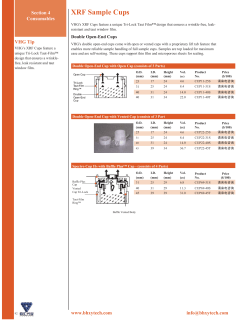

2005 CATALOG