WHAT? Sew SewWHAT? M A G A Z I N E

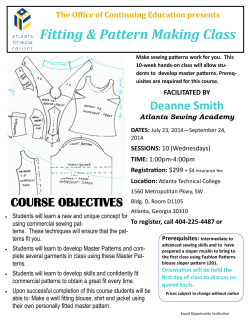

SewWHAT? Sew WHAT? M A G A Z I N E The International Magazine for Custom Home Furnishings Professionals Volume 11, Number 1 Industry Pricing Units Partial Undergarment Slipcovers Upholstery of a Vintage Camel-Back Sofa Creating Window Treatments From Photos January 2003 The Custom Home Furnishings Trade School Window and Bed Coverings Slipcovers Installation Upholstery 2003 Schedule January 4 - 5 Introduction to Upholstery 100 4 - 5 Introduction to Window Treatments 100 7 - 10 Upholstery 101 7 - 10 Installation 101 7 - 10 Window Treatment Fabrication 101 11 - 12 Installation 102 11 - 12 Cornice Boards 101 11 - 12 Iron-on Techniques 101 14 - 17 Slipcover Fabrication 101 14 - 17 Window Treatment Fabrication 102 18 - 19 Slipcover Fabrication 102 18 - 19 Creating Custom Patterns 101 21 - 24 Window Treatment Fabrication 103 February 1 - 2 Introduction to Window Treatments 100 4 - 7 Window Treatment Fabrication 101 8 - 9 Decorative Pillows 101 8 - 9 Laminating Techniques 101 11 - 14 Cornice Boards 102 11 - 14 Bed Treatments 101 March 2 - 3 Introduction to Upholstery 100 2 - 3 Introduction to Window Treatments 100 4 - 7 Upholstery 101 4 - 7 Window Treatment Fabrication 101 8 - 9 Cornice Boards 101 8 - 9 Tabs, Slouch, and Grommet-Top 101 10 - 13 Installation 101 10 - 13 Window Treatment Fabrication 102 14 - 17 Slipcover Fabrication 101 15 - 16 Installation 102 15 - 16 Creating Custom Patterns 101 18 - 21 Window Treatment Fabrication 103 April 5 - 6 Introduction to Window Treatments 100 8 - 11 Window Treatment Fabrication 101 12 - 13 “The Client Connection” 12 - 13 Decorative Pillows 101 14 - 17 Bed Treatments 101 May 3 - 4 Introduction to Window Treatments 100 5 - 8 Window Treatment Fabrication 101 9 - 12 Installation 101 9 - 10 Cornice Boards 101 13 - 16 Slipcover Fabrication 101 13 - 16 Window Treatment Fabrication 102 17 - 18 Slipcover Fabrication 102 17 - 18 Creating Custom Patterns 101 20 - 23 Window Treatment Fabrication 103 June 3 - 6 High-End Treatments 7 - 8 Introduction to Window Treatments 100 10 - 13 Window Treatment Fabrication 101 14 - 15 Laminating Techniques 101 17 - 20 Bed Treatments 101 21 - 22 Headboards 101 21 - 22 “The Client Connection” 800-222-1415 July 5 - 6 Cushions 101 5 - 6 Introduction to Window Treatments 100 8 - 11 Window Treatment Fabrication 101 8 - 11 Installation 101 8 - 11 Slipcover Fabrication101 12 - 13 Iron-on Techniques 12 - 13 Installation 102 12 - 13 Cornice Boards 101 15 - 18 Window Treatment Fabrication 102 19 - 20 Creating Custom Patterns 101 22 - 25 Window Treatment Fabrication 103 29 - Aug 1 Window Treatment Fabrication 104 August 2 - 3 Introduction to Window Treatments 100 4 - 7 Window Treatment Fabrication 101 9 - 10 Tabs, Slouch, and Grommet-Top 11 - 14 Window Treatment Fabrication 102 15 - 18 Cornice Boards 102 16 - 17 Creating Custom Patterns 101 19 - 22 Window Treatment Fabrication 103 19 - 22 Slipcover Fabrication 101 23 - 24 Decorative Pillows 101 23 - 24 Slipcover Fabrication 102 26 - 29 Bed Treatment Fabrication 101 30 - 31 Introduction to Window Treatments 100 September 2 - 5 Window Treatment Fabrication 101 19 - 22 Educational Conference and Trade Show October 4 - 5 Introduction to Upholstery 100 4 - 5 Introduction to Window Treatments 100 7 - 10 Window Treatment Fabrication 101 7 - 10 Upholstery 101 11 - 12 Cornice Boards 101 14 - 17 Window Treatment Fabrication 102 18 - 19 Creating Custom Patterns 101 21 - 24 Installation 101 21 - 24 Window Treatment Fabrication 103 21 - 24 Slipcover Fabrication 101 25 - 26 Installation 102 25 - 26 “The Client Connection” 25 - 26 Cushions 101 28 - 31 High-End Treatments November 1 - 2 Introduction to Window Treatments 100 4 - 7 Window Treatment Fabrication 101 8 - 9 Headboards 101 11 - 14 Bed Treatment Fabrication 101 December 6 - 7 Introduction to Window Treatments 100 9 - 12 Window Treatment Fabrication 101 828-686-3185 SewWHAT? is published monthly by Professional Drapery Seminars, Inc. 180 Buckeye Access Rd. Swannanoa, NC 28778 USA HelpLine (828) 686-3185 Subscriptions 888-4SEWWHAT (888-473-9942) Fax (828) 686-3186 www.CustomHomeFurnishingsIndustry.com email: Magazine@CHFIndustry.com Yearly subscription cost is $34.95 U.S. $39.95 Canada $47.95 All other foreign MC, VISA, AMEX & Discover accepted Back issues available from 1993 to date Periodical Postage Swannanoa, NC 28778 POSTMASTER SEND ADDRESS CORRECTIONS TO: SewWHAT? 180 BUCKEYE ACCESS ROAD SWANNANOA, NC 28778 Publisher/Editor Cheryl Strickland Managing Editor Mary Zellers Layout/Design Kelly Ross Terry SewWHAT? motto: “Sew generously and you will reap generously.” SewWHAT?’s mission: To help drapery, slipcover, and upholstery professionals with all of their fabrication and design needs. To eliminate the unnecessary wasting of time, the frustration of not being able to find resources, the discouraging and lonely moments of being a small business, and the managerial challenges faced by larger businesses. All featured products, services, or suppliers are intended for information-sharing purposes only. No endorsement or recommendation is intended by these profiles, which are open to any companies or individuals serving the custom home furnishings industry. Copyright © 2003 Professional Drapery Seminars, Inc. All rights reserved. Not to be reproduced in any form without written permission from the publisher. CONTENTS Industry Pricing Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 History of the Sewing Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Memphis Shawl Valance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Crewel Scalloped Valance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Partial Undergarment Slipcovers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Triangle Overlay Pillows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Trims, Part 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Creating Window Treatments From Photos . . . . . . . . . . . . . . . . . . . . 14 Five Basic Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 Upholstery of a Vintage Camel-Back Sofa . . . . . . . . . . . . . . . . . . . . 16 Upholstery Starter Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Looking Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Classifieds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Conference Videos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 FROM CHERYL Introducing Mary . . . Our new managing editor, Mary Zellers, and I hope you are enjoying our new color format. I had no idea it would be so much more labor-intensive, but I am very pleased with our progress toward better quality and an earlier timeframe. I am really enjoying working with Mary on this monumental task. I thought you would enjoy getting to know her. Mary grew up in a rural town in Virginia, the second oldest in Cheryl Strickland Publisher/Editor a family of seven children. After graduating high school, she moved to Newark, Delaware, to find work and live with her oldest sister. She met her husband, Jay, at work. After having their first child, Mary chose to be a stayhome mom and began a home-based secretarial/typing service. This business continued over the next several years during which time Mary and Jay had their second child. Jay accepted a job transfer to Asheville, North Carolina, and the family moved south. Mary accepted a full-time secretarial position with Union Butterfield Corporation. Her position evolved over the years, as Mary accepted challenges available to her. She ultimately designed and produced Union Butterfield’s literature. This included transforming a 600-page product catalog from black and white to full color. She was also responsible for managing the marketing activities for the business and working closely with distributors, sales force, and agencies to achieve aggressive sales goals. Mary received an Associate in Science degree from Montreat College in 2000 and will earn a Bachelor of Business degree in 2003. We are very blessed to have Mary as part of our team. I’m sure her talent and creativity are already evident in SewWHAT?. ~ Cheryl Industry Pricing Units By Kitty Stein W hen someone starts a workroom business, the questions they are faced with include, “What price should I charge?” and “What unit of measure