREN TS

"E" engine repairs

by Lew Gage

55 4 7

REG IO N A L N EWS . .

555 0

GROUN D CONTROL

by Nancy Johnson

5553

CALENDAR . .... .

.5554

by Jim Hughes

DES IGN EDITOR

Ji m Simpson

BPPP SCHEDULE ....• 5534

SERVICE CLINIC SCHEDULE .... 5530

D ISPLAY A DVE RTI SING DIR ECTO R

John Shoemaker

2779 Aero Park Drive, P.O. Box 968

Traverse Ci ty, M I 49664

Support the American Bonanza Society

WIth a Life Membership for $1,000

1-800-773-7798, ext. 3317

PRI NTER

Vil lage Press, Traverse Ci ty, Michigan

AMERICA'I aO'lA"IZA SOCIETY MAGAZl'I[ is published monthly by the AmeriCan !kInanziI Society at the

Wichita Mid·Conlln('nt Ailporl. 1922 Mtdiicld ~oad ,

Wichita, KS 67209. The price of iI yearly w~rip'iorl is

U'lcluded in the annl4l1 dues IS45) of Soclcty mem~.

Periodical postage paid ,11 WIChita, Kansas, and addi·

\ionallTldiling onices

The Society and Publisher CAnnot .accept responSIbility

for the corredroess or accuracy of the mailers printed

herein Of for .my opiniOflS ('xpres~. Opinions of the

EditOf" o r contribulOO do nol necessarily rC'Presenl the

flO5ition of the Society. Publisher reserves tnc righl to

rej("(t any malerial submitted (Of" publication. Copy submilled for publicJtioo shnll become Ihe property of Ihe

SOclt!1y Jnd sha ll not be return(."CI. Arlicles submitted with

accompanying pictures roc;t>i\'e publication prdereoce.

Pictures will be returned whene-.Ct" possible.

AN"UA l DUES: US--S45,

Colnada & Mexico-S45 IUS) Forcign--S75 tUS!

Ufe mcmbership-$ 1,000.

Contact ASS Ileadquarten for delOlils.

POSTMASTER, send Jddu~ss chanl:es 10: American

Bonanza Sociely, P.O. Box 128811. Wichita, KS 67277

o Copyrigl1\ 1999

Page 5521

PAST PRESIDENTS

BOARD OF DIRECTORS

Term e~pires

WIL LI AM C. CARTER, PRES ID ENT (AR EA 2) ...... 2001

7131 Driftwood Drive, SE, Grand Rnpids, M149546

TIL DEN D. RIC HARDS, V. P. (AREA 7) ..•

P.O. 801' 1047. Sutler Cl"C('k. CA 95685

HAROLD BOST, TREAS URER (A REA 3) .•..•

760 Bin"dJle Drive, FayeltC\ille, GA 302 15

IO N RQADFElDT, SECRETARY (AR EA 4 ).

1999

.. 2000

2()()1

1548 W. Sextant, Roseville. MN 55 11 3

MICHAE L HOE FfLER (AREA 1 ) .•....•.

43 Old SUSilr Road , Bolton, "IA 0 1540

2001

RICH ARD T. STRICKLAND, (AREA 5) .....

1999

9200 Chicol ROdd. little Rock , AR 72209

JACK CRONIN (A REA 6 ) ..

2& 1 Vine Slreet, Dem'ef, CO 80206

2000

WI LLIS M. HAWKI NS, (Area. 8)................ 2000

21931 Bum.ank Blvd .. • 35, \-Voodland Hills. CA 91367

RONALD K. VICKREY (DIRECTO R AT LARGE).

2084 Coun1ry Club Dr., Dnytona BeJch, rL 32124

e- rll.lil : rvick rt'y@n·jcenlcr.com

199'J

8.J . McC(an<lhlln, MD . .

Fra nk G. Ross .

Ru ssell W. Rink.

Hypolite T. Landry. JI.

Catvin R. E,l,ly. "ID, PhD .

Capt. Jesse F. Adams. USN(REn .

DJvld P. Barton .

Alden C. Barrios.

rred A. Drisc:;oU, Jr.

E.M. Anderwn, Jr..

Donald l. Mo nday .............. , .

Harry G. Hadler.

}Ohn E. Pixton .

Charles R. Gibbs .

Ioseph McC lai n, 111 .

lee larson.

\o\'illiam H. Bush ..

R.lY L. Lea dabr.md

IJMeS C. Cassell, III.

Warren E. HorfllCt" ..

lohn 11. Kil bourne.

Barrie Hiern

Rcm Vickrey.

Willis Hawkins.

1967-1971

1971-1973

1973- 1975

1975-1 976

1976-1977

1977- 1978

1978--1 979

1979-1980

1980- 1981

1981-1983

1983-1984

1984--1985

1985- 1986

198h-- 1987

1987- 1988

1988--1989

1989-1990

1990- 1991

1991 -1 992

1992-1993

1993-1994

1994- 1996

19%-1997

1997- 1998

A BS January 1999

(

I feel pril'i1eged 10 imrodllce Steve

Young 10 Ihe ABS orgmli:.orion. Stel'e

has given generollsly of his time and

knowledge concerning the BOllan:.a,

issues thm concern slIpporting older

aircraft, mId whar Raytheon's real Slip·

POrt o/Ihe lIew piston aircraft business

offers.

I first mel STel'e when he g(ll'e tlte

ABS Board of DireClOrs a IOlIr of the

RaYlheml Aircraft facilities in lVichira.

We were impressed willi Stel'e 's energy,

commitment and knowledge of Ihe air·

aafl bllsi,leSJ. I lI'as especially im·

pressed with his cam/or. We expecl 10

hear more from him as changes take

place. This is the best way 10 be prepared fo r the fut ure.

- Bill Carter, president

Business Units consist of representatives from across the company. The members of this team include Manufacturing,

Engineering, Sales and Marketing, Quality Assurance. Supply Management,

Prod uct Support and Business Managemenl. Our teams plan a product 's entire

life cycle from Engineering Development

through Sales and aU the way 10 Product

Supporl.

The two most immediate responsibilities of the Piston Business Unit are 10

identify and resolve key Baron and Bonanza issues and to represel1l the voice

and interest of the cuslOmer.

As a team, we measure our business

health, delennine priorities and then track

progress as issues are resolved. This same

team manages our program resources.

There are limits to program budgets requiring tough choices. At a minimum,

Steve Young

Guest Editorial

GreetingsABS members. My name is

Steve Young. Before you get me confused

with the San Francisco Forty-Niner quarterback, let me tell you that I am the Pi ston Airplane Business Unit Director for

Raytheon Aircraft Company. In the next

few paragraphs, I will explain what our

Business Unit is about and the opportunities we have in supporting your piston

airplanes and building new ones.

Business Units (sometimes referred to

as Integrated Product Teams) were created to focus our company on our customers' by-product line. There are similar business uni ts representing al l

Raytheon products, such as Premier [,

Hawker 800XP, Beechjet and King Air.

ABS January 1999

every program must be responsi ve to

regulatory requirem en ts . Thi s has

changed over the years from the original

CAR-3 certification basis to the current

FAR Part 23 . The recent upgrade of the

fifth- and sixth-seat attachments (as announced in Service Bulletin 25-3 159) is

an example of responding to Lhese changing requirements.

The Piston Business Unit is also focused on cost reduction. We work closely

with our suppliers to improve production

costs and importantly for you. cost of

operation. One such example is close

work with our supplier of Bonanza landing lights to increase service life. This

light is in a high-vibration environment

and we have tested several iterations of

bulbs and mounting techniques.

