AME Newsletter March 2015 - Advanced Manufacturing Education

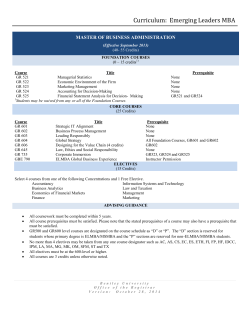

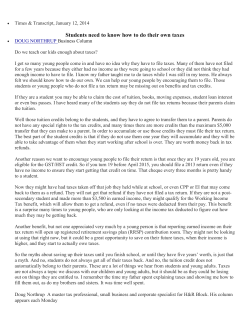

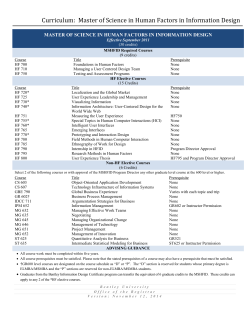

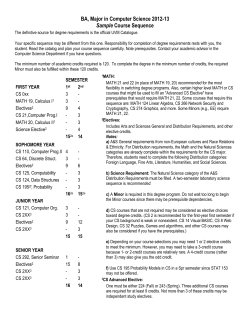

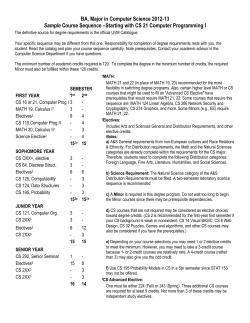

NEWS AME Alliance Newsletter Session 6 2015 The approach for effective recruiting has changed. The employees you need to find are anywhere, but not everywhere. The days of running an ad in the paper are waning as are the number of available workers declines. The tendency for some employers is to cast a wider net in an attempt to keep the funnel full at the top. Using hundreds of temp workers to find those that can be a permanent asset is costly. One manufacturer spent nearly a million dollars with a temp service last year and gained just two permanent employees. Spending five hundred thousand dollars per hire is not a sustainable model! The new paradigm for recruiting, retaining, and advancing a workforce requires a targeted approach. The new strategy is selective recruitment. You can see the work ethic, habits and competencies of your potential new hires everywhere you go. You can observe them at their current job and can make assessments about their fit into your organization. Is the bagboy at your grocer a sharp kid? Does the night manager at the corner convenience store consistently deliver customer service? Who is the most industrious at the detail car wash? Who at the full service gas station? Now your recruiting lens is focused on fewer, yet more likely prospects from the broader spectrum of the labor pool. The same holds true as you evaluate who on your front line can move into higher levels of responsibility and management. Where there is a gap in skills and education, provide support and resources. The hard part How can you determine an internal or external candidate’s employability in your organization? It begins by knowing: What characteristics and skills are needed by job candidates How you will manage effective career progression for all employees including succession planning for leadership and management positions How employee education and training contribute to achieving business results goals How to organize and manage people to promote cooperation and ensure knowledge transfer Wrestling with these topics allows you to target recruiting efforts for new hires and current worker advancement. You’ll know exactly what you need in an employee, and exactly how your training systems function to cultivate that employee. Target training for immediate needs and plan training for future needs. Make ongoing training the bedrock of employee recruitment and retention. Instill in your workforce culture that ongoing training will be supported by you, and that the responsibility lies with each employee to advance and enhance their own career options within your organization. The smaller your workforce, the larger looms this necessity. Instead of competing for machinists, find people to train as machinists. Training and development can come from traditional sources such as your community technical college or state university, from online instruction like that offered through the AME Alliance, and from apprenticeships. Look for training offered by industry associations, community education programs, and Adult Basic Education. Find out how you can put these programs to work as part of your new strategy to select, recruit, and train.-DKB See related article in the Star Tribune: http://www.startribune.com/business/285666301.html IN THEIR OWN WORDS: Ultra Machining Company manufactures, engineers and produces precision-machined parts and assemblies for the medical, aerospace, commercial, industrial, and energy industries. The company is located in Monticello. UMC makes education and training a part of its day-to-day business. The company has offered training programs to employees for some 30 years. Says Eric Gibson, president, “Our focus has always been, how do we help our current employees and advance them up the corporate ladder, and how do we get our new employees up to speed?” Jaci Dukowitz, Director of Human Resources & Development, is in the process of rewriting the onboarding process and developing a curriculum that targets what employees need to develop a career path. Initial efforts in the