Session 11, option 2, Top EBRD H&S Issues.pptx

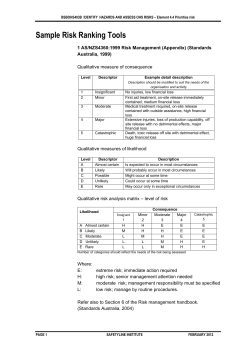

SESSION 11 PR 4: HEALTH AND SAFETY – TOP ISSUES FOR THE EBRD Presented by Monkey Forest Consulting OUTLINE PR 4: HEALTH AND SAFETY – TOP ISSUES FOR THE EBRD EBRD Project Statistics Practical Risk Management Identification of Chemical Hazards Excavation Safety Confined Spaces Dust Explosions Movement of Plant, Vehicles and Rolling Stock Electrical Safety Contractor and Subcontractor OHS Management EBRD PROJECT STATISTICS Group question: How many fatalities do you think there were on EBRD projects in 2013? Data from: EBRD Sustainability Report 2013: 72 significant incidents reported 102 fatalities (63 worker fatalities and 39 third party fatalities) 59 major injuries to workers 1 incident of property damage 3 or more fatalities were encountered in the following countries: Ukraine (19) Turkey (14) Russia (11) Romania (10) Kazakhstan, Lithuania and Moldova (3 each) PRACTICAL RISK MANAGEMENT OUTLINE Practical Risk Management Hazard and Risk Risk Assessment Overview OHS Hazards Risk Hierarchy Spot the Hazard Summary HAZARD AND RISK Hazard ü Inherent properties of chemicals, biologicals, radiation ü Characteristics of physical and mechanical situations ü Requires an exposure route Risk ü All about probability/chance/likelihood/potential for harm ü Higher probability of occurrence ⇒ higher risk ü High hazard potential + exposure route ⇒ greater injury/damage Hazard + Exposure Route (Pathway) = Risk Ø Thus, to control risk, aim to break exposure route or remove hazard Ø Prevention not Reaction RISK ASSESSMENT OVERVIEW Basic Steps Identify the Hazards (what can go wrong?) Decide who might be harmed and how (i.e. the consequences) Evaluate the risk (how much does it matter?) Record findings and implement risk management measures (what are you going to do about it?) Review and update (Keep it current) RISK ASSESSMENT OVERVIEW Risk Matrix Example 1 Trivial 2 Minor 3 Significant 4 Critical Consequence 5 Catastrophic Likelihood 1 Improbable 2 3 2 Remote 3 3 Possible 4 5 4 Likely 5 6 5 Very Likely 6 7 4 4 5 6 5 6 7 6 7 8 8 9 9 10 7 8 RISK ASSESSMENT OVERVIEW Workplace Risk Assessment Example Ac#vity Hazard Who Affected Risk Management Li;ing of container Dropped load Li;ing crew Poten#al for fatality/serious injury Li;ing plan Oversight by foreman, restricted access WHAT IS OCCUPATIONAL HEALTH & SAFETY? What topics make up key Occupational Health and Safety Hazards? OHS HAZARDS § § § § § § § § § § Chemical Physical Radiological Biological Ergonomics Psychological Environmental Health Off-site Accommodations Sensitivities (Fertility and Pregnancy) Others? OHS HAZARDS § Watch out for the “Elephant in the Room”!! OHS HAZARDS § “Elephant in the Room”? § The ‘OH’ part of OHS! § UK Health and Safety Executive said in 2013: “Ill health accounts for 43% of the health and safety incidents, 84% of the related sickness absence and over 99% of the work-related deaths each year” • 133 workers killed at work in the UK (2013/14) • That is, there are over 13,000 workrelated deaths each year in the UK are related to ill health!! RISK HIERACHY Elimination Stopping the activity entirely Substitution Switching the activity for something less inherently dangerous Engineering Control Putting in some form of control or barrier such as machine guards Administrative Control Such as a lock out/ tag out system Personal Protective Equipment Such as ear defenders or goggles Personal protective equipment is always the ‘last resort’ SPOT THE HAZARD (interactive group session with pictorial examples) SPOT THE HAZARD § If you observed asbestos-containing roofs like these on a site, what would be your recommendation? SPOT THE HAZARD SPOT THE HAZARD SUMMARY • • • • • • Practical risk management Hazard versus Risk Range of OHS Hazards Do not forget the “Elephant in the Room”! Use Risk Hierarchy to control risks Practical ‘Spot the Hazard’ exercises – stop, look, listen and think holistically IDENTIFICATION OF CHEMICAL HAZARDS Group Exercise (20 minutes total) – break into smaller groups (for 10 minutes) and report back (another 10 minutes) IDENTIFICATION OF CHEMICAL HAZARDS You have been asked to carry out a site audit to an industrial site. You know that they are likely to use some chemicals at the site as part of the process, but currently have no details. 