Our team works to improve the quality of the Beech Bonanza and Beech

Baron ai rcraft. Here at the factory, we are

continually working on riveting, aircraft

sealing, sheet metal assembly and system install ation. Today we are experi meming with improved paint formula-

tions such as base coat and clear coat like

the automotive industry. Alternate windshield sea lers and adhesives are being

tested to find improved temperature stabi lity and ease of application.

We are also working on several out-

standing customer issues. These include

Baron heated windshield leaks, Bonanza

vibration and noi se, the Bonanza landing light service life I mentioned earlier,

standby generator reliability, air and water leaks, cabin door locks and others.

Many times the resolut ion of these issues is not as straightforward as we wou ld

all like it to be. Frankly, a challenge we

face is that we are working with a 50year-old airplane design. It is fantastic in

its longevity; however, it 's not real easy

to build. The Bonanza has many detail

parts and assemblies Lhat require handfitting . We depend on skilled mechanics

and as you know, they are in demand

throughout our industry.

[n the area of spare parts support, we

have endeavored to provide the level of

service that our Bonanza owners should

rightfully expecl. We are currently undergoing several management changes and

initiatives within Raytheon Aircraft Parts

Inventory Distribution (RAPID) 10 improve service. You wi ll soon find higher

stock ing levels at Authorized Service

Centers and quicker response to your direct inquiries. We fully intend to regain

your confidence in our spares activities,

providing world-class customer support.

Along with the Bonanza heritage

comes the task of supporting a myriad of

differing airplane models. As a company,

we are committed to continue to support

Beech 18s, Travel Airs and all of the

Bonanza and Baron vari ants. We are

working V-tail Bonanza issues and Model

18 spar corrosion concerns. These ta ks

are focused on supporting customers but

do not result in needed product improvements. Product improvements are vital if

the Bonanza is to survive into the future.

[n the coming months, you' ll be hearing about some important improvements

to the new Bonanzas that will soon begi n rolling off the assembly line. ['m excited about the changes, and when they

are successful in the marketplace, they' ll

give Raytheon sound business reasons to

continue the great Bonanza tradition .

-Steve Young

DirectOl; PislOn Business Unit

Raytheon Aircraft Company

Page 5522

I

Charfie Gibbs flying over Beaver Creek, Colorado.

I

n all my years of flying-and that goes back to 1961- I' ve

always had a desire to make special trips and go special

places in my airplane. Just flying tn new places makes it so

exciting! Now that Donna and 1are new owners of a condominium in Beaver Creek, Colorado, I was challenged with the

desire to fly my Bonanza to our new mountain home. The April

1998 ABS Magazine announcement of a Mountain Flying Course

offered by the BPPP, Inc. was just what I needed.

I opted to leave my home in Jacksonville, Florida, on Thursday, June 18. After researching the chans, I found what I hoped

would be an interesting overnight stop in Dodge City, Kansas.

Fortunately, the weather was great all the way out except for a

brief period of thunderstorm avoidance in central Arkansas.

I was up bright and early Friday and left in time for an 8 a.m.

arrival at Colorado Springs (COS) to begin the course right after lunch. This was my first opportunity in many years to land

at a relatively high altitude airport. The curiosity of why I had a

sputtering engine whi le taxiing to a tiedown led me to believe 1

had a whole lotto learn in the course.

The classroom program was well administered by John and

Agnes Porter and the Friday afternoon lecture programs proved f

excellent. The classroom work included topics such as mountain weather, mountain flying wisdom, engine operation, and

the ever-present concern of "What do I do if the engine quits?"

As with all BPPP courses, the material is well prepared and

specific to Bonanzas and Barons. Our final hour of classroom

work involved flight planning for the next day's trip. At that

time, you are assigned an instructor with whom you meet and

discuss the flight plan.

My assigned instructor was Bill Hale, president of the BPPP,

Inc., a true Bonanza wizard! Bill met me Saturday morning at

the airport around 7 o'clock, I preflighted the plane and away

we went. The training began immediately upon start-up. We

flatlanders are just not used to leaning the mi xture during taxi

"Expect 30 minute delay " Aspen tower

Page 5523

ABS January 1999

After depaning Leadville, we turned nonh, made a U-turn

and even more nervous about leaning during takeoff. I became

SQuth and finally turned west to gain enough altitude to clear

comfonable with both procedures very quickly because engines

Hagerman Pass (approximately II ,SOO feet) after passing over

indeed do work bener when properly leaned.

Turquoise Lake. After clearing

As we depaned COS to the

southwest, I learned a technique

Hagerman Pass you arrive over

for telling in advance whether

the Ruedi (pronounced Rude

Eye) Reservoir with an absothe ridge ahead was going 10 be

cleared. You just view the terlutely breathtaking view of the

rain beyond the ridge, and if it

valley and mountains surroundgrows as you approach the ridge,

ing Snowmass and Aspen.

clearance is assured. If it

After calling Aspen apdoesn ' t, turn around, c limb

proach with our intentions, a

higher and try again. Now, this

relatively abrupt descent was

is an obvious geometric piece of

necessary to make sure that the

Aspen Airport (7,SI5 MSL)

information, but it's one of those

was attainable. Aspen has airthings you just don't appreciate

port survei llance radar and

until you see it up close (200 feet

they' re already looking at you

AGL) and personal.

Charlie Gibbs and Bill Hale at Leadville, Colorado

We next new over NORAD

by the time you call. Aspen is

and then the Royal Gorge, followed by a swing around the tip

also a one-way airpon with a landing on their 7,004-foot runof the Sangre De CrislO mountains, and a turn nonh up the Arway 10 the southeast and a depanure 10 the nonhwest. Even

kansas River valley for our first landing at Salida, Colorado. It

though June is not a particularly busy time there, the BPPP

has a si ngle runway (7,350 feet) with a 1.9 percent grade to the

weekend made it mighty busy.

southwest (Runway 24). You actually climb 141 feet from the

After about 30 minutes waiting for a takeoff clearance, we

east to the west end of their runway. The purpose in landing at this

depaned northwest IOward Glenwood Springs with a right tum

airpon is to become acquainted with "one-way" airpons that reeastbound at Interstate 70 to land at Eagle Airpon, which is the

quire a landing in one direction and a departing from the other.

closest airpon to both Vail and Beaver Creek. Eagle's S,OOODuring the landing ponion, we had a headwind of IS knots

foot runway is easy to navigate, but some relatively high mounds

and subsequently went 10 the end of the runway, turned around.

close to the approach end of Runway 25 would make it unacand took off downhill with that same IS-knot tailwind. We

ceptable in marginal weather.

headed nonh along the gorgeous Arkansas River valley past

We depaned Eagle to the east, followed Interstate 70 to BeaTwin Lakes and Mt. Eiben (Colorado's highest mountain at

ver Creek through Vail Valley, south at Minturn following Route

14,433 feet) to Leadville.

24 past Ski Cooper (again over Leadville), and a tum east across

Unfonunately, the IS-knot tailwind at Salida turned into an

the Tarryall Mountains using Pike's Peak as our landmark for the

IS-knot crosswind for our landing at Leadville. Leadville is

return to COS.

advenised as "Nonh America's Highest Airpon" at 9,927 MSL

During the ground school portion, one of the "no go" admonitions was to not ny if the winds aloft in the mountains exceed

which can equate to a density altitude of 13,000 feet on a hot

day. For our trip, Leadville was the only point where we shut

30 knots. Well, the forecast winds were right at30 knots. So the

down and that's nO! 10 be missed since the people who run the

final leg from Leadvi lle back to Colorado Springs included

airpon are always happy to provide a "Cenificate of Pilotage" for

enough bumps to make you appreciate how imponant that wind

speed restriction is.

your accomplishment.