partnership with AME have focused on current staff development, including the department leads. UMC is proud to offer these trainings in our newly redesigned training room. UMC pays employees to attend sessions, including an hour before each weekly class where employees can quietly study, prepare for tests or collaborate on homework. COURSE HIGHLIGHT: QUALITY PRACTICES The course focuses on quality management systems and continuous improvement concepts. Students are introduced to several frameworks for defining product and process quality, and how a quality management system integrates the frameworks with improvement efforts. Course topics include: quality philosophies ISO 9001 statistical process control problem solving corrective action programs preventative actions control of quality records control of documents control of non-conforming product internal auditing of processes “I’m really enjoying the Quality Practices course so far. It’s easy to apply what I’m learning to my job, and I’m very impressed by the instructor." Jeff Frodermann Toro Company Windom, MN For information on this and other Advanced Manufacturing Education courses contact a partner college: Dale Ray Thiesen Central Lakes College Heidi Braun Pine Technical & Community College Debra Bultnick St. Cloud Technical & Community College DThiesen@clcmn.edu 218.894.5194 BraunH@pine.edu 320.629.5178 dbultinck@sctcc.edu 320.308.5350 Look How Far We’ve Come! Growth in Participation & Course Offerings May 14 – Jan 15 (5 sessions) Total Participation 479 Total Unique Participants 339 Total Businesses 47 AME Full Course List Safety Awareness CMAE 1514 2 credits ($374) FYE Credits 915 Manufacturing Processes & Production CMAE 1518 2 credits ($374) Quality Practices CMAE 1522 2 credits ($374) AME Enrollment Growth May 2014-Jan 2015 Maintenance Awareness CMAE 1526 2 credits ($374) Career Success Skills CMAE 1529 1 credit ($187) 200 Technical Math CMAE 1502 3 credits ($561) Intro to Computers CMAE 1506 2 credits ($374) Print Reading CMAE 1510 2 credits ($374) 150 Seats Intro to Robotics ETEC1550 3 credits ($374) GD&T CMAE 1542 2 credits ($374) 100 Intro to CAM 2 credits ($374) Advanced CAM 2 credits ($374) 50 Intro to CAD 3 credits ($561) Advanced CAD 3 credits ($561) 0 13 Measuring Tools 1 credit ($187) S-1 S-2 S-3 S-4 S-5 Session 5-Axis Milling no credit All of these courses are offered in AME; costs based on the current cost per credit of $176. Free tuition not guaranteed through life of the grant. Maintaining production levels should not slow down your efforts to improve technical skills. Train your whole team through the Advanced Manufacturing Education Alliance. A USDOL grant is currently funding our courses as we work to achieve sustainability. Our courses lead to both industry and academic certification. Credits earned for basic classes such as Safety Awareness roll into credits that articulate towards future certificates, diplomas, AAS and BAS degrees. Best of all, courses are delivered to your site online or via Mediated Telepresence. That means an instructor interacts real-time with class participants from a remote location. The courses are accelerated to 8 weeks, two sessions per semester. Many of our industry partners are sending cohorts to several classes on a rotation that meets their both their training and production needs. FREE Courses Begin April 27, 2015 Mediated Telepresence FREE* (Regular price: $176/credit) On Demand $99 (Regular price: $176/credit) CMAE 1514 Safety Awareness (2) CMAE 1518 Mfg Processes & Production (2) CMAE 1526 Maintenance Awareness (2) CMAE 1528 Career Success Skills (1) CMAE 1506 Introduction to Computers (2) CMAE 1522 Quality Practices (2) CMAE 1502 GD&T (2) CMAE 1514 Safety Awareness (2) CMAE 1518 Mfg Processes & Production (2) *Fees for books, software, labs and other coursework material may apply. FREE classes are being offered for a limited time. For more information and dates/times, contact your Customized Training Representative. Deadline to Enroll is Friday, April 17, 2015 For registration information contact: Dale Ray Thiesen Central Lakes College Heidi Braun Pine Technical & Community College Debra Bultnick St. Cloud Technical & Community College DThiesen@clcmn.edu 218.894.5194 BraunH@pine.edu 320.629.5178 dbultinck@sctcc.edu 320.308.5350

© Copyright 2025