Vistafold 70A Fitting Instructions PDF

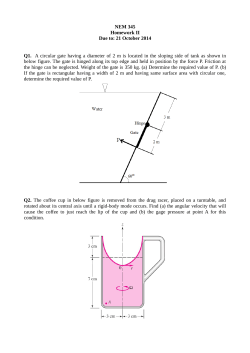

VISTAFOLD ALUMINIUM VISTAFOLD ALUMINIUM The Vistafold system is a revolutionary solution for slidingfolding doors developed by the Hillaldam team that has been taking the industry by storm over the last 15 years. The system is a complete departure from traditionally top hung solutions, relying completely on a bottom rolled concept to minimise the requirement for unsightly, costly and often impractical overhead support. Available in both odd and even number panel configurations, it is an easily adaptable system that is highly weather resistant. The Vistafold hardware is manufactured from high quality stainless steel and aluminium components, which are either anodised or powder coated to give an aesthetically pleasing and corrosion resistant finish. VISTAFOLD THE BENEFITS OF BOTTOM ROLLING There are a number of major benefits to using the Vistafold system and the reasons for making a change away from top hung assemblies is multi-faceted. The Vistafold systems support the weight of the assembly from the bottom up, which requires less bulky overhead support and allows for easier operation – especially on higher doors. With the door weight taken up by the bottom track, the perennial problem of sagging lintels is vastly reduced. This in turn all but eliminates the necessity for adjustment over the lifespan of the installation. Any possible deflection of the head opening is accommodated in the channel depth overhead. In cases where some adjustment is preferred however, Hillaldam has an easily adjusted collar-system allowing up to 5mm of movement. Whereas top hung systems traditionally have deep bottom channels that act as dirt and water traps, the relatively slimline Vistafold track is only 8mm deep and easily swept out or vacuumed clean. ADAPTABILITY Whilst many systems on the market require the customer to buy specific profiles, Vistafold allows the use of most standard door and rebate profiles. This eliminates unnecessary expense and avoids having to switch materials between swung, straight sliding and sliding folding systems. Hillaldam feels that all of these features make the Vistafold system unique in its design and operation – we hope you feel the same. PANEL SIZING Vistafold is versatile in allowing either an odd number or an even number of panels as well as a choice of offset hinge or standard hinge configurations. The easy calculation sheets make it a simple process to size the doors no matter which option you choose. VISTAFOLD One of the major advantages to the Vistafold system is that it allows both tracks and overhead channels to be completely concealed when the doors are closed. This is a major aesthetic advantage but also assists with eliminating the build-up of dirt in the bottom track. VISTAFOLD 44mm 100mm 100mm TOP GUIDE 121mm 118mm 4mm VISTA HINGE VISTA HINGE HANDLE 32mm 26mm 12mm VISTA HINGE 53mm 100mm 150mm BOTTOM ROLLER 102mm Section through Door at Roller and Guide Section through Door at Hinge VISTAFOLD VISTA HINGE HANDLE TOP GUIDE Specifications: Hardware fits standard 44mm shopfront door profiles with Vistafold frames. Max leaf mass: 70kg Max leaf height: 2700mm Max leaf width: 900mm Components: 868x6 Top Guides 870x4 Bottom Rollers 868x1 Intermediate Hinges 86VSKH Hinge Handles Fittings: VF01 Side Frame VF02 Top Frame VF03 Bottom Frame CL34 Bottom Track 868B Bubble Seal D090 Woolpile 4771 F/R Double Throw Flush EB1 Holdback Catch INTERMEDIATE HINGE BOTTOM ROLLER Finishes: Mill, Natural, White, Bronze or Black. Specialist colours available on request. CALCULATIONS - UNEVEN PANEL Where: PW = Panel Width P = No. of Panels OW = Opening Width TF = Thickness of Frame For an opening using sinkless hinges A 4mm gap between panels is allowed for and a 7mm gap between the hinge leaf and the jamb to accommodate the lock. OW = opening width P = no. of panels Panel width (PW) = OW – (2xTF) - (Px4) - 7 P For an opening using butt hinges NOTE: A 8mm gap between panels is allowed for and a 