Depanure from Leadvilie is a

Upon our return at COS,

there wasn't an unhappy face

"by the book" exerc ise in that

in the group. We all shared

after you've developed max

simi lar stories and we were

power (about 40 percent), rehappy to tell each other just

leased the brakes, you drive forhow much fun we had. It was

ever before your Bonanza is fithe "Joy of Flying" all over

nally airborne. It's critical to keep

the Bonanza within ground effect

again!

until best rate of climb speed is

Charlie Gibbs was president of

obtained which in our case, with

the American Bonanza Society in

the IS knot direct crosswind, was

1986-87.

interesting to achieve.

ABS January 1999

Page 5524

Clen "Arky" Foulk

Neil Pobanz

A36 heater problem

Joseph Bates

Sewickley, Pennsylvania

n:

n~uck

We fly a 1995 A36 and are having

getting heat to seats three and

four. I pulled the elliptical panel under

the copilot seat and found the hose securely attached to th e outlet gri ll. The aft

cabin control pulls out fouror five inches

and st ill no heat. I would very much appreciate your suggestions.

A:

Success in heating depends on several factors. These can include the absence of leaks allowing cold air into the

cabin; the absence of leaks over and above

the designed exhaust air vent flowage.

which can result in heated airflow passing

through the cabin too quickly: the collapse

or blockage of hoses or ducting, which prevents heated air from reaching the complete distribution system; and the sticking

or improper operation of valves, causing

improper distribution.

The problem ca n also be inadequate

heat transfer at the mumer. which acts

as a heat exchanger providing heated

clean air to the cabin. This can result if

the volume of cold air mo vement is too

high for the available mumer heat generated by the engine. When the outside

air is very cold, higher engine power settings may be required to generate a high

enough exhaust temperature to obtain

sufficient cabin heat. System distribution

leaks or missing mumer barnes also decrease efficiency.

If you have hot air available somewhere, but not where you need it, look

at the distribution system valves, hoses

Page 5525

and ducts. If you don ' t have hot air anywhere, check the muffler and firewall

sh utoff valve.- NP

Zeftronics (903-758-6661 ) may have a

less expensive replacement.-NP

H35 shoulder harness

Tom Stewart

Morro Bay, California

Robin Malim

Hereford, United Kingdom

Q: My aircraft is fitted with what I

think are the original seat belts: a full

harness and no inertia reels. Awful and

pretty useless! J want to equip it with

inertia-reeled diagonal lap straps. Does

anyone do an STC'd conversion kit?

What is my best bet to upgrade this installation?

A: Raytheon doesn't have a kit per my

kit catalog for your model. Wag Aero

(800-558-6868) does have a kit, but with

no inertia reel. Safety Limited (630-5849366) has a field-approval design. These

are your current choices on an H35.

Check with the UK authorities for approval before proceeding as they may

have differing requiremen ts.- NP

F33A voltage regulator

Dale Walker

New Wilmington, Pennsylvania

Q:

1 have a spare voltage regulator

made by OECO, Beech PIN 35-3800933. I have called OECO abou t rebuilding

or repairing thi s unit and they advise me

that they no longer support this part. Do

you know of another company that may

be able to repair it?

A: Try Aircraft Accessories of Okla-

homa (800-255-9924) and EMI (800851-4392) as good sta rting points.

D55 leather yokes

Q:

Can you suggest where I might get

so me leather covers for the dual ram's

hom yoke?

A:

Warren Gregoire and Associates

(800-634-0094) has been confirmed as

a provider of leather covering for ram's

horn wheels on both the Baron and Bonanza yokes.- P.

Cracks in Osborne tip tanks

Bill Olson

Nokomis, Florida

Q:

law n a Beechcraft Debonair.

Model 35-A33 , 425T, SI CD-28 I

with 20-gallon tip tanks. The original installation was accomplished in April

1965 in accordance with Beech Kit 33688-1. At that time, the tanks were called

Brittain tip tanks.

The tanks are of aluminum construction with some sort of fiberg lass or epoxy covering. The left tank is from the

original installation while the right one

has been replaced. This tank has some

cracks in the area where the tank meets

the wing section. These cracks run chordwise and are in th e curved area adjacent

to where the airfoil section meets the

body of th e tank. While there are cracks

on both the upper and lower areas, there

seem to be more cracks on the upper side.

Without removing the outer covering, it

ABS January 1999

is not easil y possible to determine if the

aluminum is also cracked.

This was one of several discrepancies

pointed out to us during an ABS Service

Clinic inspection at the Palm Beach LantanaAirport in October 1998. The cracks

have been evident for a number of years,

but no mechanic has squawked them in

recent annual inspections.

Do you have any previous history of

such crac ks in these tip tanks? What do

you suggest we do to determine the extent of the cracks? Can you tell us how to

safely remove and replace the outer covering or whether we should send the tanks to

o borne for evaluation and repair?

4542) do this type of modification. In

add ition to the seat modification. structuce change is required. Aviation Enter-

prises, Inc., 3900 E. Spring Street, Long

Beach, CA 90806 had an STC th at may

be avai lable.- ' P

A36 cabin insulation

Michael H eaton

Indianapolis, Indiana

Q:

I would bet the cracks are in the

filler covering the aiuminulll , but one

can' t tell without looking. I wou ld call

Osborne (800-963-8477) and ask for

wrillen guidance. I' ve seen cracks that I

I am considering adding some insulati on to the ca bin of my A36TC.

Would you consider thi s a worthwhile

exercise? A product by th e name of

''Thinsulator'' has been recommended to

me. Could you provide me with advice

on this product or any other insulation

products you know about? I would also

ap preciate having any installation tips

regarding th ese types of material, such

as placement of the material, adhesives

was reasonably sure were just surface

to

A:

cracks in the filler material. but they are

the experts on the continuous airworthiness of their product.-N P

A35 stall warning

F.H. "Cash " Copeland

Oakland, California

Q: Does Beech have an ap proved

drawing or has anyone obtai ned a field

approval or STC to replace the top of the

wing stall warning switch assembly with

a leading edge stall warning switch such

as is used on th e Model G35 and up?

A: Raytheon had a kit which is no

longer listed. We 're sure people have

used a home-made template made from

a later wing and. using later factory parts,

ha ve gOllen field approvals. Sources for

parts include salvage ya rd s such as

Dodson (800-255-0034), White (80082 1-7733). Dave Monti (702-782-5282)

and Atlanta (800-237-8831 ).-N P

F35 new seats

Greg Kahrs

Quincy, Illinois

Q: Can you tell me if it is possible

(legal) to put a newer style front seat in

my plane? I would very much like seats

th at adjust backward and forwa rd . I

would also settle for a new fixed-position seat. but with a few more inches of

leo room using the original seat.

A:

Both Air Mod (51 3-732-6688) and

Aviation Research Systems (503-668-

ABS January 1999

use, etc.

A:

While I have no perso nal experience with ''Thinsul ator ' as such. I un derstand the need to redo the soundproofing ar various times throughout the life

of an aircraft. One has to be careful to

replace insul ation. not add, if you don' t

want to suffer penalties in useful load.

Also, be certain to use onl y aircraft approved materials to prevent fire and airframe corrosion hazards.

I will say it 's hard to beat the professionals at this and Air Mod (5 13-7326688), Cameron Interiors (630-5849366) and Kalamazoo Aircraft (6 16-38 10790) are all near you. A variety of FAA

certified so undproofi ng material and adhesives are available from Aircraft

Spruce (800-83 1-2949). Wag Aero (800558-6868) and Chief Aircraft (800-4473408).

Some adhesi ves can cause corrosion

and, over lime. some "new improved"

materials have been determined to hold

moisture, crumble into dust or otherwise

deteriorate.-NP.

P35 leaking fuel caps

Robert Tigani

New Castle, Delaware

n:

I am losing fuel out of my rig ht

t;;;;'k . The ca p is very ti ght filling compared to the left tank. Could the problem

be the cap is too tight to seal properly or

is the fuel going back into the tank filling the tank to overflow? This does not

always happen but usually just when the

tanks are full. I have looked for leaks in

the fuel cells but have not fou nd any.

