Gorgon - A Project Update

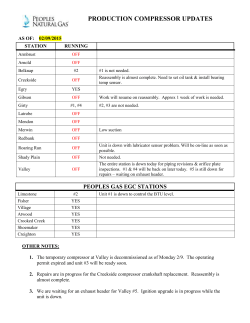

A P R O J E C T U P D AT E EDITION 5 | FEBRUARY 2015 The Gorgon Upstream scope includes the design and construction of wells and facilities to source gas from the fields, transportation to the LNG plant on Barrow Island and delivery of domestic gas to the mainland. It also includes the wells and facilities required for the Carbon Dioxide Injection Project. Jansz-Io Field Production MEG Utility Scarp Crossing Gorgon Field Umbilical n Ja rg Barrow Island on D Na am tu pie ra r t lG o as Bu Pi nb pe ur lin y e Go Io sz- Gorgon Completes Drilling Campaign The Deepwater Frontier drill ship has completed the final Jansz-Io well and demobilised from the Project. General Manager Major Capital Projects Kevin Shannon said it was a significant milestone with all 10 wells at the Jansz-Io field and eight at the Gorgon field ready to produce. “The Jansz-Io drilling campaign was completed with an impressive safety record – more than 540 days incident and 2 | Chevron Australia injury free,” Kevin said. “This is a great accomplishment given the wells were drilled in a water depth of 1,350m so the work required to connect the rig to the seabed was particularly challenging.” ExxonMobil, the Jansz-Io work operator, will officially handover the wells to Chevron over the coming months. Pre-commissioning Underway on Subsea Facilities Pre-commissioning activities are underway on the subsea facilities at the Gorgon and Jansz-Io fields following the installation of all 63 tie-in spools. Upstream Facilities Project Manager Milton Bruce said the spools were one of the final components of the Project’s subsea gas gathering system to be installed, linking the wells and subsea structures to the pipeline system. “In simplistic terms, when all the main structures that make up the gas gathering system were installed we measured the gaps between them and fabricated spools to the specific length required so we could connect the system,” Milton said. “With all spools installed and tied-in we are now pressure testing the integrity of the spool connections.” BOTTOM LEFT The Deepwater Frontier drillship has demobilised from the Project following the completion of the Jansz-Io drilling campaign. LEFT A vessel-based crane and spreader frame were used to install 63 tie-in spools offshore. ABOVE Remotely operated vehicles are assisting with subsea pre-commissioning activities. Upstream Fast Facts Jansz-Io Pipeline Pre-commissioning in Full Swing With all onshore and offshore pipelines installed and tested, pre-commissioning activities are well underway on the Jansz-Io pipelines. Gorgon Upstream Facilities Project Manager Milton Bruce said a series of activities are preparing the pipelines and associated infrastructure for the introduction of hydrocarbons. “Pre-commissioning provides assurance that our pipelines, structures and associated infrastructure are in good working condition,” Milton said. “The process involves cleaning to remove debris, gauging to check internal walls, flooding and hydrotesting to confirm the operating pressure and finally dewatering and drying before packing the pipelines with nitrogen to preserve them prior to operations commencing. “We recently completed dewatering the three Jansz-Io pipelines – production, monoethylene glycol and utility – from the inlet area to the main subsea structure, located around 140km offshore. “Our focus over the next few months is to dry and prepare the Jansz-Io pipelines so they are ready to be packed with nitrogen and handed over to our Operations team. We will then turn our attention to pre-commissioning the Gorgon pipeline system.” Gorgon’s first LNG Train will be startedup with Jansz-Io gas. The Project’s subsea gas gathering system is located on the ocean floor over the Gorgon and Jansz-Io gas fields. The Jansz-Io field is located approximately 130km northwest of Barrow Island in 1,350m of water. The Gorgon field is located approximately 65km west of Barrow Island in 200m of water. Subsea trees will contain and control the production wells at both fields. The produced gas will be gathered at several manifolds installed at each field and transported via pipelines to Barrow Island. Both field developments are supported by a feed gas pipeline, monoethylene glycol injection pipeline, utility pipeline and fibre optic, electro-hydraulic control umbilicals – a total of six product pipelines and two umbilical casings. Find out more