I Isopropyl alcohol: A techno-commercial profile Special Report

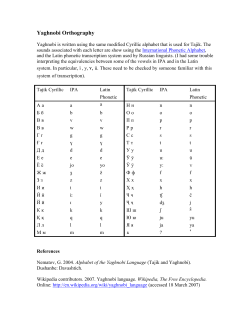

Special Report PRODUCT FOCUS Isopropyl alcohol: A techno-commercial profile I Introduction sopropyl alcohol (Isopropanol, IPA) is a colourless, flammable liquid with a characteristic alcohol / acetone-like odor. It mixes completely with most solvents, including water. PANKAJ DUTIA pankaj@chemicalweekly.com this had fallen to 4.5%. It disappeared completely in the late 1990s. ExxonMobil, the world’s leading manufacturer of IPA, for example, has quit making acetone from the IPA route. Acetone demand can now be entirely satisfied by the co-product material from the cumene/phenol process; indeed in certain cases now, IPA is made from acetone. ducts (e.g., general purpose cleaners, disinfectants, room sprays); Paints and inks (e.g. nitrocellulosebased lacquers and thinners for wood finishing, adhesives); Pharmaceuticals (e.g., as an extractive solvent); Medical applications (e.g., for sterilising and disinfecting surfaces in hospitals; preserving biological specimens and to impregnate sterilized cleaning wipes used for sanitising telephone handsets etc.); Screen wash and de-icers; In food industry (e.g. in pectin extraction); and Foundry resins. Use as solvent IPA is a popular solvent used as such in: Personal care and household pro- In the coatings industry, IPA is mainly used as an inert solvent to reduce the flammability of coatings during storage and transportation. In inks, IPA is one of the most widely used solvents in the world. It is also used as a chemical intermediate. One well-known, yet relatively small use for IPA is “rubbing alcohol,” which is a mixture of IPA and water and can be purchased in many pharmacies and grocery stores. Applications IPA was historically used for making acetone, but use in this application has been hit by the reduction in use of acetone as a solvent as a result of legislation on air pollution. During the 1980s, acetone from IPA accounted on average for about 8% of acetone production in the United States. By 1990, Table 1 Use of IPA as a solvent Function Process solvent Coating and dye solvent Cleaning and drying agent Solvent in topically applied preparations Aerosol solvent Application Extraction and purification of natural products, such as vegetable and animal oils and fats, gums, resins, waxes, colours, flavourings, alkaloids, vitamins, kelp and alginates Carrier in the manufacture of food products Purification, crystallization and precipitation of organic chemicals Synthetic polymers such as phenolic varnishes & NC lacquers Cements, primers, paints and inks Manufacture of electronic parts, for metals & photographic films and papers, in glass cleaners, liquid soaps & detergents, aerosols Pharmaceutical products: topically applied rubbing alcohol Cosmetics: hair tonics, perfumes, skin lotions, hair dye rinses, permanent wave lotions, skin cleaners & deodorants, nail polish, shampoos Cleaners, waxes, polishes, paints, de-icers, shoe and sock sprays, insect repellants, hair sprays, deodorants, air-fresheners Medical and veterinary products: antiseptics, foot fungicides, first aid & medical vapour sprays, skin soothers, house & garden type insecticides Chemical Weekly April 24, 2012 211 Special Report IPA is mainly used as an additive and thinner of water-based paints. IPA has many uses in the pharmaceutical field. As a major raw material, IPA is used to produce many pharmaceutical intermediates, such as 7-aminocephalosporanic acid (7-ACA), iohexol and chloramphenicol. IPA can also be used to produce amoxicillin, piracetam, isopropyl aluminum (catalyst), and so on. In 2010, the pharmaceutical industry consumed about 46,000 tons of IPA. It is expected that in 2015, the demand for IPA in the pharmaceutical field will reach 78 000 tons, with an average annual growth rate of 8%. Chemical derivatives Solvent use is much larger than as a chemical intermediate, but the latter is also important. IPA is used for making downstream derivatives such as: Isopropyl ether, which finds in the cosmetics and personal care industry; Isopropyl esters, for use as a solvent in cellulosics and inks; Isopropyl amines, for use in the manufacture of glyphosate herbicides; IPA reacts with carbon disulphide to give sodium isopropylxanthate, a weed killer. IPA reacts with titanium tetrachloride and aluminium metal to give titanium and aluminium isopropoxides respectively, the former a catalyst, and the latter a chemical reagent. This compound may serve as a chemical reagent in itself, by acting as a dihydrogen donor in transfer