A:

The P35 Bonanza excess fuel return from the engi ne is directed to the

tank being used- thu s prohibiting an

overflow co ndition. Since you don ' t

mention finding any fuel on the ground

under the aircraft or fuel stains under the

wing along the main spar, I assume you

are losing fuel from arou nd the fuel cap

in flight.

This should be visible to the pi lot or

passenger. If so, I suspect you may need

new O-ring seals for the cap. There is a

small O-ring around the cap's center

shaft plus a large outer O-ring that you

can readily see when removing the cap.

Check for cracks in the rubber. I suggest

you change both of the seals on each of

you r two fuel caps if they show deterioration. Performance Aero (800-2003141) and American Aero (800-3596673) both offer these seals at reaso nable prices.-NP

A36 flucuating fuel pressure

Dr. Winfried Wilcke

San Jose, California

Q:

I recently departed in my 1978 A36

(10-520) from Palm Springs, California.

The OAT was 115 F. During climbout.

the fuel flow needle vi brated noticeabl y.

The vibration stopped once we reached

higher, cooler altitudes. I assume this was

a sign of fuel vapor forming in the fuel

lines. Is it acceptable andlor recommended to turn on the electric auxiliary

boost pump when this happens? Or is

there a dan ge r of completely flooding

and killing the engine?

A:

The various Bonanza, Baron and

Travel Air fue l-injected models have different auxi liary fuel pump installations.

Some have just "on/off' positi ons while

others have "high/offllow" positions. The

Pilots Operating Handbook for so me

models states that "in hi gh ambient temperatures, low press ure boost may be

required to preve nt excessive fuel flow

flucuation s."

Check your POH fo r recommended

operation in your aircraft. Whether you

have a single- or two-speed pump, you

may have to operate it in these extremely

hot conditions if fuel press ure flu ctuation is experienced. Be aware that you

may have to lean the mi xture more when

the pump is operating to prevent f1ood-

Page 5526

ing-especially with the single-speed

pumps. Basically, with the pump operating, you should lean, if necessary. to

attain the same fuel flow you would expect to see for any given power setting

with the pump not operating. The POH

calls this "lean as required."

Note that as you change throttle setlings the amount of leaning will also

change when the boost pump is opera!ing. Unfortunately, we don't always explain this situation well enough for pilots to know what to expect should they

have to fly with the pump operating.- P

855 burning odor on takeoff

Steve Dean

Gilmer, TeX~lS

control instruction, yo ur local FSDO is

the place to apply.

On your Baron, it sounds like it could

be the gear mOlar. It could be engine

exhaust or oil breather fumes brought in

by ai r turbulence through the vent system. Also, check your nose wheel and

nose gear retract rod "boot" at the rear

of the wheel well for signs of the tire

rubbing. One member reports using one

of the products used to make your tires

nice and shiny created an odor when the

nose tire rubbed against the boot.-NP

F33C leaking cabin door

Hansen Mogens

Watford, United Kingdom

cabin door is leaking quite a

Q: I read in the magazine something bitQ:at theMy lower

right comer. This door

about a requirement for waiver for giv-

ing biennial flight reviews and dual in-

struction in Bonanzas with single control wheels. Can you clarify? How do I

get a waiver? I've been flying as a eFT

in single-wheel Bonanzas si nce 1963.

Regarding my B55 Baron, on every

takeoff since the beginning of summer I

have detected the faint odor of burning

or overcooking. I thought at first it was

the extreme heat we were having this

summer with so many days in excess of

105 F. After the weather cooled off. I

could still smell it. It happens when I

retract the gear on takeoff. I have not

tried it to see if it smells on takeoff if I

leave the gear down.

When I got the AD on the electric door

seal, I thought that must be the problem.

However, the last two flights have been

without the door seal pump turned on and

the odor is still there. Next flight I'll leave

the gear down and see if the ooor occurs.

In all cases, the odor clears up within a

minute or so after takeoff. Any ideas?

A: The Flight Instructor's waivers ap-

ply to FAR 91.109a requiring dual controIs for flight instruction except in some

situations. FAR 61.56 flight review (biennial) also calls for one hour of fli ght

instruction. There is inconsistency

among the FSDO regions as to how the

ruling is to be interpreted. We are aware

of Flight Instructors being violated for

conducting BFRs with a single wheel.

Check your local FSDO for their interpretation. If they say it is OK to use single

wheel, get it in writing and send us a

copy. If you want a wa iver for si ngle-

Page 5527

does not have a pin in this position. The

door has some movement when lifted at

(he lower right, and pins seem worn in

hinges. Please advise how I should correct this problem.

A:

If the trai ling edge of the open door

can be lifted with visible forward motion of the upper hinge where it attaches

to the fuse lage, then I would think you

need a repair of the door hinge pins.

There may be a noticeable difference in

the amount of wear, depending on

whether the door is completely open or

only open an inch or so.

You may also have evidence of wear

on the upper cabin door frame and the

door trailing edge where the door is rubbing on the door frame due to excessive

saggi ng. This type of wear is becoming

more evident as the fleet ages and varies

in degree. The result is an ill-fitting door

with air and water leaks.

One case of in-flight upper door hinge

failure was recently reported. Fortunately, the door remained on the aircraft

despite pulling away from the door several inches at the top. Hinge andior hinge

pin replacement is a quite involved and

time consuming procedure that should be

accomplished by an experienced shop

familiar with the process.-NP

855 propeller overhaul

Douglas James

Edina, Minnesota

Q :I have three-blade Hartzell props

on my Baron and am having them overhauled. I have noticed that when the engi nes stop the props stop 180 degrees

apart. One engine stops with one blade

straight up and the other engine stops with

one blade straight down. Is this normal or

should I have the props reinstalled differenlly? Also, they informed me that it was

probably no more expensive to exchange

the Woodward governors than to rebuild

them. Any advice would be appreciated.

(

A:

The props may be improperly installed. The shop manual gi ves guidance

on installatio n. The No. I blade should

be over the TC mark (top center) on the

crankshaft flange. This resul ts in one

blade stopping in the "vertically up" posi tion. Sometimes in trying to resolve

persistent vibration problems, some mechanics will reposition a propeller in an

effort to achieve a smoother running engine. This results in the engine stopping

with one blade "vertically down." I have

seen the governors cost from $300 10

$1,300 to rebuild. The number of parts

and the technica l updates required

greatly affect the overhaul costs.-NP

Locking gas caps

Daniel). Neal

Maracaibo, Venezuela

Q:

Many years ago I became a member of the ABS. Through your periodical I was able to locate a manufacturer

of locking gas caps for my BE-58. Do

you have the address of a current manufacturer of locking gas caps for aircraft?

r

A:

Locking fuel cap sets are available

from Performance Aero (800-200-3 141 )

or Email (Performance @KCTERA.net).

In addition to their ad in the ABS Maga:ille, you may visit their website at http:/

/www.bonanza.orglperformance.-NP

833 water in the fuel tank

Cary Goodwin

Brewster, Massachusetts

Q:

Perhaps you might shed some light

on a "water at the bottom of the fuel

tester" problem. My B33 (1963, SN CD66 1, N50WL) provides me with approx imately one-half inch of water (and on

occasion, sediment) in the first fuel

sample drawn from the left wi ng tank.

The airplane is hangared and the tanks

are kept at least three-fourths full at all

times. The most puzzling aspect of thi s

problem is that it's not only happening

at the flfst fuel test of the day, but water

wi ll also appea r after an hour-long flight

to a nearby ai rport when a sam pl e is

ABS January 1999

r

taken before the next takeoff.

