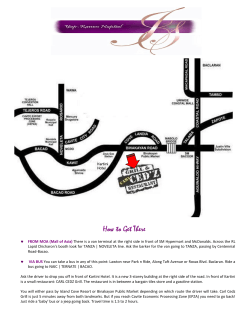

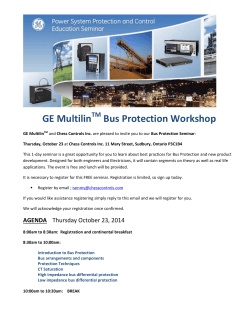

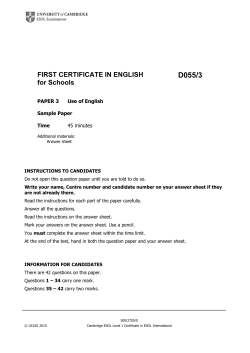

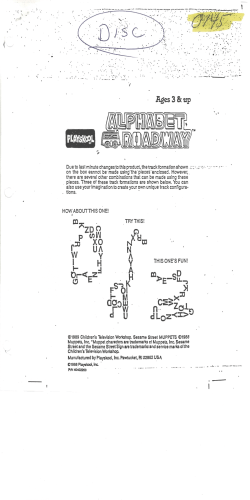

book here