1. Before you go to site, what information will you use or request from the site in relation to potential chemical hazards at the site? 2. When on-site, what types of observations and data reviews will you make to better assess chemical hazards at this site? IDENTIFICATION OF CHEMICAL HAZARDS 1. Before you go to site, what information will you use or request from the site in relation to potential chemical hazards at the site? Possible Answers: • Process details • Chemical Inventory list • Permits, Authorisations, Licences • AST and UST inventories, capacities, etc. • Site diagrams • Previous audit and monitoring reports • Your existing knowledge of other sites in this industry • Internet searches on this site and/or industry sector IDENTIFICATION OF CHEMICAL HAZARDS 2. When on-site, what types of observations and data reviews will you make to better assess chemical hazards at this site? Possible Answers: • Site observations using your senses • Strange odours (do not intentionally smell chemicals!) • Stored chemicals (labelling, drums, IBCs, tanks, warehouse storage) • Process conditions, housekeeping, ventilation • Spill management • Presence of confined spaces • Fixed monitoring units • Personnel wearing personal alarm monitors • Inventory and Safety data sheets • Documented risk assessments • Product recipes and technical sheets EXCAVATION SAFETY EXCAVATION SAFETY - VIDEO Play ‘Trench Cave In video (2 minutes) EXCAVATION SAFETY - VIDEO What caused the trench to collapse? Suggestions: Ø No shoring or shielding in place Ø Heavy equipment parked near by Ø Lack of training, management processes and supervision Ø Time and cost pressures How much does 1 m3 of soil weigh? Answer: About 1.6 tonnes! So you can imagine why people are crushed in trench and excavation collapses! RECENT EBRD EXAMPLES In recent years, there have been 14 to 15 trench and excavation fatalities on EBRD-invested projects per annum Romania: a lot of trenches and excavations in EBRD-invested water and wastewater projects Croatia: good examples of trench and excavation practices down to 4 m depth with one company Good practices needed, however, across all projects RECENT EBRD EXAMPLES Two Trench Boxes being used rather than the correct size for the excavation Not supporting lower sections of the excavation where workers are working – Should be stacked RECENT EBRD EXAMPLES Access and egress not suitable – needs to extend 1m from stepping off point and tied off to prevent slipping RECENT EBRD EXAMPLES Partial timber supports being used – Above Backhoe boxes were available on site (22 in total) although not utilised in this area RECENT EBRD EXAMPLES Sheet piling unsafely installed and not utilised in all areas of excavation - 3m BGL (Below Ground Level) RECENT EBRD EXAMPLES Recently backfilled materials – Worker entering trench with no supports RECENT EBRD EXAMPLES Unsupported excavation Other risks: build up of fume from passing vehicles and damage to gas pipe (used to assist exit out of excavation) CONFINED SPACES CONFINED SPACES Quick Fact: Accidents in confined spaces are often fatal Another Quick Fact: 55% of fatalities in confined spaces are to rescuers What does this mean? For every fatality of someone working in a confined space, more than one rescuer also dies! CONFINED SPACES Some confined spaces are fairly easy to identify, e.g. enclosures with limited openings: Ø storage tanks Ø silos Ø reaction vessels Ø enclosed drains Ø sewers CONFINED SPACES Others may be less obvious, but can be equally dangerous, for example: Ø open-topped chambers Ø vats; Ø combustion chambers in furnaces, etc. Ø ductwork Ø unventilated or poorly ventilated rooms CONFINED SPACES – RECENT INCIDENT • 17th June 2013 at 1130hrs, two workers entered a well at a sewage pumping station, to carry out maintenance work • One worker entered the well using the fixed ladder (8m deep) started to have difficulty • Second worker called for help with mobile phone and then entered the well to help – he also started to have difficulty • Three more workers arrived, one by one they entered the well to rescue the two workers (last worker rang HO to inform them of the incident before entering) - all three workers started to have difficulty • Two workers from HO arrived, one went down the well while the other rang the emergency services – once he finished the call he also went down the well • All 7 Workers Died CONFINED SPACES – RECENT INCIDENT • • • • What went wrong? Complacent? Didn’t appreciate the risks? Right equipment, training and supervision? Investigation outcome suggests workers were overwhelmed by H2S or Methane CONFINED SPACES – SUMMARY OF CONTROLS • • • • • • • • • • • Avoid Entry