Once the first sample is drawn, discarded and a second sample taken, the

water is no longer present and we get a

clean test. Upon landing a short time

later, when another sample is drawn, the

water re-appears. Always the same

amount, always only the left tank. Do

you have any suggesti ons? The airplane

is going in soon for an annual and I just

thought I'd run it by you first.

A:

Condensation can cause water in

the fuel sample even in a hangared airplane. Otherwise. we suspect leaking fuel

cap seals. The aircraft moving in fUght

or on the ground can move water to the

sump drain that you couldn't reach before. This can be due to wrinkles in the

fuel cell. Some Cessnas require rocking

the aircraft after the first sample and then

resampling. Check the condition of the

outer fuel cap O-ring seal plus the small

seal on the center shaft of the cap locking mechanism. If these are cracked and

worn, you have probably found the

source of the contamination. Also, check

the cap adjustment to assure it is tight

enough to seat properly.-NP

M35 nose tire inflation

Mike Link

Simpsonville, South Carolina

Q:

A placard located on the right nose

wheel well door of my M35 (Serial D6192) indicates the nose wheel tire

should be inflated to 30 psi. However,

the latest revi sion of the Pilot 's Operating Handbook for the M35 indicates the

nose tire inflation pressure on Serials D5986 and after should be 40 psi. What is

the correct pressure for a 5.00 x 5 nose

wheel tire installed on an M35 ?

A36 annual inspection

Bud Kamman

Atlanta, Georgia

Q:

I am looking for someone to do an

annual on my 1985 A36. I would like to

locate someone within abo ut 50-100

miles of Atlanta, Georgia. to alleviate

ferry problems. Any suggest ions?

A:

Members have spoken well of

Wayne Parks at WHP Aviation, in Monroe, Georgia (770-267-2343). Also mentioned were Bob Ripley, Southern Aero

Services, Inc., Griffin , Georgia, (770229-2563), Lowe Aviation in Macon,

Georgia (9 12-78-3491) and, in Mobile,

Alabama, John Wimpee, Gulf Coast

Aviation (334-433-0831 ).-NP

M35 annual in Seattle

Bruce Burris

Enumclaw, Washington

g:

I recently purchased a 1960 M35

an am looking for a local Seattle area

mechanic or FBO to perform the annual.

I would appreciate any recommendation

or information you could provide.

A: We have heard good reports co n-

cerning Galvin Flying Service (206 7627242). Ask for John Dominick.-NP

A33 starter problems

Ron Miller

Monticello, Illinois

Q: I am ha vi ng problems starting the

engIne. it doesn't seem to want to turn

over even after replacing the battery and

ground strap and checking for current

draw when the airplane is completely

shut down . The original generator is still

in place. I thought I would rebuild the

generator or replace with an STC alter-

lay that isn ' t corroded, one would suspect the starter.

Looking for a big voltage drop while

attempting to start the engine is also a

good indication the starter may be bad.

The alternator STCs available for your

aircraft are 60 amp. from lnterav (210344-2785) and 70 amp. from National

(800-713- 1111 ).-NP

Life jacket and raft rental

John Hinshaw

Frankfort, Indiana

Q:

A: Several Florida FBOs

Is there some place in Florida that

rents approved life vests and rafts?

at international airports offer these and other services. Some wi ll also help you fill out

your international night plans and customsJimmigration paper work. ABS

member Ron Vickrey recommends Ft.

Pierce Air Center (800-446-7830) at the

Fort Pierce, St. Lucie County Airport.

They are experts on providing information for nights to the Bahamas. U.S .

Customs and a restaurant are located

adjacen t to the FBO and air traffic is usually much lighter than at some other 10calions. Another option is FBO, Banyan

Air Service (954-491 -3170) at Ft. Lauderdale Executive Airport. Survival

Products (954-966-7329) sells and rents

equipment and is located near the Hollywood North Perry Airport.-NP

G35 electric propeller

Paul Daniels

Ashland, Kentucky

( ) : I am considering purchasing a

on the STC or any other suggestion on

my starting problem?

1~6 Bonanza. This plane is equipped

with an electric fixed-pitch prop. I would

like to know your feelings on this. I have

heard good and bad on the electric props

and would like to ask someone who

knows what they are talking about.

How well does the engine crank

when the battery is charged and what is

the current draw when cranking? Mac,

Snap-On and APA have little current

induction ammeters that are good for

troub leshooting these problems. What

Over the years, this has proved to

be a very reliable and rugged propeller

with very few service problems. More

than 4,800 were installed as standard

eq ui pment on Bonanzas between 19471956 with many still in use today. As long

two weeks or so. Aircraft tires do not

sys tem voltage do you maintain with the

as it's operating smooth ly and main-

maintain pressure as well as your auto-

engine running ? It should be 13.75 to

14.25 volts at a 1500 - 2000 rpm, while

carrying a normal electrical load. If it

doesn 't crank normally with a battery

that is in good condition and full y

charged, a good ground and a starter re-

A: My reference shows 30 pounds on

the mains and 40 pounds on the nose tire

for the M35. Other models may vary.

This same tire carries 48-52 Ibs. on some

Barons. These recommendations have

changed for many models since they

were built or from the values shown in

earlier versions of the POH.

All of us should check tire press ures

against the POH recommendation every

mobile tires and thus require frequent

checks. It is not uncommon lO see aircraft preparing for takeoff with grossly

underinflated tires--especially the nose

tire. This leads to unnecesary wear.- NP

ABS January 1999

nator. Do you have a recommendation

A:

A:

tained properly (250-hour pitCh change

bearing lubrication and overhaul as re-

quired), it 's a good prop.

However, as with many other devices

that have been out of production

for many years, it is becoming more

Page 5528

difficult to locate parts and propeller

shops with the experience to properl y

service these propellers.

The ABS CD-ROM contai ns many

lengthy articles addressing the care and

operation of the electric propeller.-NP

A36 navcom antenna

joseph Fischetti

Southold, New York

Q: [

wi ll be painting my aircraft in

the coming months. I would like to remove the "boomerang" naveom antenna

from the top of the aircraft and replace it

with a less obtrusive type. I have been

told by some radio shops that I cannot

use the new fi n-type antennas without

reskinning the vertical stabili zer. One

radio shop says they can use the Cessna

"cat's whiskers"-type antenna on my aircrafl, while yet another shop says these

will not work. They recomm end the

"towel bar" type. I do not want to compromise the current quality of reception

for cost, but I still have a budget.

A:

The "towel bar" antenna is better

than the "cat's whiskers." The fi n types

are very good, but do need more reinforcement to support the installation. A

reputable avionics shop wi th Beech experience would be able to successfully

install any of the three and still ensure

good reception . Raytheon (5 16-7530500) or Jet Aviation (617-274-0030)

should be able to provide additional information .-NP

Model 33 panel lights

james Wright

Howell, Michigan

Q:

My Debonair on ly has the overhead panel lights. 1 am looking for options to install some more direct panel

lights. One option is a new product called

FibreLite, which is a fiber optic ribbon

installed in a bezel that fits between the

instrument and the panel.

Each instrument is connected to a

si ngl e shared 12124 volt light source

through a fiber optic cable. A kit to light

eight instruments costs $2 15. The problem is that both the product and the company marketing it are new.

The owner has installed the product

on his C-I72 and is working with hi s

A&P and the local FSDO to get a 337

approved. He has no plan s to pursue

STCs for other makes at this time bePage 5529

cause of the cost. My A&P says that the

337 route with no STC to base it on is a

tough row to hoe with the FAA . What

wo uld you advise?