hydrogenation. Diisopropyl ether (DIPE) DIPE is prepared from IPA in liquid phase in contact with particular Montmorillonite clay catalysts, optionally in the presence of added propylene. The process is operated in a continuous manner by continu- ously feeding liquid IPA, optionally with added propylene, into a reaction space where the feed contacts the catalyst at 120-250°C for an average contact time of 1 to 120 minutes. Pressure is maintained in the reactor to keep a liquid phase in contact with the solid catalyst. Effluent withdrawn continuously from the reaction space at the feed rate is separated by fractionation to recover DIPE. Isopropyl esters Isopropyl esters find main applications in the personal care industries. Isopropyl laurates are used as cosmetics and lubricating oil additives. Isopropyl myristate is used as an emollient and lubricant in preshaves, after-shaves, shampoos, bath oils, antiperspirants, deodorants, and various creams and lotions. Isopropyl palmitate is used in cosmetics as a thickening agent and emollient. It is often used in mois- Isopropyl myristate/ Isopropyl palmitate Isopropyl alcohol C14/ C16 Fatty acid Soap/Water Residue Water Esterification Alcohol distillation Neutralizing Product distillation Fig. 1: Process flow diagram for preparation of isopropyl esters 212 Chemical Weekly April 24, 2012 Special Report turisers where it forms a thin layer and easily penetrates the skin. Isopropyl palmitate is said to enhance silkiness in hair and skin. The isopropyl esters of carboxylic acids are manufactured by reacting the corresponding fatty acid with IPA. The by-product of the esterification reaction is water. Isopropyl amines As a chemical raw material, monoisopropylamine (MIPA) has very versatile applications including production of pesticides (such as atrazine, prometryn, glyphosate isopropylamine salt, and bentazone), intermediates for pharmaceuticals and dyestuffs, rubber accelerators, hard water treatment agents and detergents. Health information Under usual conditions of exposure, IPA is quickly converted to acetone once taken into the body. Acetone is naturally present in virtually every organ and tissue in the human body as a result of metabolic processes. place or the environment. Over-exposure to IPA can cause irritation to the eyes, nose and throat, and may produce central nervous system depression. These effects are typically mild and end shortly after exposure is terminated, not showing any permanent adverse health affects. Swallowing small amounts is not likely to cause injury; however swallowing larger amounts may cause serious injury, and even death. Chronic, prolonged or repeated overexposure to IPA has produced adverse liver effects and kidney effects and/or tumours in male rats. Such effects are believed to be species-specific, however, and unlikely to occur in humans. Public and wildlife exposure through environmental releases is limited because IPA rapidly biodegrades in water and undergoes photo-oxidation Toxicology studies have shown that IPA poses a low health hazard and does not cause adverse health or environmental effects at levels typically found in the workTable 2 Specifications of IPA of Deepak Fertilisers Properties Purity Residue Water content Miscibility with water Acidity as acetic acid Color hazen units Distillation range Specific gravity @ 25°C Specifications 99.7% to 99.9% w/w 12 ppm w/w max 650 ppm w/w max Complete 10 ppm w/w max 10 max 81.5 to 83 0.782 - 0.784 Chemical Weekly April 24, 2012 Test method GC IS 517 1986 ASTM D 1364 ASTM D 1722 ASTM D 1613 ASTM D 1209 ASTM D 1078 ASTM D 891 relatively rapidly in the atmosphere. IPA is not expected to persist in soil due to its rapid evaporation, and has a low potential to bio-accumulate in aquatic organisms. IPA studies show low toxicity to aquatic organisms and microorganisms, and toward plant germination and growth. Manufacturing process IPA has been called the first petrochemical. It can be prepared via three different methods: Indirect hydration of propylene, using sulphuric acid and water; Direct hydration of propylene, with an acid catalyst; and Catalytic hydrogenation of acetone. This process is only suitable where excess acetone is available and where there is at least a $100 difference between the price for acetone and IPA. Indirect hydration, also called the sulphuric-acid process, was the only method used to produce IPA worldwide until the first commercial direct-hydration process was introduced in 1951. Each method has its advantages and disadvantages. For example, direct hydration is less corrosive than indirect