Poster

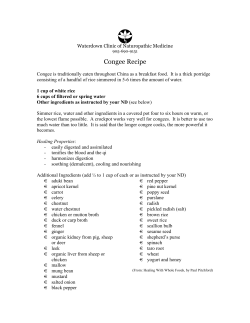

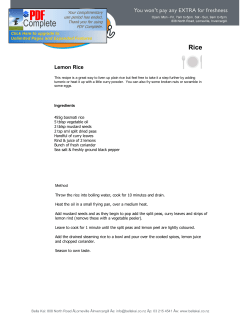

Production of Amorphous Silica from Rice Straw Using Dry Anaerobic Digestion Pretreatment Safoora Mirmohamadsadeghia, Keikhosro Karimia, Akram Zamania,b, Ilona Sárvári a Department b b Horváth of Chemical Engineering, Isfahan University of Technology, Isfahan, Iran Swedish Centre for Resource Recovery, University of Borås, Sweden Abstract The feasibility of amorphous silica production from rice straw residues of anaerobic digestion was investigated in this research. The residue of the 60-day solid-state anaerobic digestion (SSAD) , after removing the sludge, was combusted at to obtain the silica. X-ray diffraction (XRD) and X-ray fluorescence (XRF) analysis were performed on the silica. XRD analysis confirmed the existence of amorphous silica in the ash. The silica content in the ash was increased by 55% after SSAD process. XRD and XRF analysis were performed on the silica and the results were compared with the ash obtained from untreated rice straw. Results and discussion The methane yield obtained from SSAD during batch experiments was 120 litter CH4 per kg of volatile solid. XRF analysis (Table 1) showed that silica content was increased from 37.7 to 58.4% using anaerobic pretreatment before combustion. Table 1. XRF chemical analysis of ash samples Introduction Experimental Rice straw was provided from Lenjan field (Isfahan, Iran) and cut to about 1 cm length. It was fermented in the presence of a microbial consortium obtained from Isfahan municipal sewage treatment digester at TS content of 20% and feed to inoculum ratio (F/I) of 3 based on VS contents. After 60 days mesophilic digestion, the solid residues were thoroughly washed with tap water on a 20 mesh and calcined in a muffle furnace at 550°C for 8 h. Ash samples SiO2 K2O CaO Cl Untreated 37.70 30.40 10.40 10.20 Digested 58.36 0.916 23.66 0.30 The broad peak centered at 2θ=23° in XRD pattern confirmed the existence of amorphous silica in the ash obtained from SSAD residues. 1200 Ash of digested rice straw 1000 Intensity The residues of rice straw from anaerobic digestion are mainly inorganic constituents which contribute approximately 11–12% by weight of rice straw and are rich in silica. Common procedures for silica production combust the organic parts of rice straw. These methods waste organic materials and also need large furnaces to combust bulky straw. Using rice straw as a substrate for anaerobic digestion before silica production process can improve the economy of the process by converting organic part to biogas and decreasing the volume of the furnace to 11-12% of that for untreated straw. This innovation has not been mentioned in previous studies. Therefore, the feasibility of silica production from rice straw residues of anaerobic digestion was investigated. Chemical content (%w/w) Ash of raw rice straw 800 600 400 200 0 5 25 Conclusions 45 2θ (degree) 65 Anaerobic digestion of rice straw before common methods for silica production is a novel method to improve quality of the silica and improve the economy of the process by biogas production. References Wattanasiriwech, S., Wattanasiriwech, D., Svasti, J. (2010). Journal of Non-Crystalline Solids, 356(25), 1228-1232.

© Copyright 2025