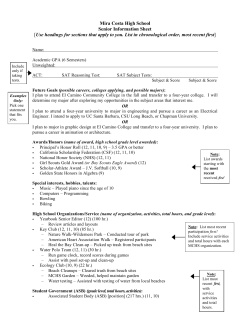

Training brochure