do I use for pricing?” The common units in the industry are each, pairs, feet and/or yards, square feet, running or linear feet, widths, and hourly. Not every workroom uses the same unit for an item as other workrooms, but the preceding units are all utilized at some time or another by all workrooms. Following is an explanation of the various ways these units have been used. "Feet or yards" "Each" Pricing by each individual unit is by far the easiest method. It is routinely applied to such products as pillows, bedspreads, tablecloths, napkins, rosettes, throw pole swags, etc. Some workrooms also price traditional board-mount swags this way. Others price swags by the running foot of the width of the window. I personally prefer to charge per swag with limits for a standard width and drop. Oversized swags are priced higher. "Pair" Anything that is usually sold in pairs, i.e. tiebacks and cascades, can be charged per pair. A center panel on a window that also has a panel on each outer side, requires 1½ pairs of tiebacks. Consider that fabricating only one tieback consumes almost as much time as fabricating two, especially if only one tieback is required and no additional pairs. Cascades are sometimes priced by the running foot across the top of the board, but this is not the most profitable way to price them. I feel that pricing cascades by the pair according to various lengths (up to 24", 63", or 84" long, as examples) and various widths makes more sense because the longer and wider they become the more work is required. For something that seems so simple, cascades can be very laborintensive! All types of trim and cording are usually priced by the yard or by the foot. Generally, pricing by the yard will result in more money. The reason is mathematical. Numbers are usually rounded UP when pricing. For a simple example, compare charging $9 for applying one yard of trim or $3 for applying one foot. If the project requires 118" of trim, it is more than 3 yards, but not 4 yards. This would round up to 4 yards and the charge would be $36. By comparison, charging by the foot this project would require more than 9 feet but not 10 feet. This would round up to 10 feet, for a charge of $30. That’s a difference of $6 on one project alone. Imagine the extra gross sales in one year from selling a lot of trimmings! "Square feet" Laminated roller shades and soft shades–such as Romans, Austrians, balloons, etc.–are priced by the square foot. It is necessary to price this way because there are no standard or semistandard sizes and because there are far more supplies (cord, rings, etc.), per square foot than in any other treatment. Shades also are a good example of the occasional need for minimum size requirements for charging. Many companies start with a minimum of 9-10 square feet. It may also be a good idea to require a 4 Copyright © 2003 SewWHAT? Magazine minimum in width and length. If a shade is very wide and very short, the cost of supplies per square foot will rise dramatically. Pricing one wide, short shade wouldn’t be a problem, but the loss of profit on shades this size for an entire house would be tremendous! NOTE: For a small workroom, it may even be necessary to have a maximum size limit for fabricating, as some sizes will be too large to accommodate in the workroom. The width limit I set for my in-home workroom is 72". "Running/linear feet" Top treatments–with the possible exception of swags and cascades–are priced by the running foot of width. Many workrooms include the returns in this dimension, while others do not. Remember minimum sizes. Consider charging for at least four or more running feet. Running feet can also be used to price pleated and rod pocket drapery panels. This may come as a surprise, as most workrooms price panels per width, but this is one way to make them more profitable. Early in my wholesale fabrication business, I discovered that many of my clients could not calculate pricing based on widths for railroaded panels made out of extra-wide fabrics. So, to make it easier for them, I used our current price per width and recalculated a price per running foot. Offerings by Kitty Stein ~ ~ ~ ~ ~ Over the years, when I raised prices, each price was raised individually– not by starting with the price per width. Eventually I was making far more profit on railroaded sheers, pinch pleated, and rod pocket panels. Now that heavier drapery fabrics are available in wider widths that can be railroaded, my suggestion is to calculate ALL drapery panels in running feet. It is less to remember than calculating both ways and it can result in more money for you! "Widths" In past years, the industry standard has always been to charge rod pocket and pleated drapery panels by the number of widths (each piece of fabric, usually 48" or 54" wide) that are sewed together. Pricing by the width also can applied to pleated, rod pocket, or other simple styles of valances. However, there is no reason not to charge by the running foot as explained above. I recommend applying a minimum of at least four running feet of pleated or flat panels. Minimums can certainly be set higher if needed. "Hourly" It may seem that pricing by the hour, rather than by the size and type of treatment, would not be acceptable to designers. Let me just say that it worked for me! It was not until after some frustrating years of continually underestimating my time that I decided to make this change. Pricing by the hour is a tool that protects workroom professionals. Many interior designers charge by the hour, because they know that their knowledge and expertise is what the client is getting. You are selling the same thing–knowledgable service, not just window coverings! Additional pricing factors to consider... I charged my wholesale clients for consultation to help them value my time so that they didn’t ask for estimates for window coverings that they cannot sell. I also charged for alternative fabrication. This category covered a wide scope of ‘sins.’ Basically, if I couldn’t take a bolt of fabric and cut it as I normally did, such as a designer trying to get more panels from the leftover bottoms after railroading 118"-sheer, then I tracked how much extra time it took and charged for that. I also began charging by the hour to do any kind of alterations. Nobody likes doing alterations, and I didn’t need the extra work or aggravation. Whenever calculating prices by units and in doubt about which way to charge for something, work the math. Use different units to see which is the most profitable and the most fair to the workroom and the customer. The above information is only suggestions based on what has historically been done in the workroom industry. It is perfectly alright to charge by a different measuring unit as long as the result is an acceptable profit to you and your client's budget! As an experienced drapery workroom owner, Kitty Stein is available for Workroom Consulting. She answers questions ranging from fabrication how-tos and pricing, to growing a business, and much more. Contact Kitty for information about a personal consultation to enhance your business. P.O. Box 283 Clear Brook, VA 22624 Phone: (540) 667-5939 Fax: (540) 667-3170 email: kstein@shentel.net www.workroomconcepts.com Price Your Work With Confidence $39.95 The Price List $49.95 Order in the Workroom $24.95 Wholesale Contract Terms & Conditions $20.00 Workroom Specifications $49.95 ~ ~ ~ ~ ~ Custom Home Furnishings Store 180 Buckeye Access Road Swannanoa, NC 28778 800-222-1415 828-686-3185 CHFindustry.com Copyright © 2003 SewWHAT? Magazine 5 History of the Sewing Machine By Mary Zellers Recently while visiting one of the Smithsonian museums in Washington, D.C., Cheryl Strickland (publisher of SewWHAT?) was surprised to find a sewing machine exhibit that Scientific American magazine listed in the late 1800s as one of the top three lifechanging inventions. It occurred to her that even though she had appreciated her sewing machines, she had never really considered what it would be like to be without one. As we thought about this, our curiosity was peaked and here is what we found out about the hisorty of the sewing machine. Walter Hunt, credited with inventing the safety pin, was the first American to build a version of the sewing machine for industrial use, but