hydration mediated by sulphuric acid. However, the direct method requires a pure propylene feed, in contrast to the indirect process, which can use a dilute, refinery stream. Indirect hydration of propylene In the indirect-hydration process, propylene is reacted with sulphuric acid to produce mono- and diisopropylsulphates, which are then hydrolysed to IPA. In the two-step strong-acid pro213 Special Report cess, separate reactors are used for the propylene-absorption phase and the hydrolysis of the sulphate esters. The reaction occurs at high sulphuric acid concentration (>80% wt) and low temperature (e.g. 2030°C). of 70,000-tpa at Raigad District (Maharashtra) and commenced production in August 2006. The weak-acid process is conducted in a single step at lower acid concentration (60-80% wt) and higher temperature (60-65 °C). Technological improvements in the IPA manufacturing process caused the Direct hydration of propylene The non-acid process, Table 3 which is used primarily Production & Sales of IPA Years Produc- Sales qty. Sales value in Europe and Japan, intion [Tonnes] [Rs. Mn] volves the catalytic oxidation of propylene with [Tonnes] water. Hydration can be 2006-07 15,886 12,552 664 gas-phase with phospho2007-08 49,447 52,239 2,549 ric acid catalyst, mixed 2008-09 51,217 51,264 2,773 phased with a cation2009-10 61,619 61,671 3,127 exchange resin, or liquid phase using a tungsten 2010-11 67,462 67,652 4,122 catalyst. The IPA is then purified by distillation. strong acid process to be replaced with the weak acid and the non-acid proIndian scenario cesses. In India, IPA is manufactured by Diisopropyl ether is a significant one company, Deepak Fertilisers and by-product of this process; it is recy- Petrochemicals Corporation Ltd. (DFcled back to the process and hydrolyzed PCL), headquartered in Pune (Maharashtra). The company put up a plant to give the desired product. DFPCL manufactures IPA through the direct hydration process, producing a colourless product of high purity, with no undesirable odour or byproduct formation. The product meets international quality standards for use in pharmaceuticals, coatings and inks, specialty chemicals and cosmetics. For critical applications in the pharma sector, DFPCL has started offering IP/BP/ USP grade IPA, conforming to stringent standards such as USP, PhEuro and IP to name a few. DFPCL recorded the highest ever production of IPA at 67,462 tonnes in 2010-2011 (production of 61,619 tonnes in 2009-10). Trade India has been importing as well as exporting IPA. Imports increased from little over 31,000-tonnes in 2005-06 to over 51,000-tonnes in 2006-07, but thereafter with commencement of local production declined and have been in the range of 27,000-tonnes to 35,000-tonnes. Exports on the other hand are in Table 4 Imports and Exports of IPA Years 2005-06 2006-07 2007-08 2008-09 2009-10 2010-11 2011-12 (Apr-Feb) Quantity [Tonnes] 31,466 51,391 28,449 26,884 28,988 35,604 34,629 Imports Value [Rs. Mn] 1,424 2,501 1,347 1,432 1,339 2,057 2,186 CIF Value [Rs per kg] 45.26 48.67 47.35 53.27 46.20 57.77 63.13 Quantity [Tonnes] – 2,627 1,920 1,605 2,288 3,975 – Exports Value [Rs. Mn] – 108 90 85 125 243 – FOB Value [Rs per kg] – 41.11 46.87 52.96 54.63 61.13 – Source: DGCIS, Kolkata and Chemical Weekly Database 214 Chemical Weekly April 24, 2012 Special Report small; during 2010-11 they were just 3,975-tonnes valued at Rs. 61.13-mn, but significantly point to the global acceptance of local material. Majority of imports are sourced from South Korea, Singapore, Taiwan, and the US, while destination of exports includes countries like UAE, Thailand, Nigeria, Iran, Kenya, Egypt etc. Consumption The local consumption of IPA in India in 2006-07 was 64,650-tonnes Table 5 Top-10 suppliers of IPA into India Country Taiwan USA Korea South Netherlands Belgium Singapore Azerbaijan China Canada Bahrain Others Total 2009-10 Quantity Value [Tonnes] [Rs. Mn] 5,559 300.26 15,426 663.05 4,032 189.79 47 5.59 0 0 2,920 124.61 0 0 22 2.11 0 0.01 0 0 982 53.79 28,988 1,339.22 2010-11 Quantity Value [Tonnes] [Rs. Mn] 13,523 790.86 8,169 465.73 4,282 240.68 2,808 168.63 2,475 137.34 2,429 131.78 1,199 69.77 308 24.33 130 7.13 100 5.95 182 14.67 35,604 2,056.89 Source: DGCIS Intermediates 10% Inks & coatings 10% Pharma 72% Chemical Weekly April 24, 2012 According to industry estimates, around 72% is consumed by the pharmaceutical industry, followed by coatings & inks industry (10%) and chemical intermediates (10%). The balance (8%) is used in diverse sectors including for agrochemicals, thinners, metal treatment, electronics