A:

1 agree with your mechanic that

some FSDOs are reluctant to approve

337s without more data. Of course, using TSO' d eyebrow lights wi th the appropriate wiring and circuit breaker are

an option but can be expensive. Sporty's

(800-543-8633) has a little Swivelite,

item #9833 A for $24.95 that uses a

lithium battery. It requires no paper work

and works well.-NP

B58 Baron seat belts

Daniel Dunn

Scott City, Kansas

Q: 1 am searching for suppliers of

shoulder harnesses for my 1970, B5 8

Baron. If you have that info, I would sure

a~preciate it.

A:

Safety Ltd. (630-584-9366) offers

one option but the installation req uires

field approval. It's best to discuss in advance wi th your IA and local FSDO to

assure they will issue an appro val. The

Raytheon factory sells approved kits,

PIN 58-5009-9P, Service Bulletin 203 1,

Revision II, 58-5009-3P and 58-5005-1 P

dependent upon which seats the installation is to be made.-NP

B55 ignition noise

Keith Knowlton

Brooklyn, Connecticut

Q:

1 have been plagued for years with

igrution noise getting into the radio stack

th rough the tachometer generator wiring.

1t has happened on both engines, and

onl y when the electrical connectors and

mouming screws are absolutely tight

does the problem go away. We have replaced both the Cannon plug connectors

on the tach generators and the ones on

the cables. We have also contri ved ways

to enhance the safety wiring to help keep

them tigh t but , with vibration, th ey

loosen ever so sl ightl y and the noise is

back. If they are just a bit looser, the noise

gets so bad that you cannot receive anything and all the marker beacon lights

light up!

On a trip to Florida, [had to transmit

blind to NY center on 12 1.5 and tell them

1 had radio failure and where 1 was going to land . 1 then landed, removed the

tach generator electrical cable and con-

tinued to Florida without incident. We

have al so replaced the generators, but the

problem is the normal staccato of ignition wi ring and changes with the mag

selected as well as the manifold pressure

and mi xture on the engi ne. Any thought

would be welcome as well as hearing that

someone else has seen this happen.

A:

We' ll publish to see if anyone has

better ideas but it sounds like plain and

simpl e shielding problems to me.

Grounds and bonding may not be good

throughout the airplane.-NP

V35B chrome parts

joe Kremp

Washington, Indiana

Q:

Could you help me locate a source

for a new or remanufactured chrome pitot

tube as well as for the chrome masts,

front and rear, for the ADF antenna? This

is for a 1970 V35B.

A:

American Aero, 800-359-6673, is

one source offering rechroming service

on pi tot tubes, masts, steps and various

other items.-NP

G35 E-series engine overhaul f

Steve Espolt

Kingfisher. Oklahoma

Q:

I live in central Oklahoma and I

am quickl y approaching a major on engi ne and electric prop. 1 have talked to a

few shops in the Tulsa, Oklahoma, area.

My concern stems from reading your

colunm and the emphasis you place on

the correct rebui Id of the accessory case.

When talking to the local shops, they tell

me "It 's only an engine. They are all the

same." This concerns me in that they

don't share your veiwpoint.1 am requesting any shops that you wo uld recommend in my area or otherwise to perform

the major on my E-series engine. Also,

any propeller shops in my area that you

would recommend for major on the

Beech electric propeller. 1 was told a

couple years ago that [ would need to

rplace the blades.

A:

For propeller overhaul, 1 suggest

you contact U.S. Propeller Service (800749-7767) and Ottosen Propeller (602275-85 14). For E-series engine overhaul,

check out Poplar Grove Airmotive (800397-8 181 ), Cal Aero West (818-9977390) and Mont y Barrett (9 18-8351089). -NP

ABS Ja nuary 1999

I

Model 36 wing tip strobes

David Pendleton

Rockdale, Texas

( ) : I recently installed wi ngt ips from

a~91 A36 with an STC. The wingtips

have a strobe, position light and a halogen recognition light that are 24 volts.

However, my 1968 BE36 is 12 volt. We

found a 12-volt position light but have

had problems fi nding a 12-volt halogen

lamp to substitute in the Grimes recognitionlamp. Additionally, what is needed

to connect the strobes (G rimes)?

A:

The 24-volt recognition light was

probably a I982175W and was considered a logo light. A type 1940 may be

similar in shape and rating in 12 volt. but

less wattage. The strobes generally need

separate cables, power suppl y and power

ci rcuitry. You may be able to find components at salvage yards such as Dodson

(800-255-0034) or White (800-8217733). That wo uld entail a separate approval process on a 337.

A36 inspections

Neel Hipp

Greenville, South Carolina

Q:

Thanks for your ideas about our

plane. 2327 A. We just had the annual

in pection done by Dave Rowl at

Raytheon ICT. We have had good luck

with his work, and I believe he did a

good job again. In future planning, we

will probably fly no more than several

hundred hours per year. This first year we

did 100-hour inspections plus the annual.

Do you think that doing 1000hour inspections are critical for a plane we do not fly

commercially as long as we get a really

good and thorough annual inspection?

A: I believe that 300 to 500 hours is

too long to go wi thout inspection and

servici ng on a complex airplane. Thi s

much fl ying activity is considerably

more than most general aviation aircraft

and would warrant consideration of an

informal phased inspection. Some items

may still be accomplished once a year

while others. such as the landing gear,

fuel injectors, spark pl ugs, filters, battery, brakes, etc. shou ld be done at recommended intervals. Al so, some ADs

need to be complied with on an operating Lime basis which could occur prior

to your next annual. Raytheon does have

an alternate inspection plan with sheets

and schedu le available through their

dealers. You should discuss this with

Dave and determine if it would serve

your needs.-NP

Oil in Model 36 alternator

Michael Bland

Overland, Missouri

Painting magnesium surfaces

John Omelia,

AVOIl, Massachusetts

Q:

What is the procedure for treating

a magnesi um surface after it has been

stripped of all the paint? I am aware of a

recipe for mixing chemicals, but I'm sure

that in this high-tech world there is an

easier method.

A:

Some years ago Norm Colvin recommended Dow 19, which has since

been classified as a hazardous material.

Magnadyne is an approved prod uct and is

easier and cheaper to use. It is available

from Aircraft Spruce (800-824-1930) and

other paint suppl y sources.-NP

( ) : I ha ve an IO-520-BA engine with

t~restolite alternator. The inside of the

fabric alternator cooling exhaust duct is

covered wi th engine oil. My mechanic

does not seen concerned about this, but I

worry about oil getting on the brushes

and possible alternator failu re. Do I need

to replace the alternator to eliminate thi s

problem , or can a seal be replaced? Can

any certified mechanic replace th is seal?

[really appreciate your help on previous

questions.

A: I agree with you and wou ld want to

know if engine oil is coming through the

alternator. If it is the alternator dri ve seal.

NEIL'S NOTES

Beech 215 prop pitch

change bearing failures

We've had recent occurrences of Beech 215 prop pitch

change bearing failures. These have been from lack of attention to lubrication. While the 250-hour greasing requirement

is val id. flight hour-wise. if you are not flying a lot, it will be

worthwh ile to have it greased ann ually or biannually.

Grease is a filler material with a lubricating oil in it. That

oil can dry out or separate over time and leave you with just

the filler. which isn' t a good lubricant. This also happens when

yo u store grease guns hanging up. We need to preserve the

old parts through care as there are few replacements of the

old systems.

ABS Jan uary 1999

1 would exchange the alternator or have

it rebuilt. I wouldn ' t try changing the seal

in the field. Aircraft Systems (815-3990225) B&S (3 16-264-2397), Aircraft

Accessories (800-255-9924) and EMI

(800-851-4392) are all sources for alternator repair.-NP

Neil Pobanz, ABS technica l co nsu ltant, is a

retired U.S. Army civilian pilot and maintenance manager. Neil has been an A&P and

IA for 40 years.

Glen "Arky" Foulk, whose business is Delta

Strut, is an A8S assistant technical consultant who has served as a part-time A8S Service Clinic inspector since 1988.