he erronously gave it up because he thought the machine would cause people to lose their jobs. The first U.S. patent for a sewing machine was granted to J.J. Greenborough in 1842. various designs were being used everywhere. The most successful of these inventors was Isaac Merritt Singer, of the same Singer brand of sewing machine we use today. Singer patented his method of feeding material and regulating the tension on the needle thread. He eventually added the fixed arm structure (still used today), presser foot, and foot treadle that made operation easier. Singer also had the marketing ability necessary for selling the sewing machine that Howe did not have. Singer’s was the first machine specifically designed for home use. He was able to convince consumers of their need for a sewing machine. When single families could not afford a sewing machine of their own, communities pooled their resources to buy a machine to share. Eventually the practice of buying on credit became available and sewing machines changed from a desired luxury to a household necessity. It was Elias Howe who patented the first lock-stitch sewing machine in 1846 which directly led to the sewing machine we use today. Howe’s machine was difficult to use. It had no material-feeding Before the invention of mechanism to feed the the sewing machine, material into the virtually everything was machine. Instead, the sewn by hand. Every material was pinned to Elias Howe, Jr. piece of clothing, every a board and was Patent #4750, 10/10/1846 pair of shoes, all linens, removed and reposiPhoto used by Permission window coverings, and National Museum of American History, tioned when the Smithsonian Institution upholstery. Everything, stitching came to the for everyone–wealthy end of the board. As and not so wealthy–required hours of were all the earlier machines, Howe’s Howe went to court to fight the painstaking manual labor. Most machine was powered by turning a infringements on his patent, and after people’s wardrobes consisted of one or wheel on the side of the machine by many years of legal battles his patent two good outfits and one or two work hand. was upheld. Singer was ordered to pay outfits. When women of that day said Most importantly though, Howe fifteen thousand dollars to Howe in that they didn’t have anything to wear, lacked essential marketing and selling back royalties. Howe also was able to they really didn’t. skills to promote his negotiate a five-dollar The first crude forms of a sewing machine. Even though he royalty for each machine machine were introduced in the middemonstrated that his sold in the United States 1700’s, before electicity was invented. machine could sew faster by the other manufacturThese early machines were designed to than five people sewing ers and one dollar for each imitate the motions used in hand by hand, he was not able machine sold abroad. He sewing, and they were not very to sell even one machine. had finally gotten the successful. During the next forty years To make matters worse, wealth he dreamed of. many great minds worked to produce his machine was too However, he died at the various other improved variations of expensive for most age of 48, the same year the intriguing earlier machine. household budgets of the that his patent expired. Isaac Merritt Singer time (a whopping $300.) Patent #10975, 5/30/1853 The first known patent for a sewing The efforts from all of So, Howe took his Photo used by Permission machine was granted in Britian to these great minds National Museum of American invention to England to History, Smithsonian Institution combined to create the Thomas Saint in 1790. This patent sell it there. This venture was followed by patents to two French was a failure, but when workable model for the men (1804-07), and two men from sewing machine that we enjoy today. Howe returned to the United States Britain (1810-30). It basically evolved to have an eyehe found that during his absence other pointed needle, continuous-thread inventors had made improvements to feeding, a horizontal table, lock stitch, his machine and sewing machines of 6 Copyright © 2003 SewWHAT? Magazine a shuttle or bobbin to create a second thread, overhanging arm, presser foot, simultaneous material feed and needle motion, the ability to create curved or straight stitching, and a mechanism to carry out these operations in the proper sequence. The invention of the sewing machine dramatically changed the way people live. It was the first major timesaving device for the home. A garment that could normally take up to fourteen hours to sew by hand could be sewn in two hours by machine. The sewing machine might be singlehandedly responsible for launching the first home-based business for women. Homemakers could sew clothing and earn money to add to the family’s income, while taking care of the other responsibilities of their children and home. If this by itself were not enough, the industrial sewing machine made inexpensive, ready-made clothing widely available to every economic segment of society. Isaac Singer sewing machine, produced in the early 1900's. It was nick-named the "Red Head." During this time, Singer’s annual sales were 1.35 million machines, and the company offered 40 different models. Singer, one of the most widely recognized and established brands in the world, remains a leading manufacturer and marketer of sewing machines today. Cover photo provided by Bill’s Sewing Machines and Repair, Hildebran, NC. Bill's is a distributor of Singer and many other brands of home and industrial sewing machines. They offer parts and repair services on all brands. Bill's Sewing Machines can be contacted at 800-445-5657 or 828-328-2557. Think about all of the sewing you did today or have waiting for you tomorrow. How long would it take to accomplish this work without a sewing machine? The saving of time is remarkable, without even considering the consistency of the stitch and the strength of the seam. We have become so complacent when it comes to our sewing machines that we take them for granted. (Well, at least I know that I do!) When they aren't running right, we all become frustrated and upset. But, after recognizing what a revolutionary timesaving marvel they are, I have gained a new perspective: one of respect, appreciation, and patience. Thanks, Hunt, Howe, Singer, and all the rest of you! (I have to run now. I need to oil and hug my sewing machine.) Footnote: Facts for this article were retrieved from the following internet sites: historywired.si.edu, sew2go.com/smhistory, and sewingweb.com/community/HistoryTips. This mid-to-late 1800s hand-crank sewing machine is part of Cheryl Strickland's collection of antique sewing items on display at the Custom Home Furnishings Trade School. Because it is completely black with no decals or inscriptions, the brand is unknown. If you recognize it, give us a call. With beautiful, gold-leaf decals intact, this double-arm Wilcox and Gibbs machine (also part of The Trade School's display) is one of the earliest electrical models. As you can see, the motor (made by Westinghouse) is attached to the wheel that previously would have had a handle attached to it for handturning. The original manual, which is still with the machine, lists patents from the late 1800's and 1904. The manual also references that at that time, women already had been enjoying their machines for over 60 years. Coincidently, "Wilcox and Gibbs" was the brand of serger that Cheryl Strickland and her mother first used in their drapery business. No, it wasn't in 1904! Copyright © 2003 SewWHAT? Magazine 7 Window Treatment Workmanship Contest Entry Memphis Shawl Valance By Jodi Stanford T his valance is made of toile and is slightly arched on the bottom to feature the design in the fabric. Halfpleats at each end fall into the cascades, which are contrast lined with a small checked fabric. The valance is trimmed with small cording in solid red. Tassel fringe embellished with the checked fabric is attached above the cording on the lower edge. This is an extremely versatile treatment which requires minimal fabric. The valance section can be cut straight, arched, or scalloped. The half pleats may be eliminated or more pleats may be added, especially on wider windows so that seams may be hidden. Seams may also be hidden with bells or horns. The lower edge may be left untrimmed. Microcording is very effective on the lower edge. If the fabric design allows railroading, two valances may be cut from one length of fabric, providing a very economical use of fabric for multiple windows. Materials: 2 yards toile 1½ yards check yard drapery lining 3¼ yards interlining ½ yard red moire 4 yards " cording 4 yards tassel fringe Fabrication: 1. Determine the finished width of the valance and the finished length of the cascades. Also determine the finished length of the valance section. In this example the FW is 30", cascade FL is 34", and the valance is arched with a FL of 13" to 17". The board width of 3.5" and seam allowances are added to the valance FL for the cut length of 22". 