7mm gap between the hinge leaf and the jamb to accommodate the lock. Cutout in door stile and roller and guide joint: Top edge: 10mm deep x 35mm wide (from edge) OW = opening width P = no. of panels Top face: 10mm deep x 7mm wide (from edge) Bottom edge: 42mm high x 33mm wide (from hinge side) Panel width (PW) = OW – (2xTF) - (Px8) - 7 Bottom face: 42mm high x 7mm wide (from edge) P VISTAFOLD UNEVEN TOP GUIDE HINGE HINGE HANDLE PLAN OF DOORS SHOWING TOP GUIDE OPENING WIDTH = OW BOTTOM ROLLER HINGE HINGE HANDLE THICKNESS OF FRAME = TF THICKNESS OF FRAME = TF PLAN OF DOORS SHOWING BOTTOM ROLLER OUTSIDE OUTSIDE HINGE HANDLE PANEL WIDTH = PW HINGE HANDLE BOTTOM ROLLER HINGE INSIDE PLAN OF DOORS SHOWING BOTTOM ROLLER TOP GUIDE HINGE INSIDE PLAN OF DOORS SHOWING TOP GUIDE VISTAFOLD UNEVEN PATENT NO. 331365 TOP GUIDE Specifications: Hardware fits standard 44mm shopfront door profiles with Vistafold frames. Max leaf mass: 70kg Max leaf height: 2700mm Max leaf width: 900mm Components: 871x5 Top Guides 871x2 Bottom Rollers 871x1 Intermediate Hinges 871VSKH Hinge Handles VISTA HINGE HANDLE BOTTOM ROLLER Fittings: VF01 Side Frame VF02 Top Frame VF03 Bottom Frame CL34 Bottom Track 868B Bubble Seal D090 Woolpile 4771 F/R Double Throw Flush EB1 Holdback Catch Finishes: Mill, Natural, White, Bronze or Black. Specialist colours available on request. INTERMEDIATE HINGE CALCULATIONS - EVEN PANEL Where: PW = Panel Width OW = Opening Width P = No. of Panels E = No. of End Panels TF = Thickness of Frame 10mm clearance to allow kick of doors For an opening using cranked hinges and all doors of even width: PW = OW – (2xTF) – (Px4) - 10 P For an opening using Non-cranked hinges where the end door is 12mm longer PW = OW – (2xTF) – (Px4) – 10 – (12xE) P Once you have PW for the non-cranked formula, simply add back 12mm to each end panel to determine its width. EG: For a 2-door Vista Duo with non-cranked hinges in an opening of 1750mm NOTE: Door stiles min 65mm wide All door leaves equal widths PW = 1750 – (2x30) – (4x2) – 10 – (12x1) 2 Cutout in door for bottom roller: 42mm high x 32mm from hinge in door edge 42mm high x 21mm from hinge in door face = 1660 2 = 830 The door hinged to the jamb is then 830 long and the door with the end roller 830+12 = 842mm. Cutout in door for top guide: 9mm high x 32mm from hinge in door edge 9mm high x 21mm from hinge in door face VISTAFOLD EVEN PATENT NO. 331365 LEFT HAND TOP GUIDE HINGE HINGE HANDLE PLAN OF DOORS SHOWING TOP GUIDE OPENING WIDTH = OW HINGE LEFT HAND BOTTOM ROLLER HINGE HANDLE THICKNESS OF FRAME = TF THICKNESS OF FRAME = TF PLAN OF DOORS SHOWING BOTTOM ROLLER OUTSIDE HINGE HANDLE HINGE HANDLE END PANEL PANEL WIDTH = PW OUTSIDE LEFT HAND BOTTOM ROLLER INSIDE PLAN OF DOORS SHOWING BOTTOM ROLLER LEFT HAND TOP GUIDE INSIDE PLAN OF DOORS SHOWING TOP GUIDE VISTAFOLD EVEN PATENT NO. 331365 RIGHT HAND TOP GUIDE HINGE TOP GUIDE HINGE HANDLE HINGE HANDLE PLAN OF DOORS SHOWING TOP GUIDE OPENING WIDTH = OW RIGHT HAND BOTTOM ROLLER HINGE BOTTOM ROLLER HINGE HANDLE HINGE HANDLE THICKNESS OF FRAME = TF THICKNESS OF FRAME = TF PLAN OF DOORS SHOWING BOTTOM ROLLER OUTSIDE OUTSIDE RIGHT HAND BOTTOM ROLLER END PANEL PW + 12mm HINGE HANDLE PANEL WIDTH = PW END PANEL HINGE HANDLE RIGHT HAND TOP GUIDE INSIDE PLAN OF DOORS SHOWING BOTTOM ROLLER INSIDE PLAN OF DOORS SHOWING TOP GUIDE VISTAFOLD VISTAFOLD EVEN TYPICAL LAYOUTS 2 Leaves 3 Leaves + 1 Leaf 2 Leaves + 2 Leaves 3 Leaves 4 Leaves 5 Leaves 3 Leaves + 2 Leaves 4 Leaves + 3 Leaves 3 Leaves + 3 Leaves 4 Leaves + 4 Leaves ADJUSTMENT Loosen M4 locking grub screw using 2mm Allan Key. Move adjustment collar up and down to desired height by adjusting hexagonal with M17 spanner. ADJUSTMENT +-2.5mm M17 SPANNER 2mm ALLAN KEY VISTAFOLD Once desired height adjustment had been achieved, lock in place by tightening M4 locking grub screw with 2mm Allan Key. Hillaldam (PTY) LTD 20 Bessemer Road Heriotdale Johannesburg 2094 Tel: (+2711) 626 1001 FAX: (+2711) 626 1341 Email: info@hillaldam.co.za website: www.hillaldam.co.za

© Copyright 2025