Risk Assessment Isolate the space Permit to work Ventilation Testing the Atmosphere Air-supplied respiratory protection Correct personal protective equipment Access and egress arrangements Emergency arrangements – rescue team present Training DUST EXPLOSIONS DUST EXPLOSIONS – RECENT INCIDENT In Belarus at a wood pelleting facility: Inadequate / inefficient dust extraction system Also not fitted with a metal-removing magnetic device Wood dust cloud exploded twice, presumably ignited by a spark from piece of metal / friction Roof of building fell down inside into the building and killed 14 persons DUST EXPLOSIONS – COMBUSTIBLE DUSTS Examples of combustible dusts: Ø Wood Ø Grain (e.g. silos) Ø Sugar Ø Coal Ø Certain metals Ø Many synthetic organic chemicals DUST EXPLOSIONS – EXAMPLE CONTROL MEASURES Controls over dust cloud formation Preventing the explosive atmosphere by inerting Avoiding ignition sources Plant controls e.g. Ø Explosion relief venting Ø Explosion suppression and containment Ø Plant siting and construction MOVEMENT OF PLANT, VEHICLES AND ROLLING STOCK TRAFFIC - RECENT INCIDENTS Serbia: During working hours in a company vehicle; crashed into another company vehicle; location was off site on Rudovci-Belgrade road close to village of Mali Crljenci; 3 workers killed Turkey: 30 year old male fatality; driving at work; a truck pulled out to cross a road and company van hit the truck head on Ukraine: 36 year old female fatality; accident happened at the trolleybus garage; after the trolleybus had been washed the driver parked vehicle in garage; defect spring on drive pedal - caused uncontrolled movement of a trolleybus; at 2130 hrs her body found under the back axle of the trolleybus Russia: Russian Railways – about 3,000 3rd parties are killed each year (e.g. walking along easily accessible tracks) and 3 to 4 workers are killed every fortnight TRAFFIC - RECENT INCIDENTS Kazakhstan: CNG-fuelled bus caught on fire; cause assessed as being due to lack of maintenance Serbia: Tipper truck accident on the Corridor 10 Road Project near Dimitrovgrad; Driver pulled away after discharging load from tipper truck but did not drop body back down on to the tipper; hit bridge and about 80 tonnes of concrete debris fell on the cab and killed the driver TRAFFIC – EXAMPLES OF CONTROL MEASURES About 33% of road accidents are business / work driving so consider: Ø Driver monitoring such as telemetry for speed and braking Ø Alcohol-test interlocks on vehicle Ø Fit-to-work assessments Ø Enforced maximum driving hours (e.g. AETR rules) Ø Properly specified & maintained vehicles TRAFFIC – EXAMPLES OF CONTROL MEASURES Site road design and pedestrian segregation Site procedures, monitoring and audits Correctly designed & maintained access roads & highway interfaces Rail track security, fencing, warnings, signage, etc. Training of site workers and vehicle operators Community education programmes ELECTRICAL SAFETY ELECTRICAL SAFETY ELECTRICAL SAFETY - STATISTICS As at March 2014 on EBRD-invested projects: 64 fatalities involving electricity Main Sectors: Power and Energy Transport (Rail) COMMON PUBLIC SAFETY ISSUES Illegal Construction – identified problem in Turkey & Moldova Illegal connections & cable theft Entering substations - homeless Downed cables – inclement weather Arcing to conductor – knocking nuts off a tree with a pole! COMMON WORKER SAFETY ISSUES Access to live conductors – bus bars Contact with aboveground cables Cable strikes during excavation Work equipment - grounding Trackside maintenance – Electrified lines ELECTRICAL SAFETY – EXAMPLES OF CONTROL MEASURES Isolate electrical system – use Lock Out Tag Out (LOTO) Follow procedures Only authorised / qualified persons to carry put work Work supervision by competent personnel Test before touch No live working Be alert to arcing potential Safe working distances Clear communications and signage Training of all site personnel ELECTRICAL SAFETY – SAFE DISTANCES ELECTRICAL SAFETY – SITE SAFETY CONTRACTOR AND SUBCONTRACTOR MANAGEMENT CONTRACTOR RISK AT SITE • Accident statistics show that contractors, subcontractors and the self-employed represent the most risk in the construction and services sectors • UK Health and Safety Executive statistics are shown in the next three slides • Similar statistics for the rest of Europe and globally CONTRACTOR RISK AT SITE Number of Fatal Injuries by Worker Status 300 Number of Fatali#es 250 200 2006/07 2007/08 150 2008/09 2009/10 100 2010/11 50 0 Employee Self Employed Worker Status