2. The valance and cascades are constructed in one continuous piece with 2.5" half pleats at the end of the board where the valance flows into the cascades. Cut the center valance section to include 2" for the seam and to go into each pleat. For our example the center section is cut 34" wide and 22" long and the toile motif is centered. The cascades are cut lengthwise of the fabric so that the pattern goes up and down when the cascades are hanging. They are cut the FL plus 6" for the pleat and seam allowances for a total of 22" wide by 40" long. 3. Lining for the back of the valance section is cut 22" long by 30.5" wide. The contrast lining for the cascades and pleats is cut 22" wide by 41" long. 4. Join the valance and cascades with ½" seams. Also join lining sections with ½" seams. Press. The lining seams and face seams do not match up. This is because the contrast lining must completely cover the pleats so that none of the drapery lining will show when the valance is pleated. At the same time, the seams in the face fabric must be hidden inside the pleats. 5. Fold the valance in half and find the center. With a disappearing marker draw the shape desired as shown in the illustration. Use the valance as a pattern to cut the lining to shape. 8 Copyright © 2003 SewWHAT? Magazine 6. Lay the face fabric on the interlining face up with the interlining railroaded. Lift up the fabric and spray with a temporary adhesive. Smooth and adhere the face fabric to the interlining. Cut out the interlining. Trim the interlining out of the corners to reduce bulk. 7. Cut 1.5" bias strips from a solid fabric to cover " cording, to go around the lower edge of the valance and cascades. This example takes about 4 yards. Cover the cording. Sew to the interlined face fabric. Place the face fabric and the lining right sides together. Sew together, leaving an opening for turning at the top board edge. Grade the seam allowances. 8. Turn the valance and press. Drop in drapery weights, which will fall to the bottom of each cascade. Close the opening with iron-on tape. Window Treatment Design Contest Entry Crewel Scalloped Valance With Banded Panels By Diane Preston and Gretchen Johnson 9. Cut 2" bias strips of the contrast check fabric to make 4 yards and sew together. Press the seams open and then fold in half and press to make a 1" band. Serge the cut edge. Use fringe adhesive to adhere the contrast band to the underside of the fringe, allowing about ¼" to show above the fringe header. Press with a hot iron to set the glue. 10. Use fringe adhesive to adhere banding/fringe to the lower edge of the valance. When the cascades fold back, the sewn-in cording will seem to finish the back side of the fringe. 11. Cut a 1" x 4" board 30" long. Cover with lining. 12. Find the center of the valance and mark the pleats with a disappearing marker. Fold in the half pleats at each end of the board. Lay the valance on the table with the back edge towards you. Slide the board under the valance and allow the back edge of the valance to lay on the back edge of the board. Check the pleats. If there is too much bulk where the pleats lie, build up the center section with interlining. Staple in place. Cover the staples with gimp. 13. Place the valance on a dressing stand and dress the cascades. You will probably need to pin or tack them until they are trained. Diane Preston and Gretchen Johnson worked together to design this window treatment. They were challenged to create two sets of window treatments from only two yards of German hand-sewn crewel and 13 yards of yellow and white four-inch checked fabric. They wanted to feature the limited amount of crewel in the best way possible and use the checked fabric creatively. Two scalloped sections of crewel were used on the front of each valance, on the returns, and in the kick pleats. The yellow and white checked material was placed on the bias to form a strip between each scallop and kick pleat. Red cording was used to bring out the red in the embroidered flowers and to set apart each individual section of the valance. The trim for the bottom of the valance was made by stitching a yellow tassel fringe just below the top edge of a flat red fringe. The two trim colors complimented the treatment perfectly. The panels feature a bias band of plaid surrounded by red cording placed on each leading edge, which compliments the valance. As a result of using as little of the crewel fabric in the valance as possible, there was enough left over to make a toss pillow for each chiar. This enhanced the room and tied the pillows and window treatments together into an attractive overall theme. Jodi Stanford is the owner of Jodi’s Window Fashions, a home-based custom home furnishings business in Bartlett, TN. Her primary focus is fabrication of custom window treatments but she also offers design services, bedding and accessories, and custom blinds, shutters, and shades. The bold mix of colors in this room evokes much joy and cheer and is surprisingly successful. Diane and Gretchen were thrilled with the overall result of the project. Diane Preston owns Diane’s Interior Creations in Murfreesboro, TN. She specializes in custom window treatments, bedding, and fabric accessories. She a member of the Professional Design Association of Middle Tennessee. Gretchen Johnson owns Gretchen Johnson Interiors. She specializes in room makeovers that create a new ambiance with minimal investment. She uses the art of creative placement to use what the client already has to create a unique look. Copyright © 2003 SewWHAT? Magazine 9 "Partial Undergarment" Slipcovers By Karen Erickson the chaise had a slight curve, and when the slipcover was laid over the batting, there were several wrinkles that would not smooth out easily. But I continued with this idea, and sewed together two pieces of batting, to make a cap to slide over the inside and outside back. When the slipcover was placed over the dacron batting, the slipcover seemed to puff up. It was too cushy, even with the thinnest layer of batting. Scrap idea #1. I n November 2002, I was called to do a slipcover job for a wonderful chaise lounge with a button-tufted, channel inside back. The customer did not want the indentions of the buttons, nor the channel back, to show through the natural canvas washable slipcover. What were we going to do? I explained to the customer that it was possible to smooth out the area that she was concerned about by making a partial undergarment. I would experiment and come up with the best option. Idea #2: Use polycotton muslin. Muslin is one of my favorite fabrics for making undergarments. The muslin grips to many different types of furniture fabrics and helps to smooth out the under-surface that the slipcover lies on. I laid the muslin over the inside back, clipped it into shape, making sure to leave enough to tuck in where the inside back and inside deck meet. A back piece was sewn to the front piece, to make a cap to slide over the back, as in the first undergarment. The seams were serged to ½", with the seams facing out. I came up with four ideas for an undergarment, and presented each of the ideas to the customer. The customer was charged for one hour of extra work and all materials that were used in the experimentation to determine the best undergarment. Idea #1: Use a thin layer of Dacron batting. In past projects I have used thin layers of dacron batting to cover over the inside back of a tufted chair. The inside back of 10 Copyright © 2003 SewWHAT? Magazine I slipped the polycotton