about the Gorgon Upstream scope at chevronaustralia.com Gorgon – A Project Update | 3 The Downstream scope includes the design and construction of a three-train 15.6 million tonne per annum LNG facility on Barrow Island and a domestic gas plant with the capacity to provide 300 terajoules of gas per day to Western Australia. It also includes operations and accommodation facilities. Domestic Gas Pipeline Ready to Import Following the final connection at the jetty, the domestic gas pipeline is now connected from the mainland through to the plant site. Gorgon Development Director Scott Young said pre-commissioning activities were also complete paving the way for gas to be imported to start-up the first gas turbine generator (GTG). “Starting up the first GTG will provide the power to start commissioning the various systems and facilities,” Scott said. Domestic Gas Pipeline Connection In operations, Gorgon will have the capacity to provide 300 terajoules of gas per day to Western Australia. LEFT The Gorgon domestic gas pipeline is now connected end-to-end. TOP RIGHT Kent Stewart (left) is presented with the Safe Transport award by Hayden Latchford. Image courtesy of Lloyds List Australia. BOTTOM RIGHT Members of the operations team have begun commissioning and monitoring plant systems. 4 | Chevron Australia Safety Inspires Innovative Device An innovative device which enables the Project to double-tow barges has been recognised with a national Safe Transport award. The barge emergency anchor release (BEAR) system, developed by Gorgon subcontractor Maritime Engineers, was recognised at the annual Australian Shipping and Maritime Industry Awards. event the tow wire parted. “The BEAR system provides a safe way of dealing with a situation where a towline parts, leaving one barge adrift while the other remains under tow. It also eliminates the potential risks associated with tug crews attempting to manually release the anchor,” said Kent. A total of 13 BEARs are now installed on Project barges and Maritime Engineers has been granted an Australian Patent for the system. Maritime Engineers Executive Director Kent Stewart said the system allowed tug masters to remotely release the emergency anchor on a barge in the Inlet Facilities Nearing Completion Construction activities are progressing on facilities in the inlet area, the entry point for raw gas flowing into the gas treatment plant from the two fields. With all the major pieces of equipment in position, work is well underway to connect the individual components. The current focus is completing the construction of eight monoethylene glycol (MEG) storage tanks and the slugcatchers. it acts as an antifreeze to absorb water and prevent hydrates forming that could block the pipelines. MEG, which will be stored in the tanks, will flow to the field in a separate pipeline and back with the raw gas in the production pipeline. MEG plays a critical role in the transportation of the gas as With several hundred people working in the area it has been a great team effort to carry out the work in a safe and coordinated manner. Operations Powering Up The first members of the Operations team have commenced commissioning and monitoring systems in the Central Control Room (CCR) on Barrow Island. The CCR is located in the Project’s Permanent Operations Facility and will be used to oversee all aspects of plant operation, including the gas treatment and liquefaction process. Barrow Island LNG Production Manager Steve Pattrick said activities in the CCR would continue to ramp up as Gorgon progresses towards first gas. “Technicians are commissioning the fire systems and monitoring equipment from the CCR. It’s a big step towards full occupancy when the control panels will be monitored 24 hours a day,” Steve said. Find out more about the Gorgon Downstream scope at chevronaustralia.com Gorgon – A Project Update | 5 Key Focus on Mechanical, Electrical and Instrumentation Work With Project execution activities now 90 percent complete, the key focus is the mechanical, electrical and instrumentation (ME&I) work on Barrow Island. Gorgon Development Director Scott Young said the ME&I work had ramped up following delivery in June last year of the final module required to start-up the first LNG train. “Essentially the ME&I scope involves all work activities required to connect the various components of the plant,” Scott said. “As Barrow Island is a Class A Nature Reserve we fabricated the plant in smaller pieces offsite to minimise the impact on the Piping and insulation work underway on the main cryogenic heat exchanger for Train 1. LNG facility insulation limits the impact of external temperatures on pipe and process equipment, keeping the liquid cool and allowing it to retain its form. Installing several long pieces of pipe (known as fingers) to one of the Project’s two slug catchers. The pipes, which are 80m long, were fabricated off-site and lifted into position by a crane before being welded together. The production fluid from the feed gas pipeline will be fed into the slug catchers to separate the natural gas from liquids before processing. 