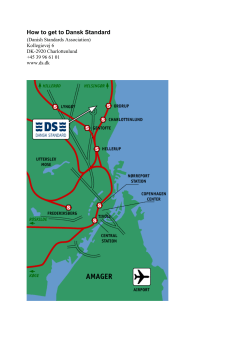

VISIT CARLSBERG