undergarment onto the chaise, and then placed the slipcover over this. The tufted button indentions could not be seen, but the channels in the back were still apparent. Scrap idea #2. Idea #3: Add bump to the muslin. What if I put something under the polycotton muslin to smooth things out? I had some bump interlining left over from another project. I cut the bump interlining to shape, pinned it to the inside back of the chaise, and then slipped the polycotton cap over the back of the chair. Next, I put the slipcover on. Well, this looked super, but when we sat in the chaise and got back up the bump moved under the polycotton muslin. Scrap idea #3. SUPPLIER RESOURCE DIRECTORY (Remove this section and keep for a permanent reference) 2 ----------------- Let Them Know You Saw Their Ad in the SewWHAT? Magazine! -------------- January 2003 SUPPLIER RESOURCE DIRECTORY (Remove this section and keep for a permanent reference) New Moreland Valance from M’Fay Patterns This window treatment design was inspired by one of the old masters of the 19th century, F.A. Moreland. The flat valance hangs from the rod with rings. It drapes long on one side with a deep tapered pleat. The other end attaches to the top of the pole with the softness of three shallow pleats. The separate rosette placed at the top gives the appearance that the valance is tied to the pole. The short jabot is made and attached separately to the back of the pole, behind the valance pleats. Three styles to choose from: #9265: 10" to 16" depth, #9266: 16" to 22" depth, #9267: 24" to 30" depth. For mor moree information, phone 704-847-1464. January 2003 -------------- Let Them Know You Saw Their Ad in the SewWHAT? Magazine! ---------------- 3 SUPPLIER RESOURCE DIRECTORY (Remove this section and keep for a permanent reference) Creative Treatments LLC 4003 Perry Hall Road • Perry Hall, MD 21128 Phone: 410-529-0342 • Fax: 410-529-4590 email: Uniquetrimman@msn.com • website: www.creativetreatments.com Specializing In Unique Brass, Wrought Iron, Wood & Resin Drapery Hardware Distributors for: The Finial Co: Decorative Wood & Wrought Iron Poles. Creative Design International: Acanthus, Empire, Western Wood, Wood Poles from 3/4" to 3" Wood Traverse Poles, Decorative Finials, Resina & J.L.Anthony. Crowder Designs: Decorative Molded Finials, Poles, Rings, & Brackets. D’Kei Trims: Imported from Germany. Decorative: Nail Heads. Award Trims & Fabrics: Decorative Trims & Fabrics. Ona: Wrought Iron Hardware, 5/8” To 1-1/2” Poles 100 Finials 30 Standard Colors. Made In U.S.A. Busche: Brass Drapery Hardware & Hold Backs, Rosettes & String Sets. Representatives for: Creative Fabrics: Fabrics & Linings. H.T.Barnes: Conso Trims, Claesson Hardware, Kirsch Hardware, Pillow Forms, Van Lathem Trims, Raymond Waites Drapery Hardware and All Products By Kirsch. 4 ----------------- Let Them Know You Saw Their Ad in the SewWHAT? Magazine! -------------- January 2003 SUPPLIER RESOURCE DIRECTORY (Remove this section and keep for a permanent reference) CALCULATOR (Used by Amy Burton and Other Instructors at the Custom Home Furnishings Trade School.) Conversions: Decimals - Fractions to 1/64th inch Yards, Feet, Inch, Metric Other W/R Related Items: Rollease - Clotilde Doris C. Graham S.S. Pearl, MS 39208 • Tel 601-939-9948 Fax 601-932-0055 Email: grmswcal@bellsouth.net January 2003 -------------- Let Them Know You Saw Their Ad in the SewWHAT? Magazine! ---------------- 5 SUPPLIER RESOURCE DIRECTORY (Remove this section and keep for a permanent reference) 6 ----------------- Let Them Know You Saw Their Ad in the SewWHAT? Magazine! -------------- January 2003 SUPPLIER RESOURCE DIRECTORY (Remove this section and keep for a permanent reference) 7 --------------- Let Them Know You Saw Their Ad in the 5AMWHAT? Magazine! ----------- January 2003 SUPPLIER RESOURCE DIRECTORY (Remove this section and keep for a permanent reference) 8 ----------------- Let Them Know You Saw Their Ad in the SewWHAT? Magazine! -------------- January 2003 Idea #4: Use Bump alone. What if I tried the bump interlining alone? The piece that I had originally cut was too small, but just to see if it would work, I pinned it in place with T-pins and slipped on the canvas slipcover. Wow it looked great, and it stayed in place when the slipcover was on top of it. The bump gripped the chaise really well. Taking everything off the chaise once more, I then laid two pieces of bump onto the inside back. I cut this larger than the original, allowing for tuckins, and lapping over the top to the outside back, so the undergarment could be pinned into place. Satisfied with the cut size, the edges were then serged together as a finish. Undergarment lapping over edges and pinned in place with T- pins. Undergarment lapping over the top to the outside back, and pinned in place with T-pins. Decorative Pillow Contest Entry Triangle Overlay By Anita Stuckey Materials: ½ yd of 3 different fabrics 3 yds of trim (I used beaded trim.) 1½ yd of bullion or other trim for actual pillow (I used 3" bullion trim.) 1. Cut two 17" x 17" triangles of each fabric. Taper the points so that they do not "dog-ear". 2. Sew together the main pillow, using two fabrics alike, sewing trim in the seam. 3. Turn, press, stuff with polyfil, and sew shut. 4. Take one of each of the remaining triangle fabrics and sew together with trim in the seam. 5. Do the same on the remaining set. Turn these two triangles right side out and put a piece of batting, cut to size, inside each. Sew shut. 6. Lay the one batted triangle right side down, lay the pillow on top of this, staggering the points. Lay the remaining batted triangle on top, right side up, matching the points with the bottom layer. 7. Tack the top and the bottom together, 2" in from the point, with a tag gun. 8. Cover six buttons from the pillow fabric and sew where the tacks are on both sides of the top & bottom layers. 9. Cover six more buttons using one or both of the other two fabrics. Sew onto the points of the pillow. Anita Stuckey is the owner of Window Watchers, in Fort Wayne, IN. She is an experienced workroom/window treatment and accessories specialist who works with several designers, as well as retail clients who use her design services. Copyright © 2003 SewWHAT? Magazine 11 Trims, Part I by Jo Woodworth T rimmings–cord, braids, tapes, fringes, piping– were extremely important to the appearance of furniture and hangings during the 17th, 18th and early 19th centuries. “Fancy goods” or “narrow goods” (as trims were variously called then) were often the most expensive component of an upholstery job. In the 17th century there were five major groups of trims: cord, gimp, woven tape, fringe, and piping. Master trimming makers used intricate looms designed especially for different types of trim, along with com- plex arrangements of wheels and bobbins. Tedious hand work was done by women working at low wages as piece workers. Early in the 20th century, the interest in decorative trimmings declined to the point that their use could be described as taboo. Now we are seeing the resurgence of beautiful trimmings to achieve a complementary relationship between covering materials and decorative finishes. Passementeries, as fine trims are called today, are both functional and decorative. Many different fibers, styles, and price ranges Types of Trims Fringe Sketch D—Ball Fringe There are many types of fringe. They are generally a narrow or woven textile consisting of a heading and an attached skirt. The heading, which is usually ¼" to 1½" wide, looks like a braid or a gimp. The yarns in the skirt can hang loose as in a cut fringe, twisted (as in a bullion), or looped. This ball fringe is called pom-pom fringe. Sketch A—Fringe Sketch E—Ball Fringe Sketch H—Netted Tassel Fringe For this fringe, the yarns from the heading are crisscrossed and knotted to form a netted skirt that gives it a trellis look. Netted tassel fringes are usually 2½" to 4" wide, however, some are made wider. They were historically used as hangings for canopy beds. Sketch I—Bullion Fringe This fringe has a skirt decorated with wood molds attached to a series of braided or crisscrossed cords. The wood molds are shaped into ovals, balls, or other curvilinear shapes and covered with fine threads or yarns, preferably silk. This particular ball fringe is called onion fringe. Sketch F—Tassel Fringe Sketch B—Fringe This is another type of ornamental fringe, which consists of a simple header and a single row of beads. The beads can be wood, glass, ceramic, clay, or crystal, all of which are readily available. This is a typical example of a tassel fringe with a header that resembles gimp, and a skirt made of small tassels. The French called it Campaign fringe, meaning bell or bell-like. Sketch C—Glass Bead Fringe Sketch G—Fan or Scalloped Edged Tassel Fringe. Yarns or cords that extend down from a plain header knot together one or more glass beads. The header for this fringe has a looped scalloped edge with tassels hung between the scallops. 