Total CONTRACTOR RISK AT SITE Percentage of Fatal Injuries by Worker Status 90 Percentage of Total Fatali#es (%) 80 70 2006/07 60 2007/08 50 2008/09 2009/10 40 2010/11 30 20 10 0 Employee Worker Status Self Employed CONTRACTOR RISK AT SITE Percentage of Fatal Injuries to Workers by Industrial Sector 40 Percentage of Total Fatali#es (%) 35 30 25 20 2006/07 2007/08 15 2008/09 10 2009/10 2010/11 5 0 Agriculture Other extracCve & uCliCes Manufacturing Water supply; sewerage; waste management and remediaCon acCviCes Industrial Sector ConstrucCon Services CONTRACT MANAGEMENT – THE CHALLENGE? Ø Fatality statistics show that contractors and the self-employed are more at risk than employees Ø Potential damage for employer and/or contractor – e.g. litigation, prosecutions, fines, media and reputation (current and future work opportunities) Ø Project management pressures Ø Risks of using the cheapest company and corners being cut CONTRACT MANAGEMENT – CO-OPERATION? • Employer – Contractor Tension RECOGNITION AND CO-ORDINATION OF INTERFACES • Interfacing issues on sites Ø Open Ø Co-ordinated Ø Clear understandings on both sides Ø Coaching and mentoring relationship rather than punitive • Make contractors part of team RECOGNITION AND CO-ORDINATION OF INTERFACES Practical Approaches to Improve Co-operation between Employers and Contractors e.g. Removal of Barriers to Co-operation Early engagement Open culture Mirrored structures and behaviours Incentives Metrics Joint publicity, branding, etc. External collaboration e.g. Local school, nature reserve, sponsorship COMPETENCIES OF SUPPLY CHAIN • Contractors treated as professionals • Demonstrated knowledge, training and experience for every member of the contractor team before the job is awarded (Suitably Qualified and Experienced Person (SQEP)) • Includes the sub-contractors and temporary or agency personnel • Assessed and approved by the client before the job is awarded, and is monitored throughout the contract MONITORING CONTRACTOR PERFORMANCE • Traditional contractual performance measures e.g. Ø On time, on budget , free from defects, right first time Ø Safely • Non-traditional (progressive) contractual performance measures e.g. Ø Apprenticeships , use of local labour and local supply chain Ø Equality and inclusion Ø Legacy Ø Sustainability POSITIVE OHS CULTURE POSITIVE OHS CULTURE • How can we encourage a positive OHS culture on a project? Group discussions for a large construction project POSITIVE OHS CULTURE Example of approaches from a construction project • Close working between Contractor & project OHS personnel common understanding, knowledge transfer, training & mentoring • Regular communications - initial inductions, daily toolbox talks, weekly OHS meetings, fortnightly OHS supervisor training sessions POSITIVE OHS CULTURE Example of approaches from a construction project • Encouragement of a ‘Reporting culture’ – management commitment and positive reinforcement engenders more near-miss incidents being identified and reported. • All near-miss incidents should be reported, investigated and feedback provided to the initiator and the workforce. POSITIVE OHS CULTURE Example of approaches from a construction project • Weekly/monthly OHS themes, promoted on site by toolbox talks, method statement reviews and specific training sessions • Daily topic-based inspections / visits by project OHS personnel to different work areas • Supervisors & managers demonstrate positive OHS behaviour - wear proper PPE, are responsible for OHS incident investigations, lead OHS meetings & carry out regular workplace inspections POSITIVE OHS CULTURE Example of approaches from a construction project • Cooperative approach in issue solving by explaining, training, coaching & mentoring before taking an authoritative approach • Monthly site newsletter • Site training / briefing facilities • Individual &work group incentive scheme to reward positive OHS behaviours SUMMARY The EBRD treats health and safety seriously on all its projects When evaluating sites, remember to consider the hazard and the risk Think holistically, and consider the whole site, process and activities not just the raw materials and products Do not forget the “Elephant in the Room”! EBRD’s Key H&S Issue areas: Ø Excavation Safety Ø Confined Spaces Ø Dust Explosions Ø Movement of Plant, Vehicles and Rolling Stock Ø Electrical Safety Ø Contractor and Subcontractor OHS Management 1 800 491 0274 info@monkeyforestconsulting.com www.monkeyforestconsulting.com

© Copyright 2025