industry etc. As mentioned earlier, the CARG of IPA consumption during last five years has been around 11.5%. At a conservative growth rate of 10% in the next three years and 8% in the subsequent two, a demand of around 155,000-tonnes of IPA can be projected for the year 2015-16. With current capacity of DFPCL at 70,000-tpa, and no expansions or new capacities announced, it is evident that the gap of around 85,000-tonnes in supply will have to be met by imports. Global scenario The total global capacity for IPA is estimated to be around 2.7-mtpa, mainly concentrated in North America, East Asia and Europe. The United States is the world’s largest producer, with an annual capacity of 0.84-mtpa, accounting for about one-third of global capacity. Others 8% Fig. 2: Propionic acid use by application and this has increased to around 100,000-tonnes in 2010-11, registering annual compounded growth rate of 11.5%. In recent years accelerating development of Asian economies has resulted in increasing production capacity in the region. The current annual production capacity of IPA in Asia has reached nearly 0.80-mtpa. Japan, Korea, China, India, and Taiwan are now the world’s major producers, having about one-third of the global capacity. Capacity in Europe is about 0.70-tpa. 215 Special Report Table 6 Global IPA capacity by region Region Capacity (tpa) Share (%) USA 840,000 31 Europe 700,000 26 Asia 800,000 30 ROW 360,000 13 Total 2,700,000 100 Table 7 Global IPA consumption by region Region Consumption (Tons) Share (%) USA 650,000 30 Europe 500,000 23 Asia 780,000 35 ROW 270,000 12 Total 2,200,000 100 Table 8 Major IPA producers Company Capacity (tpa) Shell Chemicals 480,000 Exxon Mobil 380,000 DOW Chemicals 430,000 Sasol Olefins 230,000 Deepak Fertilisers 70,000 Novapex 40,000 Lyondel Basel 30,000 Table 9 Imports of IPA by China Years Imports (Tons) 2006 96,000 2007 109,800 2008 100,100 2009 102,000 2010 110,000 216 Exxon Mobil, Dow Chemicals, Sasol Olefins, DFPCL, Novapex, LyondellBasel and Mitsui Chemicals are some of the major producers. local production satisfies 53% of demand. US Outlook IPA is considered a mature product in the US, with an expected growth rate of 1.5%/year through to 2015. US demand is expected to reach 700,000-tonnes in 2015. The strongest end-use markets are in isopropylamines, household, cosmetic and personal care products, and pharmaceuticals, growing at about 2.8%/year. These three segments collectively account for 34% of IPA demand in the US. The largest outlet for IPA in the US is solvents, accounting for 45% of IPA use in the country. This sector is expected to grow modestly, by approximately 1.2%/year, limited by regulations covering volatile organic compounds. China outlook China has a domestic IPA market of around 230,000-tonnes in 2010, out of which 120,000-tonnes is being met by the local production and 110,000-tonnes through imports. Imports thus constitute 48% of total consumption, while Table 10 IPA demand in China by end-use: 2010 End-uses Organic solvents Pharmaceuticals Chemical intermediates Others Total Demand Share [Tonnes] [%] 94,300 41 46,000 20 55,200 24 34,500 230,000 15 100 Major producers of IPA in China are: Jinzhou Petrochemicals Company (100,000-tpa capacity), Shandong Zibo Austrian Chemical Co. Ltd. (200,000-tpa) and Haike Chemical Group Company (30,000-tpa). Makers of inks and coatings are the largest consumers of IPA in China. By 2015, the use of IPA in inks and coatings will reach 127,000-tonnes, with an average annual growth rate of 6.5%. In 2010, the pharmaceutical industry consumed about 46,000-tonnes of IPA. It is expected that in 2015, the demand for IPA in the pharmaceutical field will reach 78,000-tonnes, with an average annual growth rate of 8%. In 2010, about 55,200-tonnes of IPA was used to produce organic chemicals, which figure is expected to reach 81,000-tonnes by 2015, with an average annual growth rate of 8.0%. IPA is also used in other areas, such as electronics, mineral flotation, dyeing/printing, household and personal care, cosmetics and surfactants – especially in the electronics and mineral flotation industries. In 2010, demand for IPA in such areas was about 34,500-tonnes, which is expected to reach 65,000-tonnes in 2015, at an average growth rate of 12% per year. By 2015, total demand for IPA in China is expected to reach 351,000-tonnes. The domestic output is expected to go up to around 180,000-tonnes to 200,000-tonnes, leaving a large gap of around 150,000-tonnes to 170,000-tonnes that will have to be met through imports. Chemical Weekly April 24, 2012

© Copyright 2025