12 Copyright © 2003 SewWHAT? Magazine This bullion fringe is made with cords rather than yarns. The heading can be plain or have a rolled top, which is also called a cord. Each cord used in the skirt is looped at the bottom and twisted together with itself. The cords are generally " to ½" in diameter and 2½" to 12" long. Shorter lengths of bullion fringe are used on swags, jabots, cascades, and draperies. Bullion fringe measuring 6" to 12" can be used as a skirt on furniture. Sketch J—Moss Fringe This is a combination of looped and cut yarns. It is available in a wide variety of yarn types. Moss fringes are used for pillows, cushions, table skirts, valances and the edges of draperies. are available today to enhance the beauty of window treatments and furnishings. Many of them are so detailed that they can be considered small works of art. Modernization has not simplified the complexity of making trims. It is no wonder that trims can be very expensive. The skillful, subtle use of passementerie provides the definition and detail that distinguish the finest interior designs. The following sketches provide the correct names for the many types of trims that are available today. Next month, I will share uses for these various trims. I will include applying trims to draperies, valances, pillows, and bedding. I will cover the dos and don’ts for using different fibers, tips on how to use small amounts to make great pillows, and more. Sketch K—Looped Moss Fringe This fringe is similar to the cut moss fringe except that the yarns at the base of the skirt are looped back up to the heading. Sketch L—Cut Moss Fringe Sketch M—Flat Braid or Galloon These trims are usually woven in satin, tabby or twill weaves, and generally have geometric or floral designs. Looking for fabrication instructions and timesaving tips? They probably already were in past issues of SewWHAT! Sketch O—Gimp Gimps are flat, narrow, woven textiles, " to ½" in width, made in many styles. One or both edges of the gimp can be plain, cut or have scalloped loops. They are most commonly used to cover upholstery tacks on wood framed furniture. They can also be used on screens, pillows and lamp shades for a finished edge. This is an example of a corded gimp; hand twisted cord sewn onto a flat gimp. Sketch P—Cord This fringe is 1" to 2" wide, with a plain, woven heading and a very full skirt. The loops have been cut. Some extra-full moss fringes come with two layers. What are you missing? Consisting of plied yarns that have been twisted together, the diameter of the cord " to 1". This is an example can range from of cord that has a flange or tape attached so that it can be inserted in the seams of pillows and cushions. It is commonly know as cord with "lip." It can also be used for drapery, valances, table skirts, etc. It is often used in place of fabric welting. Don't miss out! Create your own complete reference library. Order your back issues now! Only $12 per year! Sketch Q—Rope Sketch N - Braid When the diameter exceeds 1", a cord may be known as a rope. Braids or galloons are flat, narrow, woven textiles, " to about 4" in width, made in various patterns. The edges of a braid or galloon can be cut, looped, straight or scalloped. Narrow braids are used to cover staples and nails on wall upholstery and furniture. Wider braids are used to apply to edges of drapery, to skirts of furniture, table skirts, pillows, valances, and bed linens. This example is called a scalloped, fan, or shell-shaped flat braid. Jo Woodworth is a professional speaker and licensed designer with degrees in both Design and Education. She owns a drapery workroom and is founder and instructor of the Academic School for Interior Design. SewWHAT! 800-222-1415 828-686-3185 SewWhatMagazine.com Copyright © 2003 SewWHAT? Magazine 13 Creating Window Treatments From Photos - Part 1 The Five Basic Styles By Margie Nance O ne frequently asked question heard in the workroom is “can you make a treatment from a magazine?” Your first thought might be “of course I can, I do this all the time,” but as you begin to look at the magazine clipping, doubts may start to creep in. What happens when there isn't a commercial pattern available for that treatment? The design has to be created from scratch, sometimes taking many hours of trial and error to get it to "look" like the photo. By following the guidelines in this series, you will discover that all window treatments consist of a combination of three elements: the basic style, the components, and the embellishments. Some treatments may not have all three elements but there will always be a basic style that makes up the base of a window treatment. After studying pattern pieces over the last ten years, I discovered one thing that has helped tremendously in recreating a window treatment from a photo. There are only five basic styles of treatments: flat, gathered, box pleat, pinch pleat, and swags. I know there are books out there that show hundreds of window treatment designs, but they all started from one of these five basic styles or combinations of styles. Once the basic design is identified, the rest of the window treatment can be broken down into the other two elements, components, and embellishments. A component is an element that is placed over, under, or attached to the basic window treatment style. The major components are cascades, jabots, pelmits, and horns. Embellishments are all those little extras that really customize the design, creating a unique look. Embellishments include trimmings, decorative stitching, cording, banding, ruffles, buttons, knots, rosettes, etc. This first in a series of articles will explain the five basic styles and give examples of each one. Flat styles are treatments that do not have fullness. Soft cornices, hard cornices, or overlapping triangles are examples of flat treatments. They are the simplest to identify. Gathered styles have fullness. They can be created with a randomly gathered fullness or exact, uniform tucks. Gathers can be created across the top of the treatment and can also go down the sides of a treatment, like a balloon or Austrian shade. Box Pleat styles also have fullness, but the fullness is folded into flat pleats. Box pleats lie on the front of the treatment. Inverted box pleats lie on the back of the treatment. Box pleats can be placed side by side or spread apart with spacing between. 