6 | Chevron Australia Welding work to connect two pipe racks. The pipe racks form the main artery of the plant, carrying gas from one process unit to another. island during the construction phase, before transporting them to Barrow where they are now being installed and connected. “With most of the 51 modules and all 236 pre-assembled racks and units already installed, the profile of the plant site won’t change much this year. However, significant progress is taking place on the ground to complete a wide-range of activities to enable us to start-up the first LNG train later this year. “This includes welding, pressure testing and painting activities, as well as installing cabling and insulation. In the next few months there will be a change in the mix of skills required on site, with the focus of activity turning to the electrical works as we move from construction to commissioning.” Completing final testing and inspection of cabling work in one of the Field Equipment Rooms (FER). There are a number of FERs around the plant to house the Project’s instrument, control and monitoring equipment. Inspecting completed concrete works in the inlet area. The concrete is coloured to assist with identifying the location of underground power cables and instrumentation equipment. Pressure testing activities on pipe spools – pre-fabricated components of the plant’s pipe system – prior to installation. This ensures the integrity of the spools with tests run at higher pressure levels than the spools will be under when the plant is operating. Gorgon – A Project Update | 7 Innovation Drives Efficiency A Container Roll-Out Warehouse System (CROWS) has been introduced in the Barrow Island supply chain to improve the efficiency of equipment and material delivery. that fit inside shipping containers. Depending on the weight of the materials stowed on the racks, they can be stacked three high inside each container. The CROWS involves specially designed inter-connectable cargo carrying racks Once on site the racks are removed from the container with a forklift and stacked until the materials are required. Materials and Logistics Manager Rob Lowe said the island’s Class A Nature Reserve status had created additional challenges during construction. “The State Agreement under which Gorgon operates limits the land available to the Project which means the total construction footprint, including laydown, is very small for a project of this scale,” Rob said. “The introduction of the CROWS has increased storage space on Barrow as it allows four racks to be safely stacked on top of each other.” The CROWS has been a collaborative effort between Chevron, CB&I Kentz Joint Venture and Sea Box International. Monitoring an Environmental Legacy As part of the Project’s commitment to protecting the conservational values of Barrow Island and its surrounding waters more than 20 ongoing flora and fauna monitoring programs are undertaken. Terrestrial Ecologist Andy Smith said these programs helped to verify that appropriate strategies were in place to minimise Project impacts on the environment and the local fauna. “It is pleasing to see our monitoring results indicating our strategies are working,” Andy said. One of the primary purposes for data collection is to estimate population size to better predict, monitor and manage potential impacts associated with the construction and operation phases of the Project. 