Please send your questions

and/or tips and techniques to:

American Bonanza Society

Attn: Neil Pobanz

P.O. Box 12888

Wichita, KS 67277

Fax 316-945-1710 or

e-mail at bonanza2@bonanza.org

When are Airworthiness Directives issued?

We've received some correspondence with concerns about how

many occurrences are required before the FAA issues an Airworthiness Directive. Usually the writer has operated a like item without problems.

Code of Federal Regulations (CFR) 39 says that an Airworthiness Directi ve will be issued when an unsafe condition exists in a

product and that condition is likely to ex ist or develop in other

products of the same type design.

Of course, there is a significantl y more detailed process to

implement this CFR. (It used to be FAR but was changed to CFR

because Federal Aviatioll Regulation confl icted wi th Federal Acquisirioll Regulation when abbreviated.) We will research both

common practice and implementing orders and present the results in future issues.

Page 5530

Sealing the Gaps

BY GEORGE WILHELMSEN

I

fyou look at the wings of your Bonanza, you will see smooth

skin, interrupted by the heads of rivets or the occasional,

flush-mounted screw, which all dim in comparison to the tie

down lug on each wing. That appearance is maintained until

you reach the control surfaces where large gaps (relatively

speaking) exist between the ailerons and wing and the flap and

wing areas.

These gaps are designed to allow the controls to move freely,

but this feature comes at a price. Since the gap exists, small

amounts of air can slip through the gaps, causing a loss of airspeed. In low speed operations, these gaps result in mushy controls, which pilots compensate for by maintaining higher approach speeds.

With this in mind, doing something like seal ing these gaps

could result in better low speed performance, reduced drag for

improved cruise speed, and even better control in turns. Naturally, Beech originally designed and tested gap seals on the

Bonanza line in the early years, but abandoned their springloaded versions due to a number of technical issues, which included ice-binding of the controls.

Since that time, other companies have gone on to improve

the Bonanza airframe. Beryl D'Shannon, largely considered the

pre-eminent modification expert on the Bonanza and Baron line,

went away from the original spring-loaded concept, and instead

used space age materials such as Teflon to line their gap seals

and prevent icing.

New stinger-style tailcone with wings

Page 5531

Pieces and strips

Looking at the Beryl D'Shannon gap seal system, it is simple

(

to understand how it works. From the top of the wing, a small

fairing is added to each side, just above the point where the nap

ends at the fuselage. This keeps air from slipping through the

slot between the nap and the fuselage during cruise night, and

by doing so, reduces drag.

From the bottom of the wing, there are thin, formed strips of

aluminum, with their contact surfaces lined with Teflon. These

strips close the gap on the underside of the wing between the

trailing edge of the wing and the leading edge of the control

surface. The net result of these changes is less bypass air flow

in cruise and notably more at slow speeds, which improves cruise

and low speed controllability.

A short scallop of aluminum, and another strip along the

edge of the flap as it meets the fu selage complete the gap seal

installation. These pieces act to keep air from slipping through

the gap between the edge of the flap and the fuselage.

Since this work was performed on a Debonair, a fiberglass

Mike Smith stinger-style tail cone was installed. This taileone,

the design and STC of which had been recently purchased and

placed back into production by D'Shannon, had short, winglike extensions that matched the cutout of the elevator well.

This mod is available for the V-tail and Baron models, along

with other straight-tail Bonanza and Debonair models.

Installation Notes

Installation of gap seals isn't hard to do, but will require that

the ailerons on the plane be removed. While you have the ailerons off, it is always a good time to check their condition and replace, if warranted, the various rod ends in the

aileron system.

Another important point of note is rigging. It

would be an excellent idea to have your plane

rigged prior to installing the gap seals. One

key reason lies in how the upper flap seal is

installed on the fuselage. The component is

not slotted, so any changes in rig will require

that the piece be removed and re-installed in a

slightly different orientation in order to maintai n the slight pressure on the seal.

In the case of the optional taileone, the weight

of the cone must be considered. This taileone

is 1.5 pounds heavier than the original, and as

a result, may result in aft CG problems on

planes that do not have sufficient envelope.

As such, it is important to check CG and the

impact the taileone change will have on the

airframe CG.

Apart from these points, installation is simple,

and can be accomplished by just about any

shop with a decent A&P on staff. The

ABS January 1999

r

D'Shannon gap seals are STC'd,

which makes the paperwork fairly

simple as well. The gap seals in

themselves weigh very little. and

since they are oriented at the trailing

edge of the wing for the most pan,

they have almost no impact on the

aircraft CG apan from the tailcone

installation mentioned above.

Flight testing results

After flying with D'Shannon

gap seals for nearly two years, I

have noted a number of interesting points. The typical cruise airspeed of my Debonair has increased by arou nd two knots,

whi ch is certainly a welcome

change in a plane that burns 17 1..._--':::..._ _ _ _ _...;

Underside view of flap to fuselage seal

Aileron and flap sea ls

gallons per hour with the 10-550

cranking out 75 percent power.

D'Shannon does nOl claim any speed increases for their gap

seal kit, so thi s was a pleasant surprise.

In the low speed arena, the Debonair, which had previously

been a real challenge, has become more docile and controllable.

At points where a wing might have dipped on a stall in the past,

the plane drops straight and true. that is, when I can get it to

stall. The gap seal s. which are installed on my Debonair in conjunction with D' Shannon vortex generators, made power-on

stalls pretty much non-existent.

One of my favorite biannual flight review rituals is 10 spend

around 10 minutes trolling around at minimum controllable airFlap to

seal

speed. In any plane. this can be a challenge, but with the gap

seal equipped Debonair, the only fatigue I felt was in my legs

Glow and AlumiGrip, as all have a hard, high luster surface

from maintaining full right rudder to offset the prop P factor.

that should work well with the Teflon edges of the gap seals.

The plane remai ned controllable at speeds below stall, and the

Overall, the results of the flight testing show improved low

aileron authority was excellent throughout the range of slow

speed performance, a slight improvement in cruise speed, and a

general improvement in stability for the Debonair that was

flight. which included left and right 360-degree turns.

In the area of lFR fli ghts, there was little change that was

tested. It was clear that the biggest benefit in terms of flight

cost reduction would be in the cruise speed. Over the course of

noted. No control sticking has been encountered after two years

of service, which included several trips through clouds and at

an ave rage Ioo-hour-year of flying , thi s would be expected to

save about 1.4 hours of fli ght time, which translates to around

least two trips where ici ng conditions were encountered and

immediately exited. If anything, the plane seemed to be less

$50 in Avgas at a fuel consumption rate of 17 gallons per hour.

While this ignores the second, more difficult to quantify value

jumpy in turbulence, and slightly more responsive to control

in improved safety, it was demonstrated that gap seals improve

inputs during flight.

the low speed performance capability of the Bonanza. Gi ven

these facts, gap seals are something that should be considered

Two- year inspection and review

if you are looking for increased economy and improved low

After two years time in service, there is one small abrasion

speed performance.For more information , con tact Beryl

point on the existing lacquer enamel paint on one aileron . It

D'Shannon at 800-328-4629.

should be noted that the paint on my Debonair rates a Bille

Book 3 score, which means that it is thin, and if you are closer

ASS member George Wilhelmsen is a Senior System Engineer with

an SRO license with ComEdo He has more than 700 hours, is a comthan 100 feet away, it looks pretty bad. I would expect better

mercial instrument rated pilot, and is a con tributing editor for Plane

performance from the latest paint types, including Imron, Jet

& Pilot magazine and Avionics News.

ASS January 1999

Page 5532

Aeromedical

certification

BY JACK HASTINGS, MD.