14 Copyright © 2003 SewWHAT? Magazine Pinch Pleat styles have fullness stitched on the front side of the treatment. They can be placed close together or spread far apart. There are a wide variety of types of pinch pleats, such as goblets, French, Euro, and butterfly. Swag styles are identified by their unique U-shaped curved folds. The folds can be pleated or gathered and can be placed over the top of the treatment like an Empire or down the sides like a Kingston. The next time you go through your collection of magazine clippings, start identifying which basic style or styles are in each photo. The more you practice this analysis process, the faster and more natural it becomes. Over the next few months, I will be discussing the elements of components and embellishments. I will be giving tips on how to recreate any window treatment design. Editor's Note: For terrific hands-on instruction on creating patterns from photos, attend Margie Nance's "Creating Custom Patterns" class at the Custom Home Furnsishings Trade School. Margie Nance owned her own successful workroom with several employees for ten years. She now owns Drapery Patterns by Margie Nance, designing a line of detailed patterns and custom-designed patterns. Margie is the instructor for the "Creating Custom Patterns 101" and "Window Treatment Fabrication 103" classes at the Custom Home Furnishings Trade School. Margie also teaches the onlocation "Artistic Adventure" classes and organizes the instructors for the Custom Home Furnishings Educational Conference. Creating Custom Patterns 101 Class: In this 2-day class, with just a few simple tools and basic tricks-of-thetrade, you will acquire the knowledge to create your very own custom window treatment patterns from photographs. Seasoned instructor Margie Nance will walk you through all the steps on how to make custom patterns from any source, including magazine photos and client sketches. Each student will choose one sample photograph— basic to advanced—to use while learning hands-on how to trace the photo, dissect the components, create a pattern and then actually make the window treatment! For additional training, attendees are encouraged to bring their own photographs and magazine pictures to analyze during an open discussion period. The Custom Home Furnishings Trade School 180 Buckeye Access Road, Swannanoa, NC 800-222-1415 828-686-3185 CHFindustry.com The Five Basic Styles FLAT GATHERED BOX PLEAT PINCH PLEAT SWAGS Copyright © 2003 SewWHAT? Magazine 15 Upholstery of a Vintage Camel-Back Sofa By Anita Boetsma Vintage furniture can be a challenge for the upholsterer. Older pieces are often very well built and well worth saving. Sometimes there are hidden problems with frames and supports that will need to be addressed. This old sofa had two broken arms and was fairly shaky but the wonderful ball and claw feet and carved trim work were too special to pass up. A guesstimate of the age of the piece placed it in the 1920’s. It had been re-upholstered at least once. During the tear-down process we found many broken pieces on both arms, and the basic frame needed new structural supports in the back. Putting each of the small broken pieces of arm framing back together in the correct order was like assembling a threedimensional puzzle. The smaller pieces had to be matched, cleaned, glued and clamped before the next stage of assembly could begin. As the larger pieces were assembled, screws were used to anchor the glue. It is extremely important to completely remove all old adhesive from loose joints before new wood glue is applied. The old and new adhesives will not interact well together, and the piece will not hold. The assembly process could not be rushed; each segment had to cure completely before being used. Finally we reinforced the entire frame unit by taking all loose joints apart, cleaning the dowels and sockets, re-gluing and clamping the corners. Some repaired areas were reinforced with " wood glued and stapled in place. We added larger corner blocks in the seat base and new corner blocks in the back. With the additional corner supports the rebuilt frame was actually stronger than when it was originally built. Cardboard had been used to cover the inside of the curved arm sections. The cardboard was discarded and jute webbing was used to bridge the open area of the inside arms. Next we stapled burlap over both spring units and inside arms. The finished areas of wood on this sofa had gouges, scratches and worn spots. Epoxy mixed with powdered stain was used to fill the deep gouges. Once cured, the excess was sanded away. Stain powder was applied to the lightly sanded, scratched and worn areas. Spray lacquer was applied in several coats and allowed to dry. Some areas needed additional applications of both stain and lacquer. The spring units were originally tied in an inadequate four-way method and had loosened from each other, and in some places, the frame. While the springs were in good condition, they needed to be retied completely, in both the seat and the back. We re-tied the spring units with an eight-way pattern, securing the springs firmly to each other and to the frame. 16 Copyright © 2003 SewWHAT? Magazine Large jute edge roll was sewn to the front of the seat spring and small jute edge roll was stapled to the curved inside edge of the arm frame. Finally the sofa was ready for upholstery! Beginning with the fabric layout, the pattern was carefully centered in the middle cushion. Pattern placement on the side cushions was matched to the center. An interesting note: the center cushion is wider than the side cushions to correspond with the center section of the inside back. In order for the cushions to be turned, one of the two matched top sections cut for the left cushion must be sewn to the bottom of the right cushion and vice versa. So, not only can the cushions be turned over, they must be switched from side to side to maintain pattern match across the seat. The seat cushions were spring units and, again, were in fairly good condition. We discarded the soiled top layer of padding and applied fresh cotton to add softness. The cushions were constructed with long zippers extending approximately 6" toward the front of the boxing to Equipment Focus Upholstery Starter Kit make stuffing the cushions easier. Spring units can be difficult to insert into covers. Using the center cushion as a pattern guide, we cut the gusset section so that the pattern matched from the boxing to the gusset. The gusset section was sewn to the stretchable decking fabric. The decking and gusset were hand-sewn to the burlap-covered spring base. Padding was added to the front and seat area. The fabric was stretched and stapled in place along the carved wood front and the bottom of the frame. Some of the original sphagnum moss padding was replaced and tacked into position with large stitches using button twine. Fresh sheets of cotton were layered over the moss. Again, using the center cushion as a pattern guide, the inside back fabric was positioned, stretched, and stapled into place. The top corner sections of fabric were left unfastened until the inside arms were complete. Original inner layers of inside arm padding were positioned and covered with a fresh layer of cotton. Fabric panels were then positioned. Wide pieces of fabric were used to allow the fabric to wrap the front “keyhole” area of the arm with crisp pleats. Welt cord was applied underneath the arm from front to back and down the curved front edge. Fabric panels were fastened using cardboard tacking strip along the top edge only. Fabric was then tacked in place along the bottom edge and stretched forward to the curved front welt cord. Excess fabric was trimmed away from the curve and fabric was tacked in place with t-pins. Fabric was secured by hand slipstitching using a curved needle. The back was tacked in place last, to pull out any slack in fabric. The fabric left loose on the inside back corners was then positioned over the completed inside arm areas and tacked in place. Next welt cord was fastened to the outer edge along the top and sides of the outside back using cardboard stripping. Lining fabric was stretched across the outside back to create a firm base for the back padding. Padding and fabric were then positioned within the welt cord “frame.” Outer fabric was trimmed and pinned in place using T-pins. Back fabric was slip-stitched into place. Excess slack was pulled downward and the fabric was stapled under the bottom edge of the sofa frame. The final step in finishing this fabulous vintage sofa was to carefully trim the fabric along the carved wood trim on the front and sides and apply double welt cord to hide the staples. Ready for delivery…a vintage gem. Now it's easier than ever! Add lucrative upholstery services to your window covering business with this “intermediate” starter tool kit. Everything you need to get started: Tack Hammer Staple Lifter Web Stretcher Ripping Chisel Knife Taylor Chalk 3" Upholstery Pins Set of 4 Curved Needles 8" Needle 8" Regulator 10" Upholstery Shears Instructional Booklet $110.99 (Item # S-168) Anita Boetsma is a professional designer who owns and operates a full-time design center and funiture store with her husband on the shores of Lake Maxinkukee in Culver, Indiana. Custom Home Furnishings Store 180 Buckeye Access Road Swannanoa, NC 28778 800-222-1415 828-686-3185 CHFindustry.com Copyright © 2003 SewWHAT? Magazine 17 Looking Up Praise and Prayer…A to Z By Anita Boetsma S ome time ago I took a course on