8 | Chevron Australia Flatback Turtle Tagging Seabird Monitoring Turtle tagging, one of nine marine turtle-related monitoring programs, is carried out annually during the nesting season from November to January. Surveys monitoring three seabird species – the Bridled Tern, the Wedgetailed Shearwater and the Silver Gull – are carried out on Barrow and surrounding islands. Undertaken on the beaches of Barrow Island and Mundabullangana – a reference site located west of Port Hedland – teams of volunteers tag, measure and collect data on the nesting turtles. The 2014-15 season marked the tenth year of the program which has seen more than 700 volunteers tag and measure more than 9,000 turtles. In the previous two surveys more than 543 Bridled Tern nests and 365 Wedge-tailed Shearwater burrows were inspected across three islands. The monitoring team walked more than 34km, counting and recording more than 5,500 Silver Gulls. Ear Health Program on the Road Again With Chevron’s support, Telethon Speech & Hearing has launched Australia’s first advanced mobile audiology vehicle as part of the Chevron Ear Health Program. audiology booth and specialised equipment to provide infant diagnostic testing as well as paediatric hearing tests for children most at risk of middle ear disease. The vehicle will enable Telethon Speech & Hearing to reach remote communities in the West Pilbara where ear health services are greatly needed. The aim of the Chevron Ear Health Program is to prevent middle ear infection and ultimately improve child health, learning and development. As well as the mobile clinic, the program provides health resources kits and The vehicle has its own mobile Community Spirit Bolstered in the Pilbara Chevron’s latest round of Community Spirit Fund grants has provided much needed support to 21 local community and not-for-profit groups. education session for families, teachers and health providers. It is the only program in Western Australia providing mobile screening, diagnosis and clinical care pathways to address the significant ear health concerns of Aboriginal children. It will also deliver resource kits and education to teachers, parents and health professionals in the Pilbara. 2014 Community Spirit Fund Recipients: Baynton West Primary School In total, funding worth more than $110,000 will support 25 separate community programs. This is in addition to the $1.2 million already contributed to community projects across the West Pilbara since 2007. Karratha Family Centre Karratha Senior High School Karratha Young Professionals Exmouth Gymnastics Club The aim of the Community Spirit Fund is to contribute to community vibrancy Exmouth Motorcycle Club and celebrate local culture. The recent round of grants supported a diverse range of programs and activities, including: • School recycling programs • Y outh leadership, networking and development workshops • Motorist first aids kits and training • A rchiving of local historical documents and collections • C ommunity concerts featuring local musicians, dancers and performers Ngarliyarnu Bindirri Pilbara Population Health Karratha Primary School Exmouth CARE Exmouth Cultural Arts Centre Pegs Creek Primary School Exmouth Senior Citizens Club Ngarluma Yindijibarndi Roebourne Girls’ Academy Tura New Music Exmouth Bowling Club TOP LEFT An innovative collaboration has improved the efficiency of material delivery and storage on Barrow Island. BOTTOM LEFT Turtle tagging on Barrow Island. ABOVE LEFT Glen Toby and Eileen Wright from Ngarluma & Yindijibarndi Foundation Ltd (NYFL) with some of the carved Aboriginal artefacts, slides and photographs in its historical collection archive. NYFL was awarded a grant to purchase a commercial de-humidifier to preserve the collection for future generations to enjoy. ABOVE RIGHT Zoe Waterstrom Muller, a student at Baynton West Primary School in Karratha. The school received a grant to develop environmentally friendly and sustainable practices in the canteen through the introduction of reusable cutlery and cups. They have also purchased an energy efficient and water wise industrial dishwasher. Local Information Network Exmouth Tennis Club Pegs Creek Musical Saving Animals from Euthanasia Gorgon – A Project Update | 9 MEG PIPELINE UTILITY PIPELINE Special devices known as pipeline pigs are being propelled more than 140km from the plant site on Barrow Island to the offshore Jansz-Io field. variety of sizes to pre-commission the pipelines. Soft foam pigs were used in the initial and latter stages to clean and dry the pipelines,” Sven said. Pre-commissioning Engineer Sven Rolfe (pictured above) said the pigs are being sent through the three pipelines – production, monoethylene glycol (MEG) and utility – to confirm they are free of internal obstructions and debris, as well as inspect the internal diameter of the pipelines before the final product is