A common source of worry for pilots,

parti cularl y as we grow older, is loss

of airman medical certification. Pilots,

though by and large healthy, are not immune to illness and, like our airplanes,

the ravages of time. Most who fly do so

with a passion, and the threat of medical

disqualification is no small mailer. Fortunately for pilots in the United States,

allowing aeromedical certification is emphasized and fi nal denials are rare.

The FAA processed some 437.457 airman medical certificate applications in

1997. Of these, there were 3,059 denials

by the FAA (0.7 percent). Of these 3,059

applicants, 2,714 did not provide information requested by the FAA for further

consideration. The remaining 345 were

final denials (0. 1 percent). Denial of certification in the United States is far less

common than in other countries. where

flying is treated more as a privilege than

an individual right.

Many airmen who once were disqualified can now obtain airman medical cer-

Out of 437,457 airman medical certificate applications in 1997,

there were 3,059 denials (0.7 percent). 2,714 applicants did not

provide information requested by the FAA. The remaining 345 were

final denia ls (0. 1 percent). Denial of certification in the United States

is far less common than in other countries .

tification. Myocardial infarction (hean attack) once was permanently disqualifying. In 1997, there were well over 2,000

airmen flying who have had hean attacks.

In that same year, there were more than

2,300 flying with a history of coronary

artery bypass surgery and more than

1,400 who have had an angioplasty (a

balloon procedure to dilate the arteries

to the heart).

More than 100 insulin-dependent diabetics are now fl ying in the United States,

the onl y country in the world allowing

certification of insulin-dependent diabet-

Suggestions for efficient and painless renewal of airman medical certificate

All/icipate Ihe quesTiolls the FAA might ask if your medical

status has changed. Obtain the records of your condition. Di scuss the situation with your aviation medical examiner (AME)

before you go in for an exam. Obtain assistance and advice

so that you can carry all necessary records when you visit

your AME for your flight physical.

Take persollal charge of gathering your records and following up. YOli have the greatest illferest in your cenification.

You want to fly tomorrow, and your specialist or other physician may not share your degree of enthusiasm. Don' t assume

that others will share your sense of urgency and concern.

• Document YOllr medical condition and its treatment. The

single greatest obstacle to a certification decision by the FAA

is lack of documentation. Try to provide as complete a record

as possible so that endless cycles of correspondence (each

Page 5533

consuming one or more months) are not required to tease out

sufficient information for a certification decision.

GaTher YOllr records. This is pan of documentation. Always

read carefu lly what the FAA wants when they send you a

letter. Provide all information requested and make sure it is

within the propertime frame. (A stress test done to years ago

may not be relevan!.)

• Aeromedical cerTificarioll is The respollsibility of The FM. Your

specialist or primary care physician may render an opinion, but

is not the final authority regarding aeromedical certification.

Sillgle package plallllillg. If at all possible, assemble all needed

medical data in one package. If your AME can send the records

along with your certification application, all the better. If

records are sent piecemeal. delays may occur while each piece

of information finds its way to your medical record.

ABS January 1999

r

Aeromedical assistance program

On another note, other aviation organizations have developed aeromedical assistance programs. The AOPA has an

aeromedical department headed by Gary

Crump. The EAA has an Aeromedical Advisory Program. a medical advisory council and a cadre of volunteer EAA aeromedical advisors. Medical forums have been

popular at our annual ABS meetings in reics. There are more than 1.400 airmen

with a history of alcoholism who have

been rehabil itated and are now flying .

And there are more than 3,000 monocular (one-eyed) pilots now flying .

If an airman has a disqualifying condition, he or she may be able to fly under

a "Special Issuance" provision, which allows fl ight despite the condition as long

as it can be monitored. In 1997, there

were 6,23 I special issuances, representing about 1.4 percent of all applicants.

As expected, the most common reason for denial of aeromedical certification involves cardiovascular disease, including hypertension, a disease of the

coronary arteries supplying the heart and

hean valve disorders. Neurologic disorders, including seizures, fa inting and

strokes rank second, with numerous other

general medical conditions ranking third.

It is estimated that approximately fi ve

aviation accidents per year are related to

medical factors, most commonly cardiac

conditions and most commonl y involving general aviation ai rmen. If an airman

has a condi tion that causes a snag in the

certificati on process, frustrating delays

may be encountered whi le things are

sorted out.

Much of the problem is logistical. The

FAA Aeromedical Certification Branch

in Oklahoma City receives about 39,000

applications per month or roughl y 2,000

a day. Some 50-55 percent are rejected

by the computer for defi ciencies of one

sort or another, and require "hand working" by FAA personnel. Some erro rs are

common omissions on the form, others

unnecessary deferrals by tbe aviati on

medical examiner and still others incor-

cent years.

I would like to invite comment from

the readership as to their interest in aeromedical activities within the ABS. Would

a medical column with questions and answers be of interest? Are periodic articles

desired? Should the ABS explore an advisory program enl isting the support of

ABS members who are AMEs and might

be will ing to support an advisory program

for its members? Should we contin ue the

medical forum at the annual meetings or

add other acti vities?

Please give these mailers your consideration and send your tho ughts to ABS

Headquarters. Your interest will provide

guidance for ABS aeromedical activities.

Let us hear from you.

feet issuance.

This paperwork burden on FAA personnel limited by budgetary constraints

can result in lengthy and frustrating delays for the airman while his or her case

is be ing deci ded. Delays of several

months or more are not uncommon.

Hopefull y, by stayi ng healthy we can

avoid problems with aeromedical certification. evertheless, some of us wi ll

develop medical conditions which will

arouse the interest of the FAA at the time

of our next medical examination.

Although the process sounds rather

form idable. in reality, it is not diffic ult.

Just ask yourself what any prudent physician wou ld want to know about your

condition in determini ng your

fitn ess to fl y,

gather that informati on, wo rk

with your AME in

assembling a package that will provide sufficient infonnation to the FAA and send it off. As

you can see by the statistics, most decisions

are favorable.

Jack Hastings, M.D., is a senior consultant

to the Federal Air Surgeon. He has been an

aviation medical examiner since 1976 and

has taught neurological aspects of aviation

medicine for the FAA since 7978. He is chairman of the EAA Aeromedical Advisory Coun·

cil and president of the Civil Aviation Medi·

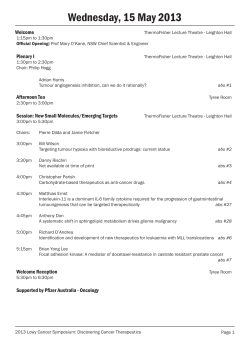

BPPP Inc. Schedule for 1999

Bonanzas/Barons/Travel Airs at all locations. Subject to change.

DATE

Jan. 22-24

Feb. 19-21

Mar. 5-7

Apr. 9- 11

Apr. 23-25

May14-16

June 4-6

June 25-27

Sept. 17-19

Oct. 1-3

Oct. 22-24

Nov. 5-7

PHASE

CUTOFF DATE

Phoenix (Deer Valley) Ariz.

Orlando, Fla.

Initial/Recu rrent

Austin, Texas

Initial/Rec urrent

Dec. 21, 1998

Jan. 29

Feb. 5

Mar. 25

Mar. 22

Apr. 12

May 13

May 18

Aug. 26

Sept. 14

Oct. 14

Oct. 14

LOCATION

Fresno, Calif.

Columbus, Ohio

St. Paul, Minn.

Spokane, Wash.

Colorado Springs, Colo.

little Rock, Ark.

Nashua, N.H.

Fresno, Calif.

Greensboro,

.c.

Initial/Recurrent

Initial/Recurrent

Initial/Recurrent

Initial/Recurrent

Initial/Recurrent

Mountain flying

Initial/Recurrent

Initial/Recurrent

Initial/Recurrent

Initial/Recurrent

Cockpit Companion Course available at all locations

except Colorado Springs.