prayer. One of the requirements of the course was to spend an hour a day with God. That hour was so long…what could I possibly say to GOD for a WHOLE HOUR? One day as I struggled to find things to pray about it came to me…this should be as easy as ABC! Since that day, when I need to jump start my prayer life, I thank God for who he is from A to Z and then I pray for someone or something from A to Z. I hope this helps inspire your praise and prayer. A B C D E F G H I J K L M N O P Q R S T U V W X Y Z Abba, my Father Bible, my guide Christ Diety Everlasting life Faith to move mountains Almighty God Holy, Holy, Holy Infinite wisdom Jesus King of Kings Lord of Lords, Lover of my soul Messiah Never far away Alpha and Omega Prince of Peace Quick to forgive Righteousness, my gift Saviour of my soul Teacher of all truth Unlimited love Victory over fear Wonderful and wise The Cross of Calvary Yahweh Zookeeper of this crazy world! "The effective, fervent prayer of a righteous man avails much" ~ James 5:16 18 Copyright © 2003 SewWHAT? Magazine CLASSIFIED • Wanted: Experienced workroom Manager. Fastgrowing, high-end furniture and window covering company with eleven stores, is seeking a motivated, responsible manager for its workroom in Sterling, VA. Salary depending on experience. For more information, call Cheryl Strickland at 828686-3185. (Cheryl is their consultant.) • For Sale: Retail business. Over 100 wallpaper books and 2 bookcases to hold them. Seabrook, Sunworthy, Imperial, Brewster. 22 Conso trim cards. D50 Dofix w/ceiling track. 12' x 5' table, padded, gridded. Bernina 950 industrial machine. Full line of Kasmir, RM Coco sample books. All poles and set-up to hang fabric bolts. All workroom supplies. 2 border racks with borders and 9 cases of sidewall wallpaper. All pillow form stock. $11,000 for all. Must sell together, will not separate. E-mail: fjseaton@cox.net for more information. • For Sale: Many 16" x 16" and 18" x 18" cushion covers for sale. Multiple colors and patterns. Very beautiful pieces. Price, $7.99 each and up. See details at www.curtainhouse.com. • For Sale: Maxant Miracle Buttons for covering. Size 1 " and 1½" buttons, push on, no prongs. Great prices. Contact Michelle Stender, Sew What’s New, sewwhatsne@aol.com. • For Sale: Dofix D25 Iron with teflon shoe. Track package, including bow, balancer and boiler wall mount. $1,100 (includes shipping) OBO. Contact Pat at J & J Design Workroom, 952-894-2142. • For Sale: Singer walking foot, Model 111/153, with table, motor, accessories. Excellent for heavy upholstery work, including leather and naugahyde. $450. Cape Cod, Massachusetts, 508-833-2211. • For Sale: Lavelle Pinders Homeowners Guilde to Purchasing Custom Window Coverings. Very informative and helpful. Excellent condition. $20. E-mail shadelady1@hotmail.com for more information. • For Sale: One new Hunter Douglas Silhouette Shade, color Misty Almond. Top of the line window treatment suitabe for inside or outside mount. Size, 94.25" x 57.75". Retail price, $1,373.00. Selling price, $550.00. Photo available upon request. Please email me at maywooddesigns@hotmail.com. Classifieds Policy: SewWHAT? will list your products, services, or needs free of charge. Listings will run for one issue and can be repeated at the request of the submitter. Call 888-4SEWWHAT or 828-686-3185 fax 828-686-3186, or email: classified@SewWhatMagazine.com. 2002 Educational Conference Videos Videos Item #V02-5d/6d Growing Your Business to the Next Step Item #V02-5i/6i Running an Upholstery Business with Sally Tucker ........................ 3 hrs with Steve Cone ......................... 3 hrs This class will provide practical information and creative approaches that will attract more clients who will pay you what you are worth. Sales strategies, techniques to become a better “closer”, setting realistic business goals, working a business plan that generates repeat and referral business. In this detailed class “Upholstery Guru”, Steve Cone, will walk you through all of the typical situations that a small upholstery business has to deal with, including how to get started, how to find a customer base, how to track customers, how to give an estimate that you get the results you are looking for, how to make more money with your estimates, how to build your client base and how to keep them. This class will even cover how to deal with too many customers! Item #V02-5e Marketing Tools for Your Business with Patty Pedersen .................. 1½ hrs Drawing from her own marketing experiences, Patty will provide the information you need to design marketing materials and show you how to develop a logo, business cards, stationary and much more. Item #V02-5f Feng Shui Window Treatments with Jo Woodworth ............... 1½ hrs Ch’i, the energy force that is all around us, when directed in the right path, can bring harmony and well-being into our lives. This Ch’i can be directed by simple placement of objects in a room or in our home in general. Feng Shui is based on using various existing knowledge to choose, construct, or create the most suitable living and working conditions that can be. Bring more peace and harmony in your life. Item #V02-5g Slipcover Skirts with Karen Erickson ................ 1½ hrs Explore the many skirt possibilities when making slipcovers. The sky is the limit. Review of the basics and then on to exciting options. Power point presentation of skirts, and samples will be included. Item #V02-5h/6h Building a Chair, Part I with Anita Boetsma .................... 3 hrs Start with a bare frame and build a high-quality upholstered piece. The first class in this series will cover "bare frame" to "ready for finish fabric." Learn base and spring systems and how to hand-tie springs to create a sturdy base. Learn how to “break” the springs for comfort and types of padding. Learn to evaluate frames to determine the best finishing technique. NOTE: These videos of live seminar presentations were not professionally filmed and are being sold for educational content only. Item #V02-5k/6k Tricks to Making Unique Treatments with Ori Katzin .......................... 3 hrs In this new class, Ori will share, in great detail, some of his techniques and methods of creating unique window treatments that are based on basic styles. The class will also feature some of Ori’s solutions to specific challenging situations where no ordinary window treatment will do. The presentation will include: 50 window treatments throughout the classroom, digital video and photo slideshow, color printed handouts and more. Item #V02-6a Drapery Panel Headings with Ginny Conner ................. 1½ hrs Fabric is in. Draperies are in. But if you are looking for something a little different than the familiar pinch-pleated heading this seminar is a must. You will see over one dozen actual samples of stylish headers for side panels and traversing draperies. You will also learn how to fabricate these beautiful headers. Increasing your choice of header styles will enable you to better enhance the beauty of the fabric, complement the style of the room as well as match the taste and budget of your customer. Item #V02-6b Calculating Yardages 2002 Custom Home Furnishings Industry Educational Conference and Trade Show Class Videos 4 WAYS TO ORDER! By phone: 888-4-SewWhat or 828-686-3185 By mail: 180 Buckeye Access Rd. Swannanoa, NC 28778 By Fax: 828-686-3186 Online: www.CHFindustry.com with Ann Neel ......................... 1½ hrs Do you “quesstimate” how much fabric or trim is needed and then get caught short? Do pattern repeats make you light-headed? You didn’t get into this business to do math, but your’re stuck with it and cringing at any numbers without dollar signs in front. Come learn the basics of how to calculate fabric and trim yardages from a math whiz. Ann teaches you how to calculate everything on the spot and wrap up the sale in one visit. You will learn how to figure the number of widths and cut lengths, how pattern repeats affect the calculations, and how to calculate with 118" wide fabric. 1½-hour videos are $24.95 3-hour videos are $49.95 * For a complete list of all 165 Conference videos, visit the SewWhatMagazine.com website or request a catalog at 888-4SewWhat or 828-686-3185. Copyright © 2003 SewWHAT? Magazine 19

© Copyright 2025