introduced. “Bi-directional pigs have been used to remove debris, such as sand and welding material from the internal pipe. The bi-directional pigs used in the MEG and utility pipelines weigh around 12kg, while those used in the larger 34-inch production pipeline weigh up to 250kg. “We’re using three types of pigs, in a Soft Foam Pig 10 | Chevron Australia “Finally, caliper pigs are used to measure and record the internal geometry of the MEG and utility Bi-directional Pig pipelines. These pigs are sometimes referred to as intelligent pigs as they have ‘little fingers’ that travel 360 degrees around the pig as it moves through the pipeline to detect changes in diameter. “We can safely load lighter pigs into the pipelines by hand and use a crane to lift the larger, heavier pigs. A pig launcher is then used to propel the pigs down the pipeline, with chemically treated filtered water or compressed air providing the pressure to move the pigs through the pipelines to the offshore field.” Caliper Pig A temporary accommodation support vessel has berthed at Barrow Island, with the capacity to house 1,200 additional construction workers. Train 1 Train 2 Both LNG Tanks are now ready for LNG. Construction is complete on three of the four condensate tanks. LNG Tanks Condensate Tanks Project execution activities are now 90 percent complete. Delivery of modules required for LNG Train 2 continues. All Train 1 modules and 13 of 17 Train 2 modules are on their foundations. Gorgon was recently awarded a national Engineering Excellence Award by Engineers Australia for the JanszIo Subsea Pipeline Scarp Crossing. Gorgon Upstream Facilities Project Manager Milton Bruce (second from left) said winning the award capped off close to 10 years of detailed research, planning and execution activities. “Accessing the Jansz-Io field required crossing an underwater escarpment at the edge of the continental shelf where the water depth goes from 500m at the top down to 750m. Typically subsea pipeline span lengths are in the order of 40m. However, the steepness of the scarp route resulted in the design of 270m long spans,” Milton said. At the end of last year the Salvation Army received a much needed boost to its Christmas Appeal following a $10,000 donation raised from ticket sales to Gorgon’s Got Talent. Gorgon’s Got Talent has been held annually since 2009 to showcases the hidden talents of those working on the Project. Each year the winner selects a charity of their choice to donate $10,000. Gorgon – A Project Update | 11 weight off,” Ja mie said. “The Tastelife Ch allenge was an excellent alterna self-paced diet tive to the I had been tryin g to maintain. I of support from received a lot the ALCs with m y exercise regim made easier wi e and it was th so many healt hy food options in the diners.” As part of his ex ercise program Jamie walked a after work each 4.5km track day, before getti ng on a bike an 20km. d riding 15 to His advice for ot her people look ing to develop healthier lifesty and sustain le habits is to inv olve loved ones in the journey. “I have since pu rchased a cros s-t ra iner and boxing home. I think it’ bag for s important to get your family caught my wife involved, I’ve at the punching bag a few times better my prev trying to ious efforts,” Ja mie said. Chevron Australia Pty Ltd ABN 29 086 197 757 250 St Georges Terrace Perth Western Australia 6000 Australia Tel +61 (8) 9216 4000 Fax +61 (8) 9216 4444 Email: ask@chevron.com chevronaustralia.com Printed on 100% Recycled Paper RECYCLED Paper made from recycled material C000000 ABU150200318 When Jamie Hislop (picture d above) ente Challenge in th red the Tastel e spirit of frie ife nd ly competition lose more we his goal was to ight than his te am mates. Nearly later Jamie wa three months s 17kg lighter, not only beat but losing the ing his team m most amount ates of weight sitewide. There were 38 2 participants in the annual on Barrow Isla Tastelife Chal nd last year. Th lenge e 12-week heal program is m th and fitness anaged by Ca mp and Caterin contractor ES g Services S. The progra m aims to incr about healthie ea se awareness r lifestyle choi ces through ex nutritional ad er cise plans, vice, motivatio nal lectures an personal traine d th e support of rs known as Ac tivelife Coache s (ALCs). Jamie said th e program ca me at a good time for him. “I noticed my blood pressure had jumped up metabolism wa and my s slowing dow n, making it ha rder to keep th e

© Copyright 2025